Flotation machine and flotation column combined gradient extraction method with copper sulphide ore embedded unevenly

An extraction method and flotation machine technology, which are applied in flotation, solid separation, cyclone devices, etc., can solve the problems of low recovery rate, high copper tailings grade, and ineffective recovery, and improve recovery efficiency. The effect of increasing copper content and reducing grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

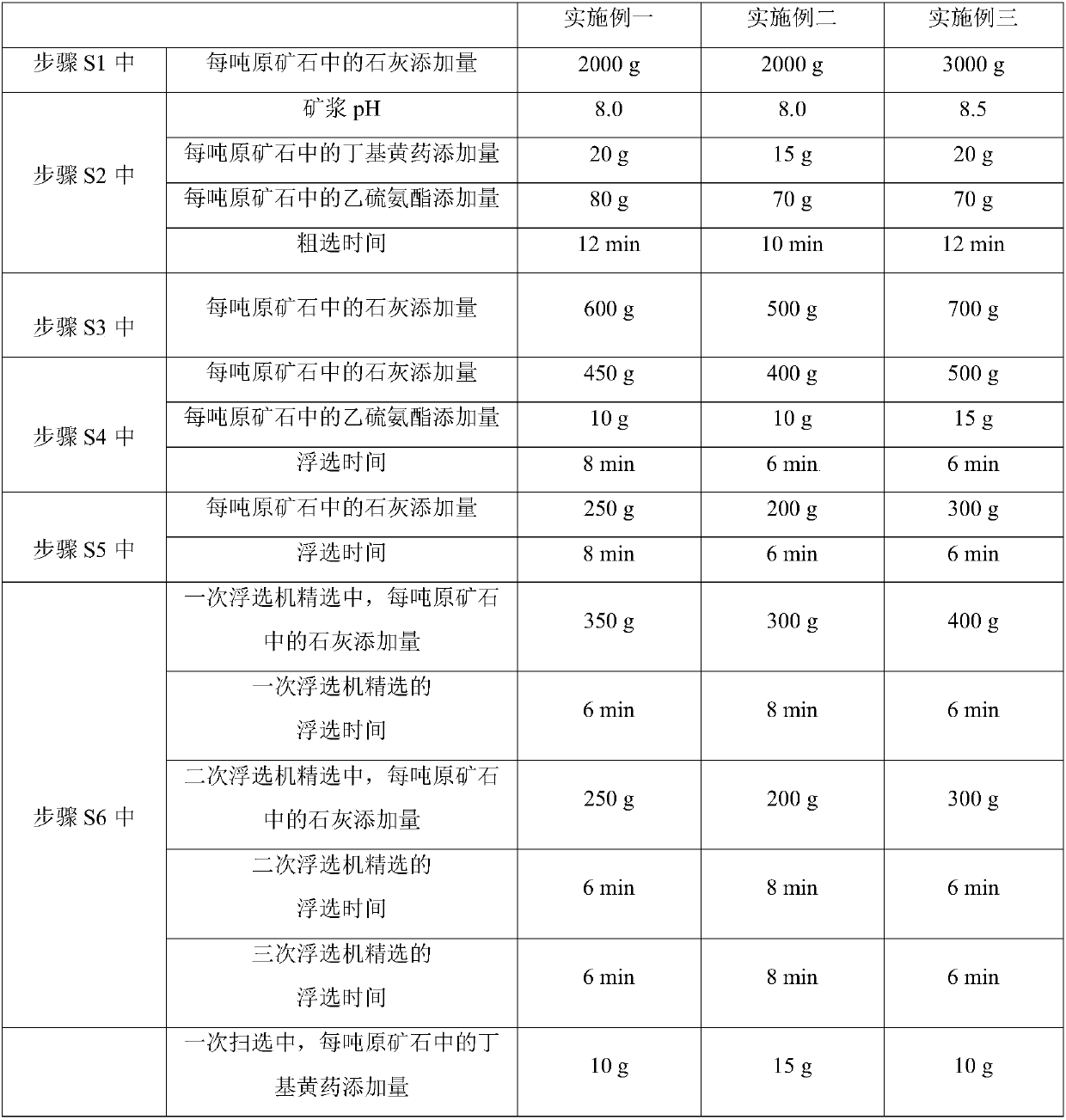

[0035] see figure 2 , which is a schematic flow chart of the combined gradient extraction method of a flotation machine and a flotation column with unevenly embedded copper sulfide ores of the present invention. The flotation machine and flotation column combined gradient extraction method of unevenly embedded copper sulfide ore of the present invention comprises the following steps:

[0036] S1 Grinding: Crushing and grinding the raw ore, adding lime as a pH adjuster and pyrite inhibitor during the grinding, according to each ton of raw ore, the amount of lime added is 2000-3000g / t, and water is added to adjust the slurry to The mass concentration of ore particles in the pulp is 32-35%, and the pH of the pulp is 7.5-8.0.

[0037] S2 flotation machine roughing: add lime to the pulp obtained in step 1 to adjust the pH of the pulp to 8.0-8.5, and add 15-20g / t butyl xanthate and 70-80g / t ethyl sulfide per ton of raw ore Urethane, stirred for 2 to 3 minutes, put into a flotatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com