Separation process of ferrous high silicate type iron ore

A silicate and iron ore technology, applied in the field of mineral engineering, can solve the problems of low equipment utilization efficiency, difficult to grasp the balance point, poor sorting index, etc., to improve the comprehensive utilization rate of resources, low cost and energy consumption less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

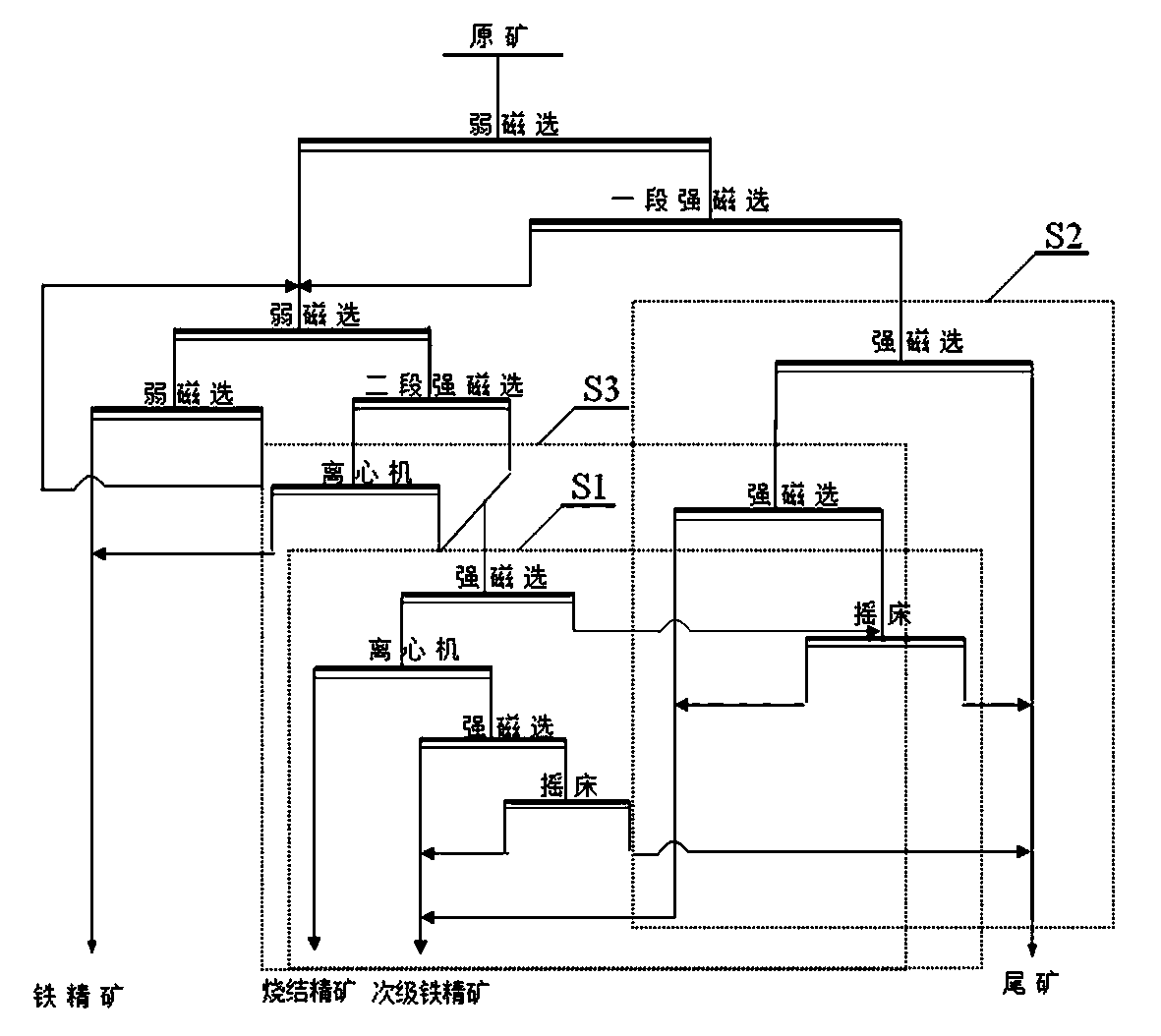

Image

Examples

Embodiment 1

[0064] 1) The iron grade is only about 50%, SiO 2 The high-silicon-type strong magnetite concentrate with a content of about 15% is fed into the SLon centrifuge for gravity separation, which is a SLon-2400 continuous centrifuge. The separation process conditions are: centrifuge speed 250 rpm, jet pressure: 0.4 -0.5Mpa; Ore feeding concentration: 16.0%-17.0%; Washing water volume: 9.0L / min-11.0L / min; Sorting time: The time for beneficiating ore is 70s-80s. After re-selection by centrifuge, about 61% iron grade, SiO 2 Iron concentrate with a content of about 5.7%.

[0065] 2) After concentrating and mixing the tailings produced by the centrifuge with a grade of about 37% and the second-stage strong magnetic tailings with an iron grade of 26%~28%, they are fed into the S1 tailing reduction process, firstly through SLon2000 Lihuan veins are subjected to strong magnetic separation, the magnetic field strength is 8000-10000 Oersted, and the grade of strong magnetic concentrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com