Processing method for generating highly copper containing sewage sludge with copper containing wastewater or waste liquor

A treatment method and technology for copper sludge, applied in the field of treatment of copper-containing wastewater or copper-containing waste liquid to produce high copper-containing sludge, can solve problems such as expensive treatment costs and no recycling value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

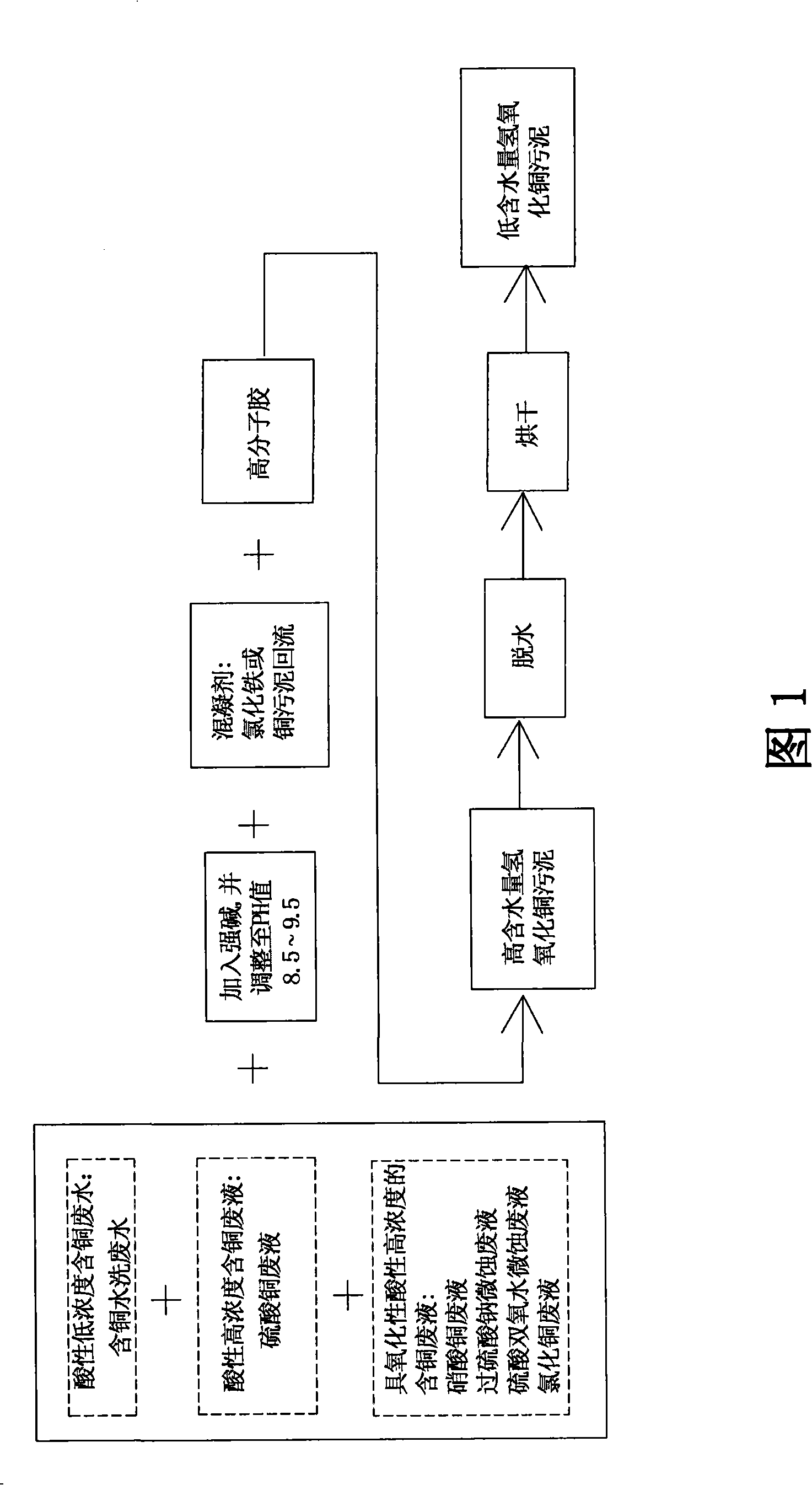

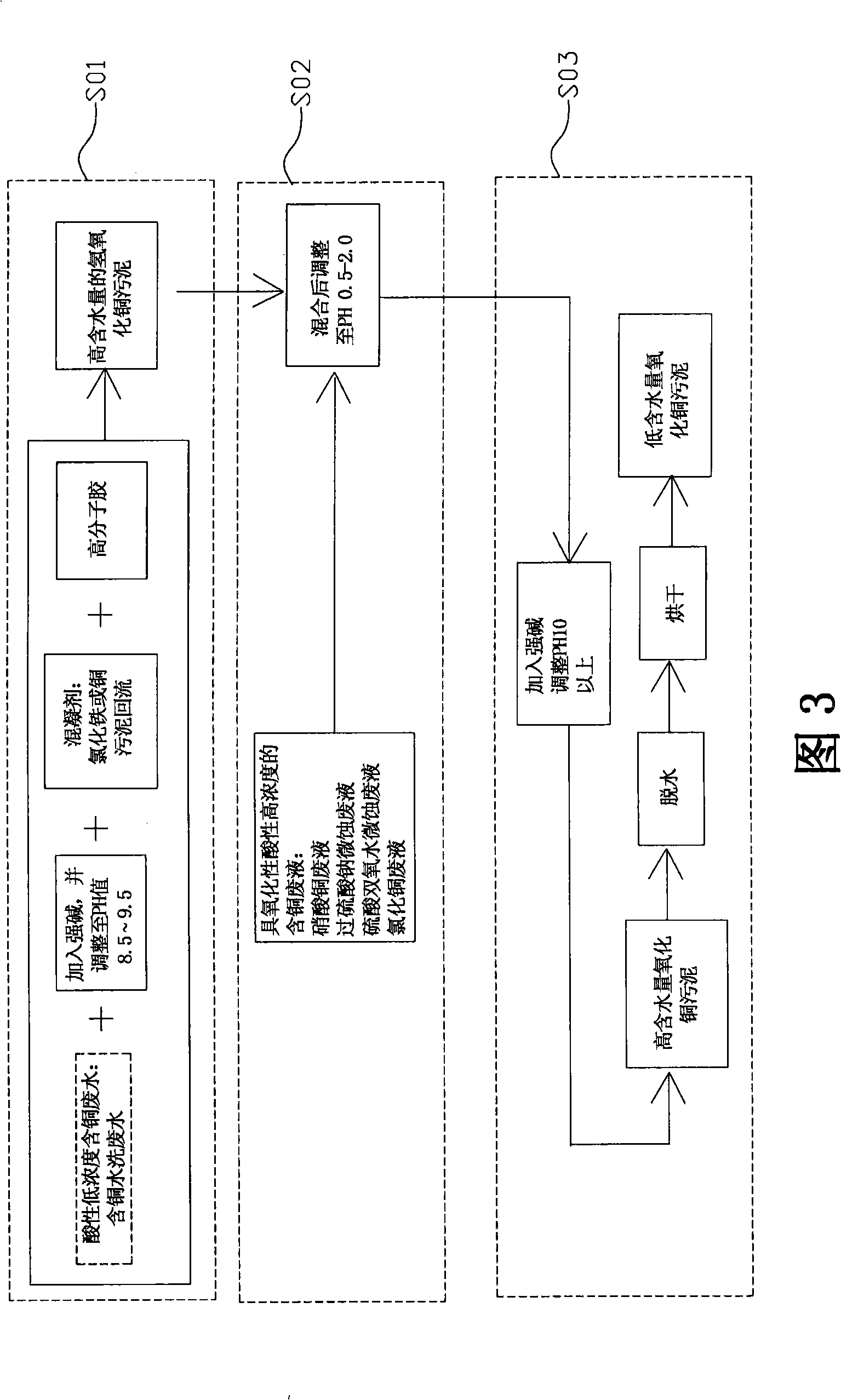

[0024] Please refer to shown in Fig. 3, as steps S01~S03, it is the second kind of embodiment of the present invention, and it is mainly the copper hydroxide sludge (as shown in step S01) that the step S01 reaction of the first kind of embodiment is generated ) after mixing with oxidizing acidic high-concentration copper-containing waste liquid, and adjusting the pH value to PH0.5-2.0 (as shown in step S02); then mixing with strong alkali (such as sodium hydroxide) , and adjust the pH value to more than PH10 to react to form copper oxide (CuO) sludge (shown in step S03);

[0025] Please refer to shown in Fig. 4, it is the third kind of embodiment of the present invention, and this method is after the copper-containing waste liquid with high concentration of oxidative acidity is mixed with strong base (such as sodium hydroxide), and the pH value Adjust to react above PH10 to form copper oxide (CuO) sludge;

[0026] Please refer to Figure 5, which is the fourth embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com