Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Increased copper content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

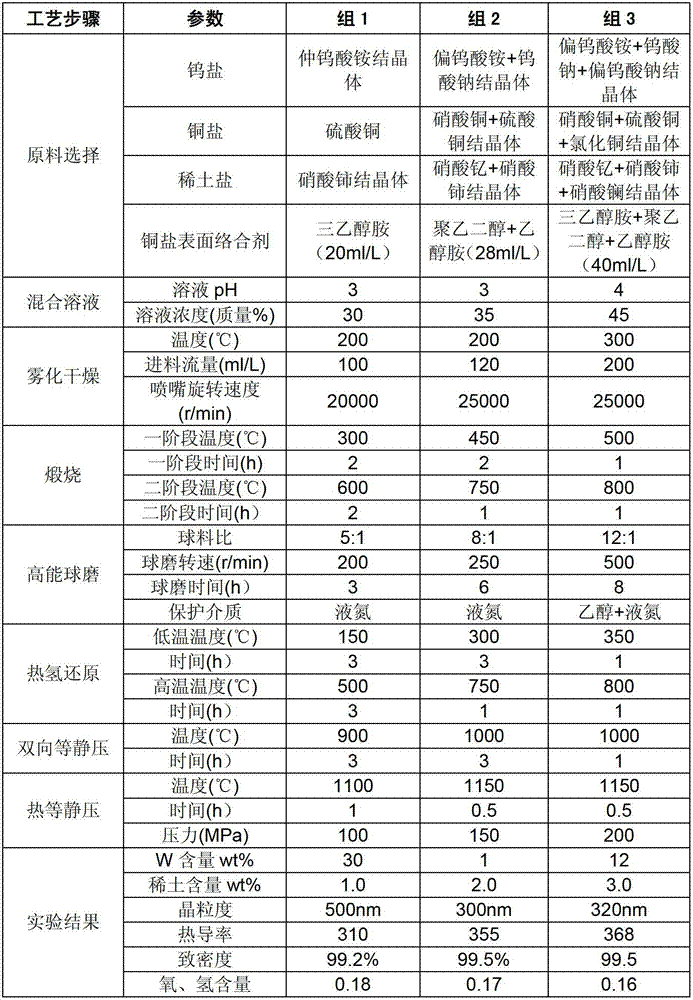

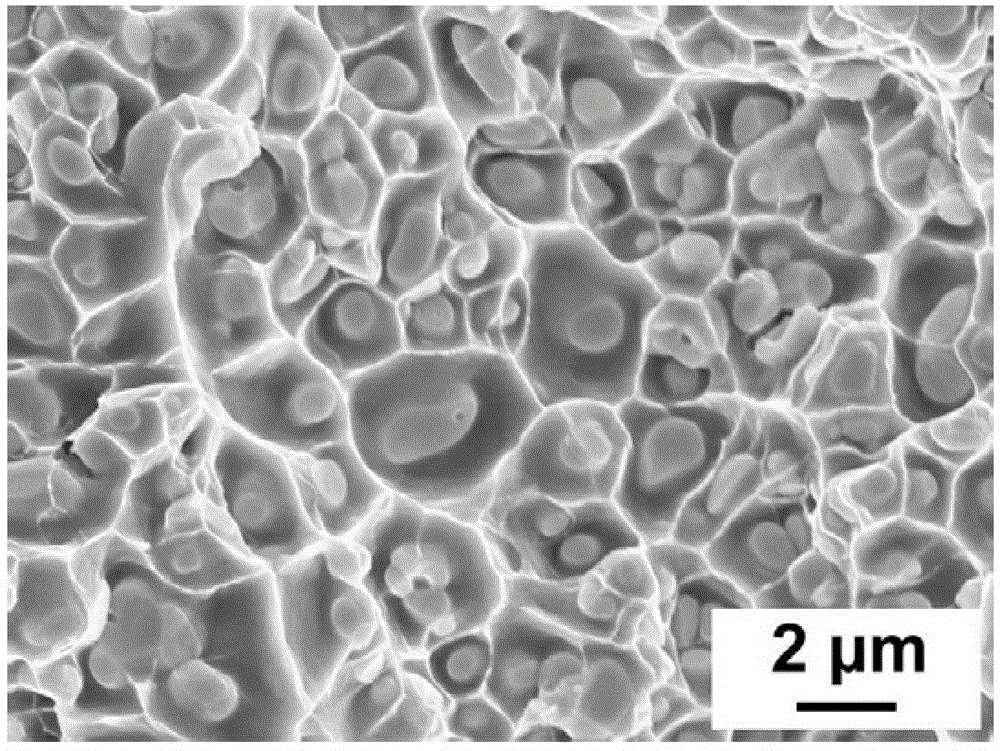

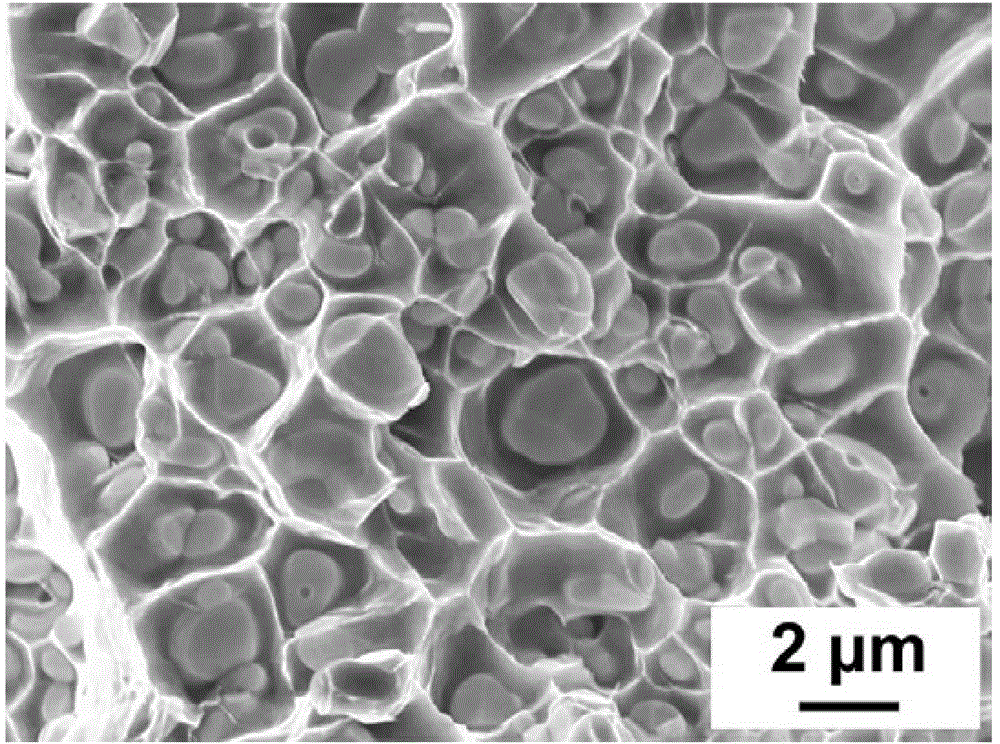

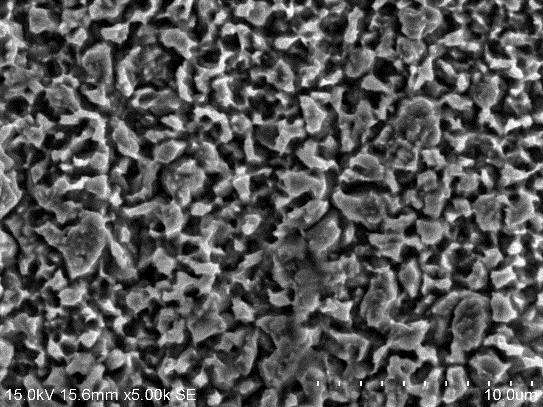

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

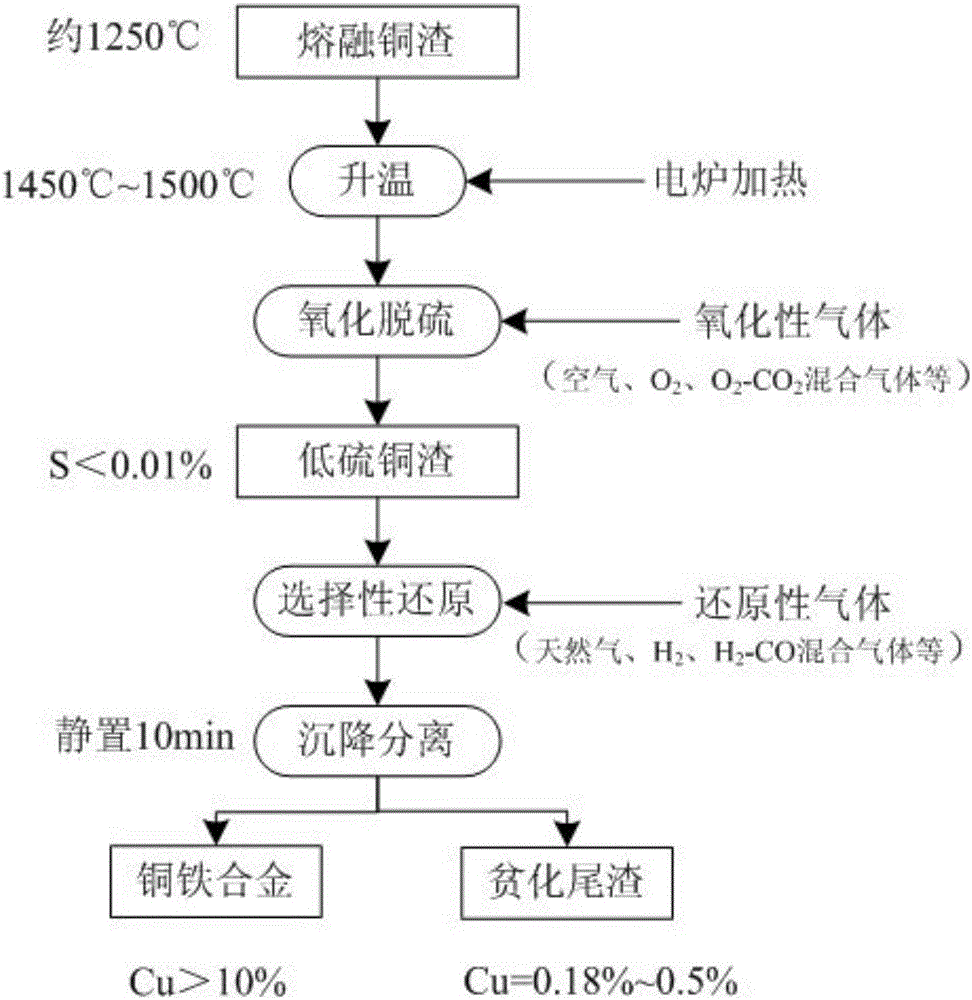

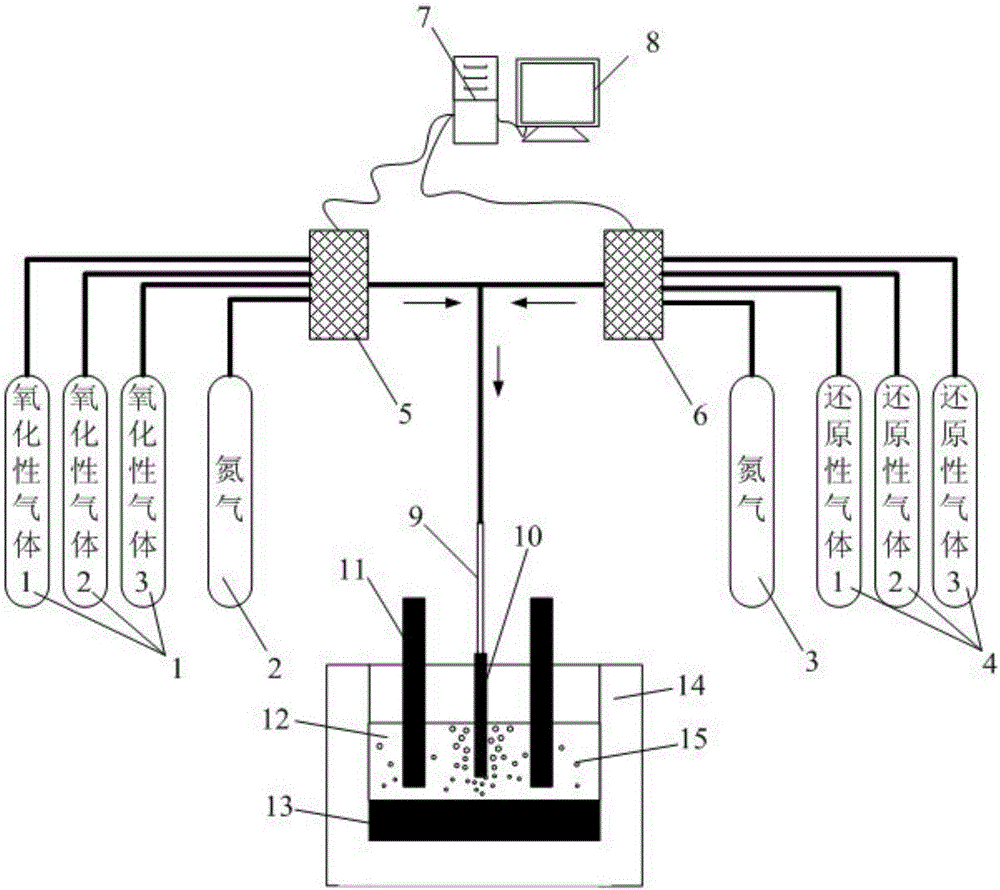

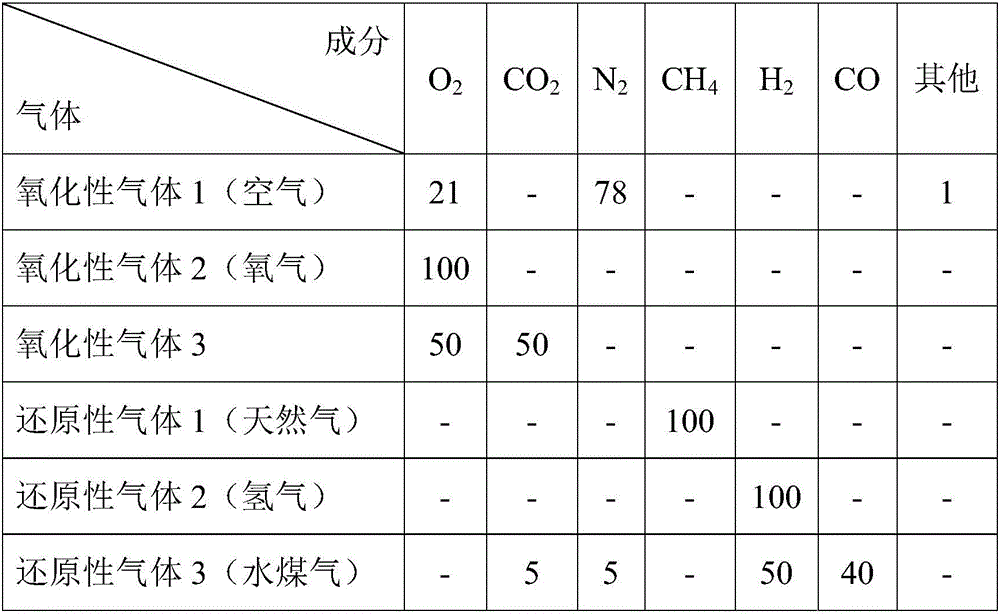

Method for realizing deep depletion on copper slag through multielement gas substep injection

ActiveCN106756062ARealize deep depletionComprehensive depletion results are excellentRotary drum furnacesCrucible furnacesLow copperMaterials science

The invention provides a method for realizing deep depletion on copper slag through multielement gas substep injection. The method fully utilizes waste heat of molten copper slag, copper matte is converted into oxide through gasification desulphurization, then selective reduction is carried out to obtain copper iron alloy with higher copper content, the problem of copper slag depletion in a smelting process is solved, and low-sulfur low-copper depletion slag is produced, so that conditions are created for a follow-up iron extracting process, and the deep depletion on the copper slag is realized; the traditional matte-producing depletion process is abandoned, but a gasification desulphurization process is firstly carried out for converting the copper matte into the oxide, then the oxide is subjected to selective reduction by virtue of a reducing agent, so that a copper-iron alloy phase is obtained. Operation is simple, adaptability is strong, the method can be realized by modifying the original electric furnace, nickel slag similar to the copper slag in properties can be treated, and metal elements such as Cu, Ni, Co and Fe can be comprehensively recycled.

Owner:UNIV OF SCI & TECH BEIJING

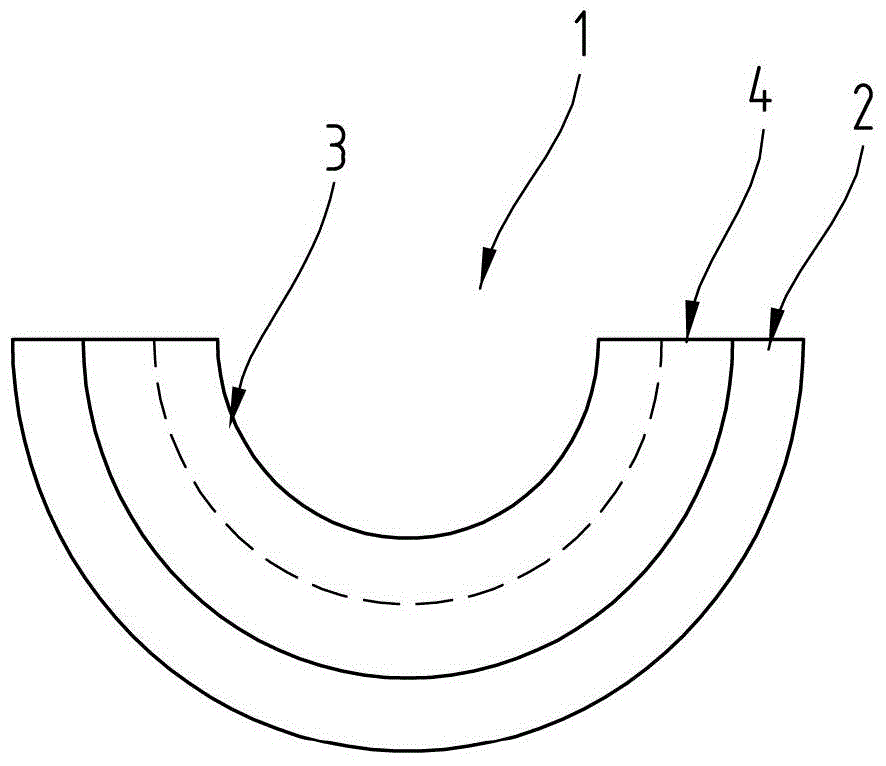

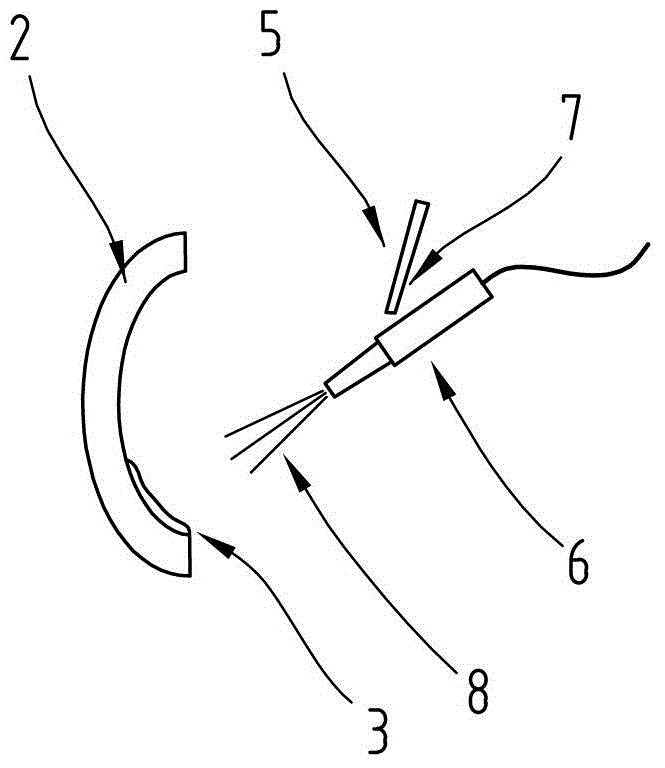

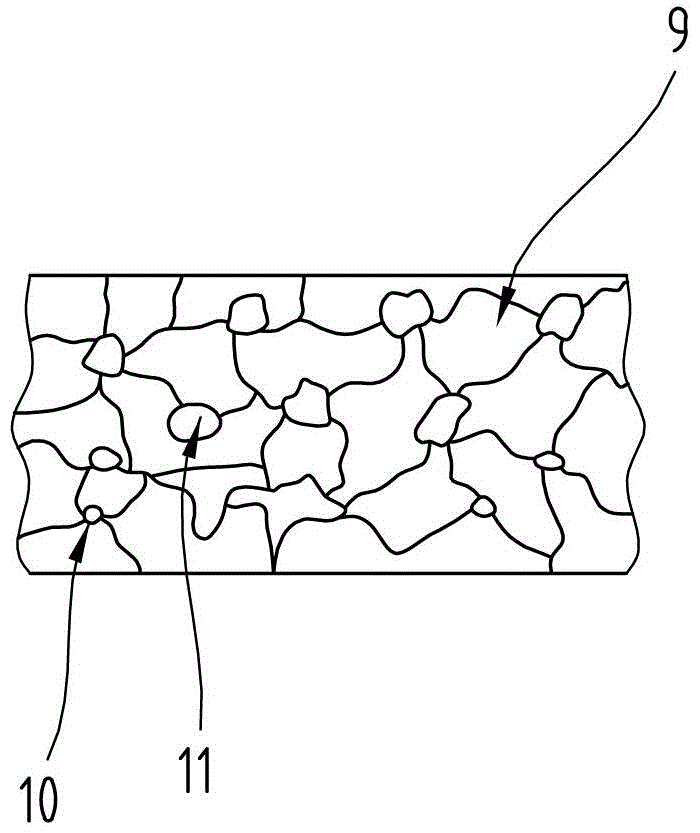

Method for manufacturing sliding bearing

The invention discloses a method for manufacturing a sliding bearing (1). The method includes the following steps that a metal supporting layer (2) is provided, and an additional metal layer made of a spraying material is directly sprayed on the metal supporting layer (2) or sprayed on the metal supporting layer (2) through at least one metal interlayer, wherein the additional metal layer is made of a tin base alloy provided with a tin-rich substrate in which hard particles (10) and / or soft particles (11) are added, the hard particles (10) are harder than the substrate and / or the soft particles (11) are softer than the substrate; and the spraying material (5) is adopted, under the condition that the spraying material (5) contains the hard particles (10), the additional metal layer with the hard particles (10) is formed, and / or under the condition that the spraying material (5) contains the soft particles (11), the additional metal layer with the soft particles (11) is formed, wherein the hard particles (10) and / or the soft particles (11) maintain a solid form in the spraying process.

Owner:MIBA PRECISION COMPONENTS CHINA

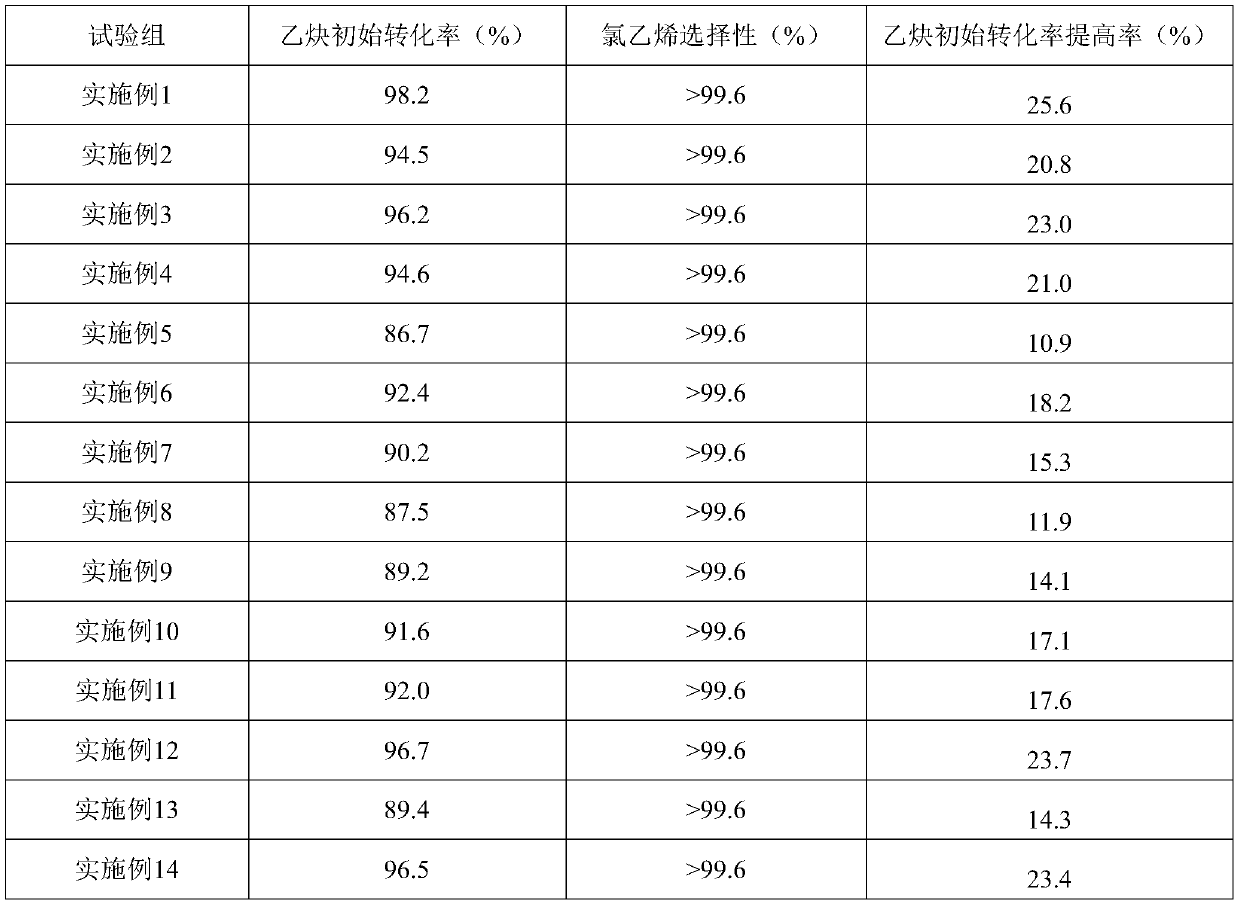

Copper-based catalyst taking nitrogen-modified activated carbon as carrier as well as preparation method and application thereof

PendingCN111420694AHigh activityIncreased copper contentPhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonPtru catalyst

The invention provides a copper-based catalyst taking nitrogen-modified activated carbon as a carrier as well as a preparation method and application of the copper-based catalyst, and belongs to the field of acetylene hydrochlorination catalysts. One or more of urea, melamine, ammonium bicarbonate and ammonia gas are used as modifiers to modify wood activated carbon, a nitrogen-modified activatedcarbon carrier is obtained, a copper salt is used as an active component and adsorbed to the surface of the nitrogen-modified activated carbon carrier through an impregnation method, and the copper-based catalyst with the nitrogen-modified activated carbon as the carrier is obtained. The activated catalyst is applied to an acetylene hydrochlorination reaction, the acetylene conversion rate is 96%or above, the vinyl chloride selectivity is 99.6% or above, the catalyst activity and stability are high, the catalyst provided by the invention is a mercury-free non-noble metal catalyst, and the preparation method is relatively simple, low in cost and free of mercury pollution.

Owner:鄂尔多斯市瀚博科技有限公司

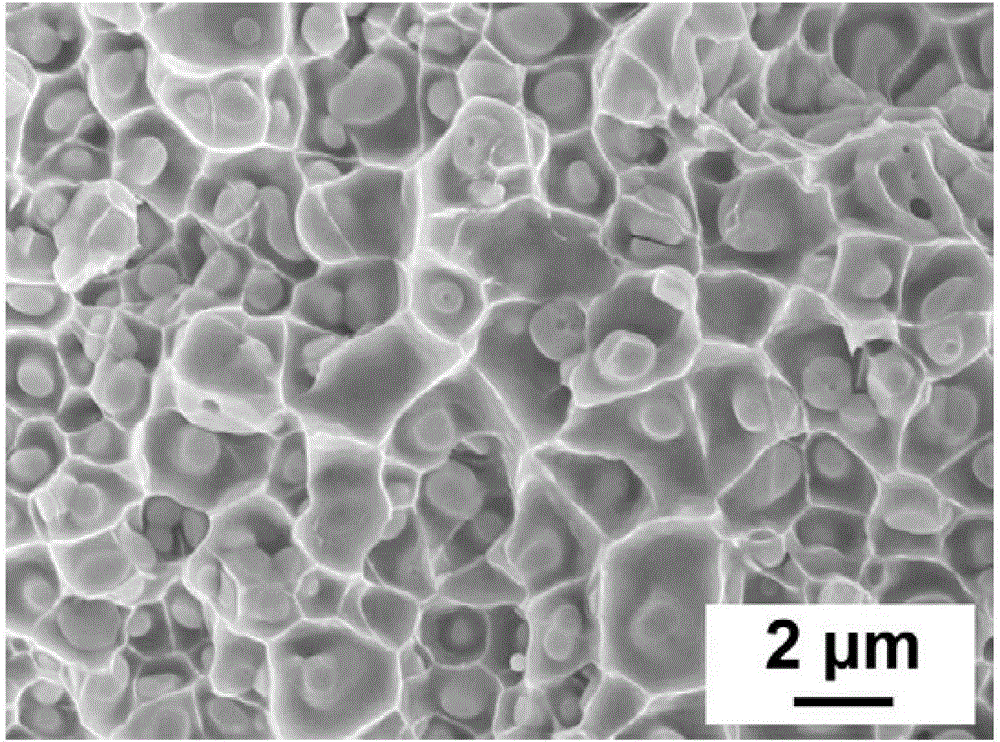

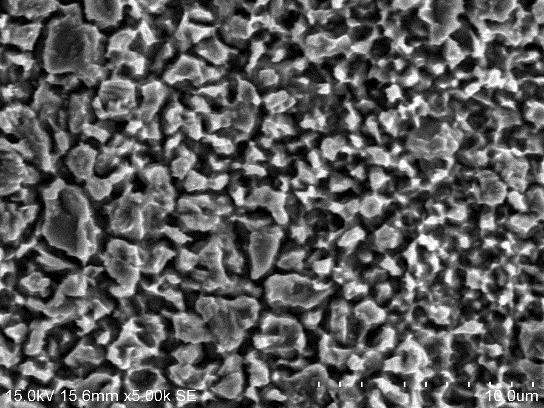

Method for preparing tungsten-copper alloy by low-temperature sintering of tungsten skeleton

ActiveCN103981389ALow impurity contentAchieve low temperature sinteringHydrogen atmosphereTube furnace

The invention discloses a method for preparing tungsten-copper alloy by low-temperature sintering of a tungsten skeleton. The method comprises the steps of carrying out wet grinding on tungsten powder of which the purity is 99.9% and the particle size is 1-7 mum and WOx powder which accounts for 5%-20% of the total mass of the powder and of which the particle size is 1-15 mum, uniformly mixing, drying and sieving, carrying out isostatic pressing on the mixed powder to obtain a green compact, sintering the green compact to obtain the tungsten skeleton, calculating the copper infiltration amount, cutting a copper plate of which the purity is greater than 99.5% into copper sheets with the same surface size as that of the tungsten skeleton, placing the copper sheets on the tungsten skeleton, feeding into a tubular furnace, heating to 1200-1400 DEG C under hydrogen atmosphere and carrying out copper infiltration. The content of copper in the tungsten-copper alloy is 15wt%-40wt%, and the balance is tungsten; the tungsten-copper alloy has more than 98% of density and the tungsten-copper alloy is suitable for being used as an electrical contact and electrode material, an electronic packaging material, a high-temperature sweating materials and the like.

Owner:XIAMEN UNIV OF TECH

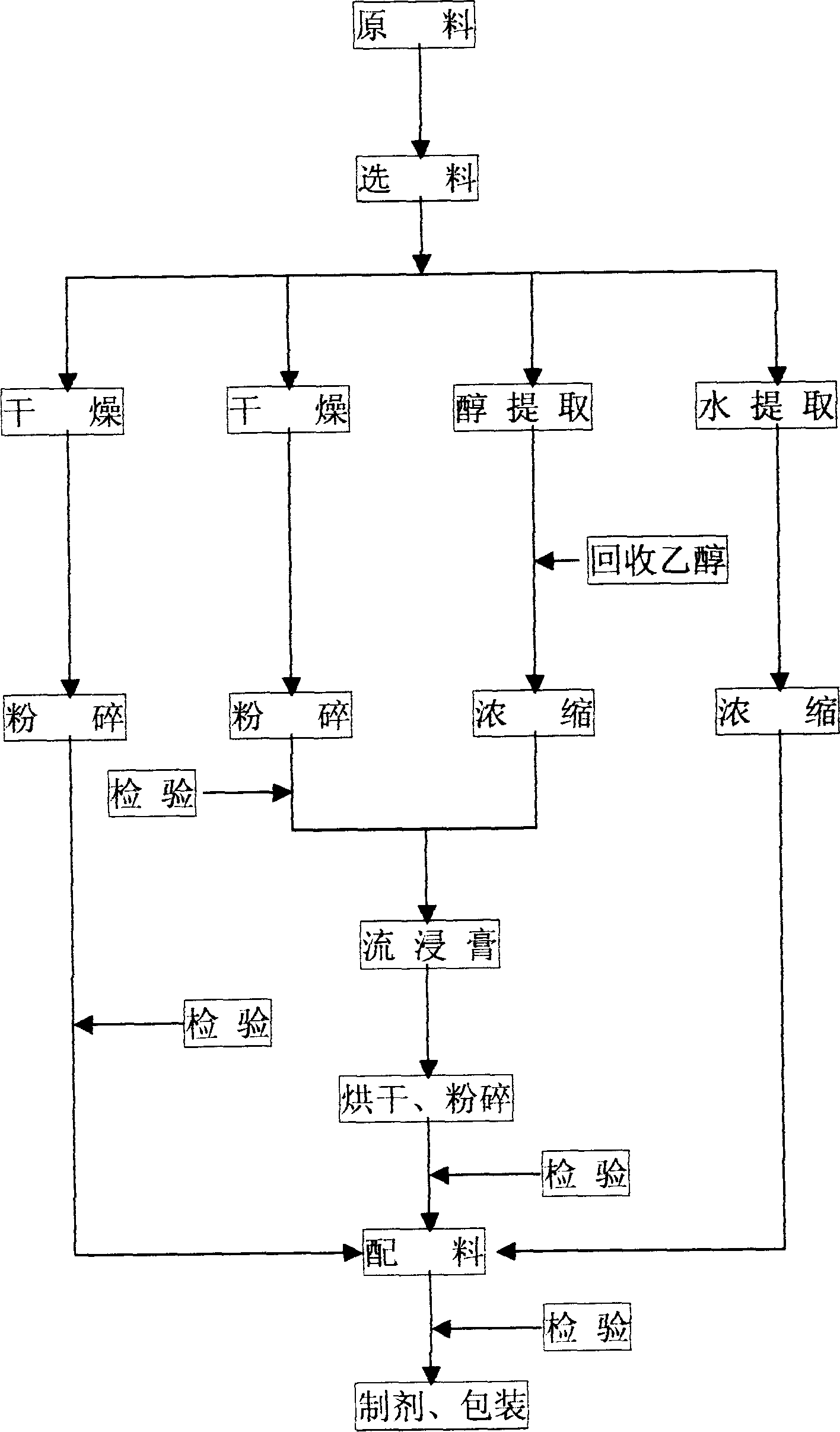

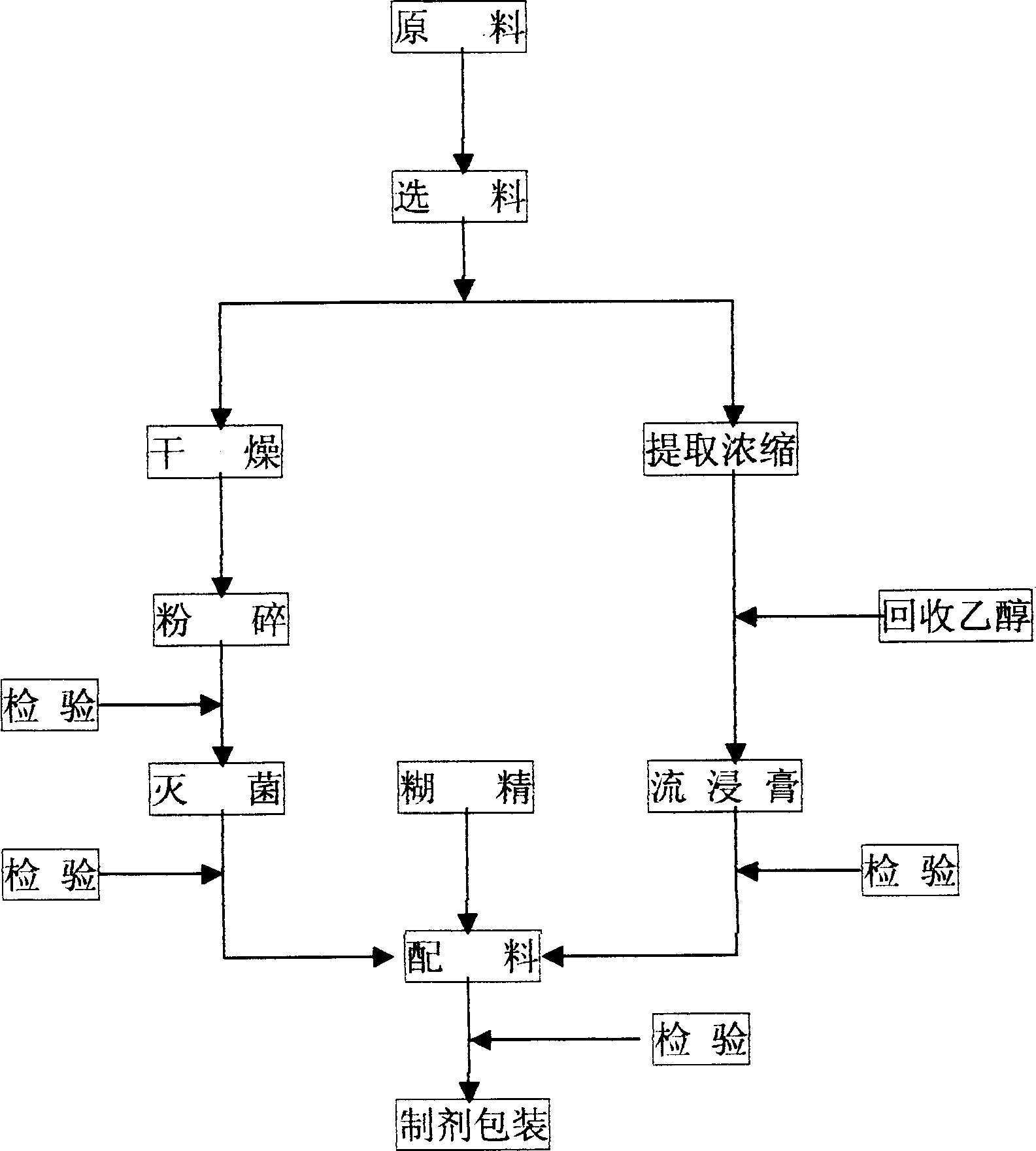

Nutritious health care food and preparation prlcess thereof

InactiveCN1483450ASimple processThe process is simple and easy to operateDigestive systemUnknown materialsNutrientPhysiological function

The present invention relates to a nutrient health-care food with the functions of regulating physiological function of human body, raising immunity of human body, nourishing yin and strengthening yang and quickly raising sexual function. Said nutrient health-care food is made up by using velvet deerhorn, ginseng, epimedium, dioscorea root, lycium berry, flowery knotweed, morinda root and Chinese leak seed.

Owner:鲁骏

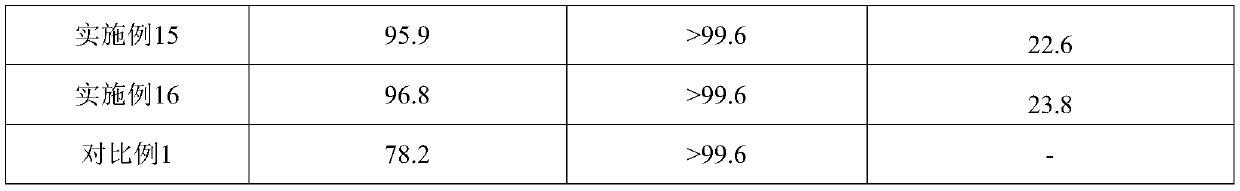

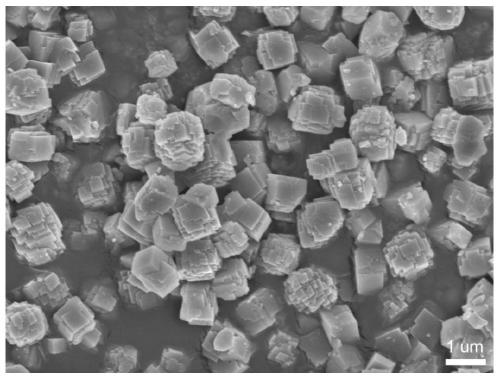

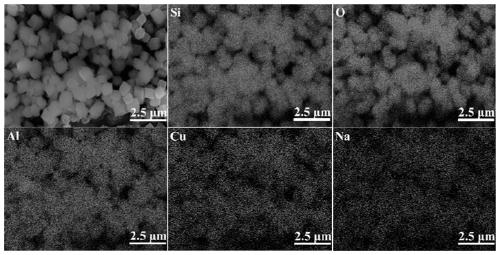

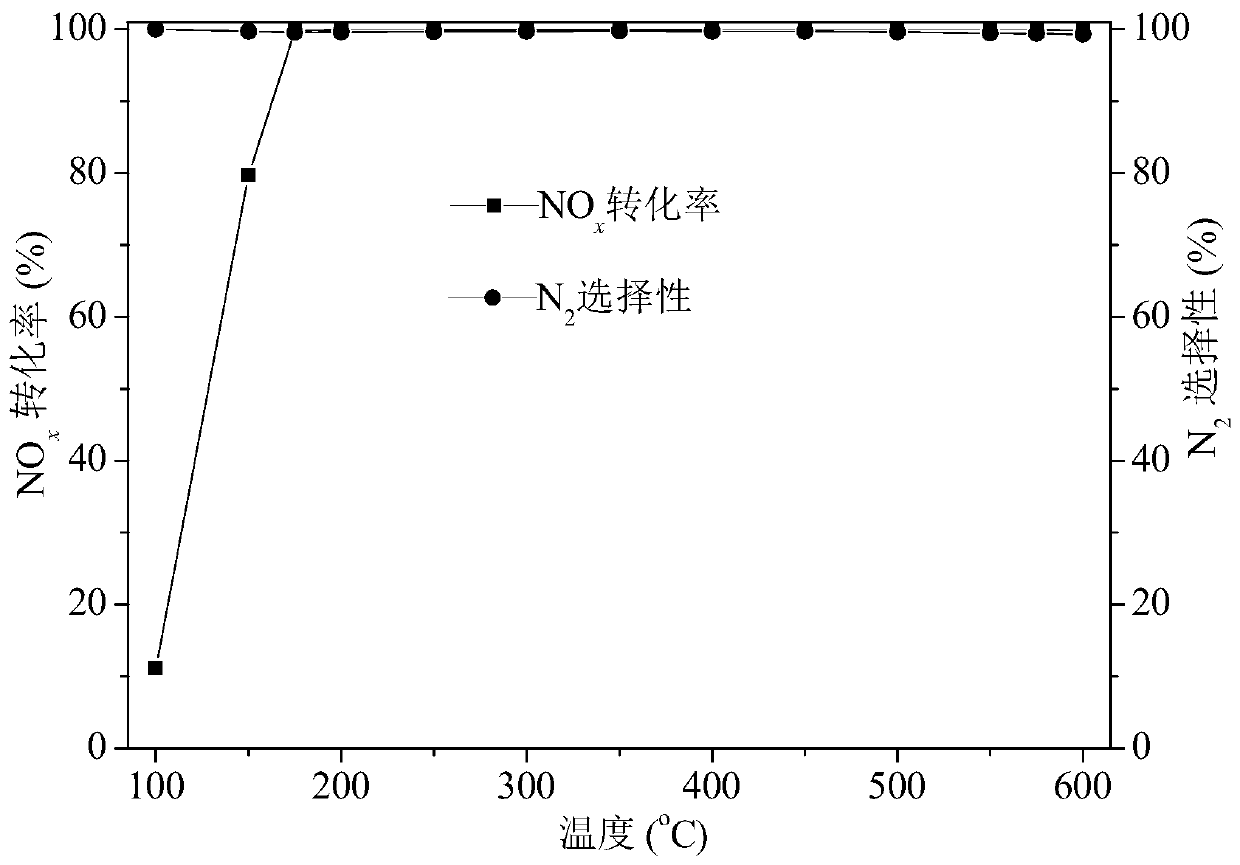

Preparation method of Cu-SSZ-13 with wide temperature window, obtained product and application thereof

ActiveCN111408401AIncrease loadImprove dispersion uniformityMolecular sieve catalystsDispersed particle separationMolecular sievePhysical chemistry

The invention discloses a preparation method of Cu-SSZ-13 with a wide temperature window, an obtained product and application thereof, the method uses a Na-type SSZ-13 molecular sieve with a low silica-alumina ratio as a raw material, and then NH4NO3 and CuSO4 exchange is carried out on the Na-type SSZ-13 molecular sieve in order to obtain Cu-SSZ-13. According to the preparation method, the content and the dispersing performance of Cu are improved, the obtained Cu-SSZ-13 product is high in copper content (the Cu content is about 5.3-5.6 wt.%), and copper is in atomic dispersion; the excellentNH3-SCR performance is realized in a wide temperature window; and when the air speed is 100000 h <-1>, the NOx conversion rate in the temperature interval of 175-600 DEG C reaches 100% or above, the N2 selectivity close to 100% is kept in the whole temperature interval of 100-600 DEG C, and the good application prospect is achieved.

Owner:UNIV OF JINAN

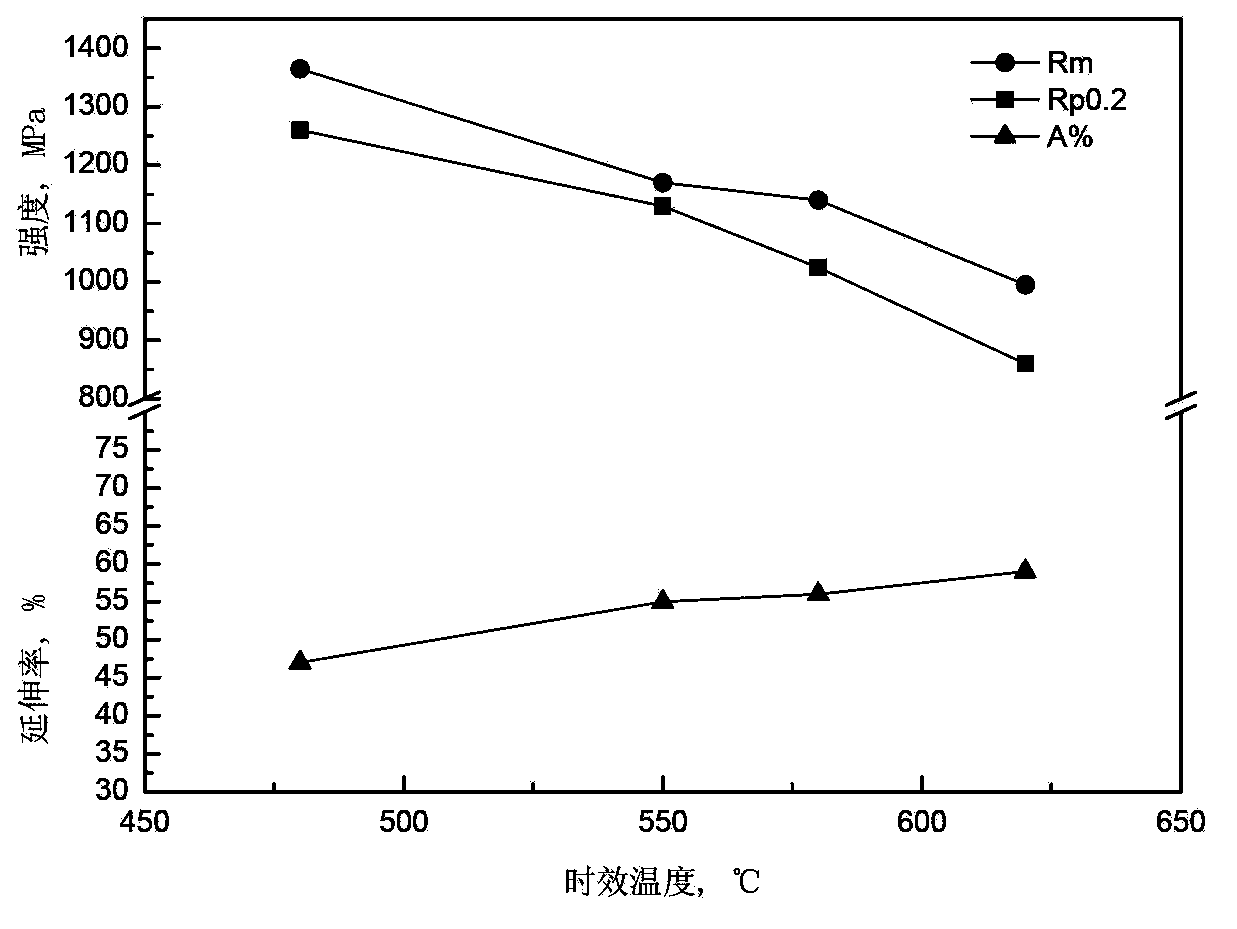

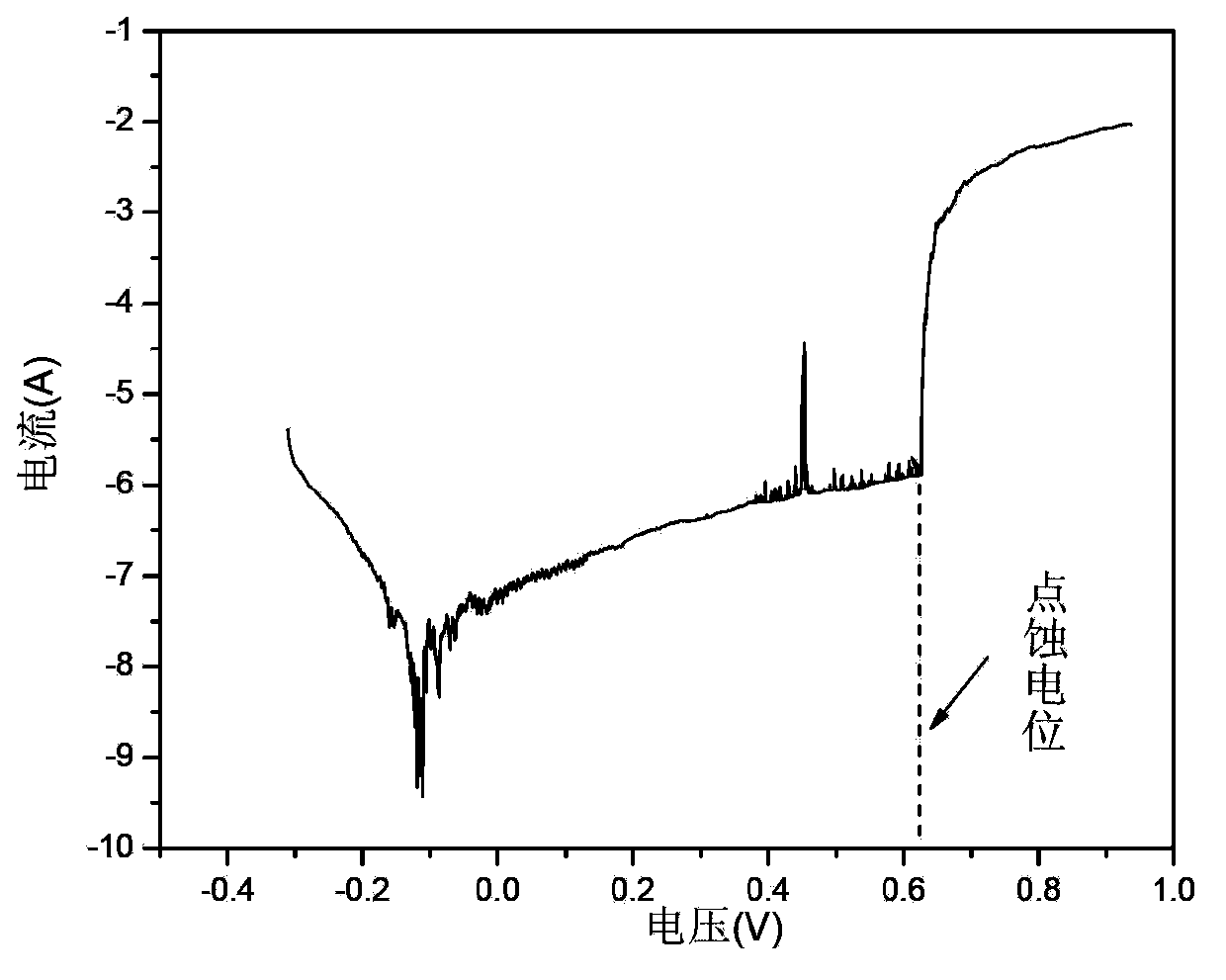

Precipitation-hardening martensitic stainless steel for surgical operation and heat treatment process thereof

ActiveCN103866198AImprove antibacterial propertiesImprove mechanical propertiesSurgical operationChemical composition

The invention discloses precipitation-hardening martensitic stainless steel for a surgical operation and a heat treatment process thereof, and belongs to the technical field of stainless steel material. The stainless steel comprises the following chemical composition: not more than 0.07 wt% of C, not more than 1.00 wt% of Si, not more than 1.00 wt% of Mn, not more than 0.040 wt% of P, not more than 0.030 wt% of S, 3.00-5.00 wt% of Ni, 15.0-17.5 wt% of Cr, 3.5-5.5 wt% of Cu, 0.05-0.15 wt% of N, 0.15-0.45 wt% of Nb, and the balance Fe. After the stainless steel is subjected to special heat treatment, a copper-rich phase can be precipitated evenly and dispersedly in a stainless steel matrix, and thus the stainless steel is endowed with an antibacterial function. The stainless steel solves the problem of bacterial infection caused by the use of stainless steel tools in a conventional surgical operation, is widely applied in various stainless steel appliances such as scalpels, surgical scissors, surgical forceps, intestinal forceps and curettes used in the surgical operation in the medical clinical field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

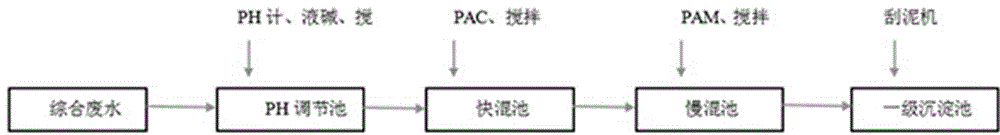

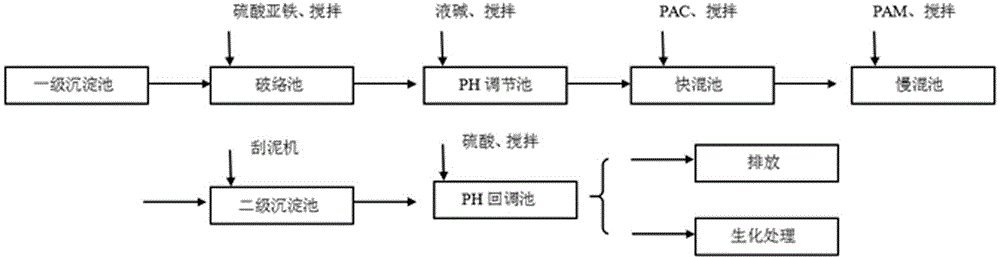

Two-level copper removing technology for treating low-concentration comprehensive wastewater in PCB electroplating

InactiveCN104944698AReduce dosageLow costWaste water treatment from metallurgical processMultistage water/sewage treatmentSludgeResource utilization

The invention discloses a two-level copper removing technology for treating low-concentration comprehensive wastewater in PCB electroplating. The two-level copper removing technology comprises a two-level copper removing process: hydrated copper ions in wastewater are removed in a primary cooper removing process; complex cooper irons are removed in a secondary cooper removing process. The two-level copper removing technology specifically comprises the following steps: after being lifted, the wastewater enters a pH adjustment tank; through pumping, an alkaline chemical agent is added to control the pH value of the wastewater to be 8.5-9; the adjusted wastewater I enters a quick mixing tank and a slow mixing tank in sequence; clear water obtained through primary precipitation is lifted through pumping and enters a complex breaking tank; a proper amount of ferrous sulfate is added for complex breaking; the pH value of the primarily treated wastewater is adjusted to be 8-9; the adjusted wastewater II enters the quick mixing tank and the slow mixing tank in sequence; the wastewater subjected to secondary precipitation enters a pH call-back tank for biochemical treatment; the standard wastewater is discharged. The two-level copper removing technology has the advantages that the chemical agent treatment cost is reduced, the discharged water quality is stabilized, the sludge minimization and the recovery value resource utilization are facilitated, and a high popularization value is achieved for wastewater treatment in the conventional PCB industry.

Owner:湖南景翌湘台环保高新技术开发有限公司

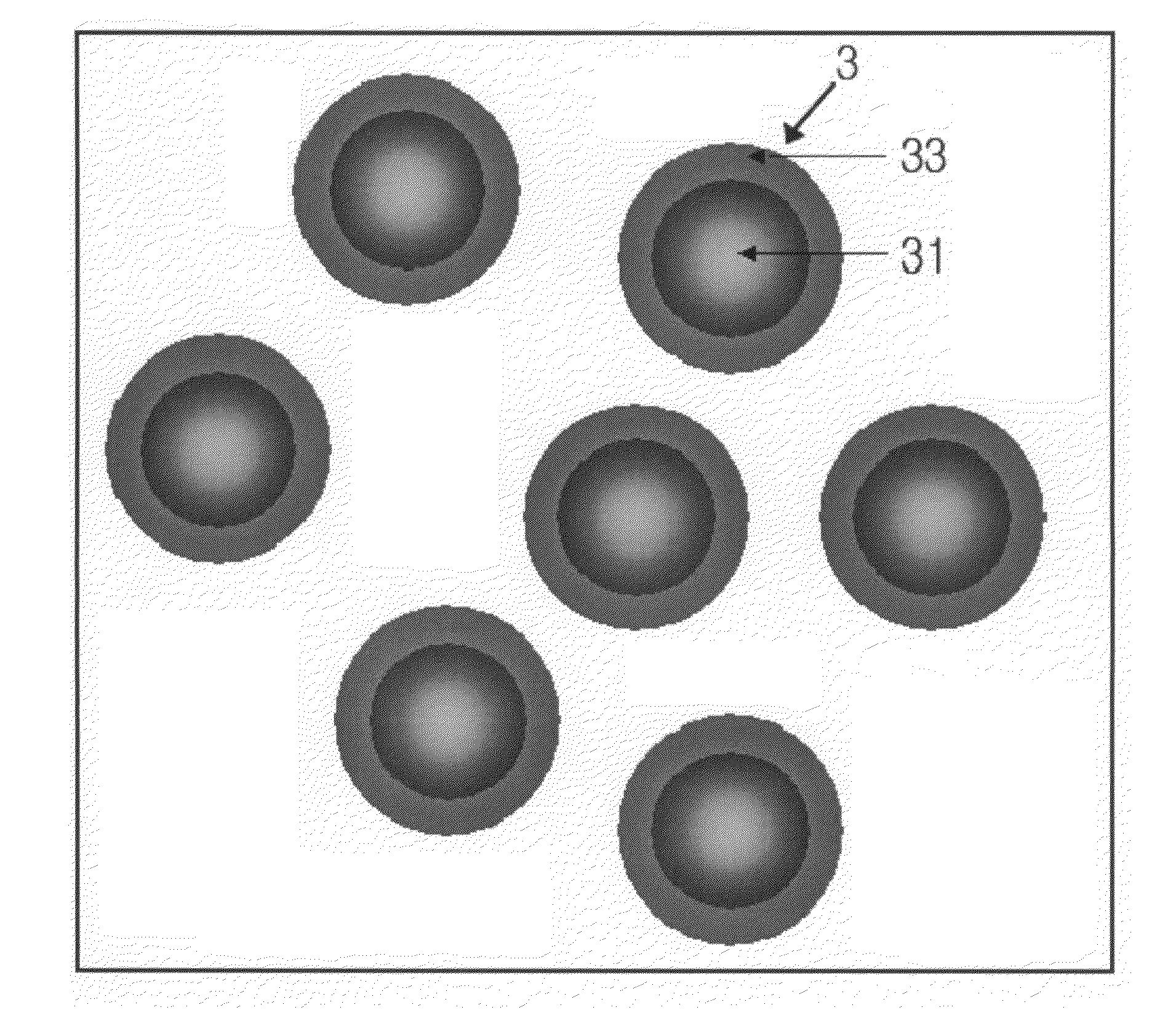

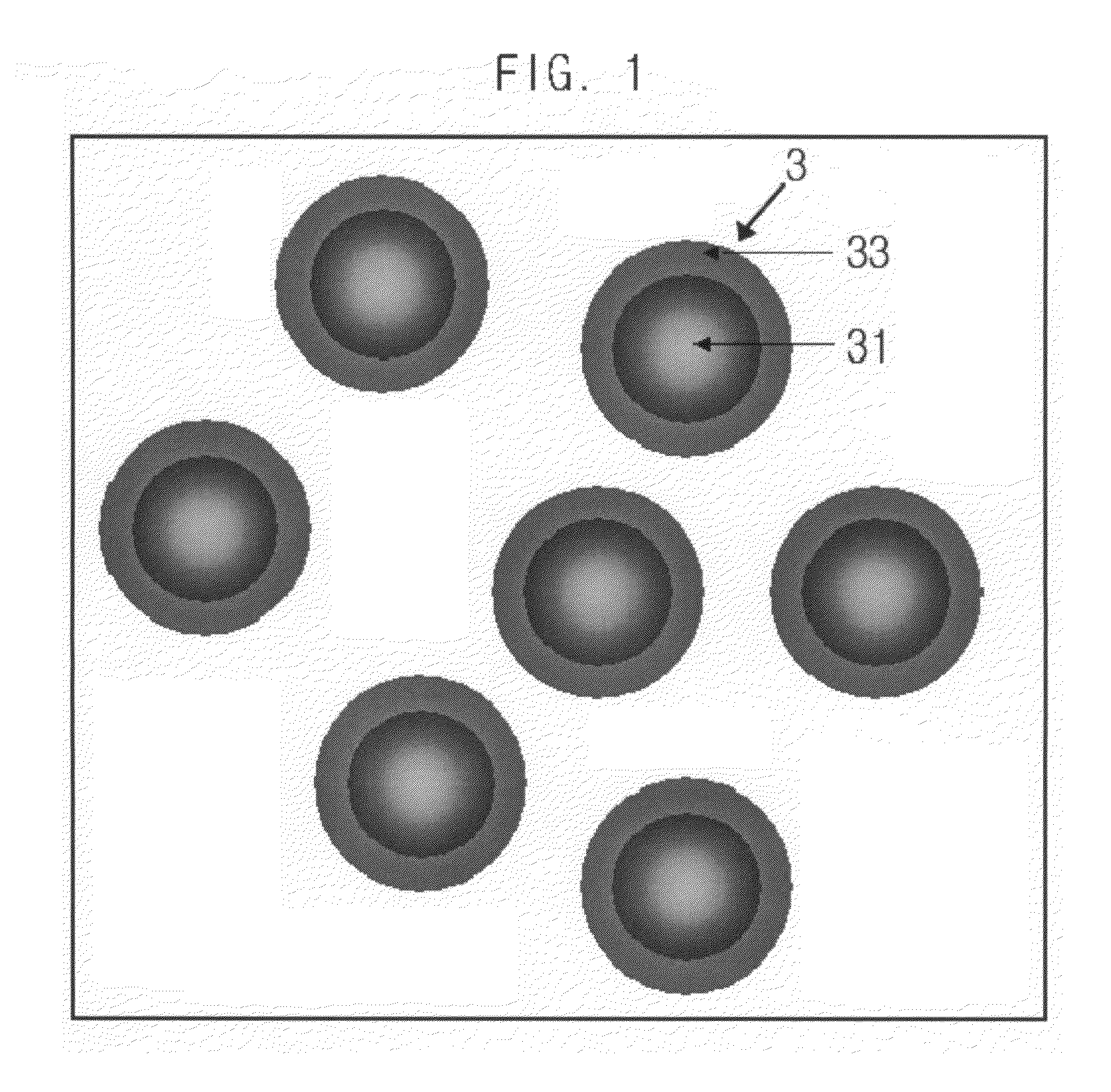

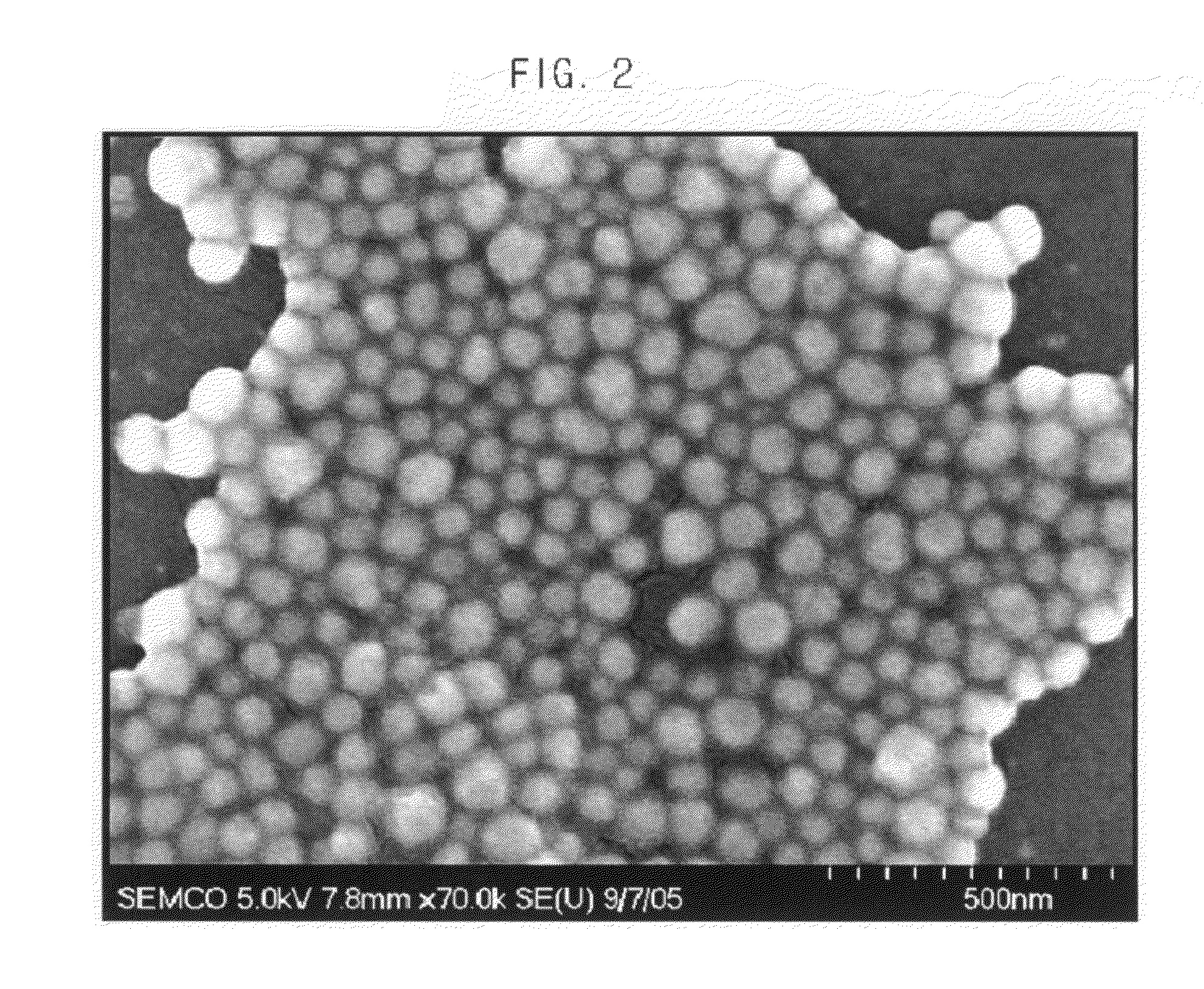

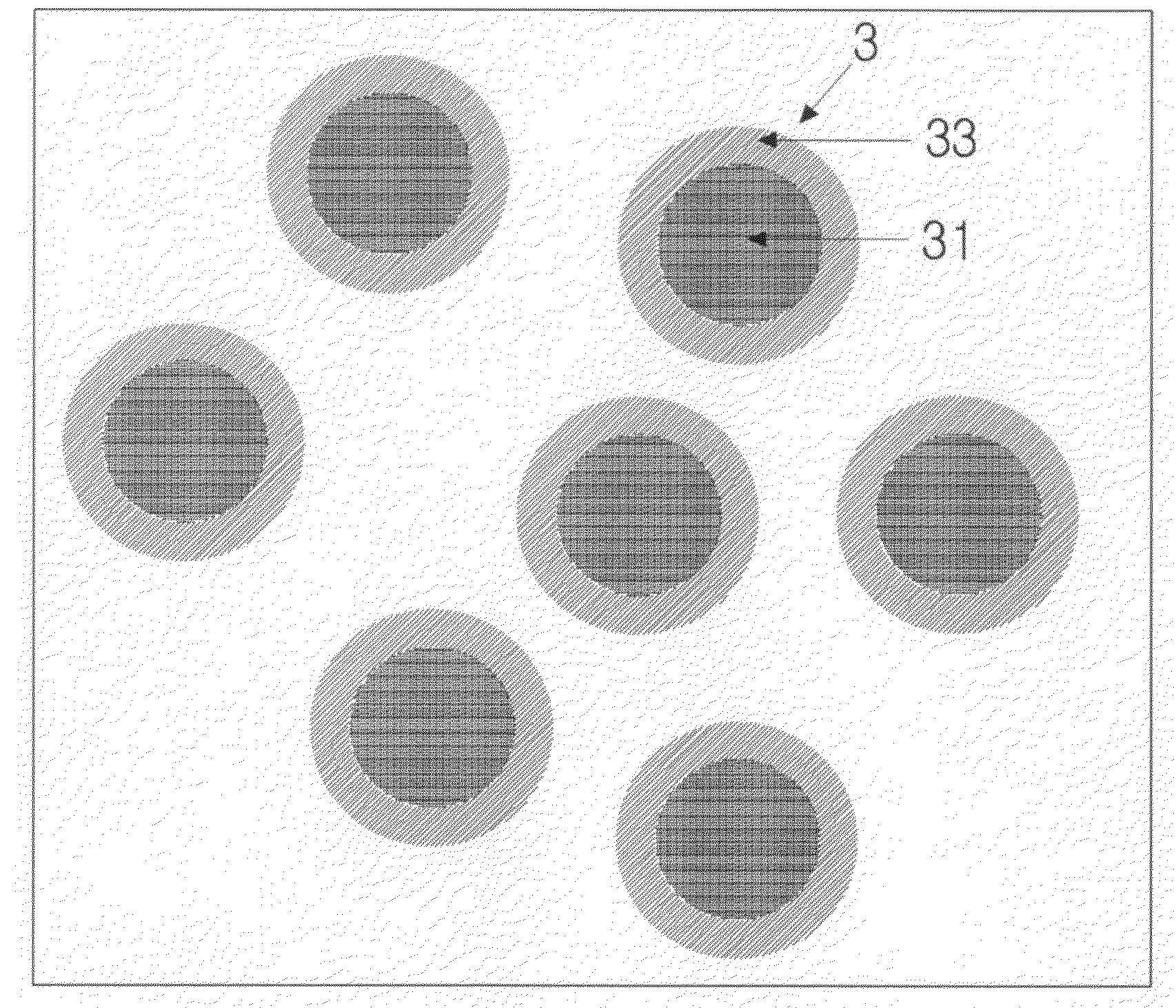

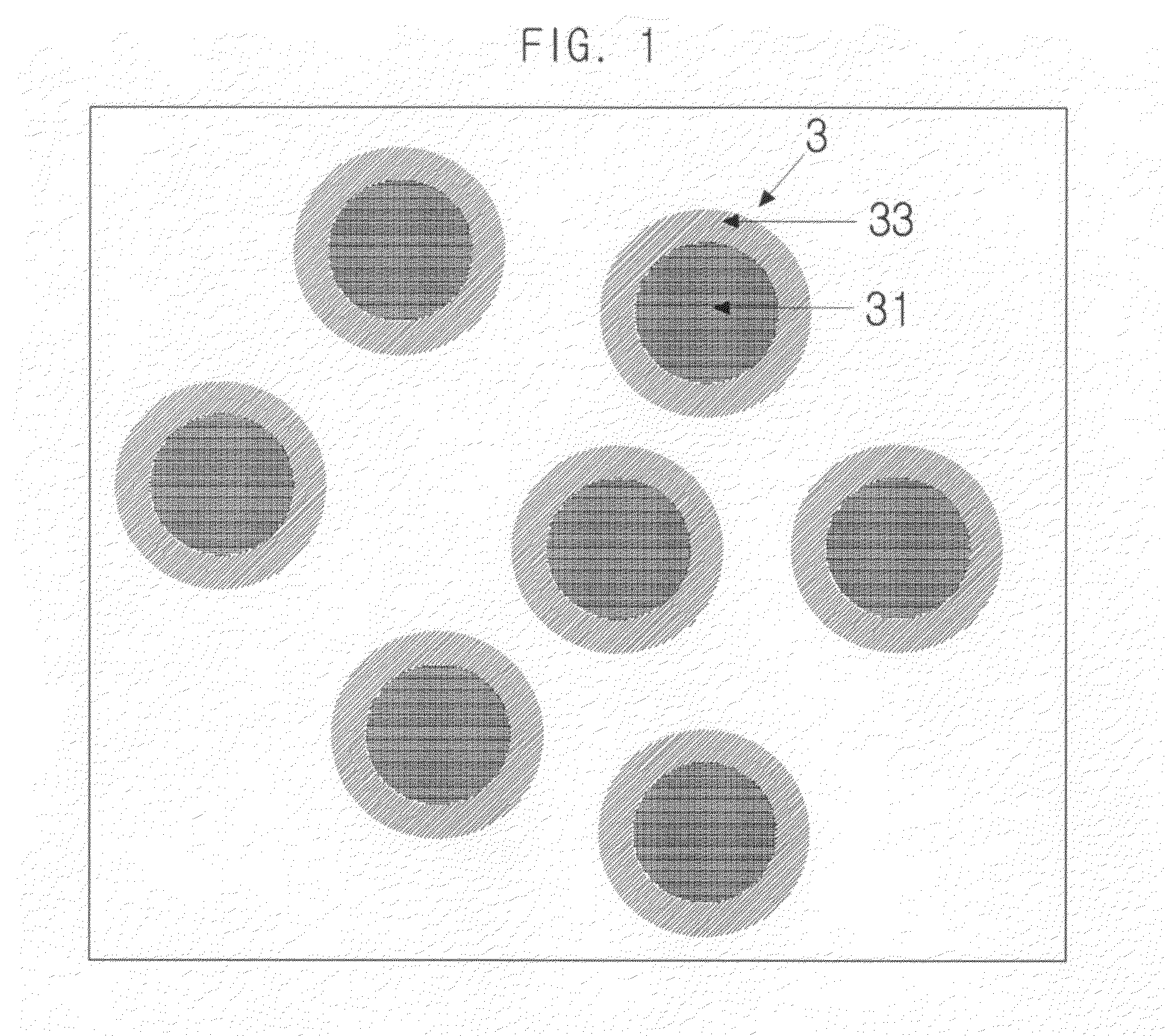

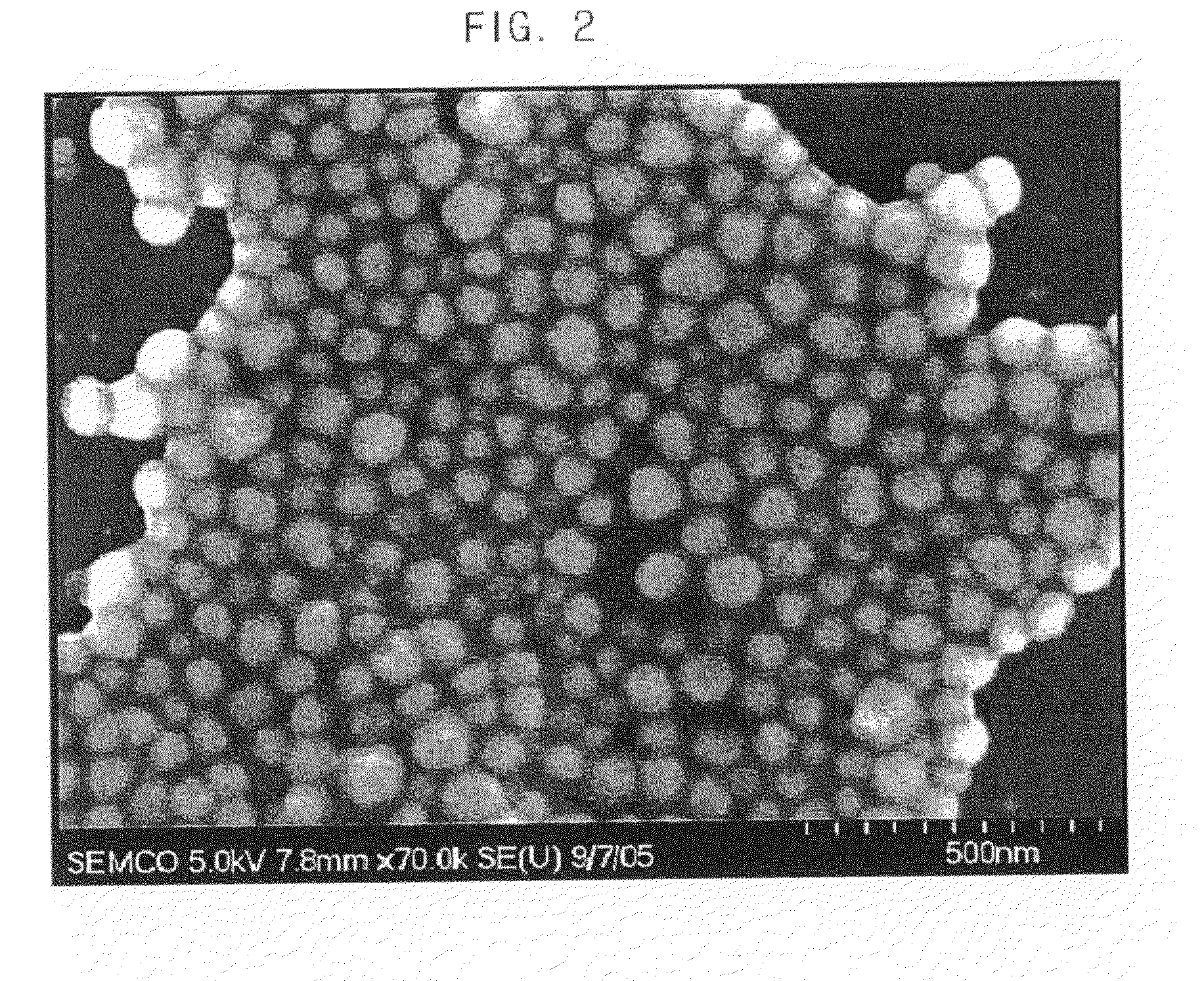

Core-shell structure metal nanoparticles and its manufacturing method

InactiveUS7611644B2Prevent oxidationEconomical efficiencyMaterial nanotechnologyNon-insulated conductorsElectricityThin layer

The present invention provides metal nanoparticles, containing copper core and thin layer of precious metals enclosing the core to prevent oxidization of copper, in which manufacturing the metal nanoparticles is economical efficiency because of increased copper content and since such metal nanoparticles contain a metal having high electrical conductivity such as silver for a thin layer, they can form a wiring having better conductivity than copper and there is little concern that silver migration may occur.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Preparation method for graphene-enhanced copper-niobium multi-core composite wire

ActiveCN106448799AHigh strengthImprove ductilityConductive materialMetal/alloy conductorsReduction treatmentAlcohol

The invention provides a preparation method for a graphene-enhanced copper-niobium multi-core composite wire. The preparation method comprises the following steps: firstly, uniformly mixing graphene powder, niobium powder and copper powder to obtain mixed powder; secondly, adding a tackifier and the mixed powder into alcohol ketone mixed solution, stirring uniformly, drying to obtain a powder material, and then performing thermal reduction treatment on the powder material to obtain graphene-enhanced copper-niobium composite powder; thirdly, filling a pipe with graphene-coated copper-niobium composite powder to obtain a piped composite body; fourthly, drawing to obtain a single-core composite wire; fifthly, performing primary compounding moulding to prepare a 19-core composite wire; sixthly, performing secondary compounding moulding to prepare a 192-core composite wire; seventhly, performing tertiary compounding moulding to obtain the graphene-enhanced copper-niobium multi-core composite wire. The wire prepared by the preparation method has the characteristics of high strength, high extensibility, high conductivity and the like of the graphene, and the obstacle that the performance of a Cu / Nb material prepared by a conventional process cannot be further improved is overcome.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

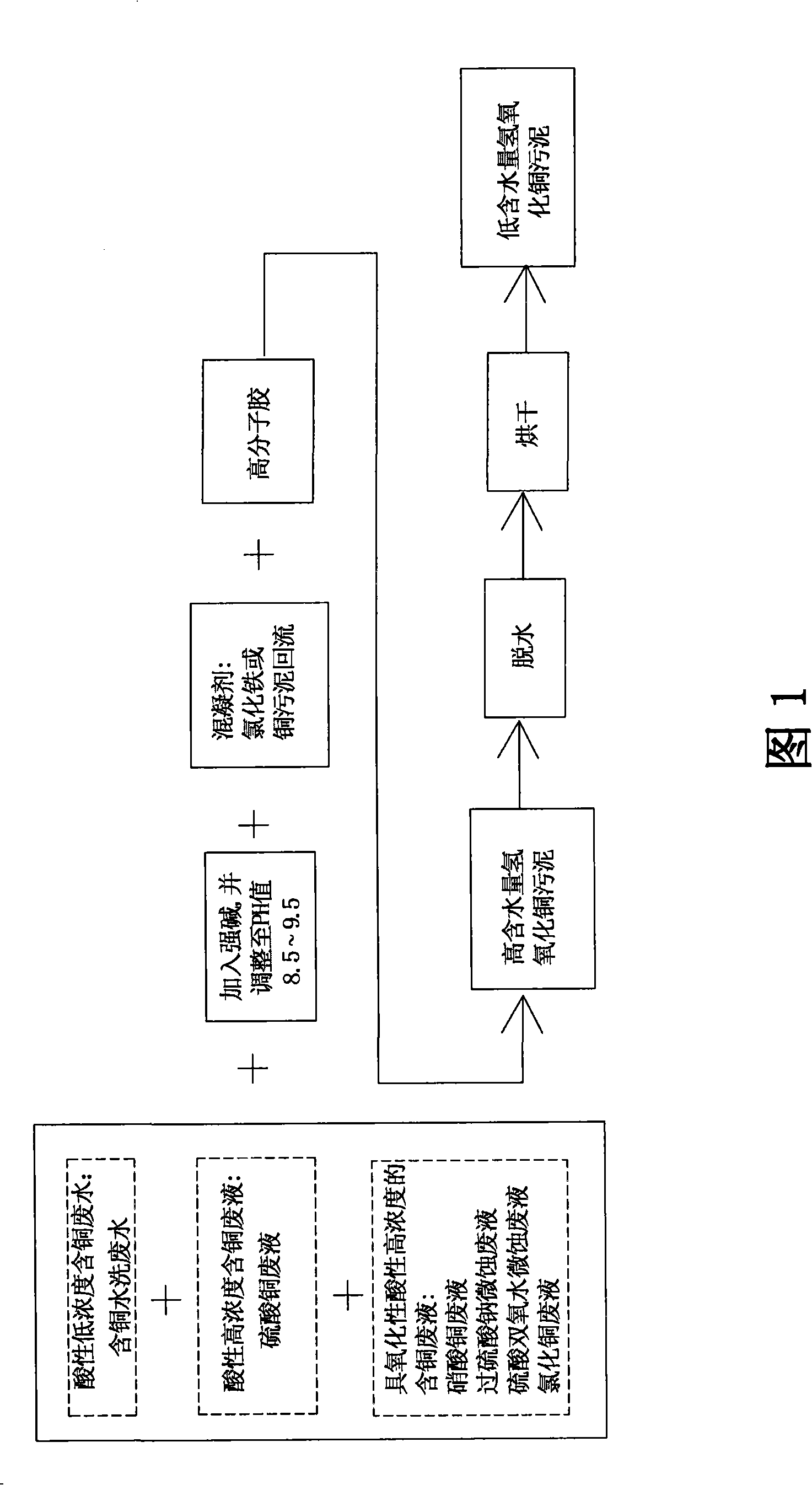

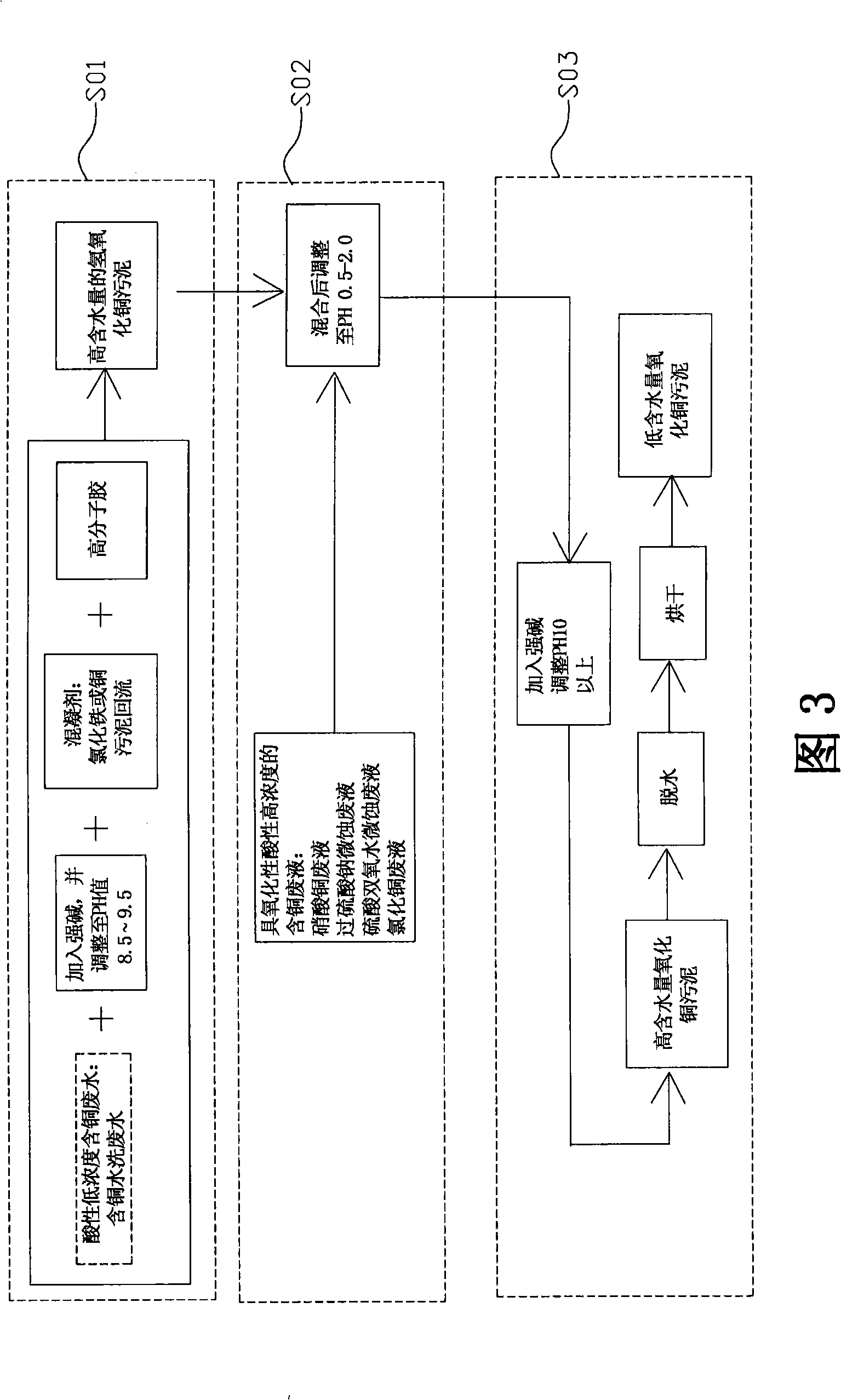

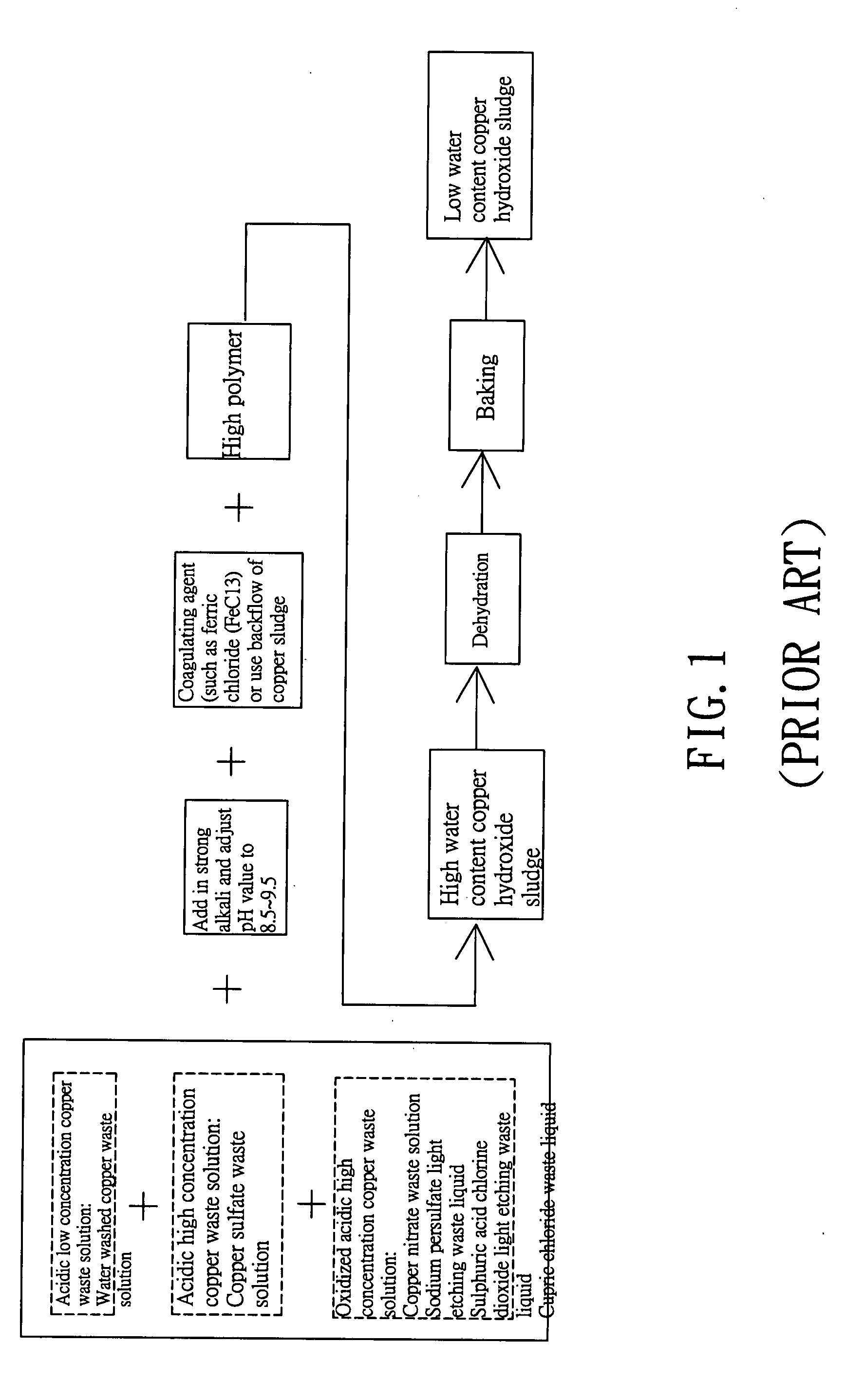

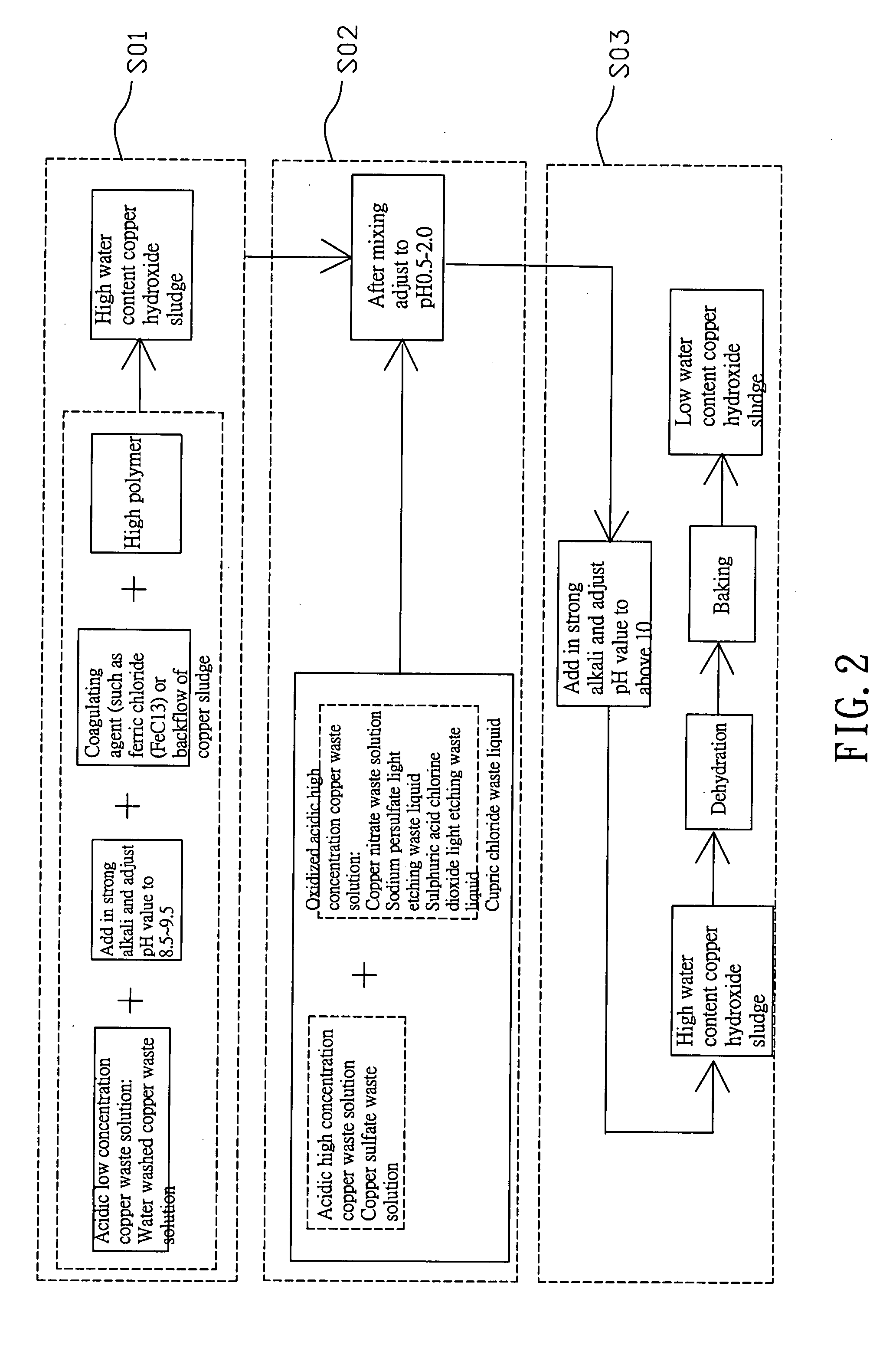

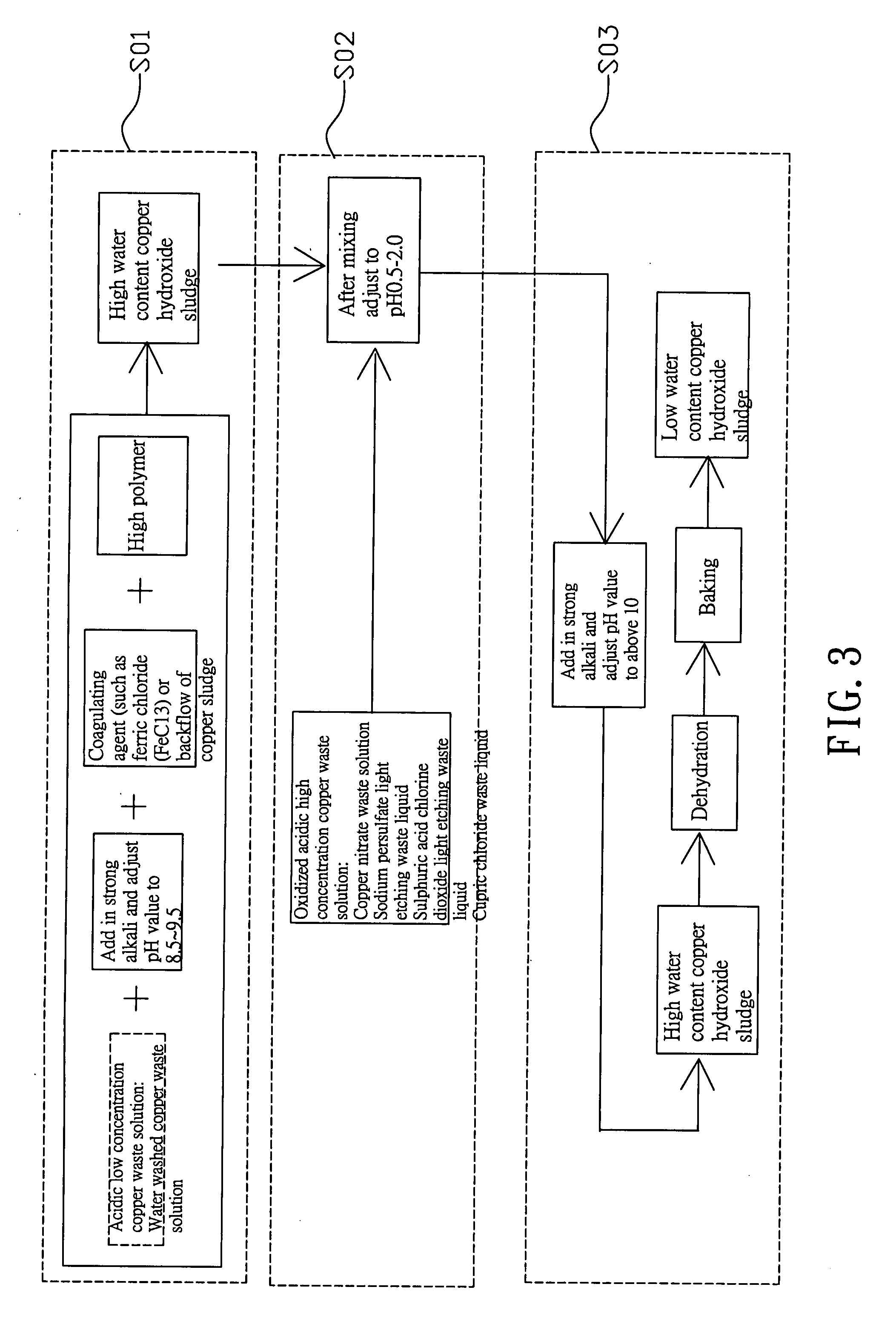

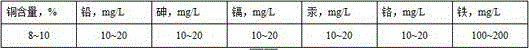

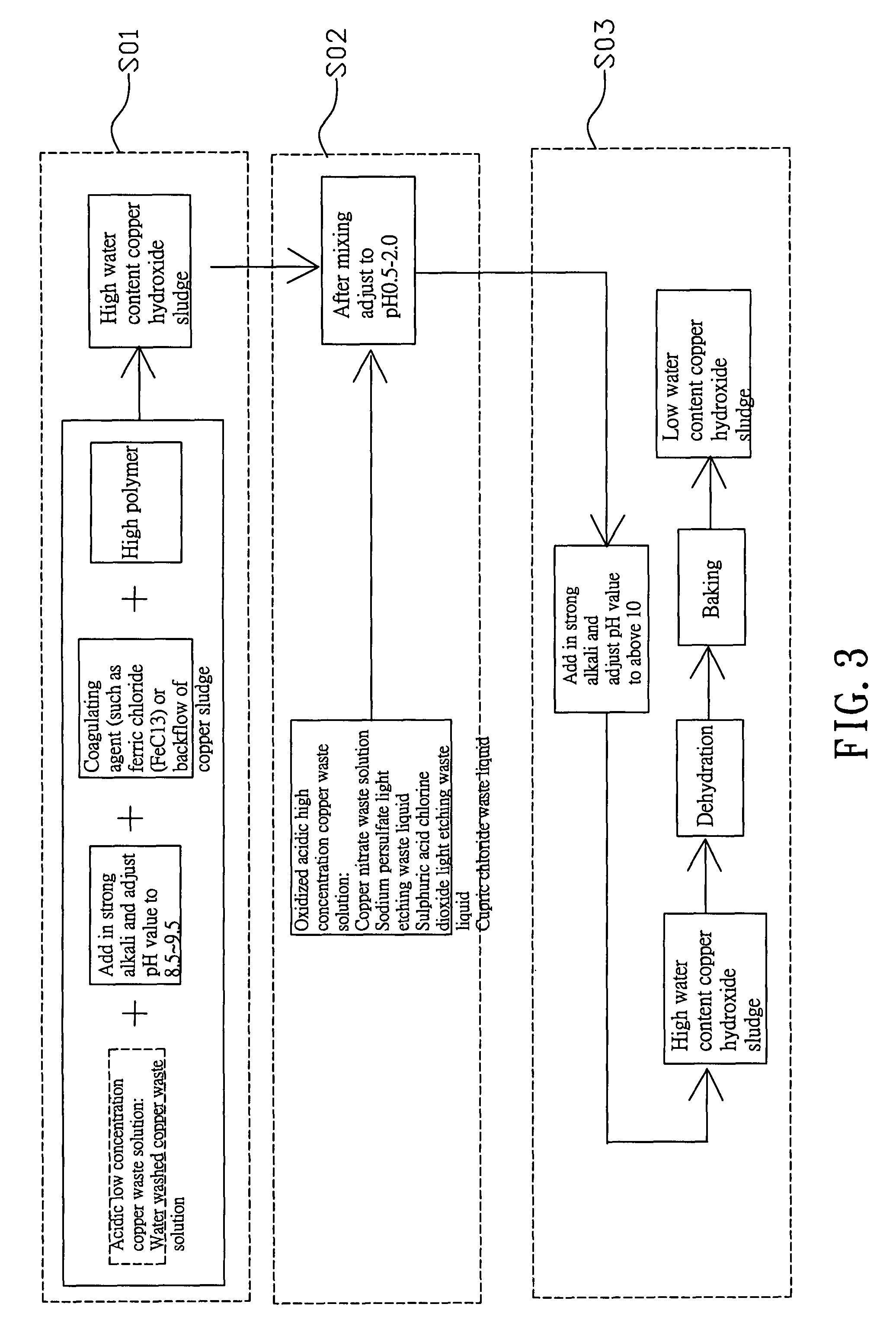

Processing method for generating highly copper containing sewage sludge with copper containing wastewater or waste liquor

InactiveCN101293688AIncreased copper contentReduce moisture contentCopper oxides/halidesWater/sewage treatment by flocculation/precipitationHigh concentrationLiquid waste

The invention provides a processing method for producing high copper sludge from copper-containing wastewater or waste cupric liquor, which includes the following steps: the invention mainly recycles and treats the copper-containing wastewater or waste cupric liquor which is produced after a printed circuit board is made, so as to precipitate copper sludge with higher copper content; the copper-containing wastewater or waste cupric liquor which is produced after a printed circuit board is made is firstly classified into acid copper-containing wastewater with low concentration, acid copper cupric liquor with high concentration and copper cupric liquor with oxidizability and high concentration and then is mixed and react with strong base to generate copper oxide sludge and then water is removed from the copper oxide sludge by a dehydration / drying device, so as to obtain the copper sludge with higher copper content. The method can transform cupric hydroxide to copper oxide without adding other transforming agents and can convert the low copper sludge in valueless copper-containing wastewater or waste cupric liquor into high copper sludge with recovery value.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

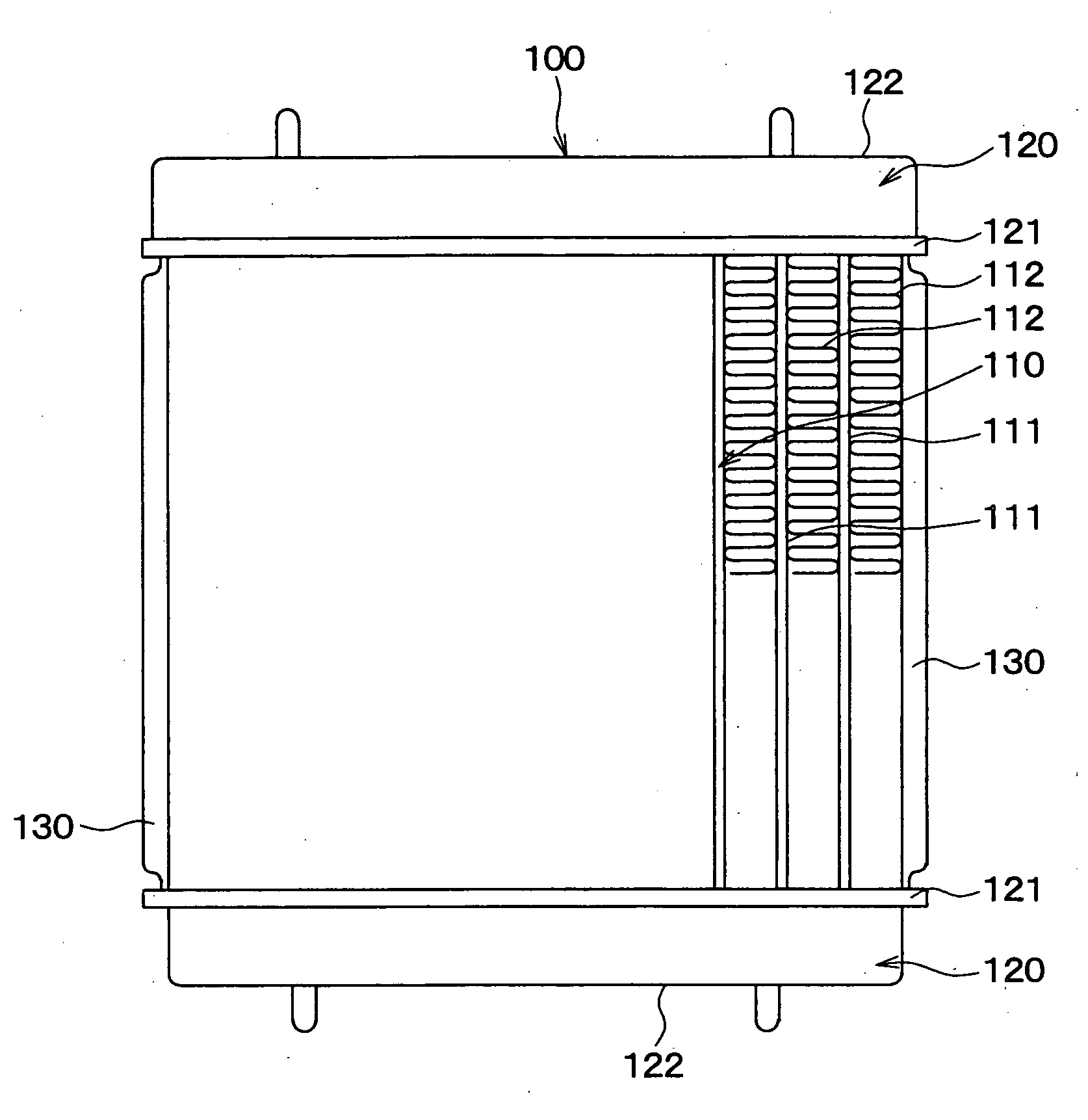

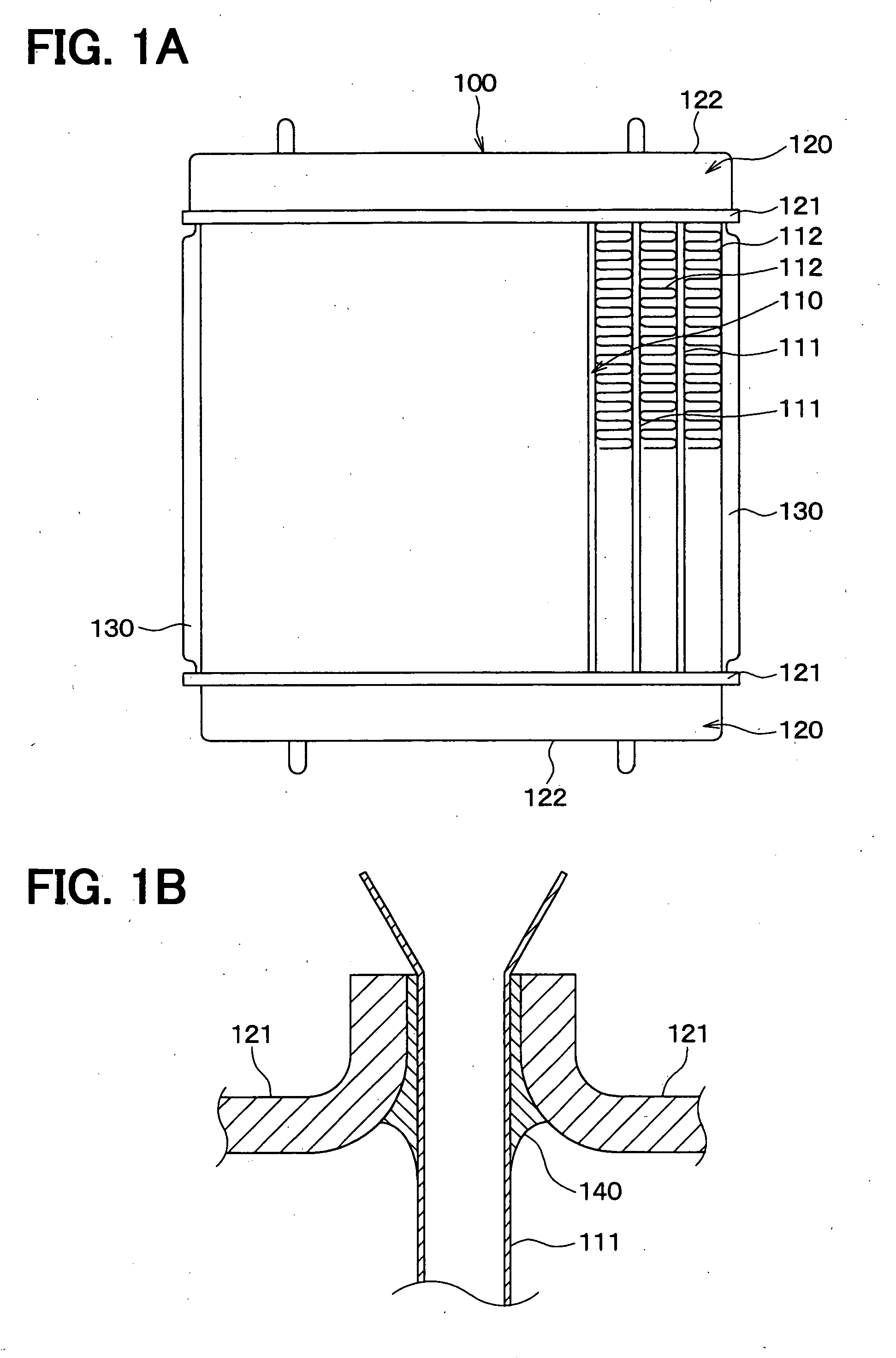

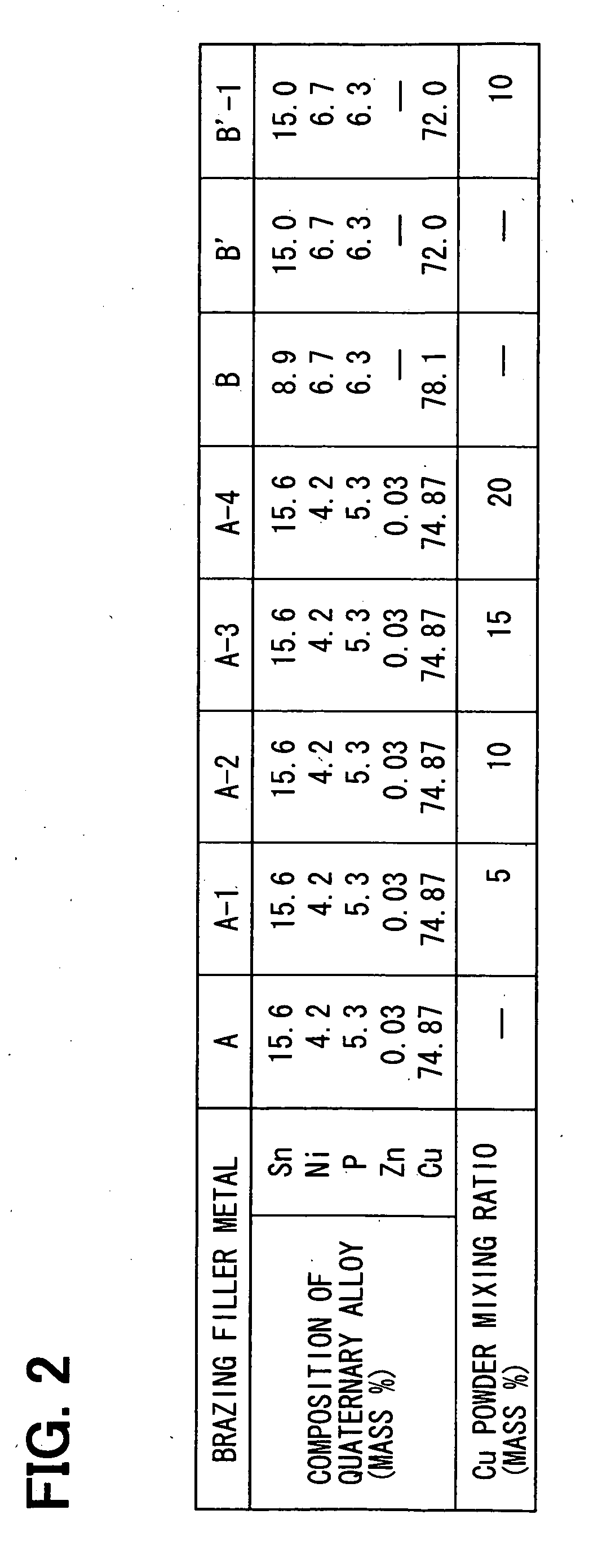

Brazing filler metal, brazing filler metal paste, and heat exchanger

InactiveUS20090297882A1Reduce tin contentImprove joint strengthWelding/cutting media/materialsThin material handlingOrganic solventPlate heat exchanger

A brazing filler metal includes quaternary alloy powder and copper powder. The quaternary allow powder consists of from 0.1 to 27.4 mass percent tin, from 0.8 to 5.1 mass percent nickel, from 2.2 to 10.9 mass percent phosphorous and a balance including copper and any unavoidable impurity. The brazing filler metal can be used in a form of paste by being mixed with an organic binder and an organic solvent. The brazing filler metal and the brazing filler metal can be used for joining members made of copper or copper alloy, such as members of a heat exchanger.

Owner:DENSO CORP +1

Core-shell structure metal nanoparticles and its manufacturing method thereof

InactiveUS20100108952A1Prevent oxidationEconomical efficiencyMaterial nanotechnologyPigmenting treatmentThin layerNanosized particle

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Powder metallurgy iron copper-based oiliness antifriction material containing rare earth oxides and preparing method

The invention provides a powder metallurgy iron copper-based oiliness antifriction material containing rare earth oxides and a preparing method. The oiliness antifriction material comprises, by mass, 67.0%-71.0% of Fe, 27.2%-32.1% of Cu, 0.6% of Sn, 0.3%-1.2% of CeO2, 0.7% of zinc stearate and the balance unavoidable impurities. The oil content of the oiliness antifriction material is 17%-22% by volume. Powder which is uniformly mixed undergoes pressing, sintering, finishing, oil immersion and other work procedures, and the powder metallurgy iron copper-based oiliness antifriction material containing the rare earth oxides is obtained. Compared with a base material, when the antifriction material contains 0.6% of CeO2 by mass, the mechanical performance including crushing strength and hardness is improved in a certain degree, the antifriction performance is greatly improved, and the friction loss is nearly reduced by 40%. The oiliness antifriction material has the advantages that the wear-resistant performance of the material is greatly improved due to the CeO2 in proper amount, service life of the material is prolonged, the copper content is high, the friction coefficient is low, the anti-corrosion performance is excellent, the raw material is mixed powder of iron powder and copper powder, price is low, and the material contains no lead and meets requirements of environment protection.

Owner:SOUTHEAST UNIV

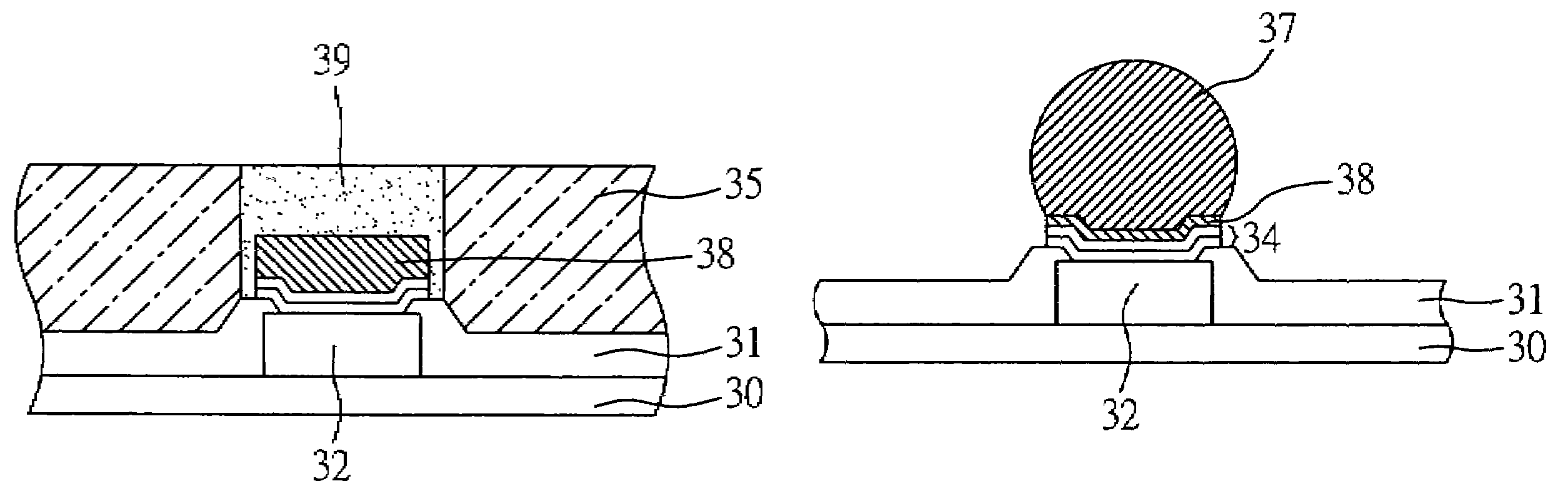

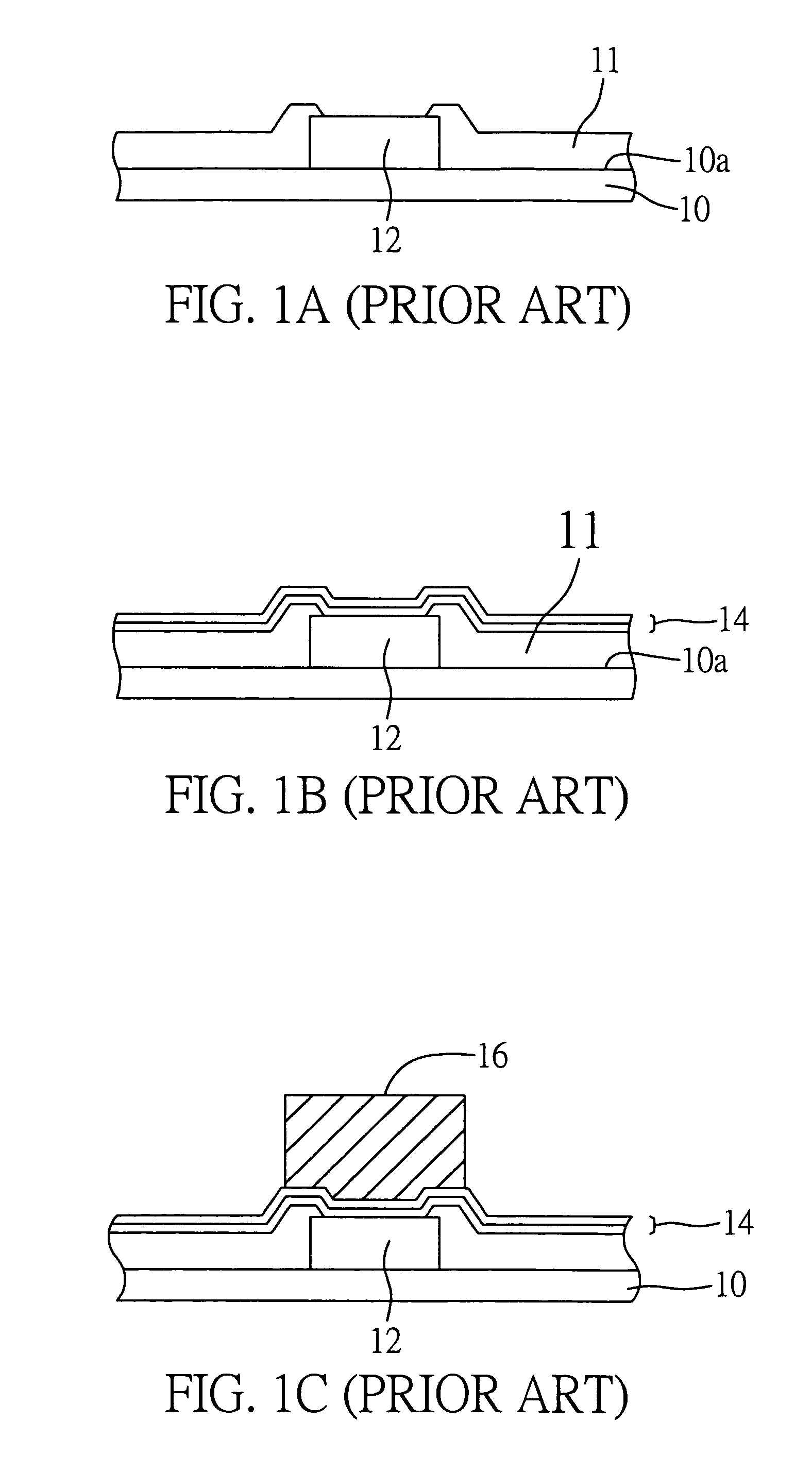

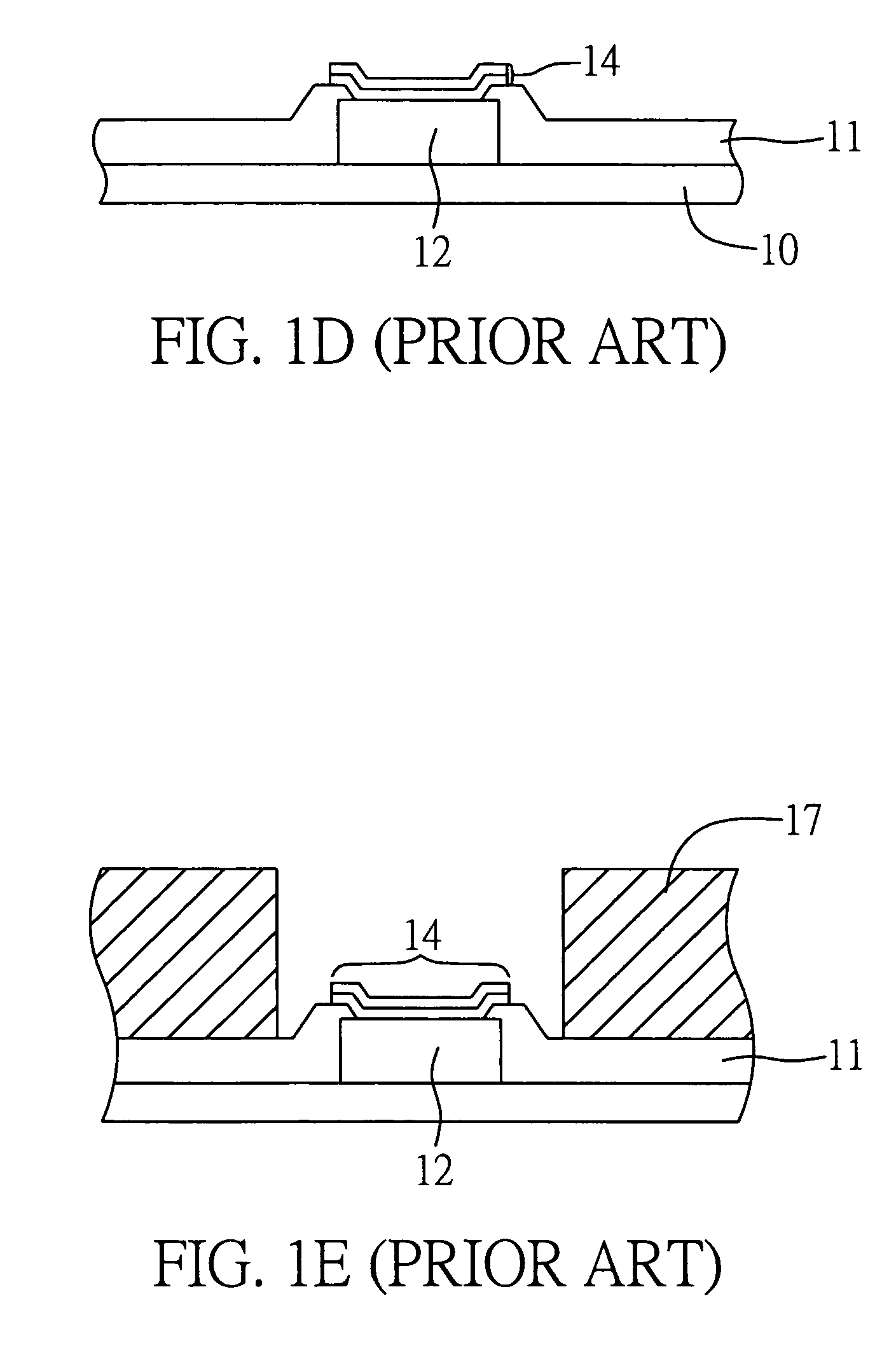

Process for forming lead-free bump on electronic component

ActiveUS7341949B2High mechanical strengthIncreased copper contentSemiconductor/solid-state device detailsSolid-state devicesResistElectronic component

A process for forming a lead-free bump on an electronic component includes preparing the electronic component with at least one bond pad and a passivation layer formed thereon; forming an under bump metallurgy (UBM) structure on the passivation layer and the bond pad; applying a photoresist over the passivation layer, the photoresist having at least one opening corresponding to the bond pad; depositing a thick copper layer (about 1 to 10 μm thick) in the opening by electroplating; applying a copper-free or low-copper-content solder material on the copper layer; and performing a reflowing procedure under a suitable reflow temperature profile to allow copper ions to diffuse from the copper layer to the solder material so as to form the lead-free bump. This increases the copper content in the solder material but not raising the reflow temperature profile, thereby preventing deterioration of the photoresist due to over heat.

Owner:SILICONWARE PRECISION IND CO LTD

Water-based bronze-like coating and application thereof

ActiveCN101914327ARealistic imitation copper effectIncreased copper contentDoors/windowsUnspecified rubber coatingsWater basedEmulsion

The invention belongs to the technical field of coatings and in particular relates to a water-based bronze-like coating and application thereof to manufacturing of a bronze-like door. The water-based bronze-like coating of the invention consists of a bronze powder emulsion and a wire-drawing black, wherein the bronze powder emulsion comprises the following components in part by weight: 50 to 60 parts of bronze powder, 120 to 130 parts of white latex and 95 to 105 parts of bone glue solution which contains 2 mass percent of bone glue; and the wire-drawing black comprises the following components in part by weight: 10 to 20 parts of black colour paste, 25 to 35 parts of white latex, 35 to 45 parts of bone glue solution which contains 2 mass percent of bone glue, 100 parts of water and 4 to 6 parts of ethanol. The method for manufacturing the bronze-like door by using the water-based bronze-like coating comprises the following steps of: a, performing routine pretreatment on the surface of a steel door to make the surface of the metal clean, smooth and flat; and b, uniformly coating the bronze powder emulsion on the surface of the steel door, wherein the thickness of the bronze powder emulsion layer on the surface of the steel door is 0.2 to 0.3mm, drying the bronze powder emulsion layer, coating the wire-drawing black onto the bronze powder emulsion layer, after drying the wire-drawing black, drawing wire, and glaring. In the invention, the water-based coating is adopted to manufacture the bronze-like door and only two times of baking are needed, so that the cost is relatively low and the process is environmentally-friendly.

Owner:浙江九合环保科技有限公司

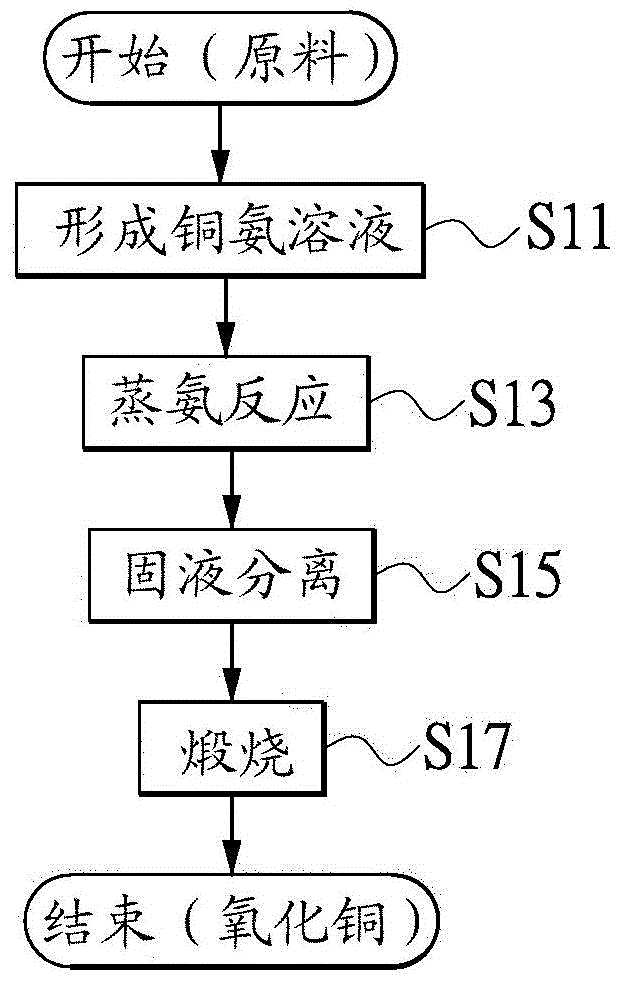

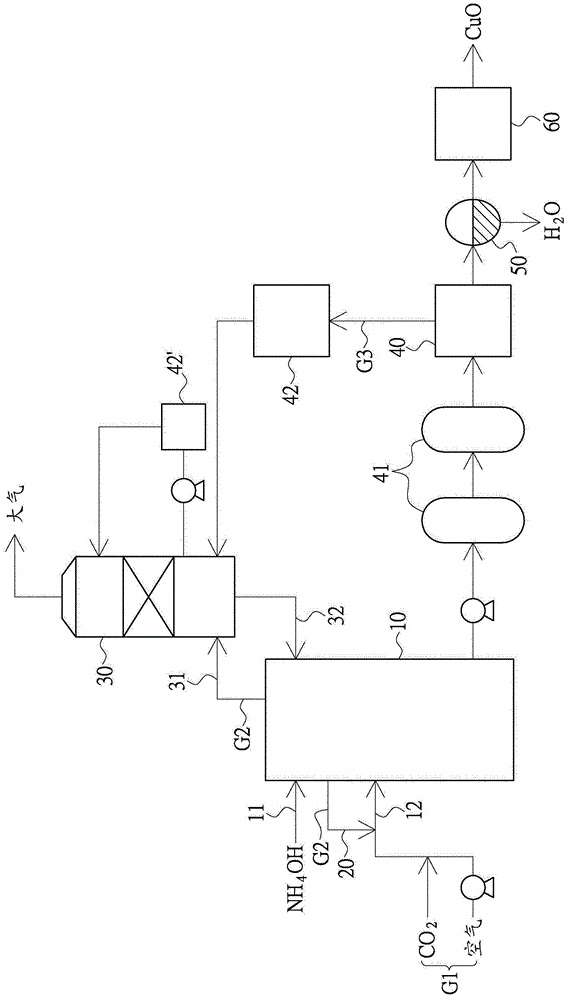

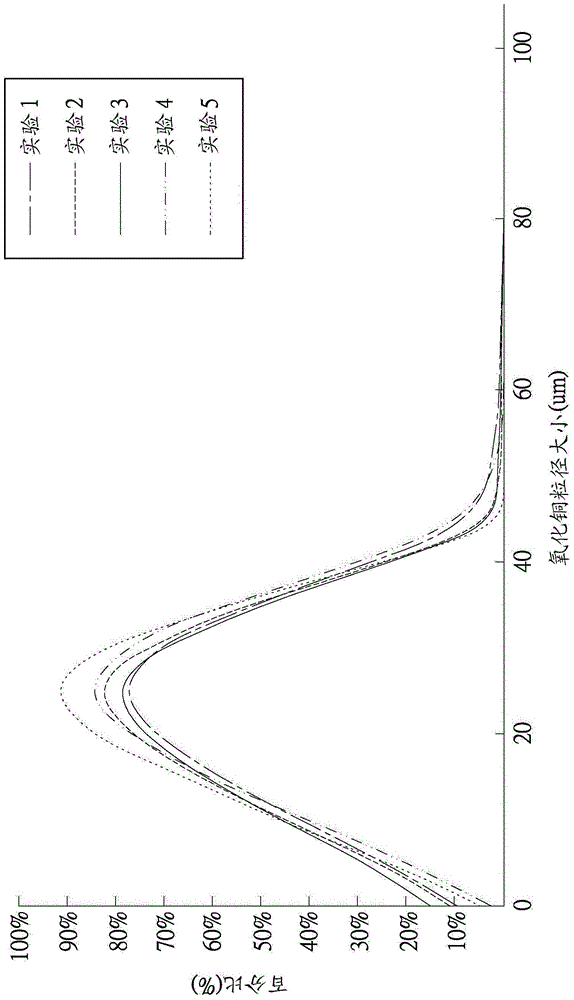

Copper oxide making method and copper oxide making equipment

InactiveCN104891551AIncrease productionReduce usageCopper oxides/halidesBasic copper carbonateAmmonium hydroxide

Owner:CO TECH DEV CORP

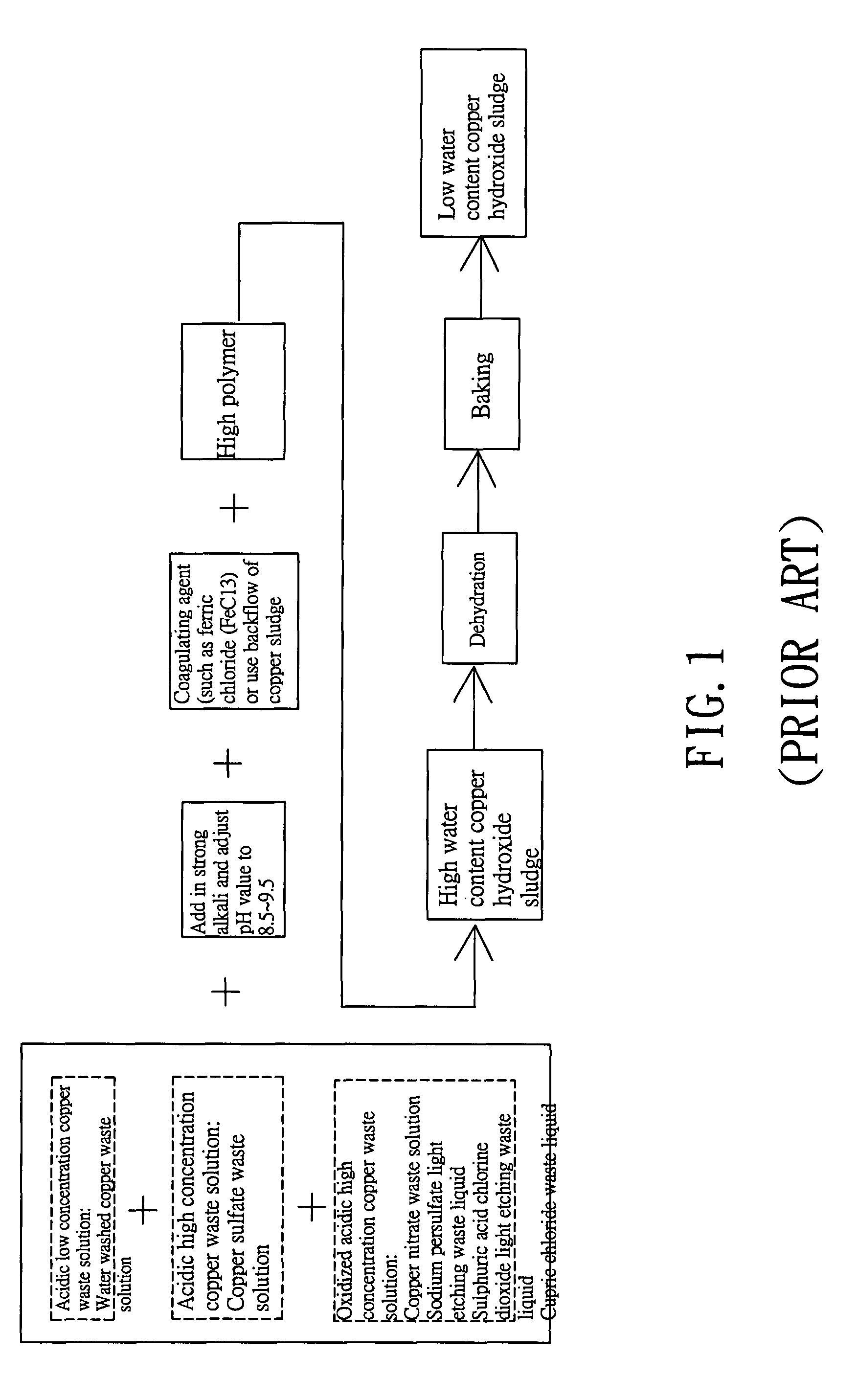

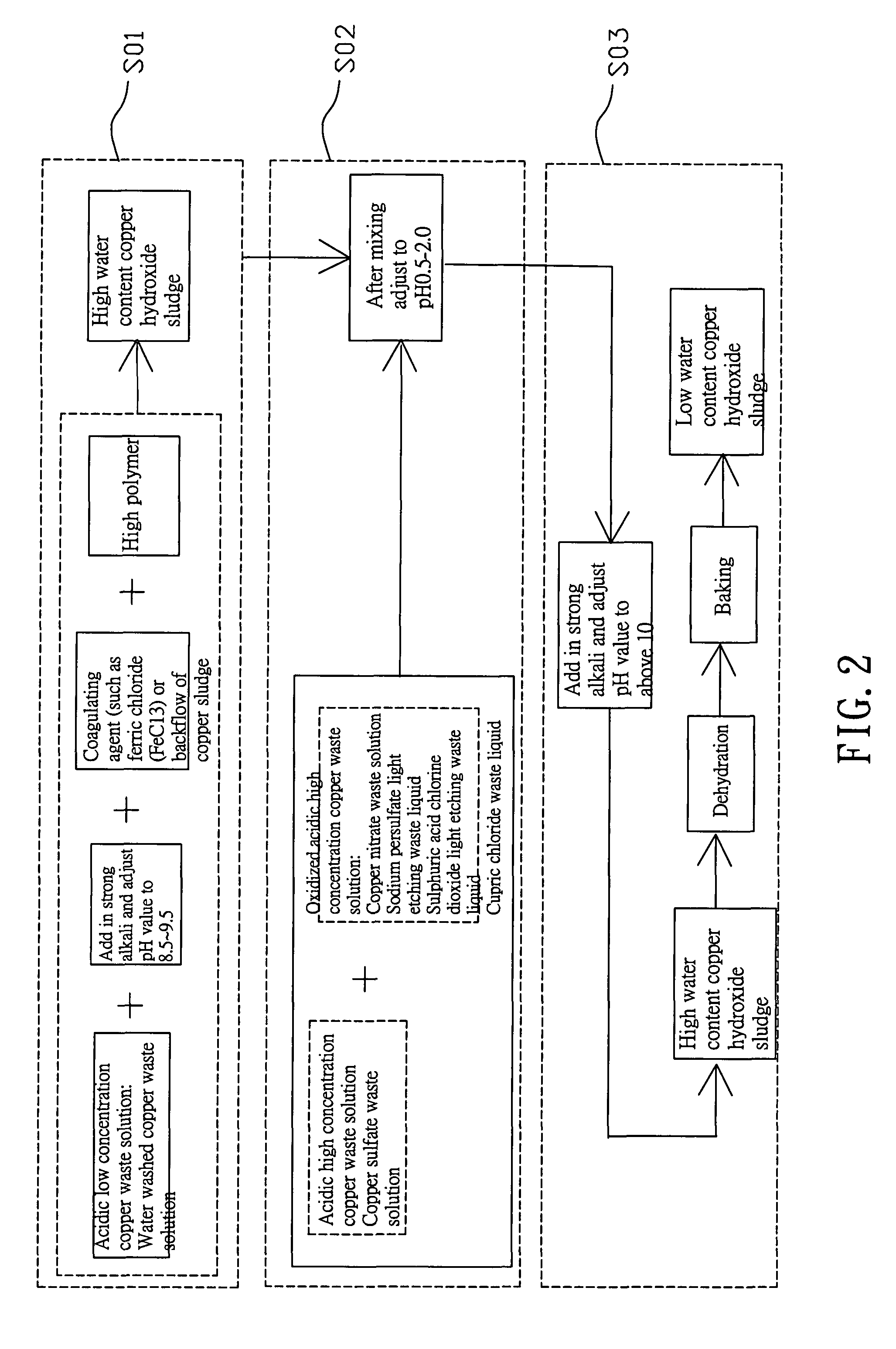

Method for processing waste copper solution/liquid to produce high copper content sludge

InactiveUS20080279737A1Reduce disposable treatment costIncreased copper contentGold compoundsSedimentation separationOxideHigh concentration

The present invention discloses a method for processing waste copper solution / liquid to produce high copper content sludge, mainly by recycling a low copper content waste solution from production of PCB in order to discharge a comparatively higher copper content sludge; first classify the waste solution into an acidic low concentration copper waste solution, an acidic high concentration copper waste solution, and an oxidized acidic high concentration copper waste liquid, and then mix with a strong alkali to react and form a cupric oxide sludge, then undergo dehydration / baking by an applicable equipment to remove water and get a comparatively higher copper content sludge; therefore, it is unnecessary to add other conversion agents to convert copper hydroxide into cupric oxide, thereby turning the valueless low copper content sludge from a waste water (or liquid) into a valuable recyclable high copper content sludge.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

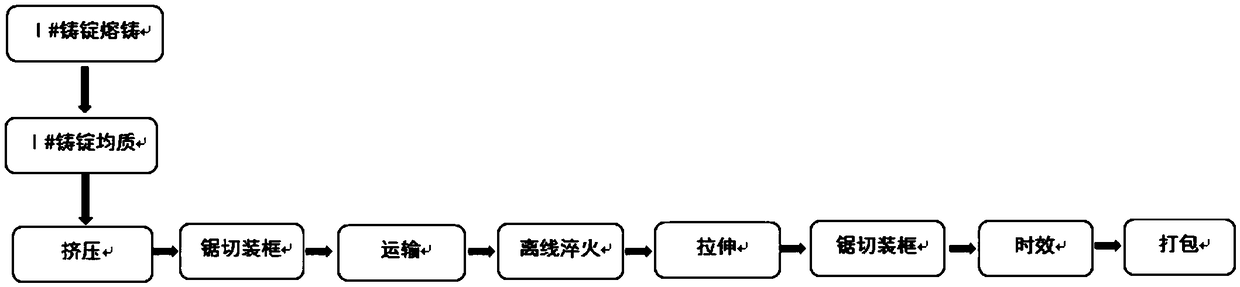

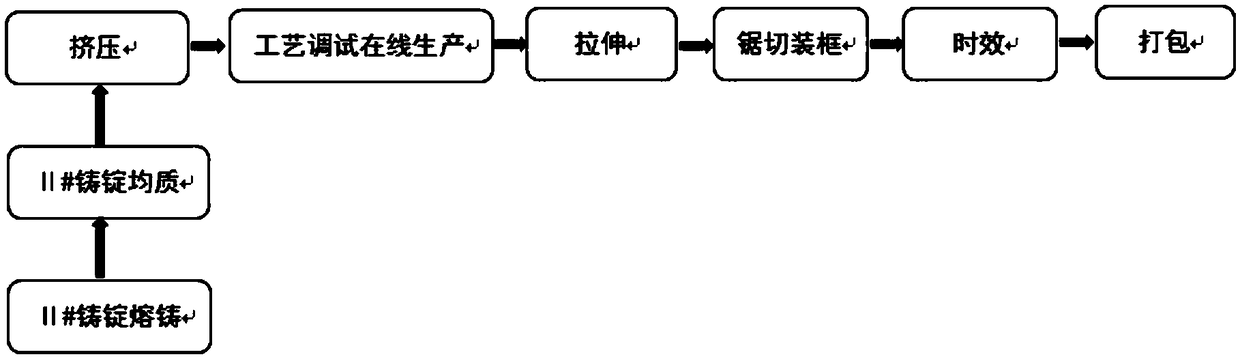

2007 aluminum alloy rod manufacturing process

The invention belongs to the technical field of aluminum alloy manufacturing and relates to a 2007 aluminum alloy rod manufacturing process. The 2007 aluminum alloy rod manufacturing process comprisesthe following steps of casting, homogenizing, extruding, online quenching, stretching, sawing and framing, aging heat treatment and packaging, wherein the homogenizing process comprises the steps ofheating an aluminum alloy cast ingot obtained by casting to a temperature of 480 degrees centigrade, preserving the heat of the aluminum alloy cast ingot for 8 h, heating the aluminum alloy cast ingotto 510 degrees centigrade, preserving the heat of the aluminum alloy cast ingot for 3 h, and cooling the aluminum alloy cast ingot 360-420 degrees centigrade to obtain the homogenized aluminum alloycast ingot; and therefore, the breakthrough pressure of an extruder in the extruding process is reduced to 260 Bar, stable extrusion is made easier in the whole extruding process, a situation of pressure building of equipment is uneasy to cause, the equipment and a mold are uneasily damaged, and a problem that the online quenching of a 2007 aluminum alloy rod is difficult is solved.

Owner:CHINA ZHONGWANG

Nutritious health care food and preparation method thereof

InactiveCN1483353AImprove the quality of lifeImprove immunityUnknown materialsPill deliverySexual functionLife quality

The present invention relates to a nutrient health-care food and its production method. Said food composition contains (by weight) 1-2 portions of malurong, 0.5-1.5 portions of ginseng, 5-10 portions of epimedium, 0.5-2 portions of diascorea root, 0.5-1 portion of lycium berry, 0.5-1 portion of flowery knotweed root and 0.5-1.5 portions of dextrine. Said nutrient health-care food has the functions of enriching yin, strengthening yang, invigorating sexual function and raising immunity of human body.

Owner:鲁骏

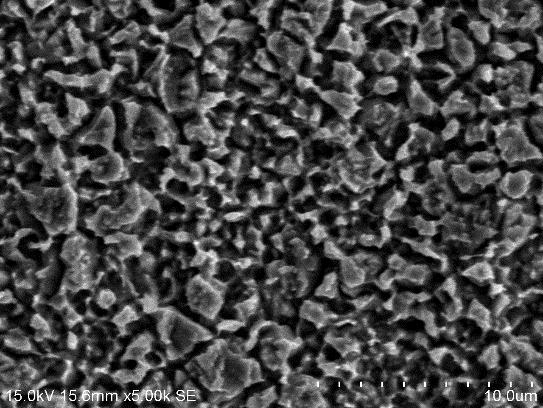

Organic acid super-coarsening micro-etching solution with high copper content and application of organic acid super-coarsening micro-etching solution

InactiveCN114672807AIncreased copper contentNo crystallizationConductive material chemical/electrolytical removalOrganic acidCu2 ions

The invention discloses an organic acid super-roughening micro-etching solution with high copper content and application thereof, and relates to the technical field of printed circuit board treatment. The organic acid super-roughening micro-etching liquid comprises the following components in mass concentration: 10-70g / L of bivalent copper ions from a copper ion source, 10-180g / L of organic acid, 5-80g / L of chloride ions from a chloride ion source, 5-90g / L of a complexing agent, 0.0005-2g / L of a polyhydroxy compound, 0.0001-0.6 g / L of a water-soluble polymer and a solvent which is deionized water. Through innovation of the copper complexing agent and the polyhydroxy compound, the copper content of the organic acid super-coarsening micro-etching liquid can reach 50 g / L or above, the coarsening morphology of the copper surface under the high copper content is uniform, the color of the plate surface is uniform, and crystallization and separation of copper salt cannot be generated.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

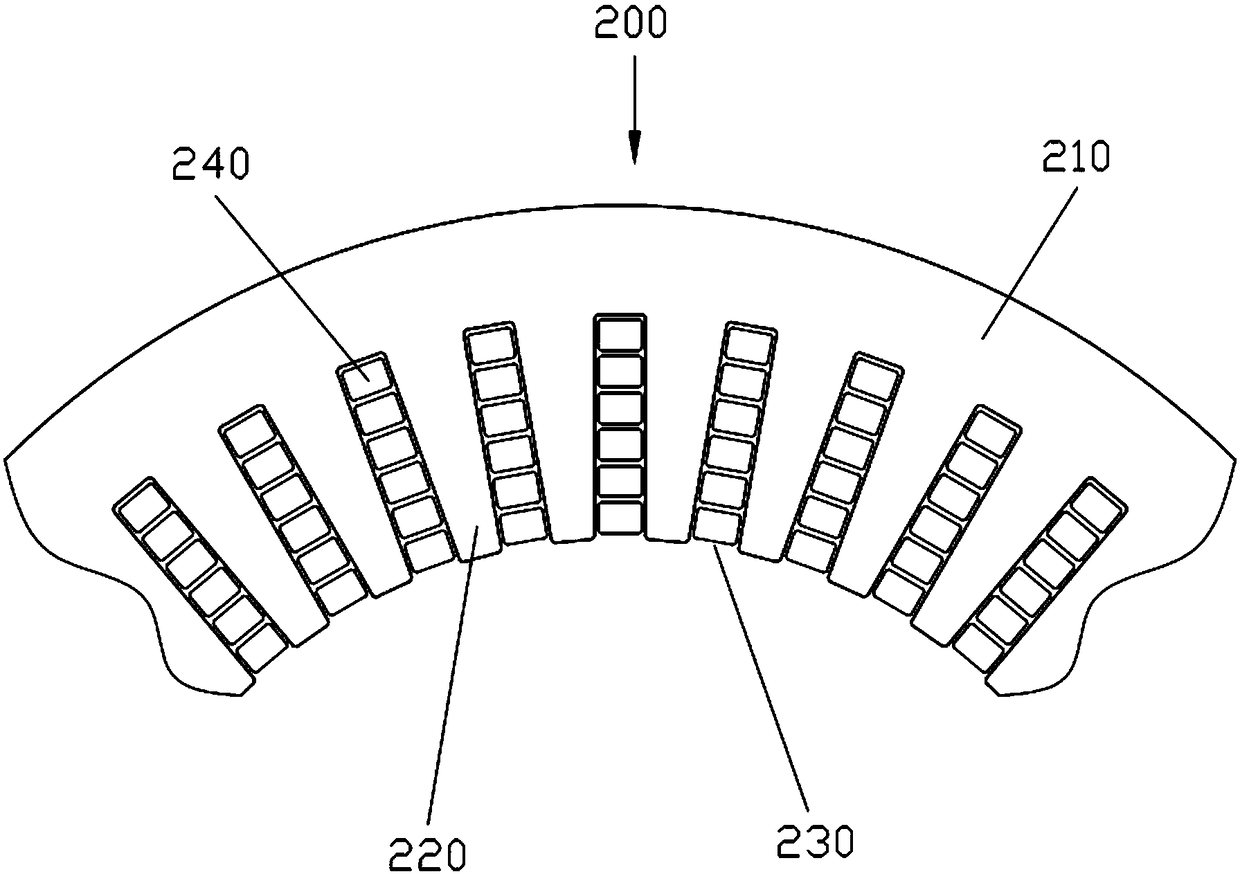

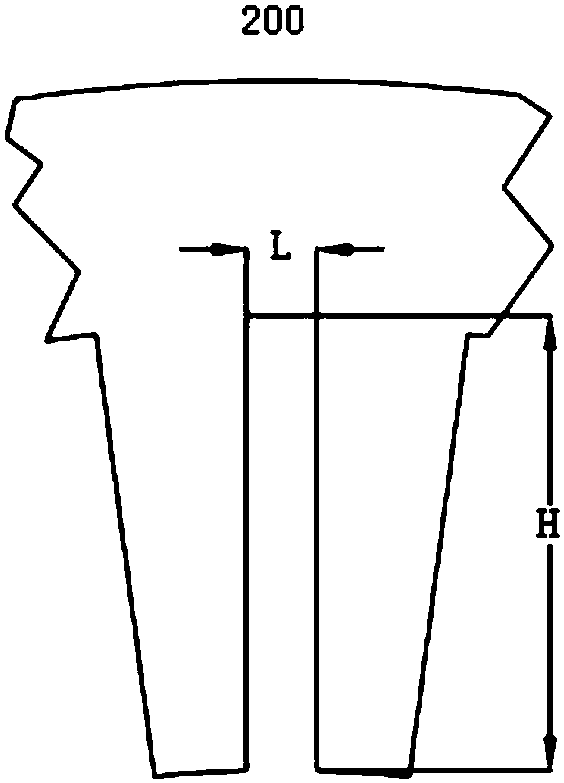

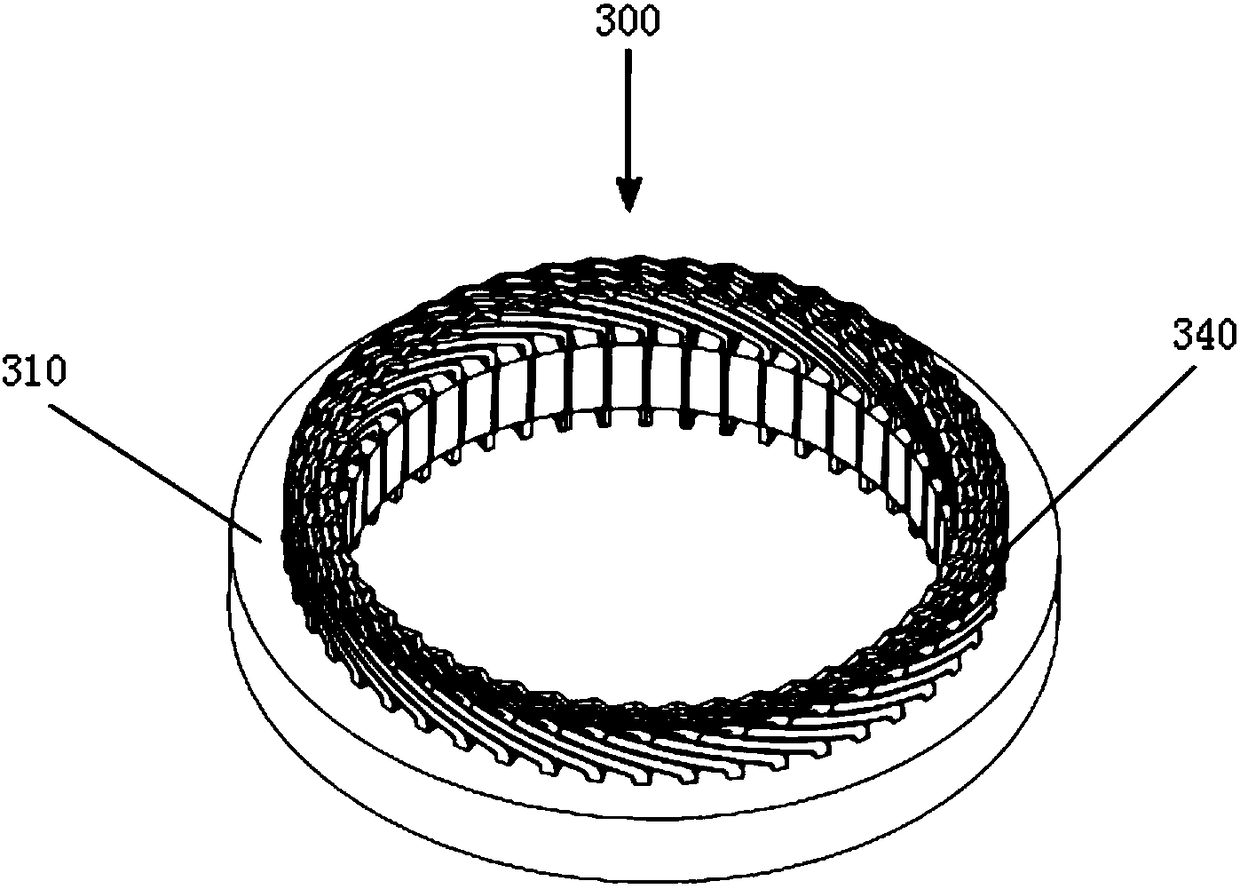

Motor stator and motor

PendingCN108199511AReduce iron consumptionImproves Iron UtilizationMagnetic circuit stationary partsElectric machineCopper wire

The invention relates to the technical field of motors and discloses a motor stator and a motor. The motor stator includes a stator iron core. The stator iron core is therein provided with a pluralityof stator teeth. Stator grooves are formed between the adjacent stator teeth. Each stator groove is provided with a plurality of cooper wires having rectangular sections. The stator grooves are stepgrooves composed of rectangular grooves of different widths. The widths of the rectangular grooves increase gradually successively from inside out along the radial direction of the stator iron core. The heights of the rectangular grooves decrease successively from inside out along the radial direction of the stator iron core. The section widths of the copper wires in the stator grooves are identical to the widths of the corresponding rectangular grooves. According to the invention, copper loss of the motor is reduced and efficiency of the motor is improved. At the same time, the sizes of rootparts of the stator grooves are increased, so that iron consumption of the motor is reduced, iron utilization rate of the stator is improved, copper content in the stator grooves is increased and power density of the motor and motor efficiency are improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

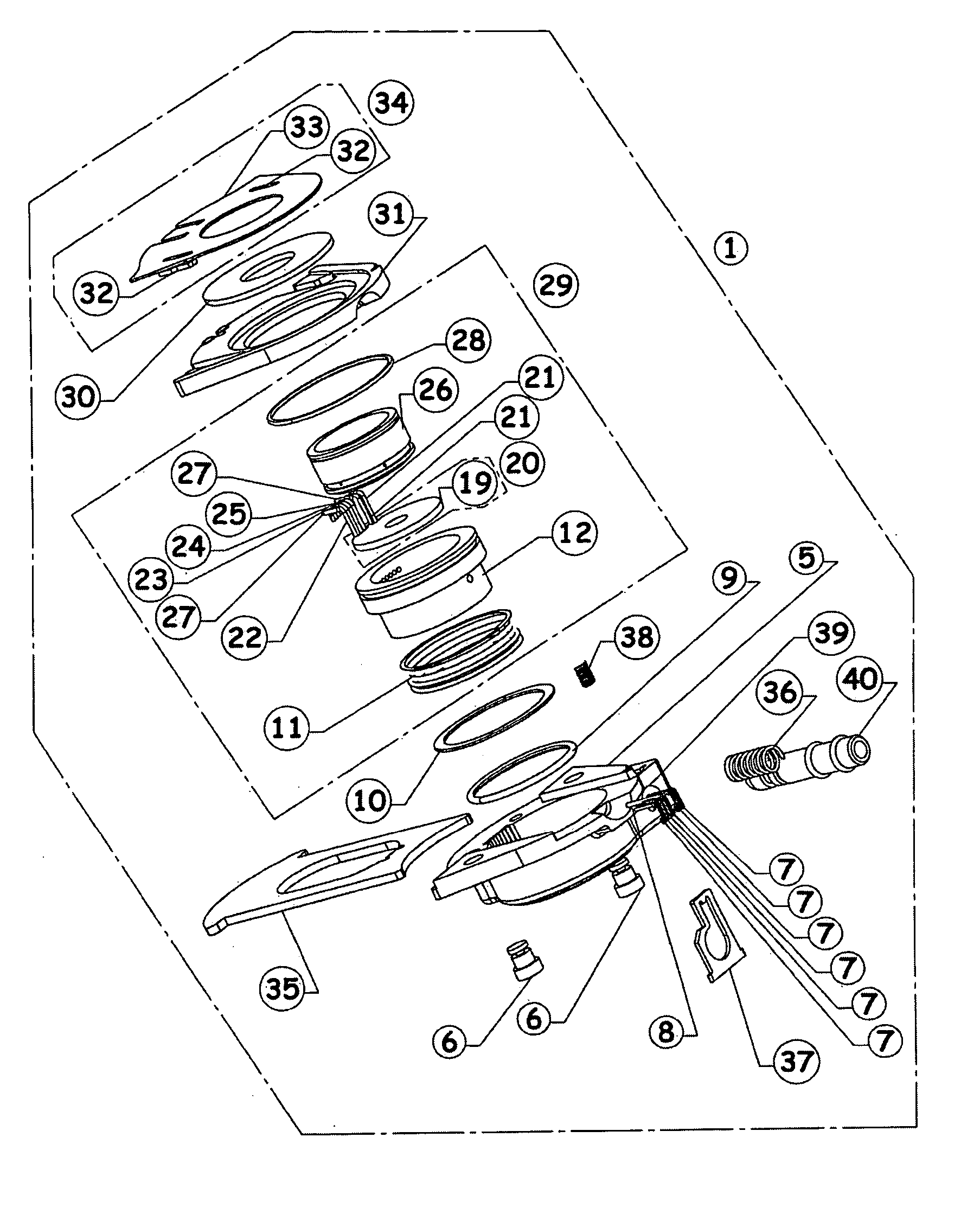

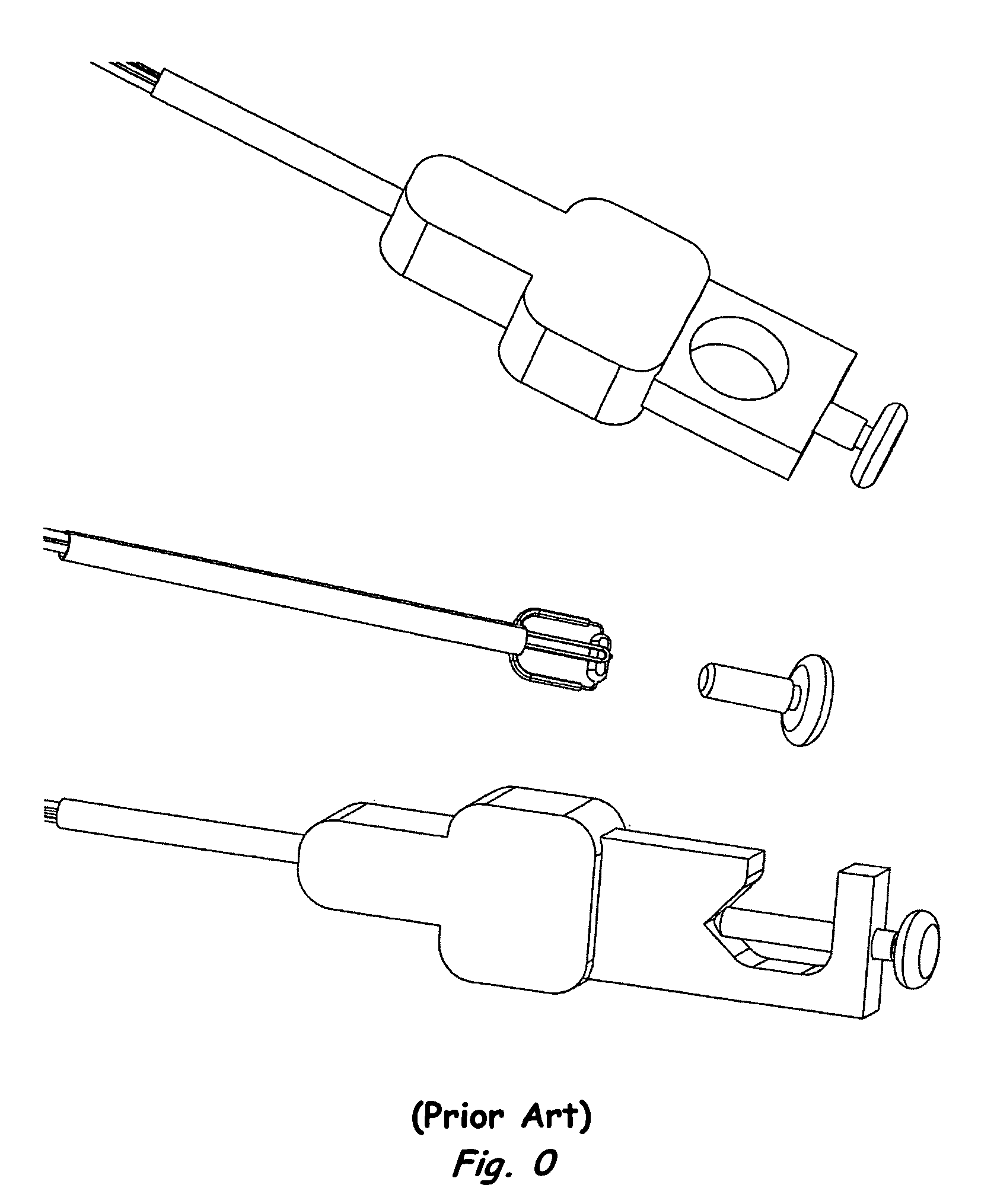

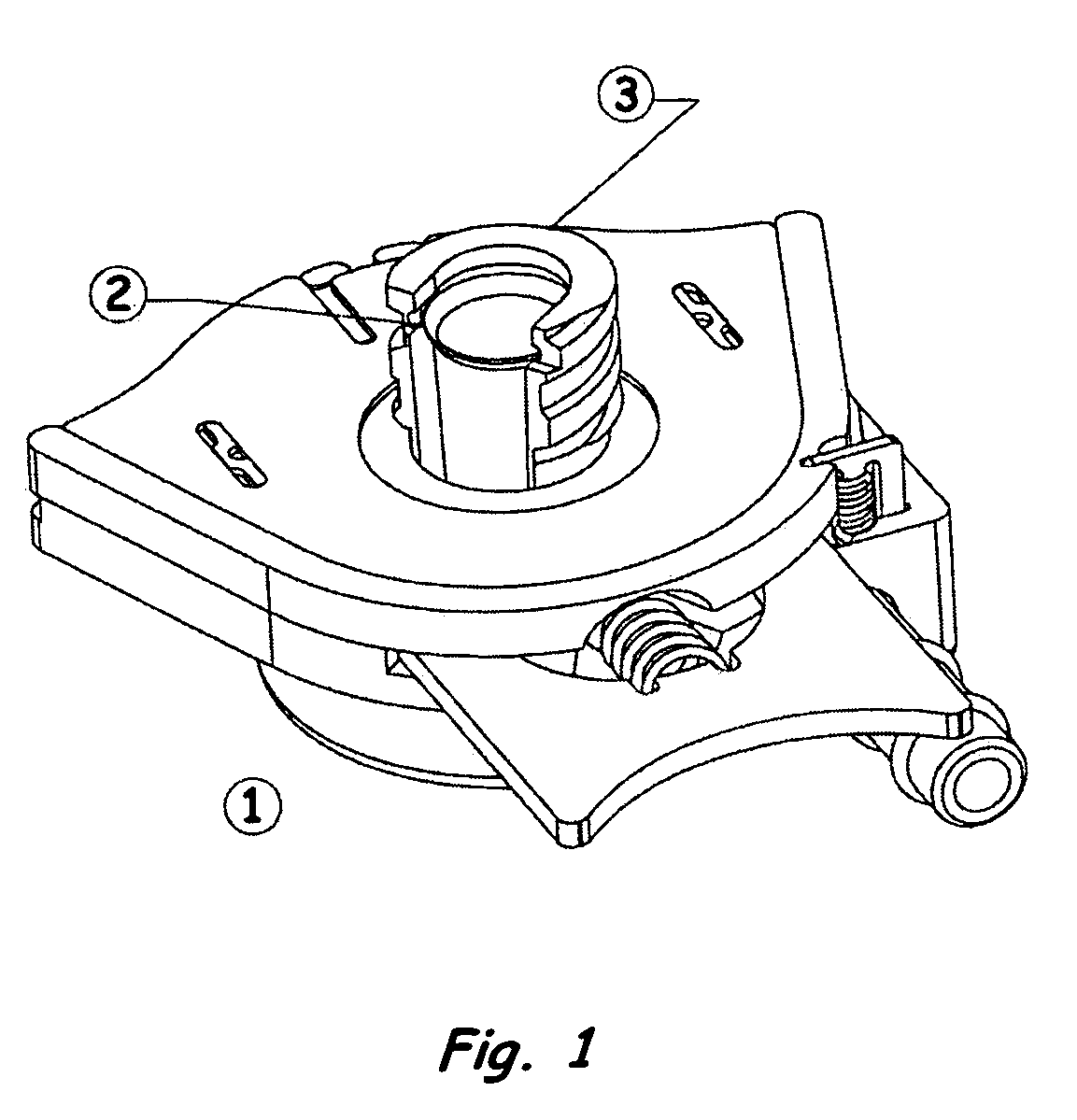

Heating-cooling system for a nozzle

ActiveUS7190891B2Easy maintenanceEasy to removeVacuum evaporation coatingSpray nozzlesProduction rateEngineering

A novel nozzle heater design, that facilitates fast thermal response on demand, to achieve rapid reduction in viscosity, allowing fluid to flow through the exit aperture of the nozzle with less pressure, reduced surface tension and elastic behavior at break off. A rapid cool down after a temperature spike alleviates problems associated with prolonged exposure of the fluid at temperature. Prolonged exposure manifests the following problems: volatiles are driven off, premature cross-linking is initiated and fluid in the heated region is subsequently ruined. The fluid path heater is designed to prevent the occurrence of these problems by virtue of the exceptionally fast thermal response rate. This heater design requires no fasteners and is simple to assemble; parts are held in place by inherent geometric relationships and connection to the nozzle hub is tool-less and self-compensating for tolerance variation in the nozzle hub to which it is connected. The heater lowers cost by improving the productivity of the fluid dispensing system on which it is installed.

Owner:VERRILLI BRIAN LEONARD

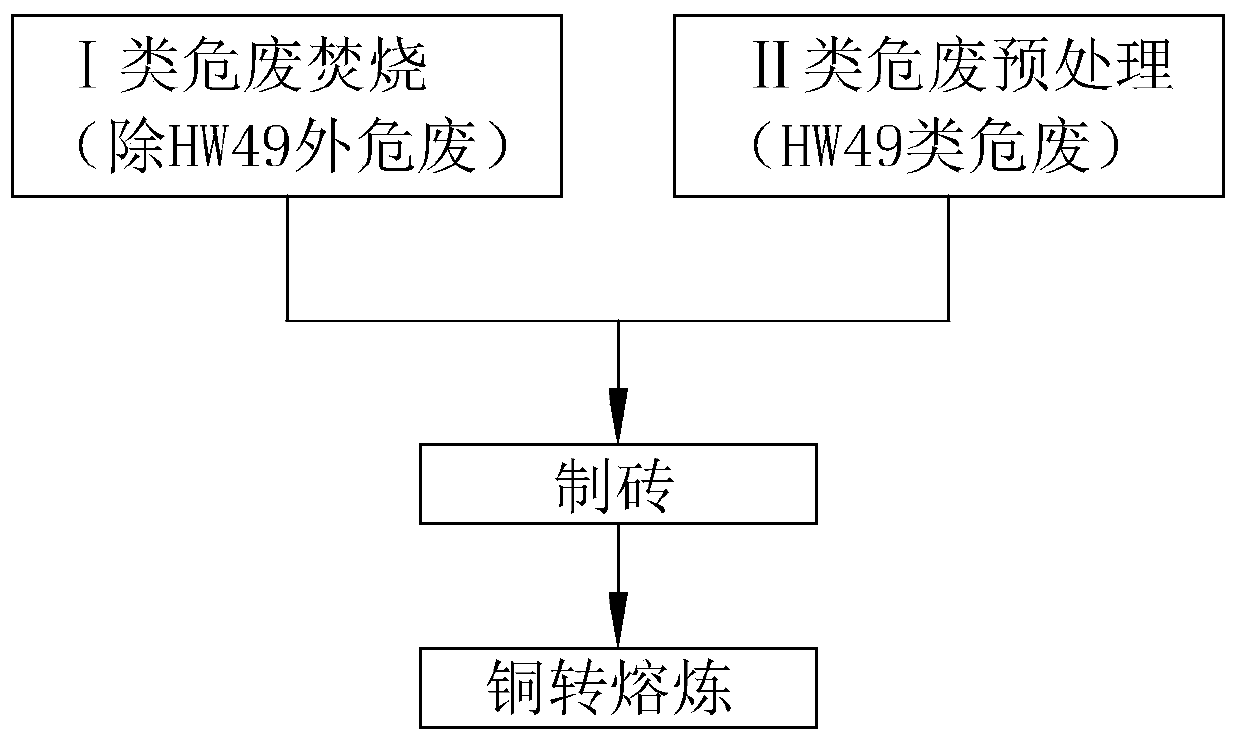

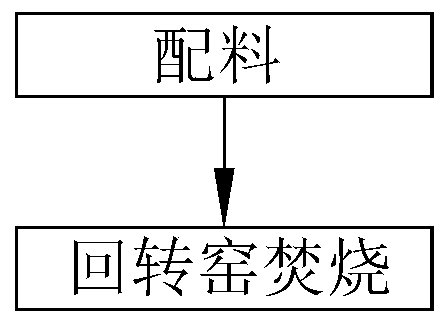

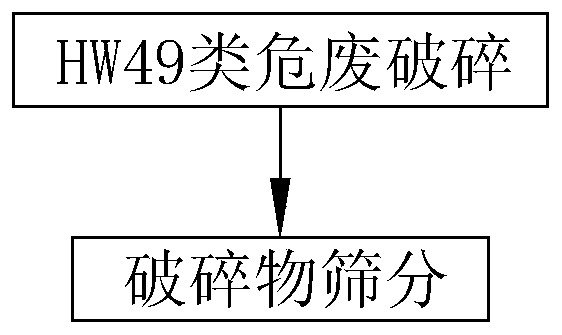

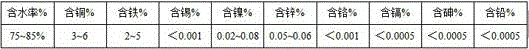

Copper-containing hazardous waste treatment process

ActiveCN110976481AReduce pollutionStable outputSolid waste disposalTransportation and packagingBrickWaste treatment

The invention relates to a copper-containing hazardous waste treatment process, relates to the technical field of copper-containing waste treatment, and aims to solve the problems of incomplete treatment and environmental pollution caused by the fact that the specificity of various copper-containing wastes is not considered in the existing copper-containing waste treatment process. The process comprises the steps of class I hazardous waste incineration, class II hazardous waste pretreatment, brick making and copper brick smelting; class I hazardous waste incineration includes proportioning andincinerating to obtain combusted clinker; class II hazardous waste pretreatment includes the steps of pretreating HW49 hazardous wastes to remove organic matters, and collecting copper-containing powder; brick making comprises the steps of mixing the clinker collected after incineration of class I hazardous waste and copper-containing powder collected in class II hazardous waste pretreatment, andcarrying out briquetting treatment to prepare a copper-containing brick; and copper brick smelting comprises the step of feeding the copper-containing brick into a side blowing furnace for smelting to produce matte. The copper-containing hazardous waste treatment process can carry out differential treatment according to the characteristics of copper-containing hazardous wastes, and has the advantages of high copper conversion rate and small environmental pollution.

Owner:洛南环亚源铜业有限公司

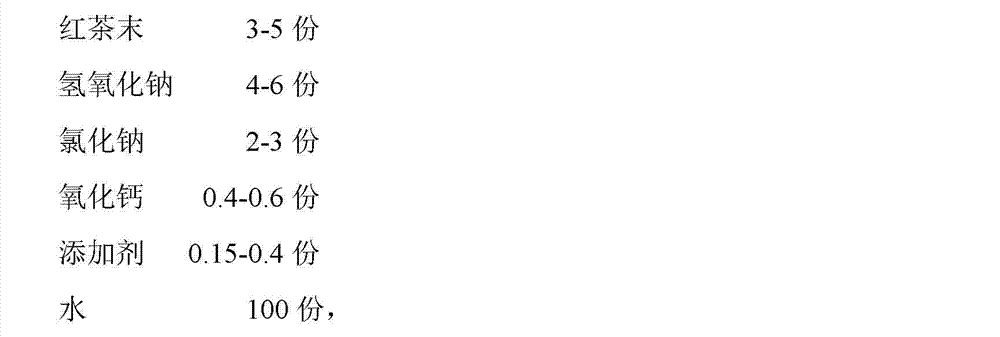

Composite curing agent for lead-free preserved eggs and preparation method thereof

The invention discloses additive for composite curing agent for lead-free preserved eggs. The additive comprises zinc sulfate, copper sulfate, ferrous sulfate, and zinc chloride. The invention further discloses the lead-free composite curing agent for preserved eggs. The composite curing agent for lead-free preserved eggs is made from black tea dust, sodium hydroxide, sodium chloride, calcium oxide, water and the additive. The invention further discloses a preparation method of the composite curing agent for lead-free preserved eggs. The lead-free preserved eggs made with the composite curing agent are stable in quality, high in yield and fine in storage performance and further have the advantages of short processing cycle, high food safety and high nutrition value.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Method for preparing copper chloride hydroxide by simultaneously treating waste etching solution and circuit board sludge

ActiveCN104692447AEfficient recyclingReduce energy consumptionCalcium/strontium/barium chloridesCopper chloridesAcid etchingFerric hydroxide

The invention discloses a method for preparing copper chloride hydroxide by simultaneously treating a waste etching solution and circuit board sludge. The method comprises the following steps: (1) preparing the circuit board sludge into slurry, screening and activating; (2) performing aeration on the activated slurry to ensure that ferrous iron contained in the sludge is converted into iron hydroxide; (3) mixing a waste acid etching solution with hydrochloric acid, injecting into the aerated slurry, adjusting the pH value, and stirring to obtain acid leached slurry; (4) injecting the aerated slurry into the acid leached slurry to obtain acid liquor containing copper and a solid phase containing iron; (5) adding the solid phase containing iron into a waste alkaline etching solution to prepare alkali liquor containing copper; and (6) controlling the temperature to be 60-85 DEG C, injecting the acid liquor containing copper and the alkali liquor containing copper, controlling the pH value of the system to be 4.0-6.0, reacting for 2-5 hours, and filtering to obtain a copper chloride hydroxide solid and a copper chloride hydroxide production mother solution, wherein the flow ratio of the acid liquor containing copper to the alkali liquor containing copper is 2:(0.5-1.2). By adopting the method disclosed by the invention, the energy consumption of treatment with one of waste acid and alkaline etching solutions can be reduced, and the 'treatment of wastes with processes of wastes against one another' is truly implemented.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

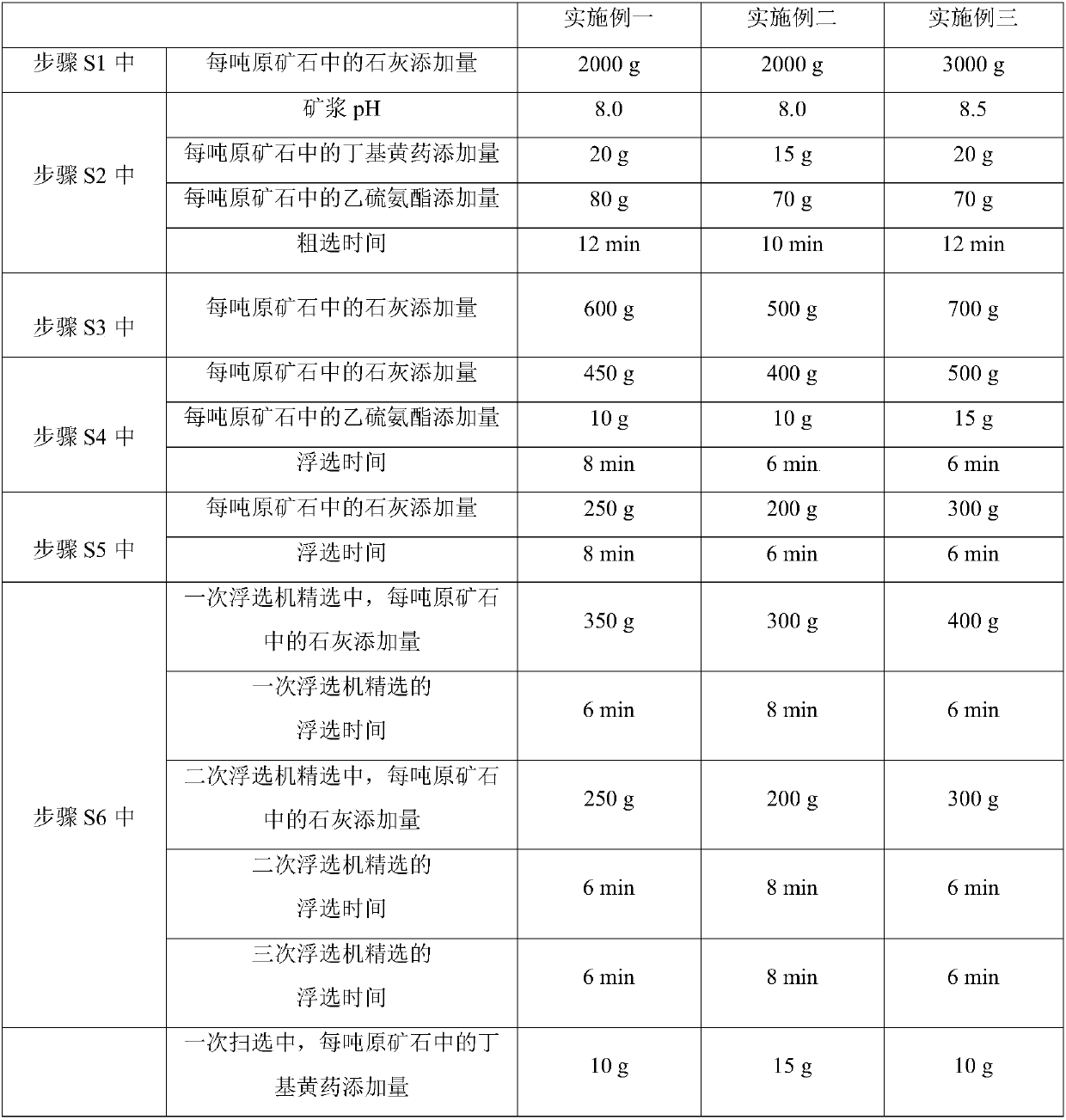

Flotation machine and flotation column combined gradient extraction method with copper sulphide ore embedded unevenly

InactiveCN109530095AIncreased copper contentRaise the gradeVortex flow apparatusFlotationOre concentrateEngineering

The invention relates to a flotation machine and flotation column combined gradient extraction method with copper sulphide ore embedded unevenly. The method comprises the following steps that S1, after being crushed, raw ore is added with water to be ground into ore pulp with the proper concentration; S2, the ore pulp is put into a flotation machine to be subjected to roughing to obtain roughing concentrates and roughing tailings; S3, the roughing concentrates are reground; SS4, the reground roughing concentrates are subjected to flotation column concentration to obtain primary concentration concentrates and primary concentration tailings; S5, the primary concentration concentrates are subjected to flotation column concentration to obtain first-step copper concentrates; S6, the primary concentration tailings are subjected to flotation machine concentration three times to obtain second-step copper concentrates; and S7, the roughing tailings are subjected to scavenging to obtain copper tailings. Compared with the prior art, fine-grain copper ore is recycled through a flotation column, the flotation machine is used for carrying out concentration on the tailings obtained after flotation column concentration, and therefore coarse grains which cannot be recycled by the flotation column are effectively recycled by the flotation machine, both coarse grains and fine grains are recycled,the recycling efficiency is greatly improved, and the grade of the copper concentrates is also increased.

Owner:GUANGDONG PROVINCE DABAOSHAN MINING CO LTD

Method for processing waste copper liquid to produce high copper content sludge

InactiveUS7749470B2Reduce disposable treatment costIncreased copper contentGold compoundsSedimentation separationLiquid wasteHigh concentration

A method for processing waste copper liquid produces high copper content sludge, mainly by recycling a low copper content waste liquid from production of PCB in order to discharge a comparatively higher copper content sludge. First, the waste liquid is classified into an acidic low concentration copper waste liquid, an acidic high concentration copper waste liquid, and an oxidized acidic high concentration copper waste liquid. Then mix with a strong alkali to react and form a cupric oxide sludge that then undergoes dehydration and baking by applicable equipment to remove water and get a higher copper content sludge. It is therefore unnecessary to add other conversion agents to convert copper hydroxide into cupric oxide, thereby turning the valueless low copper content sludge from a waste liquid into a valuable recyclable high copper content sludge.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

Dressing and smelting method for recovering copper from bonded copper oxide minerals

InactiveCN104988333AImprove beneficiation indexImprove product qualityProcess efficiency improvementCopper oxideOperability

The invention discloses a dressing and smelting method for recovering copper from bonded copper oxide minerals. The method comprises the steps that 1, the bonded copper oxide minerals are smashed and ground and then are mixed with water, and raw ore pulp is obtained; 2, ore dressing is carried out on the raw ore pulp through a low-intensity magnetic separation-gravity separation-high-gradient magnetic separation ore dressing technology; 3, gravity concentrates and high-gradient magnetic concentrates separated out through the ore dressing technology are combined and then filtered to obtain enriched product residues, and primary ore pulp is prepared; 3, sodium hydroxide is added for pretreatment, and pretreatment liquid and pretreatment residues are obtained after filtering; 5, after secondary ore pulp is prepared, acid leaching is carried out on the secondary ore pulp to obtain copper-bearing acid leaching liquid. The recovery rate of copper is not smaller than 80 percent, spongy copper with the mass purity not lower than 90 percent can be obtained through further extraction, and the advantages of being high in ore dressing index, high in product quality, high in operability and simple in technological process are achieved.

Owner:新兴发展集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com