Organic acid super-coarsening micro-etching solution with high copper content and application of organic acid super-coarsening micro-etching solution

An organic acid and ultra-coarsening technology, which is applied to the removal of conductive materials by chemical/electrolytic methods, printed circuit manufacturing, printed circuits, etc., can solve problems such as easy crystallization, high copper ions, and clogged nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the organic acid ultra-coarsening micro-etching liquid with high copper content:

[0067] Step 1: Weigh the copper ion source, organic acid and chloride ion source of the formula, add them in deionized water and stir to dissolve;

[0068] Step 2: Weigh the water-soluble polymer complexing agent and the polyhydroxy compound of the formula amount in the solution obtained in step 1, and stir evenly;

[0069] Step 3: Dilute the solution obtained in Step 2 to 1L with deionized water, and stir evenly to obtain the micro-etching solution.

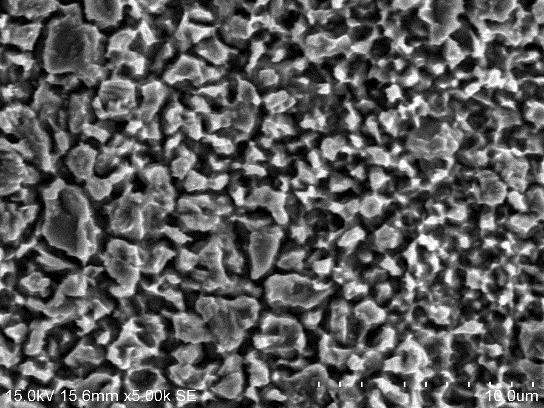

[0070] Ultra-roughening method of printed circuit board

[0071] The ultra-roughening method includes the following steps: S1: degreasing; S2: washing with water; S3: micro-etching; S4: washing with water; S5: pickling; S6: drying.

[0072] Among them, in the degreasing step, a solution of 3%-5% HCl is selected for cleaning at 25°C-35°C for 10s-15s. The micro-etching step adopts the ultra-roughening micro-etchin...

Embodiment 1

[0076] 1) Including the following components and their mass concentrations:

[0077] Formic acid: 50g / L;

[0078] Divalent cupric ion: 30g / L, from cupric chloride;

[0079] Chloride ion: 33.28g / L, from copper chloride;

[0080] Complexing agent: 55g / L, wherein, ammonium acetate: 52g / L, imidazolidinone: 3g / L;

[0081] Polyol: 0.09g / L, from glycerol;

[0082] Water-soluble polymer (I): 0.001g / L, water-soluble polymer (I) is polyethyleneimine;

[0083] Deionized water: balance.

[0084] 2) Preparation method:

[0085] Step 1: Weigh the copper ion source, organic acid and chloride ion source of the formula, add them in deionized water and stir to dissolve;

[0086] Step 2: Weigh the water-soluble polymer and the pyridine derivative in the formula amount in the solution obtained in step 1, and stir evenly;

[0087] Step 3: Dilute the solution obtained in Step 2 to 1L with deionized water, and stir evenly to obtain the crude solution.

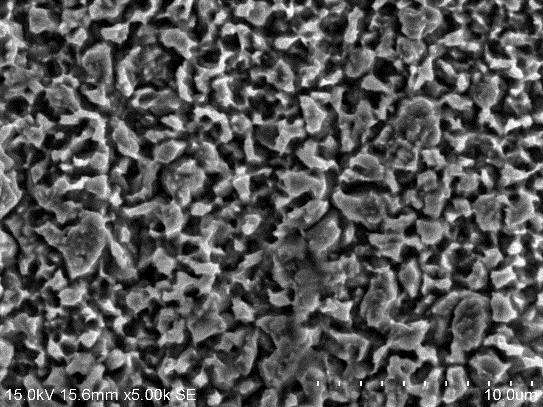

Embodiment 2

[0089] 1) Including the following components and their mass concentrations:

[0090] Formic acid: 50g / L;

[0091] Divalent cupric ion: 35g / L, from cupric chloride;

[0092] Chloride ion: 38.8g / L, from cupric chloride;

[0093] Complexing agent: 55g / L, wherein ammonium acetate: 52g / L, hydroxymethylimidazolidinone: 3g / L;

[0094] Polyhydroxy compound: 0.075g / L, from methyl glycerol;

[0095] Water-soluble polymer (I): 0.030g / L, water-soluble polymer (I) is polyethyleneimine;

[0096] Deionized water: balance.

[0097] 2) Preparation method: the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com