Precipitation-hardening martensitic stainless steel for surgical operation and heat treatment process thereof

A martensitic stainless steel, precipitation hardening technology, applied in the field of stainless steel materials, can solve problems such as bacterial infection, and achieve the effect of strong antibacterial performance, excellent mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Calculate the bactericidal rate of precipitation hardened martensitic antibacterial stainless steel and control samples (ordinary stainless steel or other solid materials without bactericidal ability) to common infectious bacteria (Escherichia coli, Staphylococcus aureus, etc.) according to the following formula:

[0022] Bactericidal rate (%)=[(number of viable bacteria in control sample-number of viable bacteria in antibacterial stainless steel) / number of viable bacteria in control sample]×100 where the number of viable bacteria in control sample refers to the number of viable bacteria after bacterial culture on the control sample The number of live bacteria in antibacterial stainless steel refers to the number of live bacteria after bacterial culture on precipitation hardening martensitic antibacterial stainless steel.

[0023] In this embodiment, the chemical composition of the precipitation hardening martensitic antibacterial stainless steel is (% by weight):

[00...

Embodiment 2

[0031] In this embodiment, the chemical composition of the precipitation hardening martensitic antibacterial stainless steel is (% by weight):

[0032] C: 0.03%, Cr: 15.90%, Ni: 3.55%, Nb: 0.22%, Cu: 4.8%, N: 0.08%, and the rest is Fe.

[0033] The heat treatment process of above-mentioned precipitation hardening martensitic antibacterial stainless steel is:

[0034] Insulate at 1050°C for 1 hour, and cool to room temperature with water to make the copper in the steel in a supersaturated state; then keep it at minus 70°C for 0.5 hours to completely transform the retained austenite into martensite in the steel; finally, at 480°C, Heat at 550°C, 580°C and 620°C for 10 hours to precipitate a sufficient volume fraction of copper-rich phase in the steel, then air-cool or water-cool to room temperature.

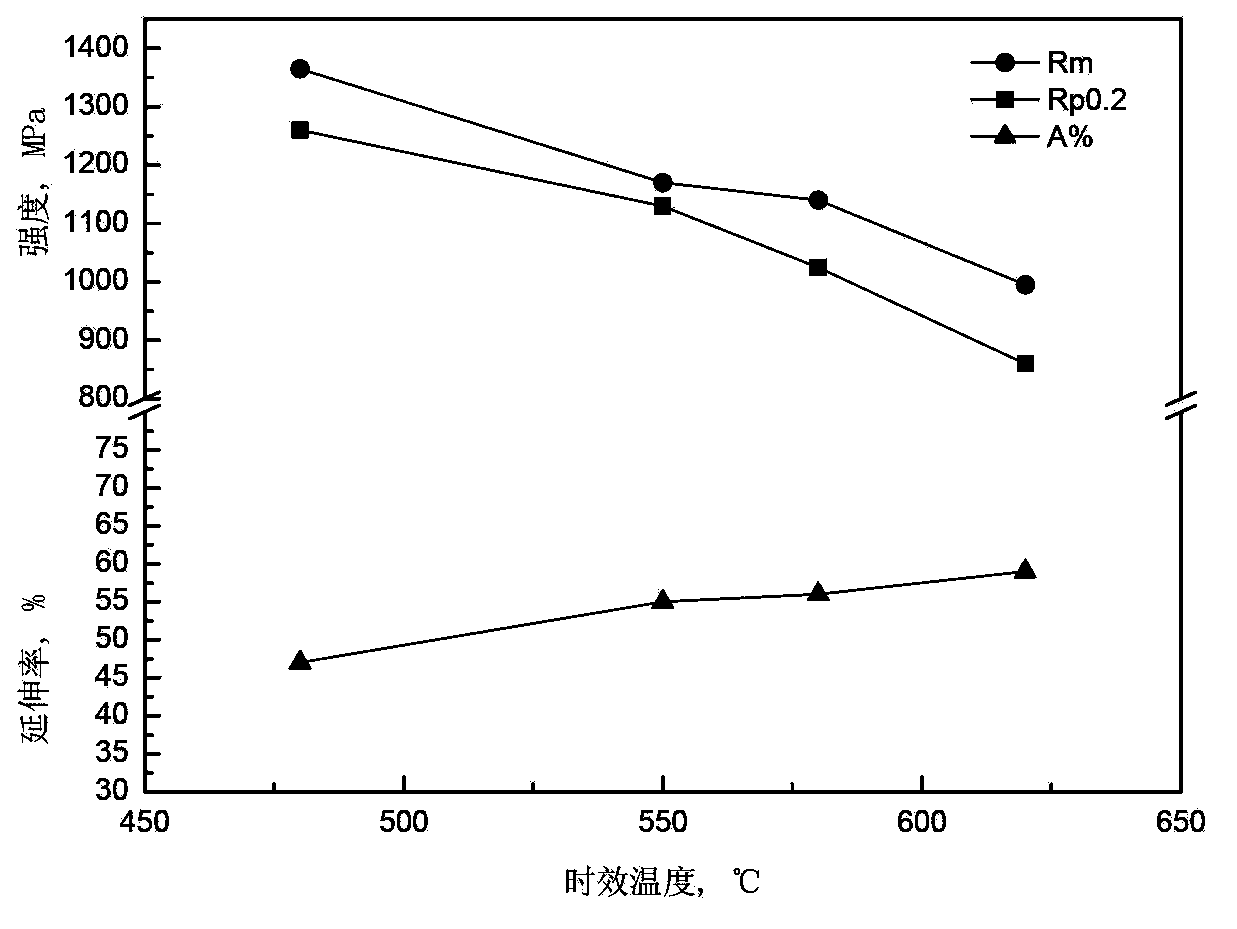

[0035] The mechanical properties of the precipitation hardened martensitic antibacterial stainless steel after these four aging temperature treatments are as follows: figure 2 s...

Embodiment 3

[0038] In this embodiment, the chemical composition of the precipitation hardening martensitic antibacterial stainless steel is (% by weight):

[0039] C: 0.02%, Cr: 16.10%, Ni: 3.47%, Nb: 0.26%, Cu: 5.2%, N: 0.12%, and the rest is Fe.

[0040] The heat treatment process of above-mentioned precipitation hardening martensitic antibacterial stainless steel is:

[0041] Insulate at 1050°C for 1 hour, and cool to room temperature with water to make the copper in the steel in a supersaturated state; then keep at -70°C for 0.5 hours to completely transform the retained austenite into martensite in the steel; finally hold at 620°C for 10 hours , to precipitate the copper-rich phase in the steel, air-cooled or water-cooled to room temperature.

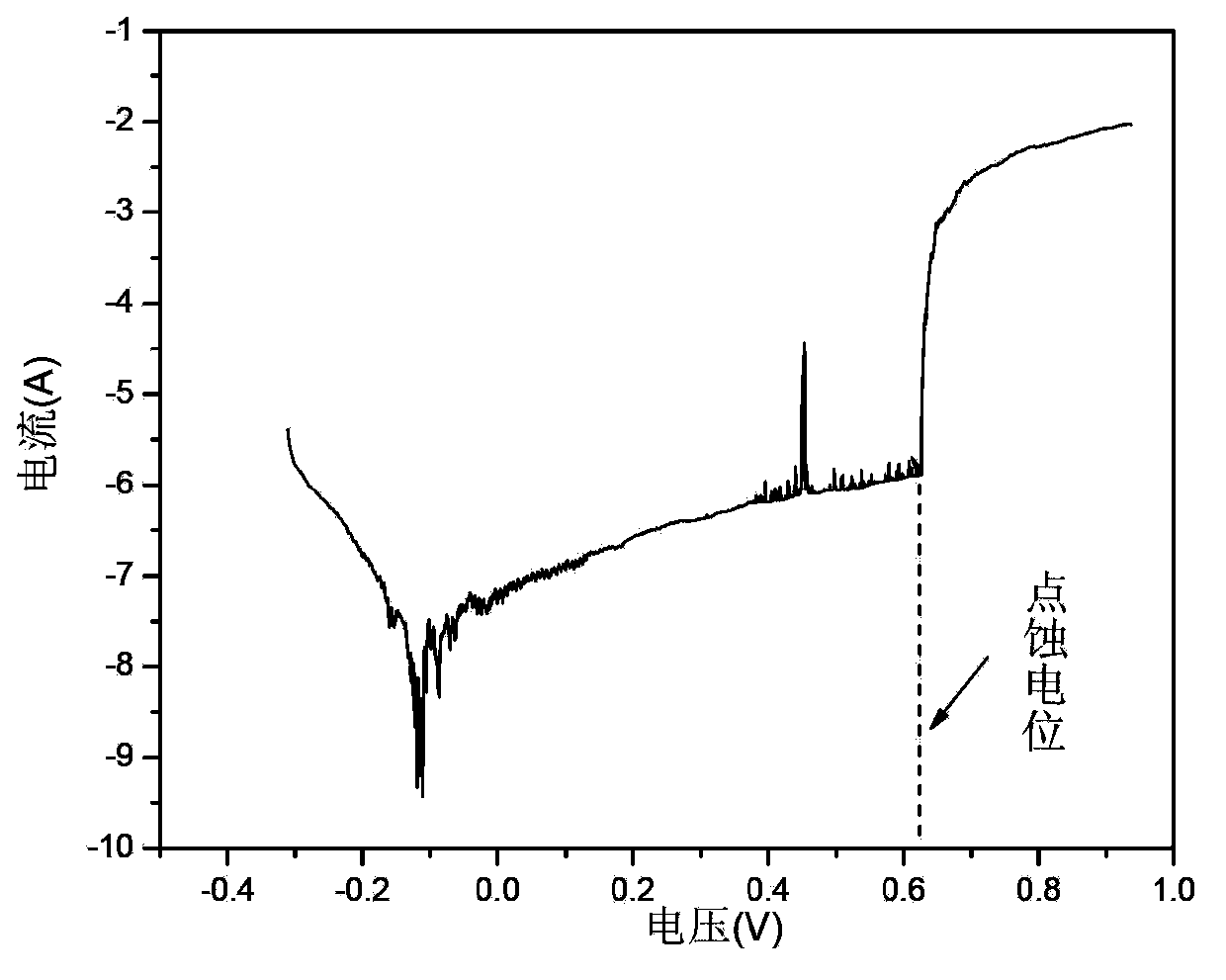

[0042]Using conventional electrochemical three-electrode system method to test the polarization curve of the above stainless steel on PRINCETON273A electrochemical comprehensive analyzer and SOLATRON1287 potentiostat, the reference electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pitting potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com