Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Inhibit aggregate growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

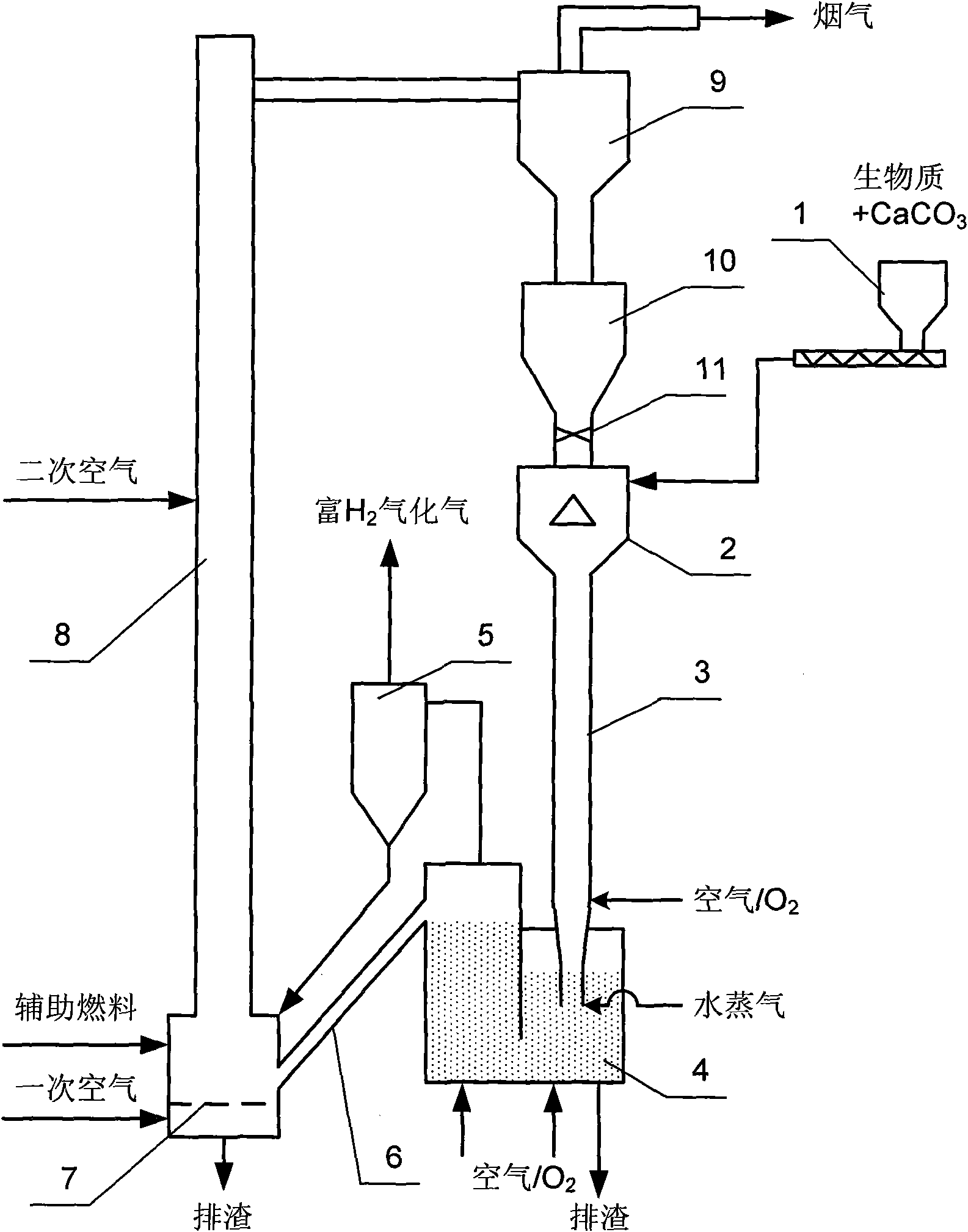

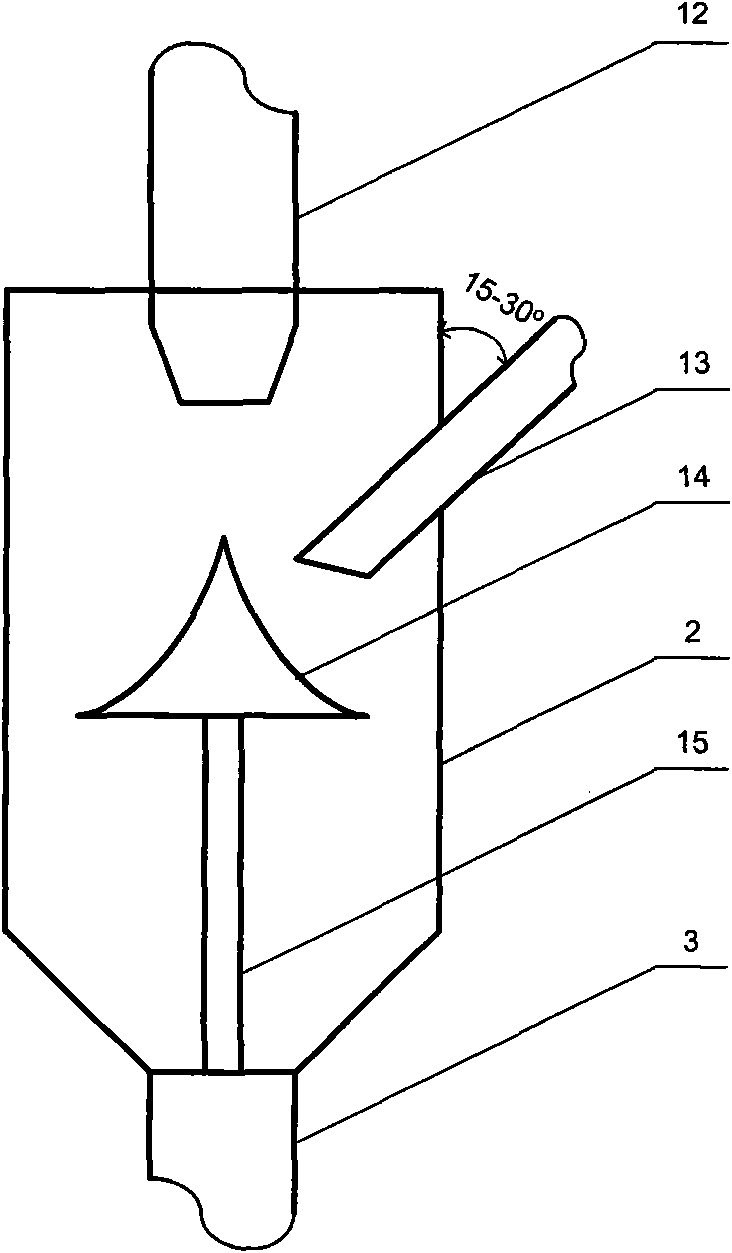

Gasification device and method for preparing hydrogen-rich synthetic gas from biomass

ActiveCN101880552AAvoid aggregate growthUniform temperature distributionGranular/pulverulent flues gasificationTarHeat carrier

The invention provides a gasification device and a gasification method for preparing hydrogen-rich synthetic gas from biomass. The device comprises a biomass feeder, a mixer, a pyrolysis chamber, a gasification chamber, a gasified gas separator, a combustion chamber, a flue gas separator, a bin and a butterfly valve. In the method, the biomass gasifying process is divided into three parts, namelybiomass pyrolysis, semicoke gasification and heat carrier circulation. Through the method and the device, the synthetic gas with the tar content less than 200mg / Nm<3> and the H2 / CO ratio more than 1.1 can be obtained, and the energy utilization rate and the process economy are obviously improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

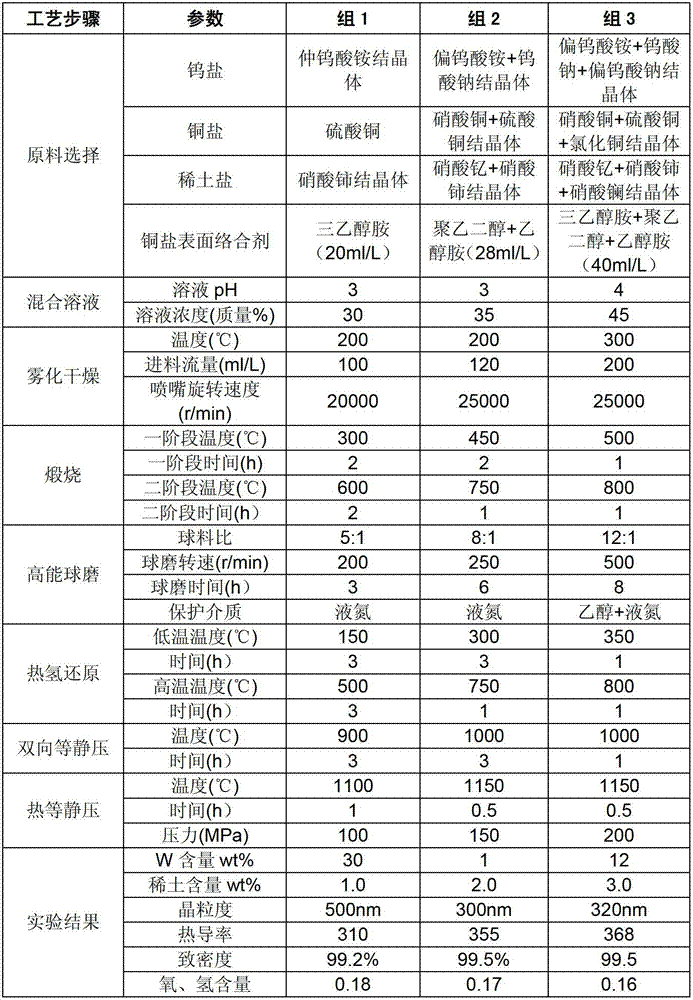

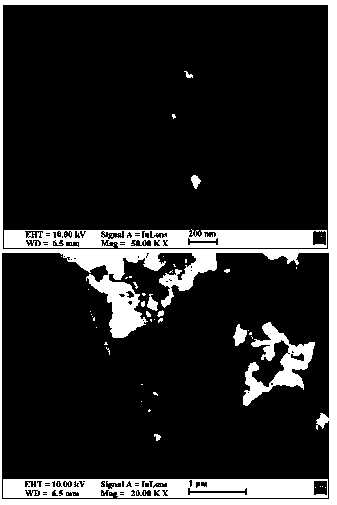

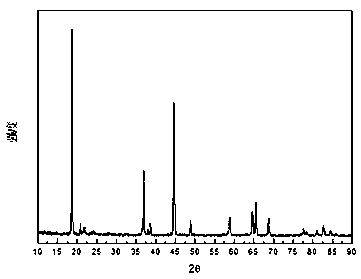

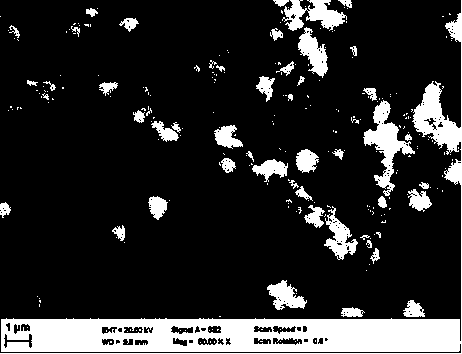

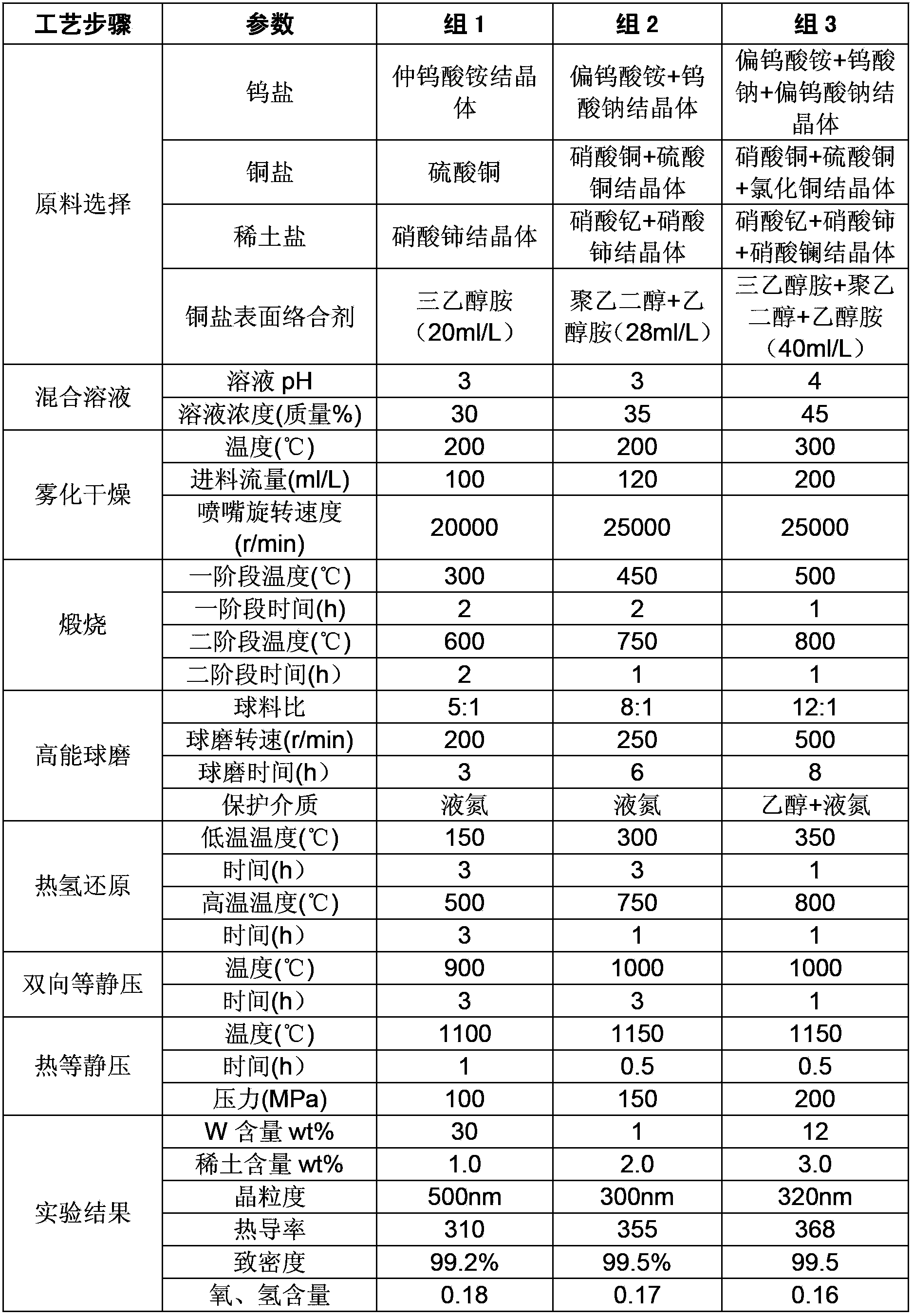

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

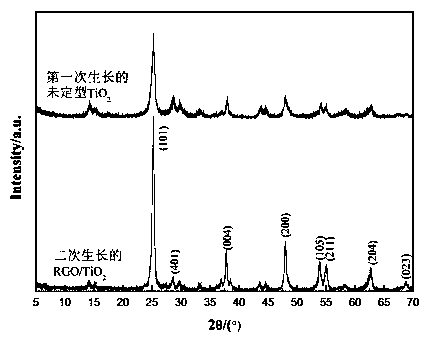

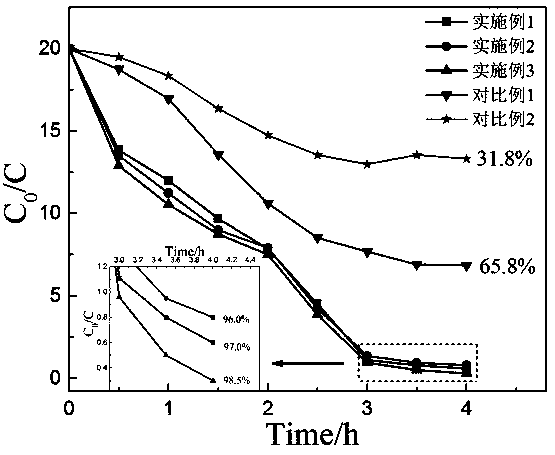

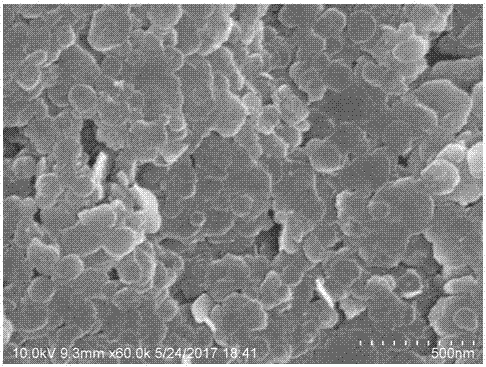

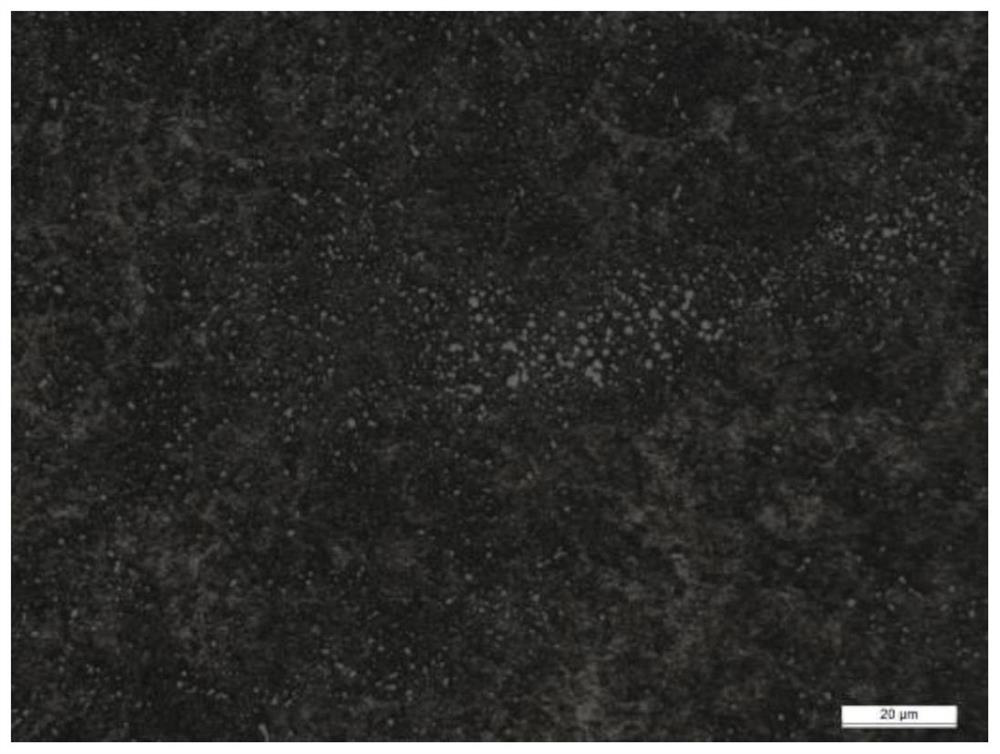

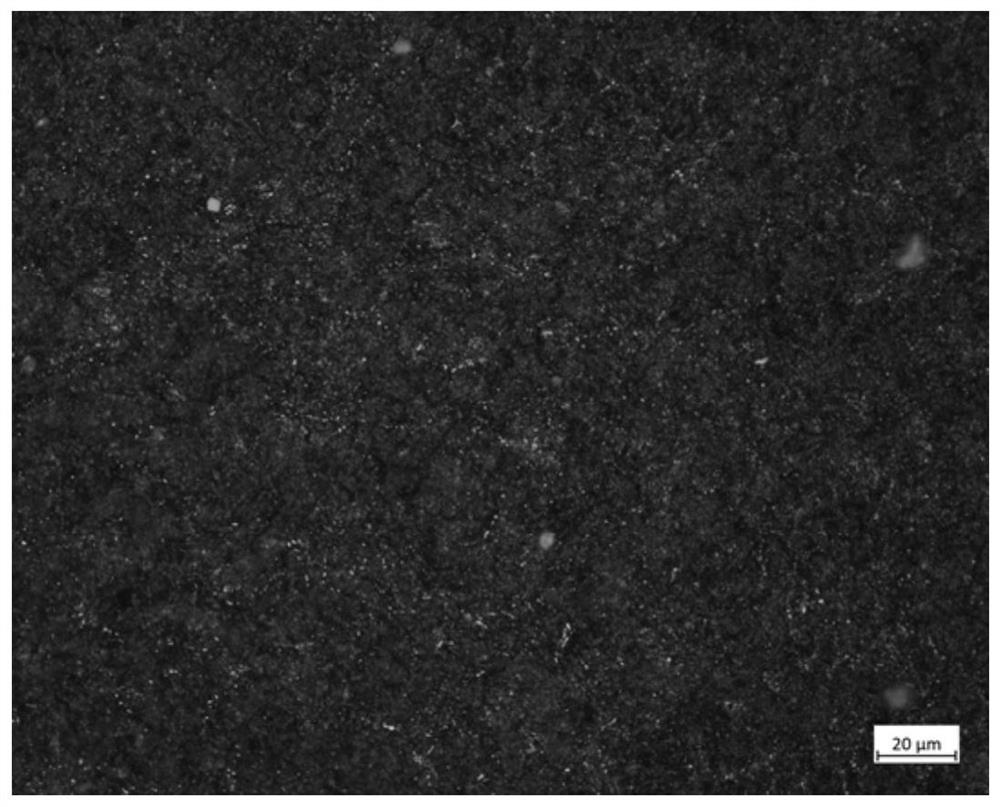

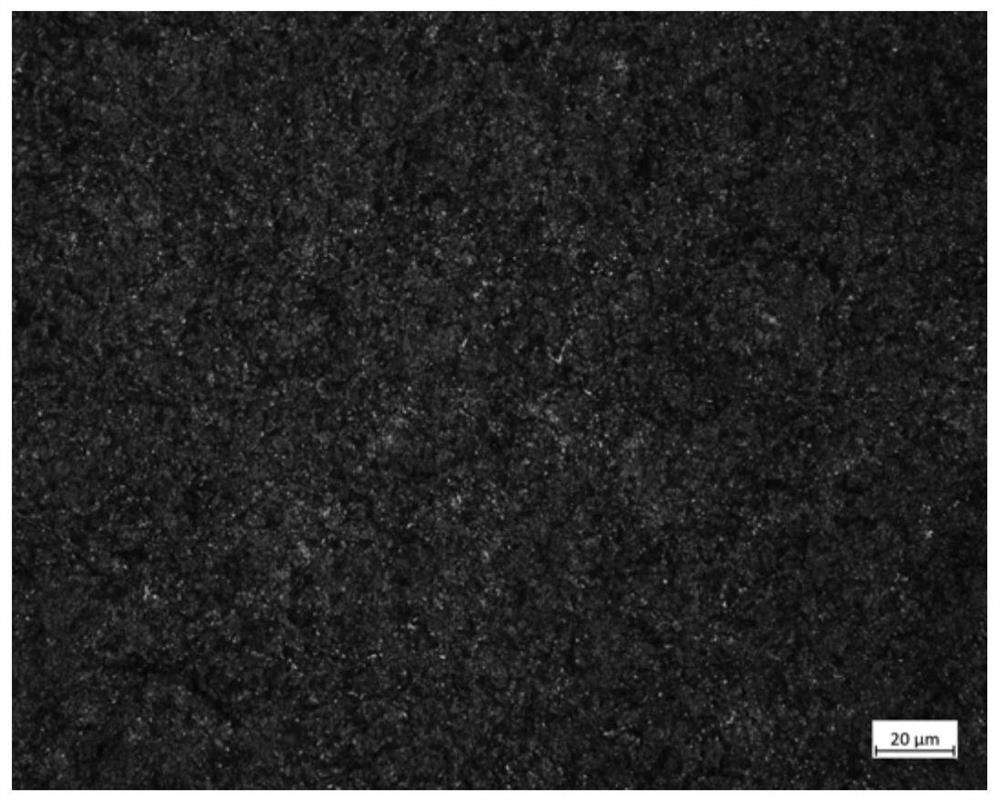

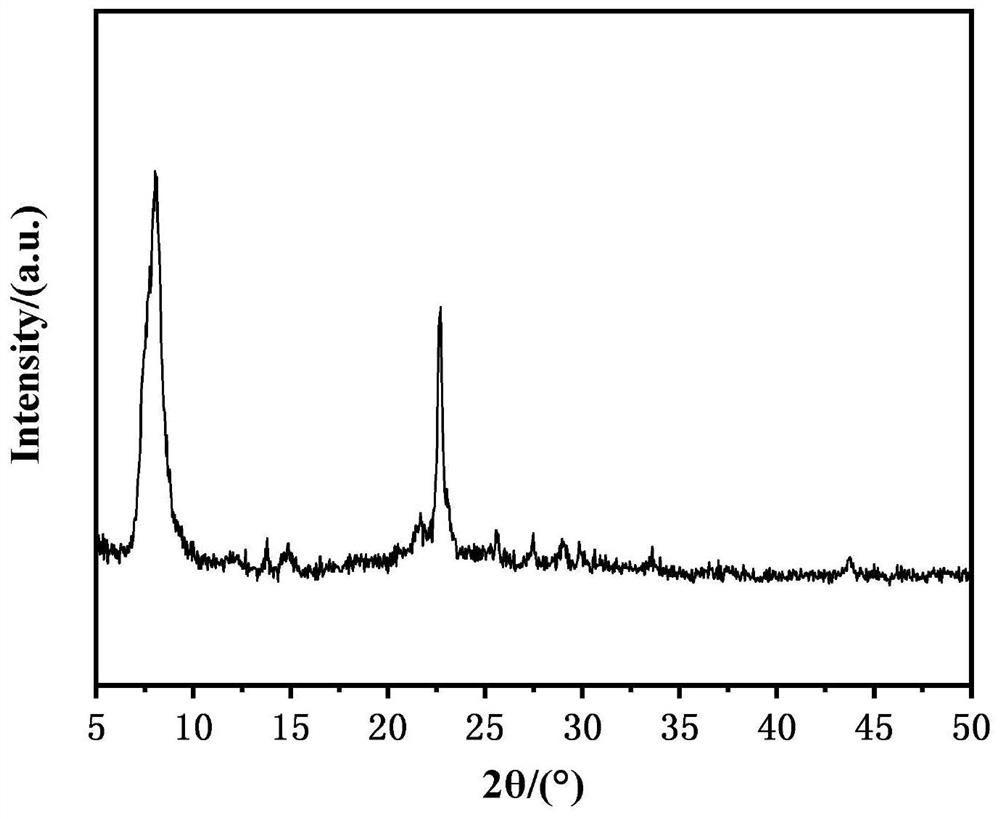

Photocatalysis composite material of graphene coated titanium dioxide with twice growth

ActiveCN108671903ASimplify the reduction processStable growth environmentPhysical/chemical process catalystsWater/sewage treatment by irradiationCvd graphenePhotocatalysis

The invention discloses a RGO / TiO2 (Reduced Graphene Dioxide / TiO2) photocatalysis composite material of graphene coated titanium dioxide with twice growth and belongs to the field of photocatalysis composite materials. Firstly, primary growth of TiO2 is regulated and controlled by adjusting the volume ratio of ethylene glycol to ethanol, types and concentrations of acids and hydrothermal reactiontime and temperatures, and thus unformed TiO2 is prepared; secondly, in secondary growth of TiO2, GO (Graphene Dioxide) is added to take a synergetic effect into play with the TiO2, and then GO is reduced into RGO. Under coating of the GO, the unfoamed TiO2 has a stable secondary growth environment and has the maximum contact area with graphene, the ultrahigh conductivity of the graphene is effectively utilized, hole compounding of TiO2 photoproduction electron pairs is greatly delayed, light absorption red shift is also resulted, and a light response area is widened to a visible light range.Meanwhile, pi-pi accumulation is allowed on a highly conjugated surface of graphene, so that the composite material has the characteristic that an aromatic compound is adsorbed preferably, and the properties of the material are greatly improved.

Owner:福建威鹏实业有限公司

Supported gold-PGM alloy catalyst with stable storage property and preparation method thereof

InactiveCN101698149AHigh activityInhibit migrationCatalyst carriersDispersed particle separationAmbient humidityAlloy catalyst

The invention relates to a supported gold-PGM alloy catalyst with stable storage property and a preparation method thereof. An active component is Au, an accessory ingredient is Pd or Pt in PGM, and a carrier is a Al2O3 composite oxide modified by Al2O3 or MIOx and MIIOx, wherein the atomic ratio of Au to PGM is 1.0:1.0-1.0:1.0*10<-2>; the atomic ratio of Au to MI+MII is 1.0:1.0-1.0:10; the atomic ratio of MI to MII is 2.0:1.0-0.2:1.0; the atomic ratio of Au to Al is 1.0:1.0*10<3>-1:0:10; MI is La; and MII is Fe, Co or Ni. The composite oxide carrier is prepared by an impregnation method or a coprecipitation method. After being supported with MIOx and MIIOx, Al2O3 is roasted at a temperature of between 800 and 1,000 DEG C to generate a spinelle or perovskite structure. The catalyst of the invention catalytically oxidizes micro CO (0.1 percent to 1.5 percent) in the air into CO2 at ambient temperature and in ambient humidity, and has the advantages of stable catalysis property, pressure drop meeting the requirements of a gas mask and a mining self-rescuer and low cost.

Owner:安立敦

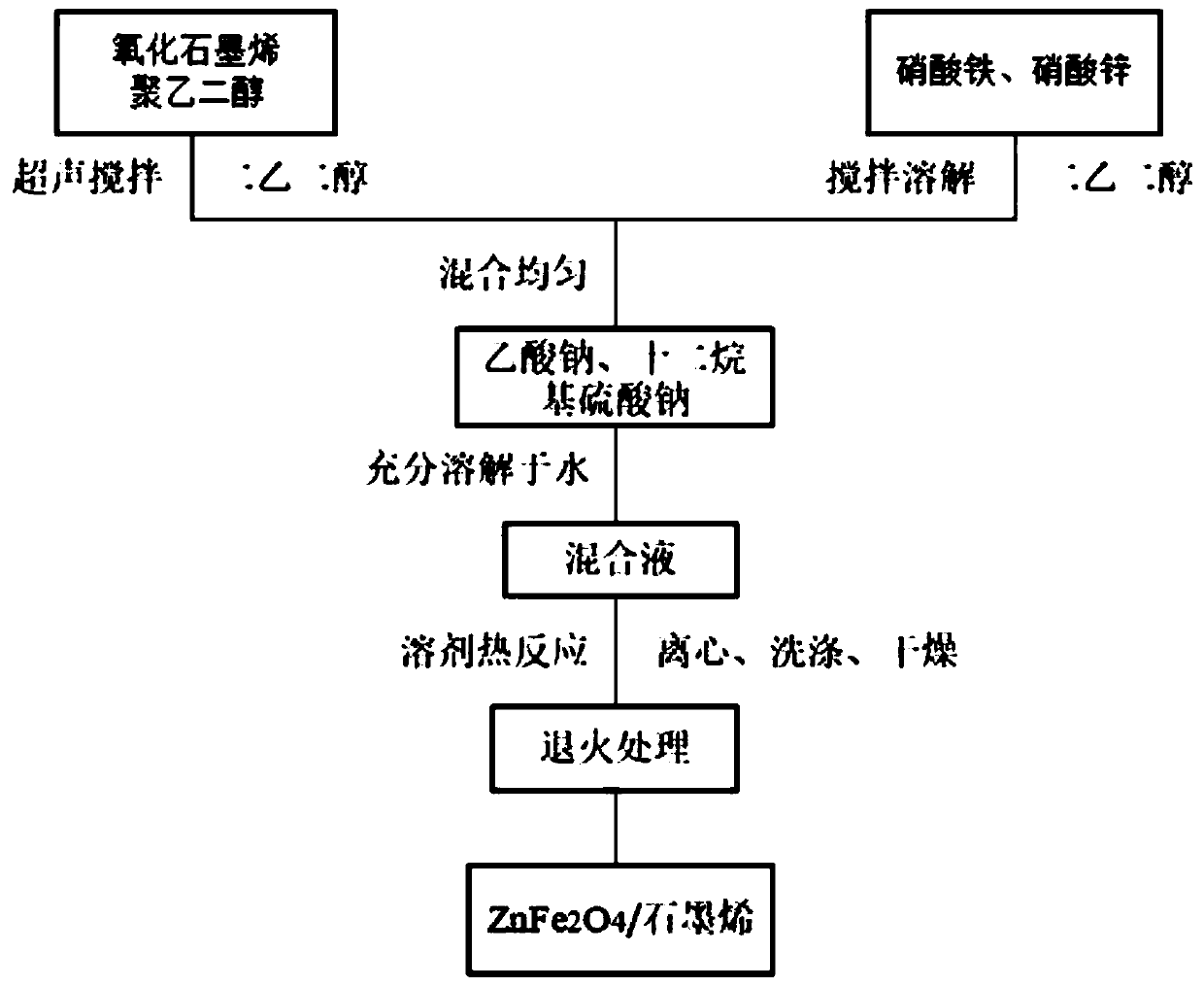

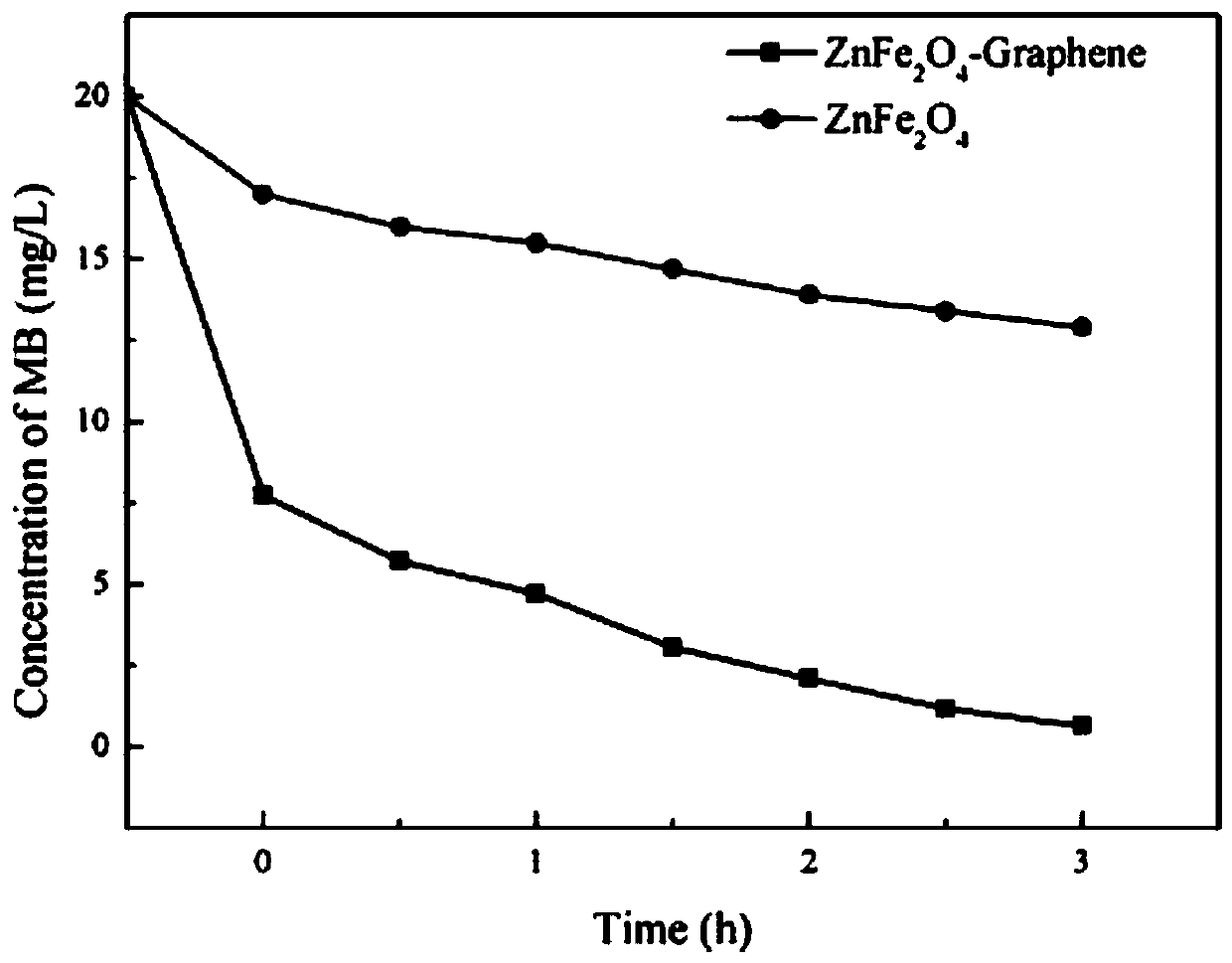

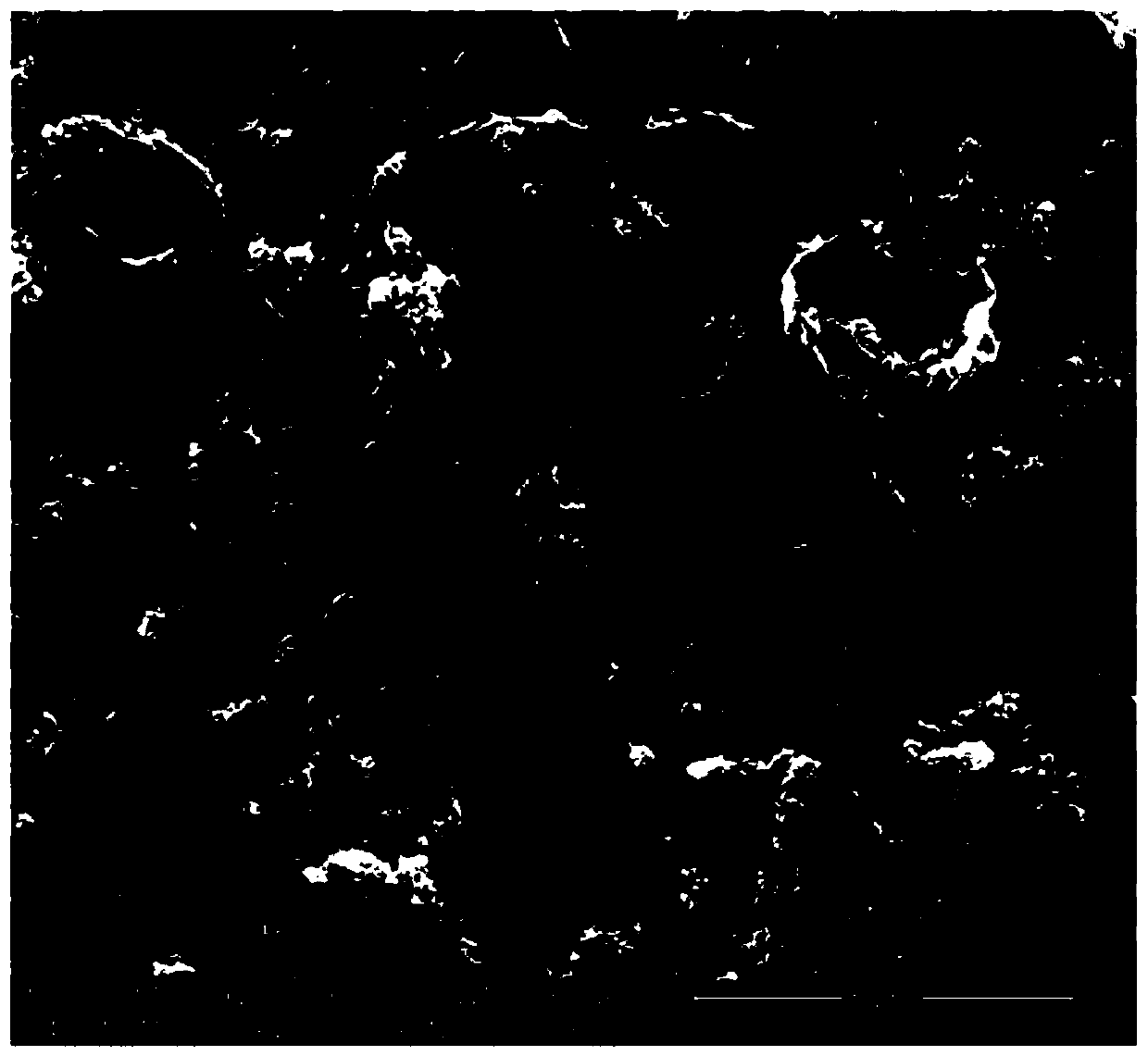

Magnetic ZnFe2O4/graphene nanometer composite photocatalyst as well as preparation method and application thereof

ActiveCN109806876AThe synthesis process is simpleEase of mass productionWater/sewage treatment by irradiationWater contaminantsSodium acetatePhotocatalytic reaction

The invention discloses a magnetic ZnFe2O4 / graphene nanometer composite photocatalyst as well as a preparation method and application thereof. Diethylene glycol is used as a solvent; polyethyleneglycol is used as an appearance controlling agent; sodium dodecyl sulfate is used as a dispersing agent; basic conditions are provided by sodium acetate hydrolysis, so that zinc ferrite realizes the uniform core forming growth on the surface of graphene; meanwhile, zinc ferrite crystals can also prevent the unordered stacking agglomeration between the layered graphene, so that the surface area of the composite material is improved. Compared with a single ZnFe2O4 photocatalyst, the composite material has high specific surface area and excellent electronic conductivity; the sufficient reaction activepositions can be provided for the photocatalysis reaction; the migration and the separation of photon-generated carriers can also be promoted, so that the ZnFe2O4 / graphene nanometer composite photocatalyst can show excellent visible light photocatalysis capability.

Owner:ZHEJIANG UNIV OF TECH

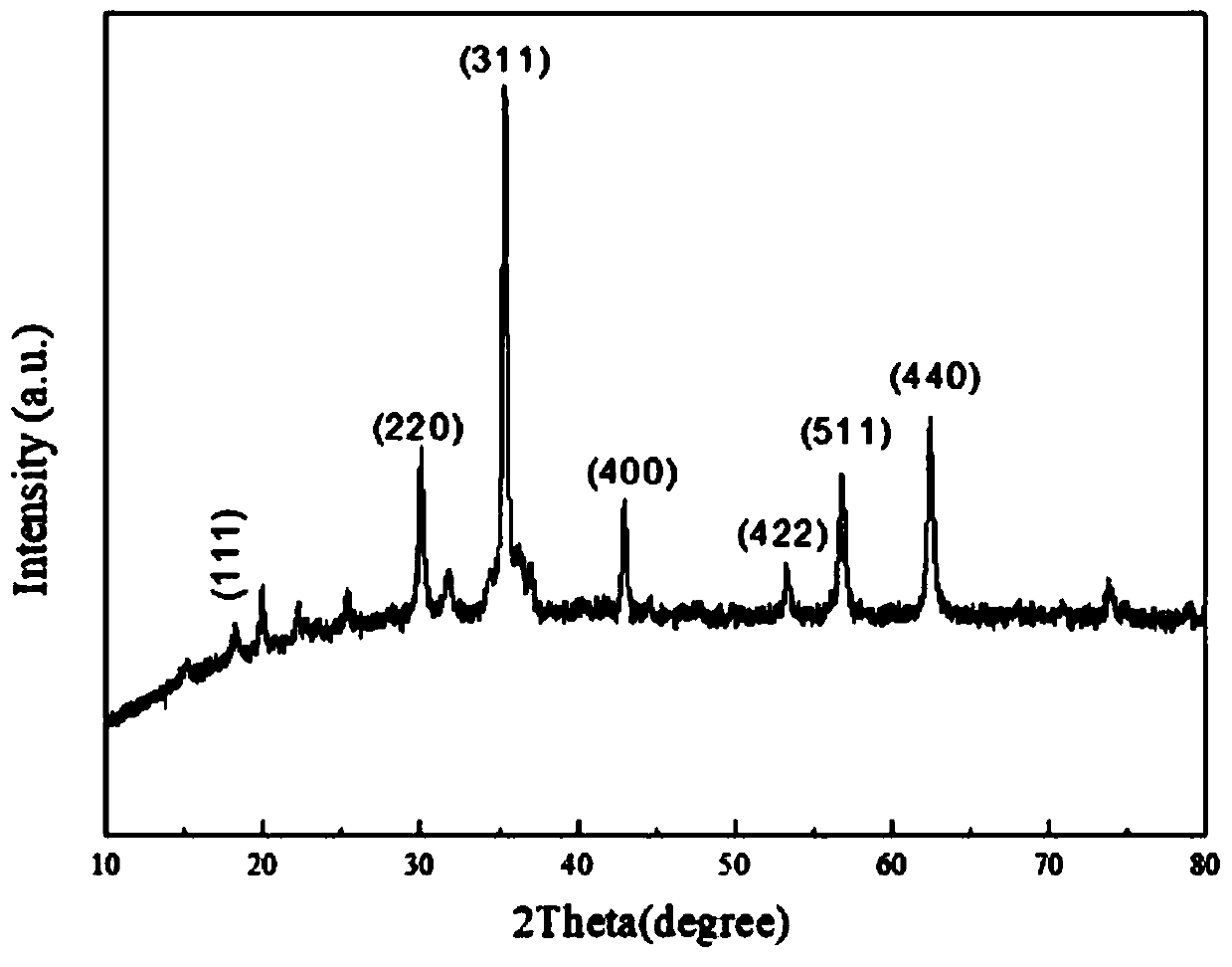

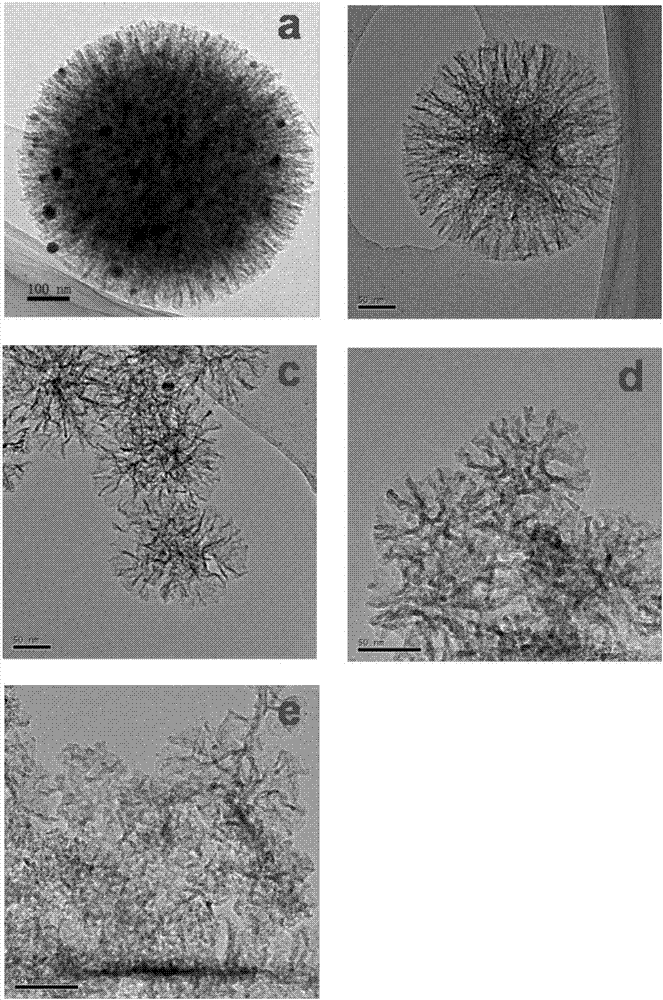

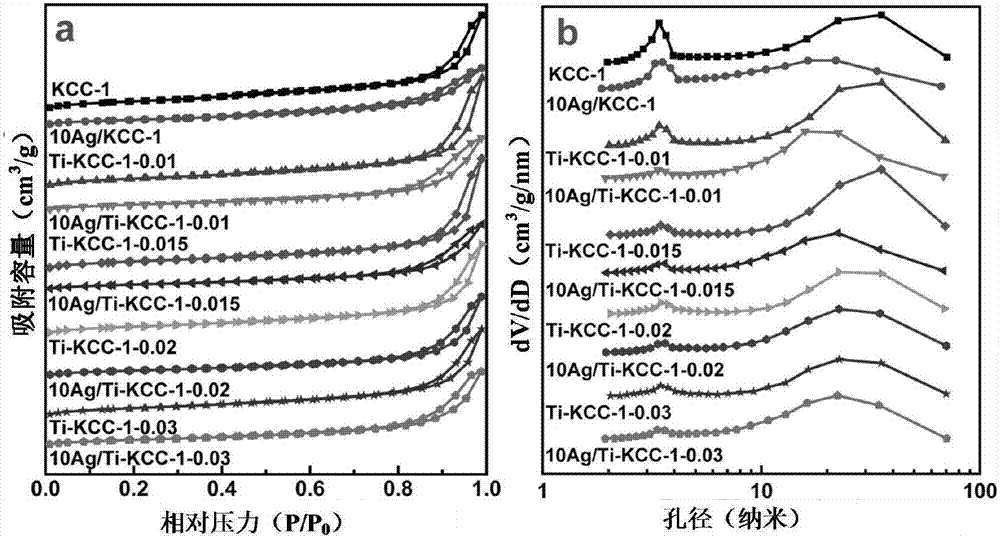

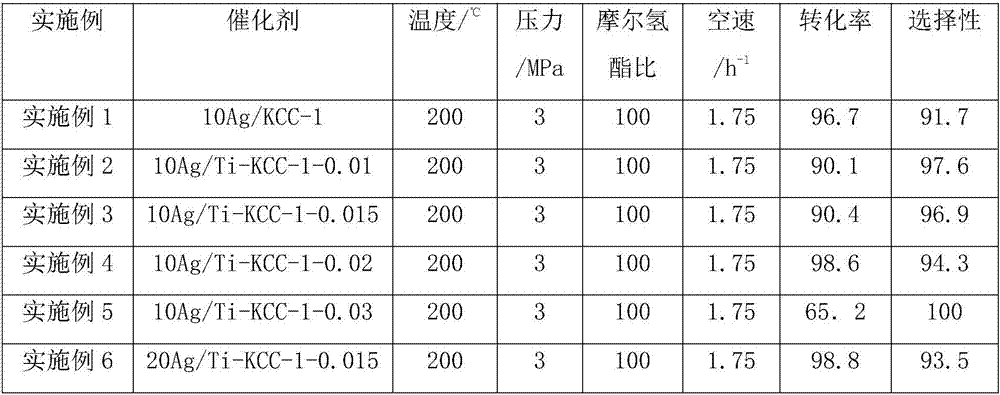

Hierarchical pore nanometer flower-like structure Ag catalyst of methyl glycolate prepared through oxalic ester hydrogenation

InactiveCN107442113AOvercoming easy pluggingImprove hydrogenation activityOrganic compound preparationCarboxylic acid esters preparationPtru catalystHydrogenation reaction

The invention relates to a hierarchical pore nanometer flower-like structure Ag catalyst of methyl glycolate prepared through oxalic ester hydrogenation. Titanium-doped hierarchical pore nanometer flower-like silica balls are taken as a carrier, and silver is taken as an active ingredient; the weight percentage of the components in the catalyst is as follows: the weight percentage of the active ingredient such as silver is equal to 5 wt% to 20 wt%, the weight percentage of an additive such as TiO2 is equal to 0.5 wt% to 2.5 wt%, and the balance is silicon oxide; the preparation method comprises the following steps: adding a mixed liquor containing a silicon oxide precursor into a template mixed liquor, adding a titanium precursor after uniform stirring, carrying out hydrothermal crystallization, taking a product to carry out centrifugal separation and washing, vacuum drying and calcinations to obtain a hierarchical pore nanometer flower-like titanium silicon compound carrier; and adding a soluble silver precursor solution into the carrier, stirring, aging, and finally carrying out calcinations and reduction on an obtained drying product. The catalyst is of a hierarchical pore nanometer flower-like structure, so that the accessibility of active metal silver can be improved; and besides, the carrier is regulated and controlled by adopting titanium, and the dispersity of silver is improved through mutual effect of silver and titanium, so that the hydrogenation reaction activity of oxalic ester and the selectivity of methyl glycolate are strengthened.

Owner:TIANJIN UNIV

Method for preparing sulfuration-type gasoline selective hydro-desulfurization catalyst

ActiveCN105521791AGood dispersionImprove catalytic activity of hydrodesulfurizationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationSulfur

The invention provides a method for preparing sulfuration-type gasoline selective hydro-desulfurization catalyst. A main content of the method is characterized in that hydrogenation active metal elements of the gasoline selective hydro-desulfurization catalyst are combination of Co and Mo, the hydrogenation active metal element Co is introduced and is calcinated, the hydrogenation active metal element Mo is introduced by employing an impregnation method and then is dried, the dried catalyst is directly and rapidly procured in short time without calcination, preferably, surface sulfur polymer reduction operation can be carried out. The catalyst has obvious usage performance by the method, and the method has the advantages of simple precuring step, short on-stream time of the catalyst, low heat energy consumption, less amount of a toxic vulcanizing agent which has easy corrosion performance, and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

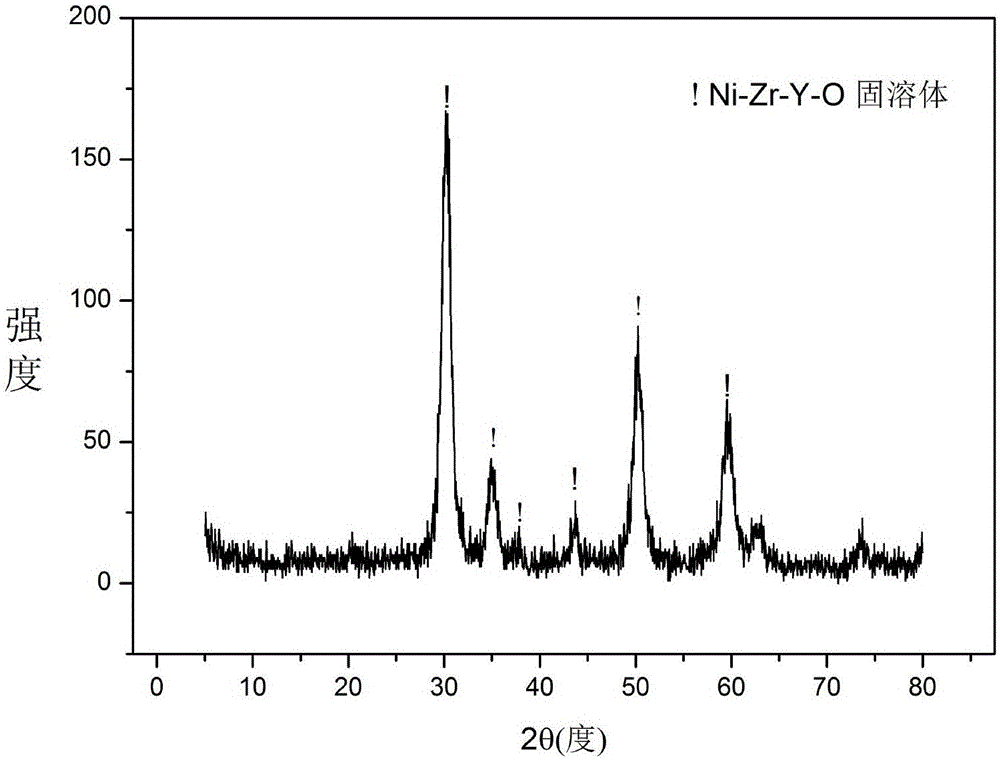

Solid solution catalyst for acetic acid self-heating hydrogen production by reforming and preparation method

ActiveCN106391036AGood dispersionImprove thermal stabilityHydrogenHeterogenous catalyst chemical elementsPolyethylene oxideEvaporation

The invention relates to a solid solution catalyst for acetic acid self-heating hydrogen production by reforming. Aiming at the problem that in an acetic acid self-heating reforming reaction of an existing catalyst, by means of oxidizing, sintering, carbon depositing and other factors of the active components of the catalyst, the catalyst is inactivated, the novel catalyst is stable in structure, resistant to sintering, resistant to carbon depositing and oxidization and stable in activity, and the composition by weight of the catalyst is (NiO)a(YO1.5)b(ZrO2)c, wherein a ranges from 0.07 to 0.20, b ranges from 0.02 to 0.35, and c ranges from 0.58 to 0.91. According to the catalyst, zirconium oxide is adopted as a carrier, an aid yttrium oxide is introduced, a polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer is adopted as a template, a mesoporous structure is formed through evaporation self-assembly, and the nickel-based catalyst with the stable ZrxY1-xOy solid solution as the main structure is obtained. The hydrogen productivity, stability and carbon depositing resisting capacity of the acetic acid self-heating reforming process are effectively improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Coke oven flue gas denitration catalyst and preparation method thereof

ActiveCN106984349ALower surface energyGood dispersionPhysical/chemical process catalystsDispersed particle separationWater bathsPhosphate

The invention discloses a coke oven flue gas denitration catalyst and a preparation method thereof. The preparation method utilizes ammonium metavanadate as an active precursor, chromium nitrate as an auxiliary agent and oxalic acid and hydrochloric acid as reducing agents, and utilizes phosphoric acid to adjust and control the surface acidity of an active component. The preparation method comprises stirring, water bath heating, drying, calcining to obtain a Cr-doped oxyvanadium phosphate active component, adding the Cr-doped oxyvanadium phosphate active component and anatase TiO2 as a carrier with a specific surface area of greater than or equal to 250 m<2> / g into distilled water according to a ratio, carrying out stirring mixing, and carrying out water bath drying and calcining to obtain the catalyst. The catalyst utilizes phosphoric acid to adjust and control the surface acidity of the catalyst, and utilizes aid chromic nitrate to form an intercalation structure and promote formation of adjacent V<5+> and V<4+>. The catalyst has good low temperature denitration activity and strong SO2 and steam poisoning resistance and is suitable for industrial coke oven flue gas denitrification.

Owner:马鞍山方信环保科技有限公司

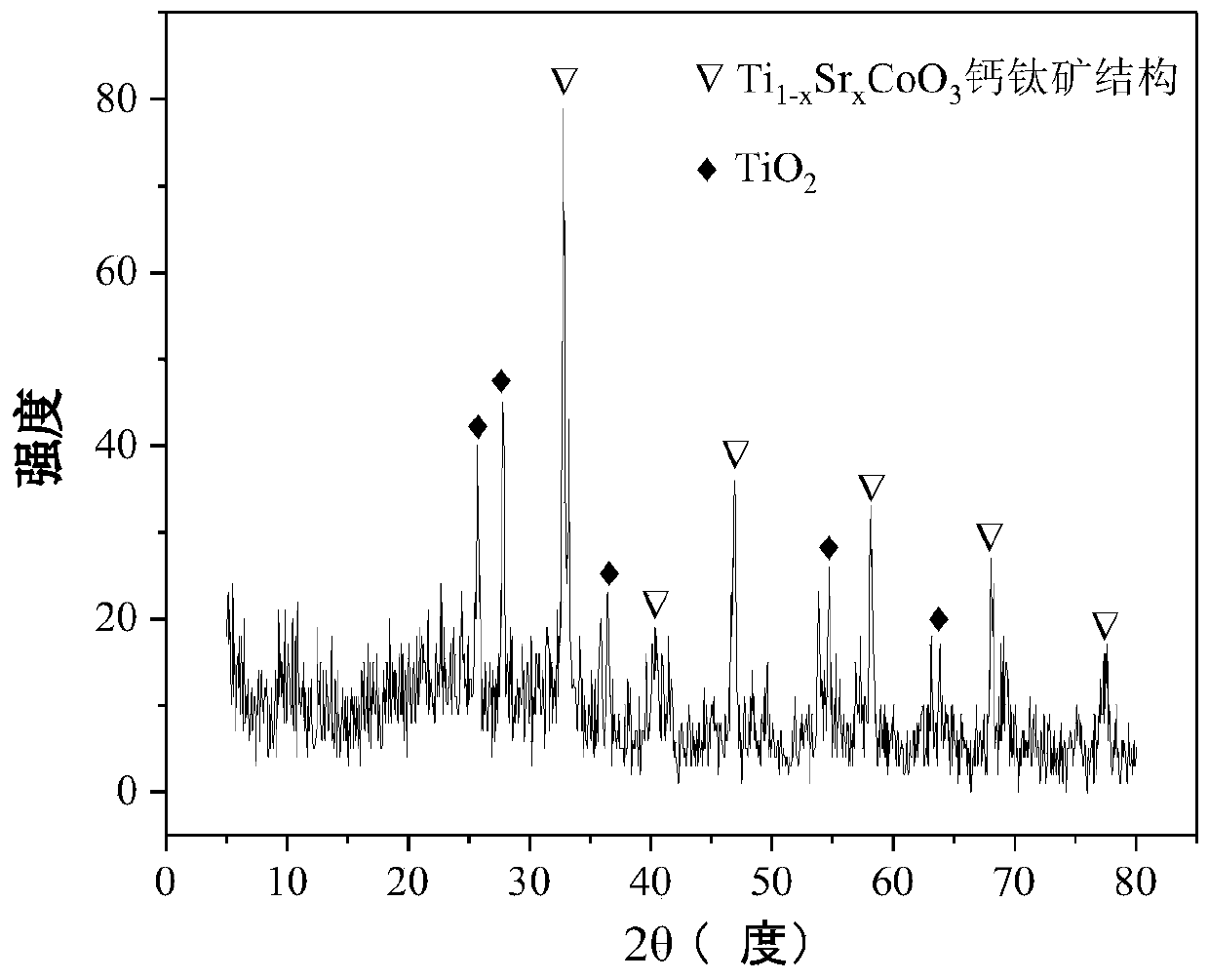

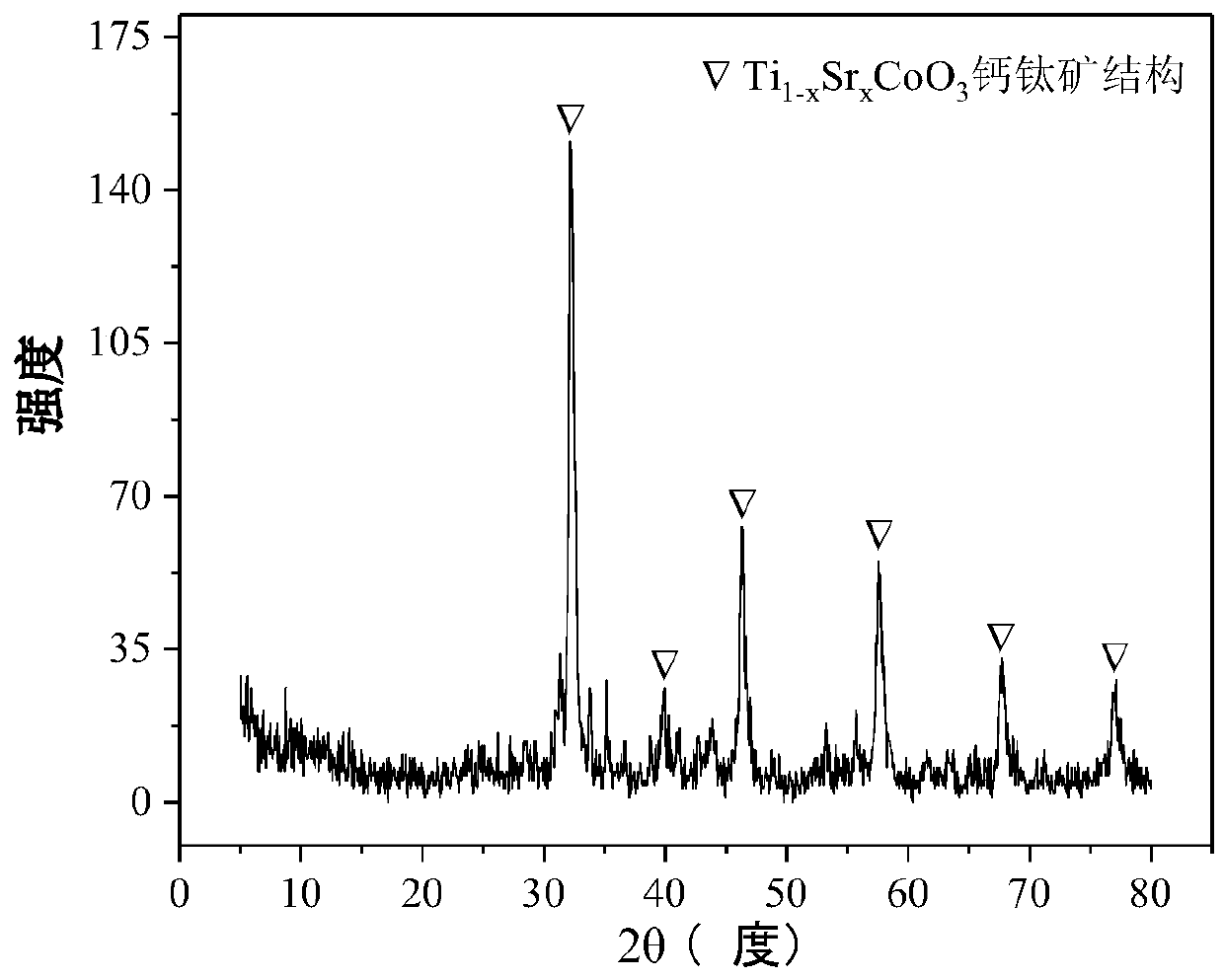

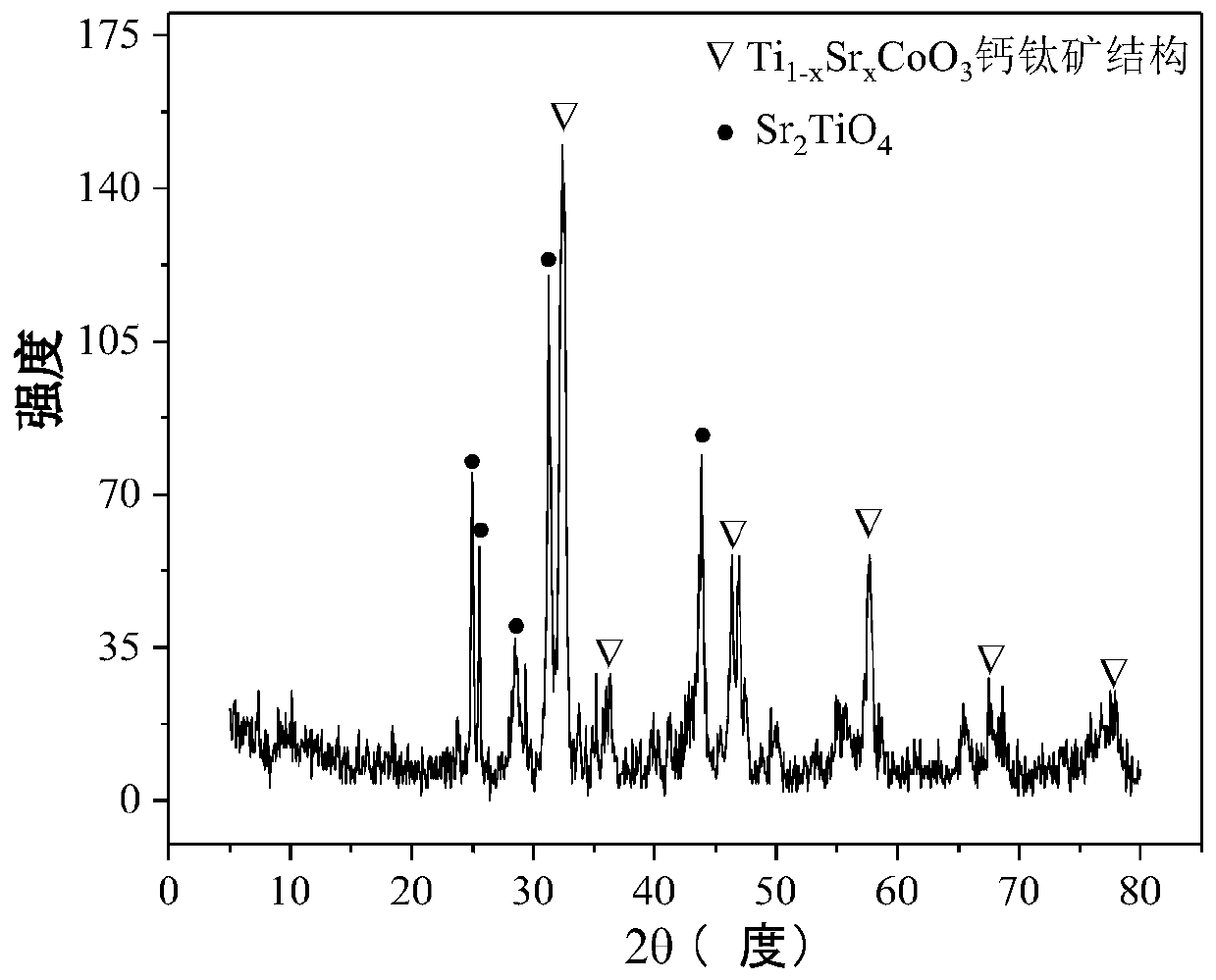

Perovskite-type titanium-strontium-cobalt catalyst for hydrogen production by autothermal reforming of acetic acid

ActiveCN109759070ALower activation energyStable activityMetal/metal-oxides/metal-hydroxide catalystsComposite oxideSol-gel

The invention relates to a perovskite-type titanium-strontium-cobalt catalyst for hydrogen production by autothermal reforming of acetic acid and a preparation method. The catalyst with resistance tosintering, anti-carbon deposit, oxidation resistance and high activity is provided to aim at solving the problems that an existing catalyst has carbon deposits, sintering and oxidation of active components in the autothermal reforming process of acetic acid, and deactivation of the catalyst is caused. According to the perovskite-type titanium-strontium-cobalt catalyst for the hydrogen production by autothermal reforming of acetic acid and the preparation method, a sol-gel method is adopted to prepare the perovskite-type titanium-strontium-cobalt catalyst, and after calcination, a perovskite composite oxide catalyst Ti<1-x>Sr<x>CoO3 is obtained, wherein x=0-0.8. The perovskite structure facilitates the dispersion of an active component Co, strengthens the synergistic effect between the active component and a carrier, and inhibits the aggregation and growth of Co, thereby obtaining stable small-particle-size Co particles. In addition, Ti is partially replaced with Sr to increase the surface defect position and lattice defect structure of the perovskite-type catalyst, so that the carbon deposit resistance, oxidation resistance and thermal stability of the active component cobalt are improved, the diffusion of acetic acid, water vapor and oxygen is further facilitated, and the catalytic activity is increased.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of high-strength alumina ceramic substrate

InactiveCN108129139AImprove adhesionPrevent deformation and crackingAluminium hydroxideSodium aluminate

The invention discloses a preparation method of a high-strength alumina ceramic substrate, and belongs to the technical field of ceramic substrate preparation. Carbon dioxide is introduced into a sodium aluminate solution, then ultrafine aluminum hydroxide crystal grains can be formed, the ultrafine aluminum hydroxide crystal grains are mixed with a precursor sol, and tape casting is performed toobtain a tape-casted raw material tape with good cohesiveness. Because the thermal expansion coefficient of the sol is high, the bonding toughening effect is played, and thus cracking and deformationof the alumina ceramic substrate during sintering molding are avoided; mullite whiskers can grow after the sol in micro through holes of the alumina ceramic substrate is sintered and then cooled, alumina particles of the alumina ceramic substrate are wound by the whiskers, the whiskers are beneficial for uniform distribution of internal stress, the relative displacement between alumina and the silicate crystal grains is reduced, and the whiskers can inhibit aggregation and growth of the crystal grains and can effectively reduce pores in ceramics, so that the compactness of a sintered body is improved, the crystal grains in the alumina ceramic substrate are distributed uniformly, the crystal grain distribution is compact, the mechanical strength is enhanced, and the application prospect isbroad.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

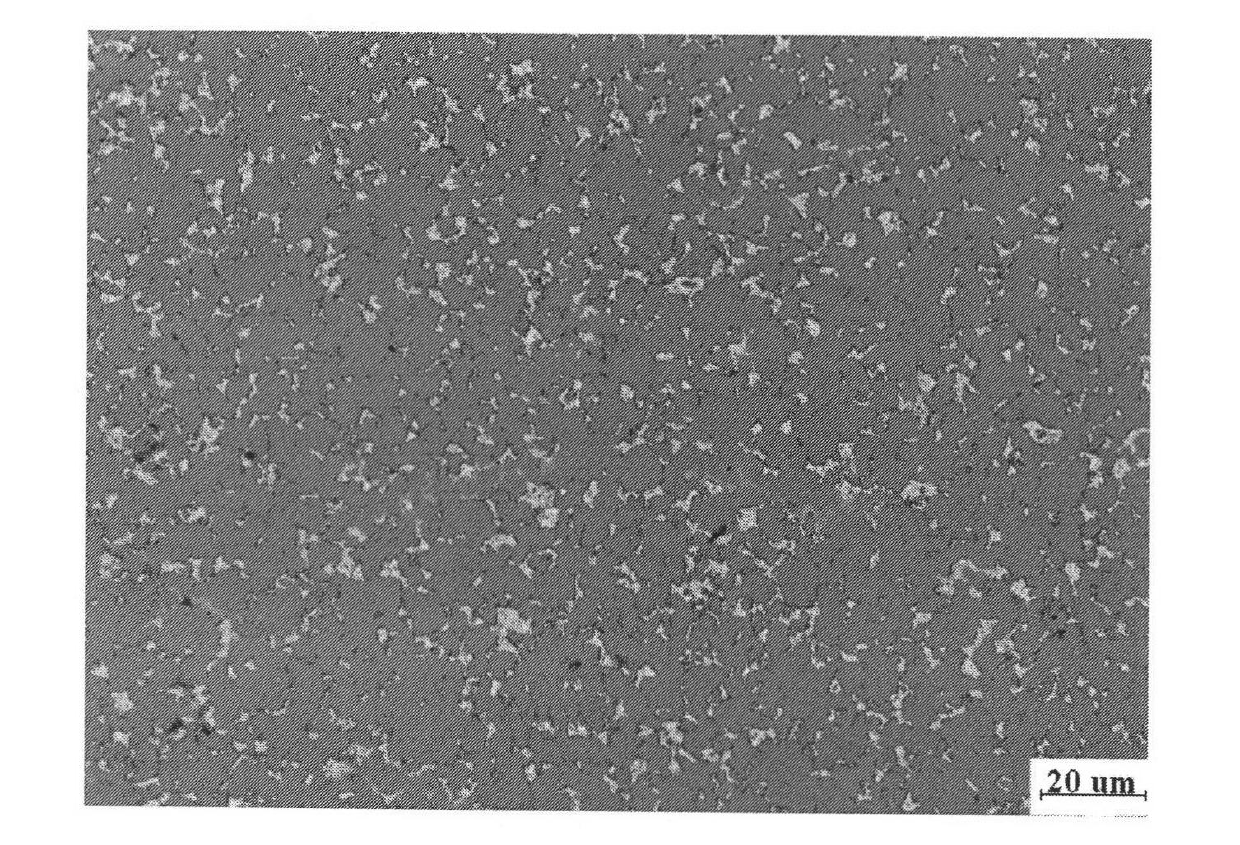

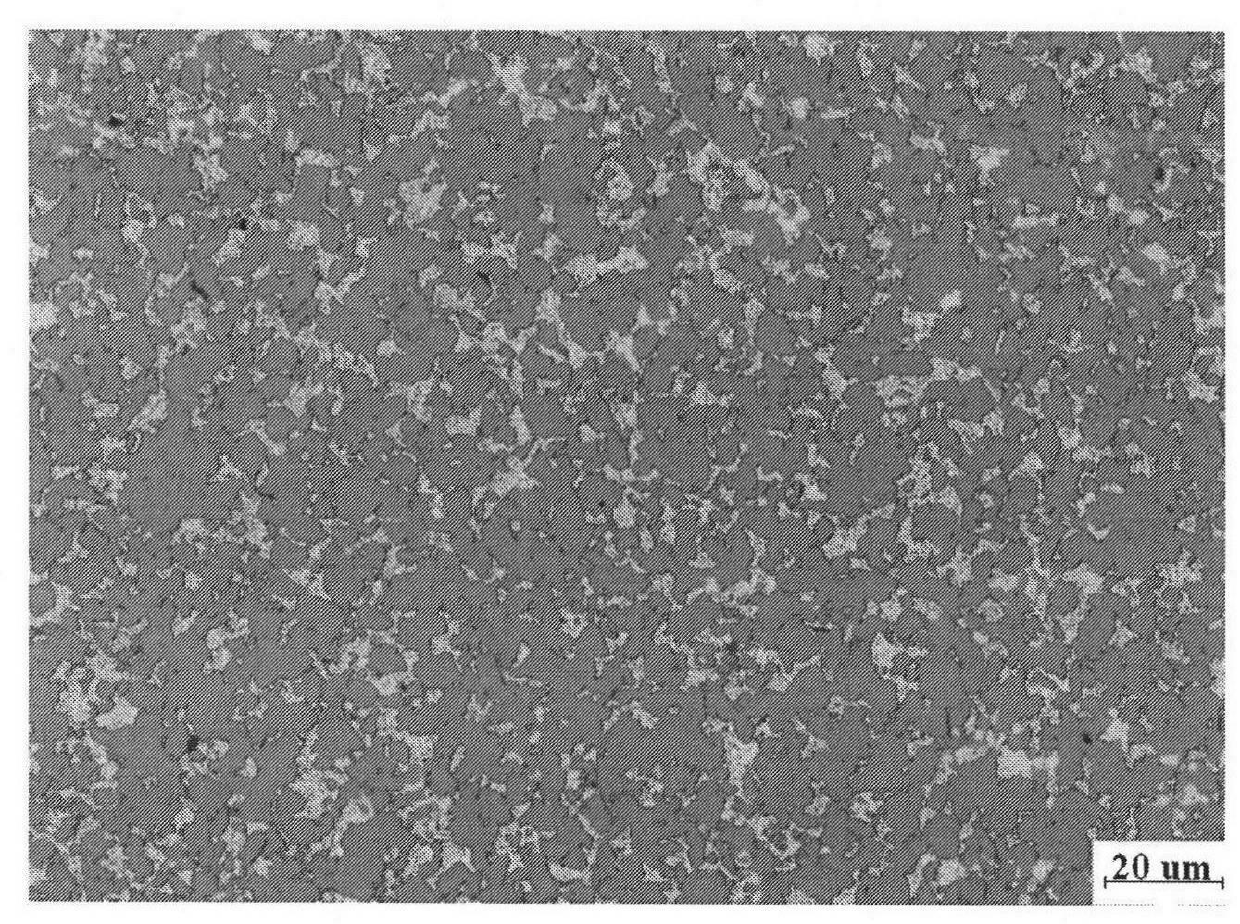

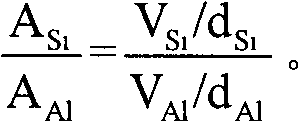

Silicon-aluminum bicontinuous composite material and preparation method thereof

The invention relates to a bicontinuous composite material which has excellent comprehensive properties due to the special interpenetrating network structure. Aiming at the silicon aluminum material having wide application prospects, the invention implements a silicon-aluminum bicontinuous composite material and a powder metallurgy preparation technique thereof. The technique overcomes the defects of overgrowth of silicon, and material nonuniformity and noncompactness in the casting method and liquid phase impregnation method, and prepares the bicontinuous composite material with controllable composition, phase dimensions and microstructure. The invention implements uniform mixing of the two phases silicon and aluminum by selecting reasonable composition and powder size; and the alloy elements of the aluminum alloy are added by an element powder direct mixing method. The billet is completely compacted within a proper temperature range; and silicon atoms are diffused, so that the silicon powder particles are connected with each other and interpenetrate with the aluminum alloy to form the bicontinuous composite material. The silicon content in the composite material is 40-80 vol.%; and the composite material is completely compact and has a uniform structure. The composite material has excellent comprehensive properties, and is applicable to various conventional machining means.

Owner:有研金属复材技术有限公司

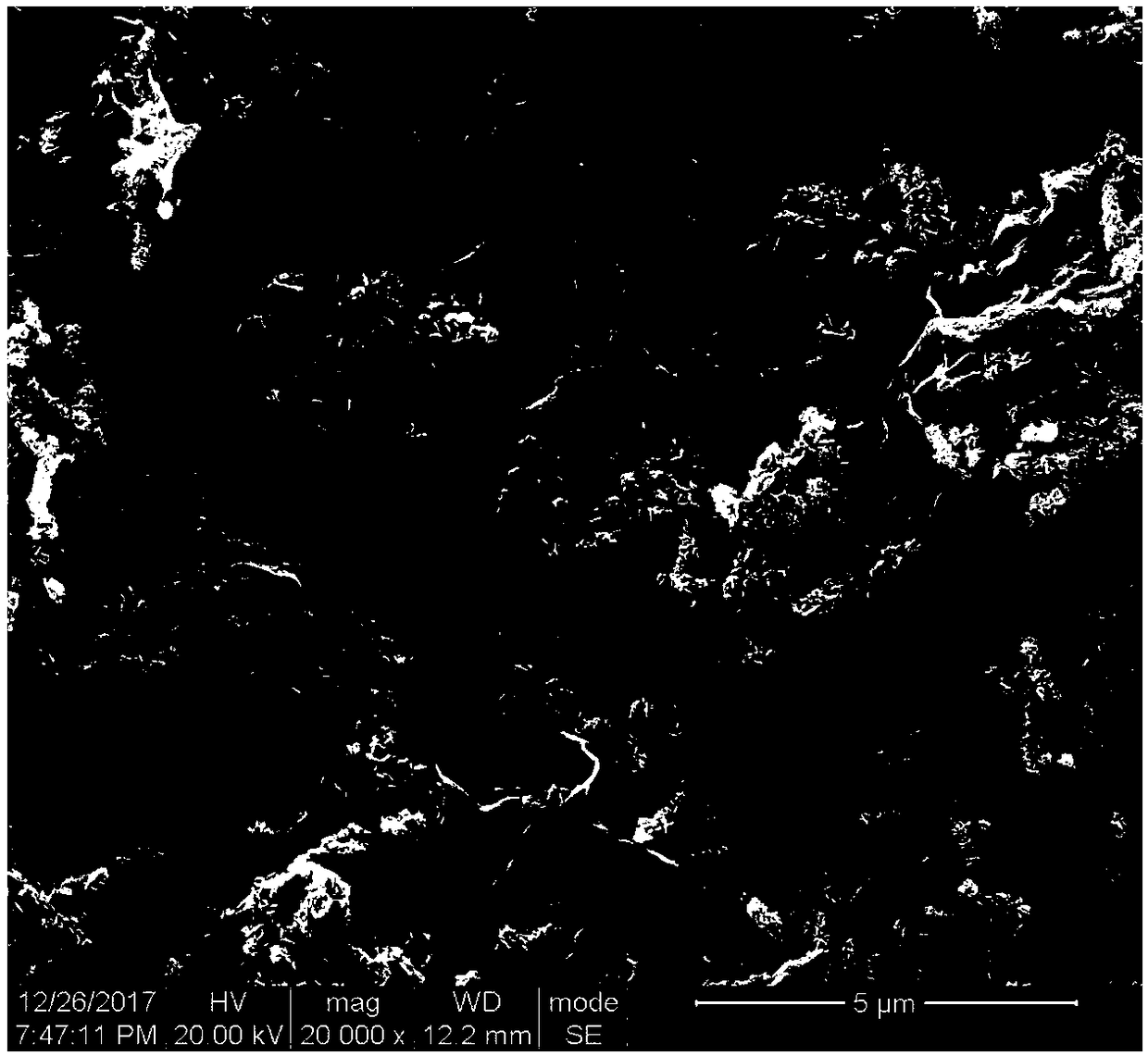

Composite material for in-situ growth of ternary cobalt nickel molybdenum oxide on graphene and two-step synthesis method thereof

ActiveCN108428562ALarge specific surface areaAvoid failureHybrid capacitor electrodesCapacitanceSynthesis methods

The invention provides a composite material for in-situ growth of ternary cobalt nickel molybdenum oxide on graphene and a two-step synthesis method thereof, and relates to the field of graphene and metal oxide composite materials. The composite material adopts the graphene as a substrate, and cobalt oxide nanorods of a rod-like structure are in-situ grown and combined on the graphene substrate; nickel molybdenum oxide nanorods of a rod-like structure are in-situ grown and combined on the cobalt oxide nanorods. According to the composite material, the extremely thin graphene increases the specific surface area of the material, and the utilization ratio of an active material is improved; cobalt oxide materials are connected together through the graphene, so that the materials are in whole conduction, and the material failure caused by weak electric conductivity is avoided; a layered structure avoids the agglomeration phenomenon of the material, a three-dimensional loose porous morphology is formed, the specific surface area of the material is further increased, and the material capacitance is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing carbon-loading noble metal catalyst by solvothermal method

InactiveCN109433195AGood dispersionInhibit aggregate growthMetal/metal-oxides/metal-hydroxide catalystsActivated carbonWater soluble

The invention discloses a method for preparing a carbon-loading noble metal catalyst by a solvothermal method. The method comprises the following steps: I, pre-treating activated carbon; II, uniformlydispersing a water soluble noble metal compound and the pre-treated activated carbon in a solvent to obtain mixed slurry; III, putting the mixed slurry in a closed pressure container, and keeping thetemperature for 2-24 hours at 140-240 DEG C; and IV, naturally cooling the insulated closed pressure container to filter a product in the closed pressure container, and washing the filtered intercepted objects with deionized water to obtain the carbon-loading noble metal catalyst. The carbon-loading noble metal catalyst which is high in dispersibility is prepared by means of the solvothermal method. A novel concept is provided for preparing the carbon-loading noble metal catalyst. By taking ethylene glycol and water or formamide and water as a solvent, a series of carbon-loading noble metal catalysts which are high in dispersibility are prepared by means of high-temperature reducibility of ethylene glycol and formamide and the complexing ability with noble metals.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

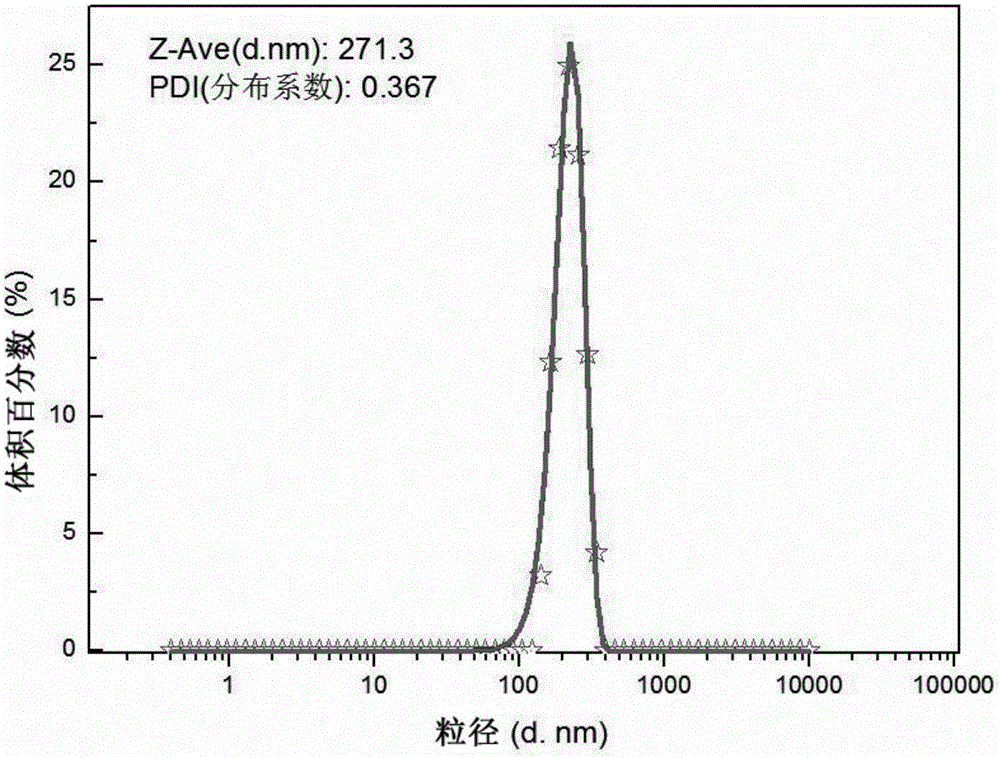

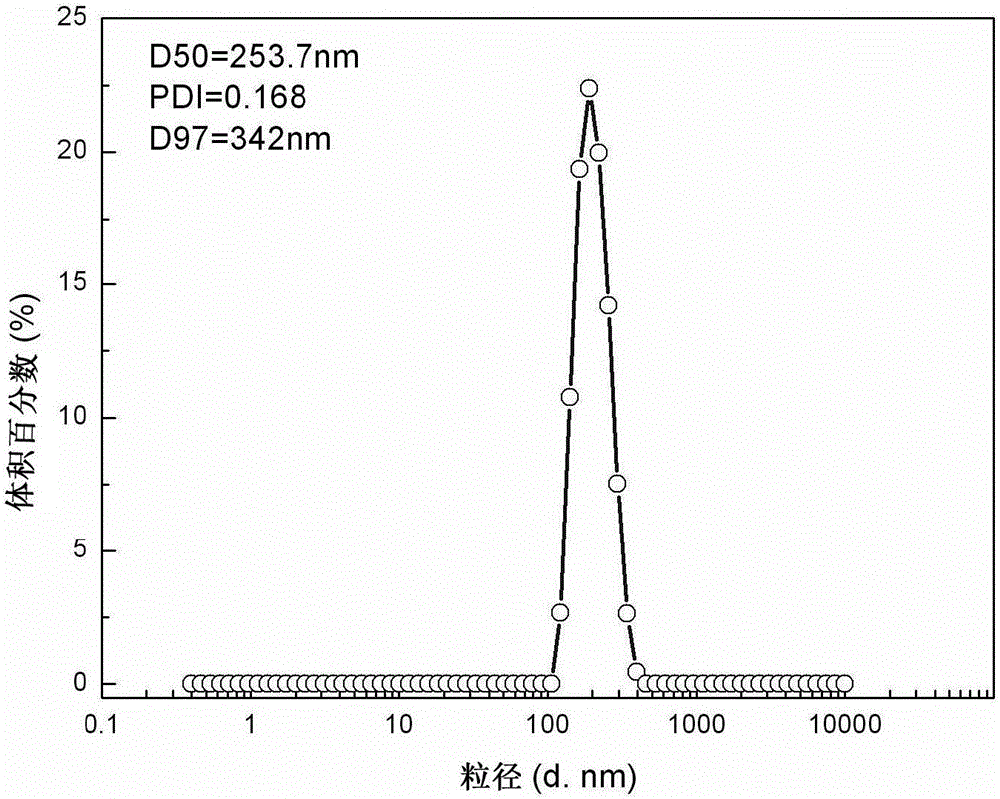

Device system and preparation technology for preparing submicron material through continuous hydrothermal method

ActiveCN104986796AAchieve growthHigh crystallinitySolution crystallizationTitanium dioxideProcess engineeringSlurry

The invention provides a device system and preparation technology for preparing a submicron material through a continuous hydrothermal method. The device system comprises burdening kettles, a preheater, a first crystallizer and a second crystallizer. The first burdening kettle is communicated with the first crystallizer through a first feeding pump and the preheater, and the second burdening kettle is communicated with the first crystallizer through a second feeding pump. The first crystallizer is communicated with the second crystallizer, a discharging opening of the second crystallizer is communicated with an inlet of a heat exchanger, one outlet of the heat exchanger is communicated with an outer circulating unit and then communicated with an inlet of the second crystallizer, and the other outlet of the heat exchanger is communicated with an aftertreatment unit and a slurry collector. The first crystallizer is a tubular reaction crystallizer, and the second crystallizer is a continuous crystallizer. The device system is adopted in the preparation technology. According to the device system and preparation technology, the device cost is low, meanwhile, the submicron material with even particle size distribution and the high degree of crystallinity can be prepared continuously, and the device system and preparation technology are suitable for industrial production.

Owner:ZHANGJIAGANG HEZHI NANO TECH CO LTD

Core-shell catalyst as well as preparation method and application thereof

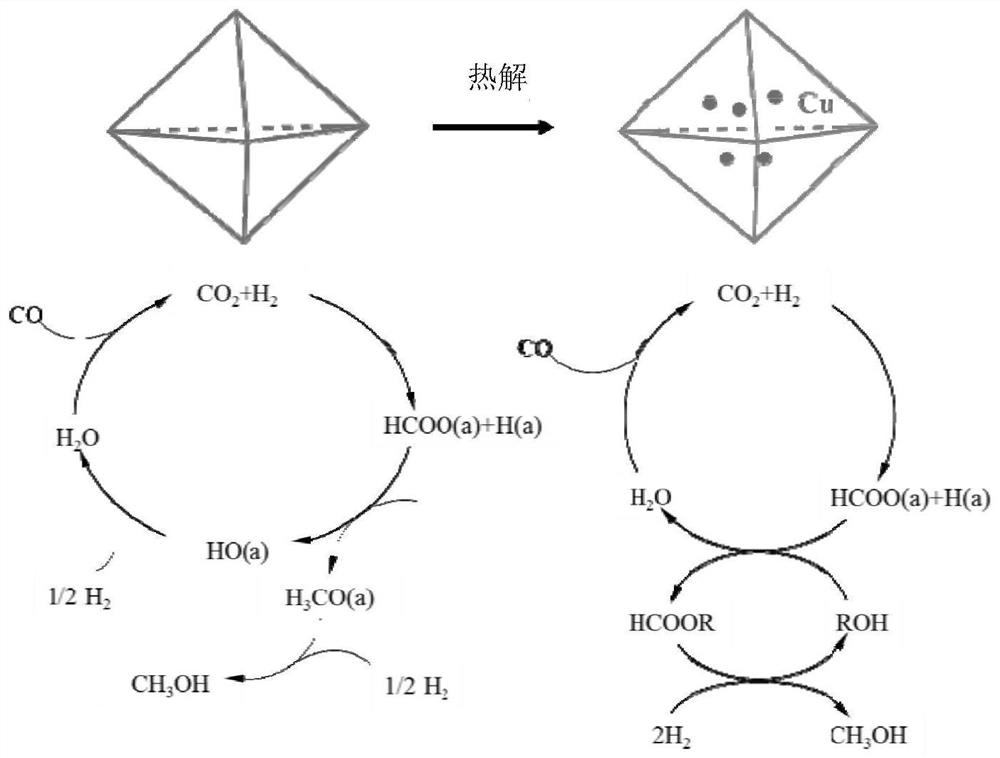

PendingCN113351251AGood dispersionLarge specific surface areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystNanotechnology

The invention discloses a core-shell catalyst. The core-shell catalyst comprises MOFs, an active component and an auxiliary agent, wherein the active component and the auxiliary agent coats pore channels and cavities of the MOFs; the active component comprises a Cu element; the auxiliary agent component comprises at least one of a Zn element and a Cr element. The invention also discloses a preparation method and application of the core-shell catalyst. The core-shell catalyst provided by the invention has the characteristics of high dispersity and high specific surface area, is used for CO / CO2 / H2 low-temperature methanol synthesis reaction, and has the advantages of high CO conversion rate, high methanol selectivity, long catalyst life, mild reaction conditions and the like.

Owner:石河子市中易连疆新能源有限责任公司 +2

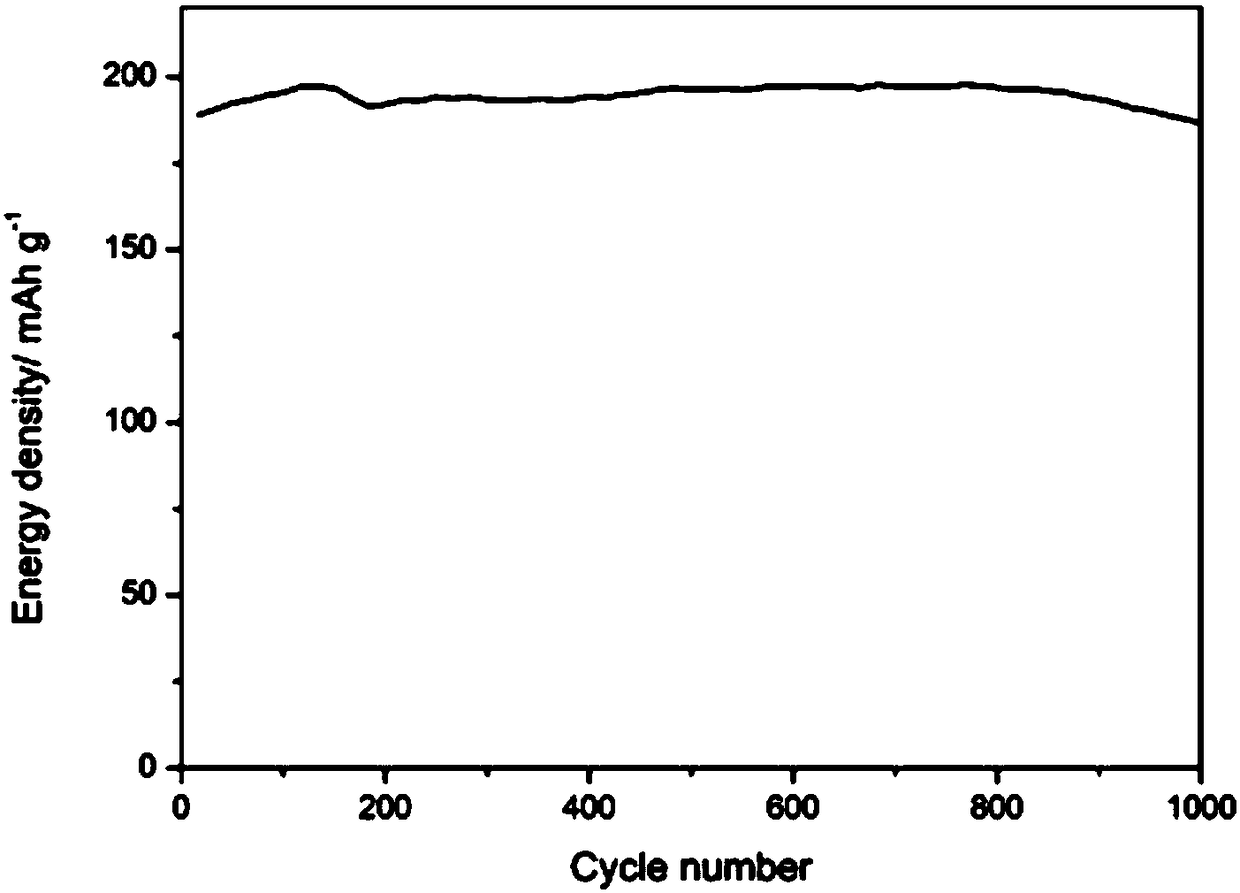

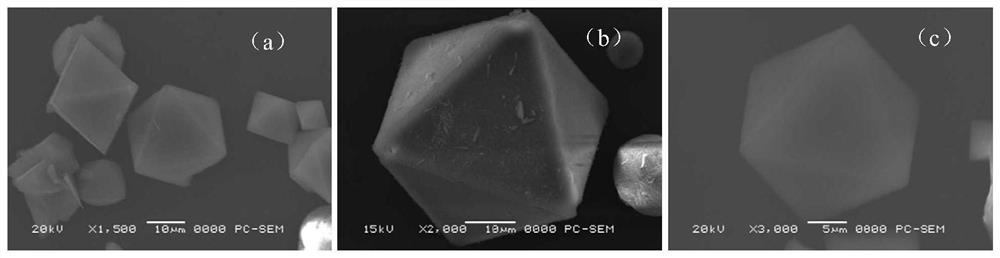

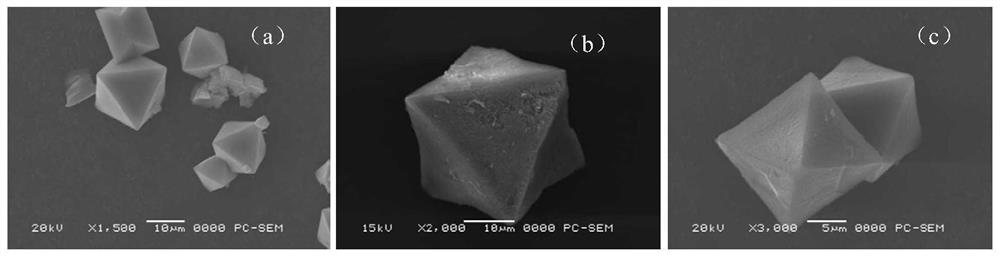

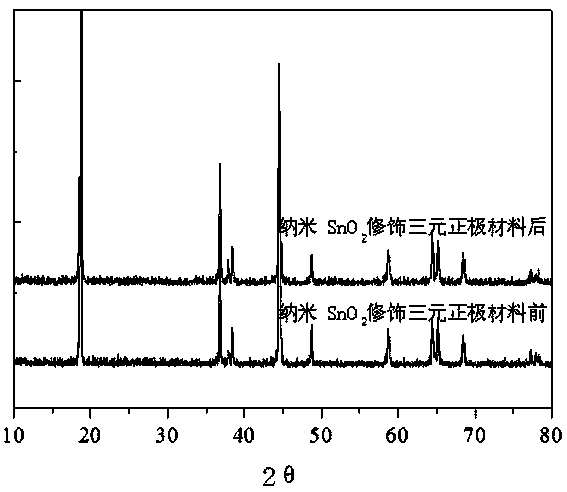

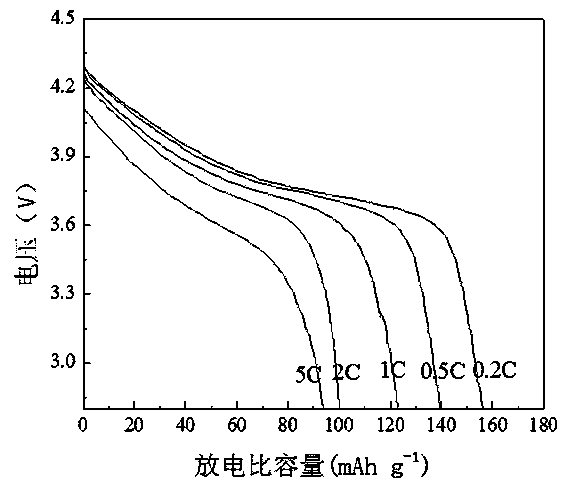

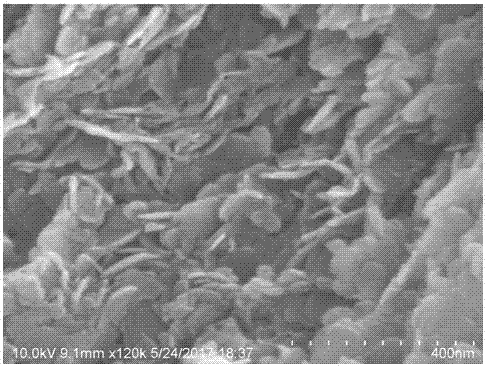

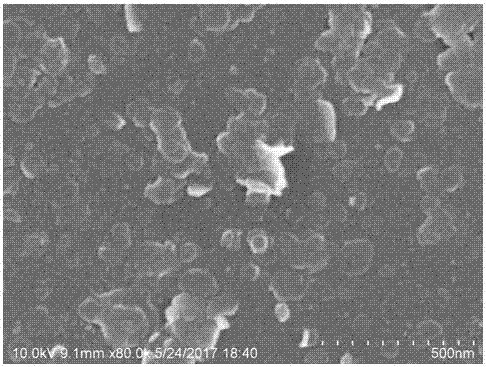

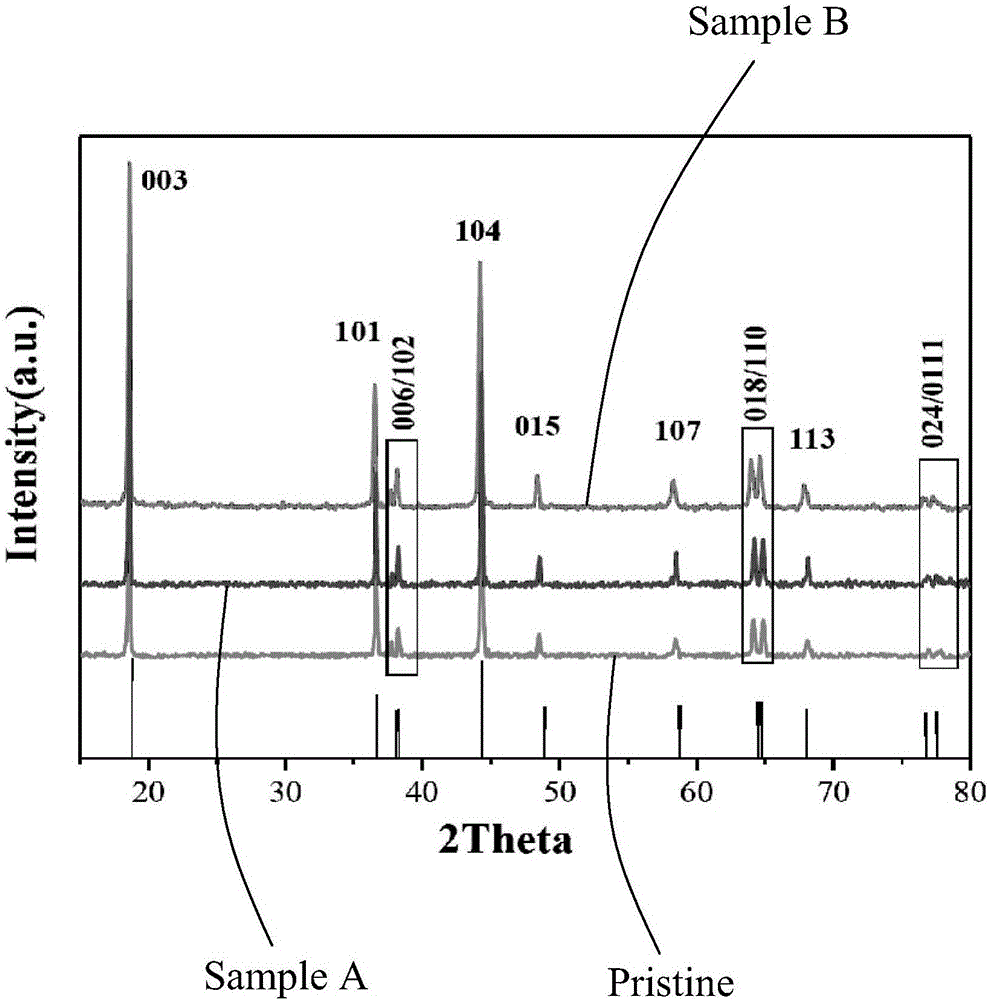

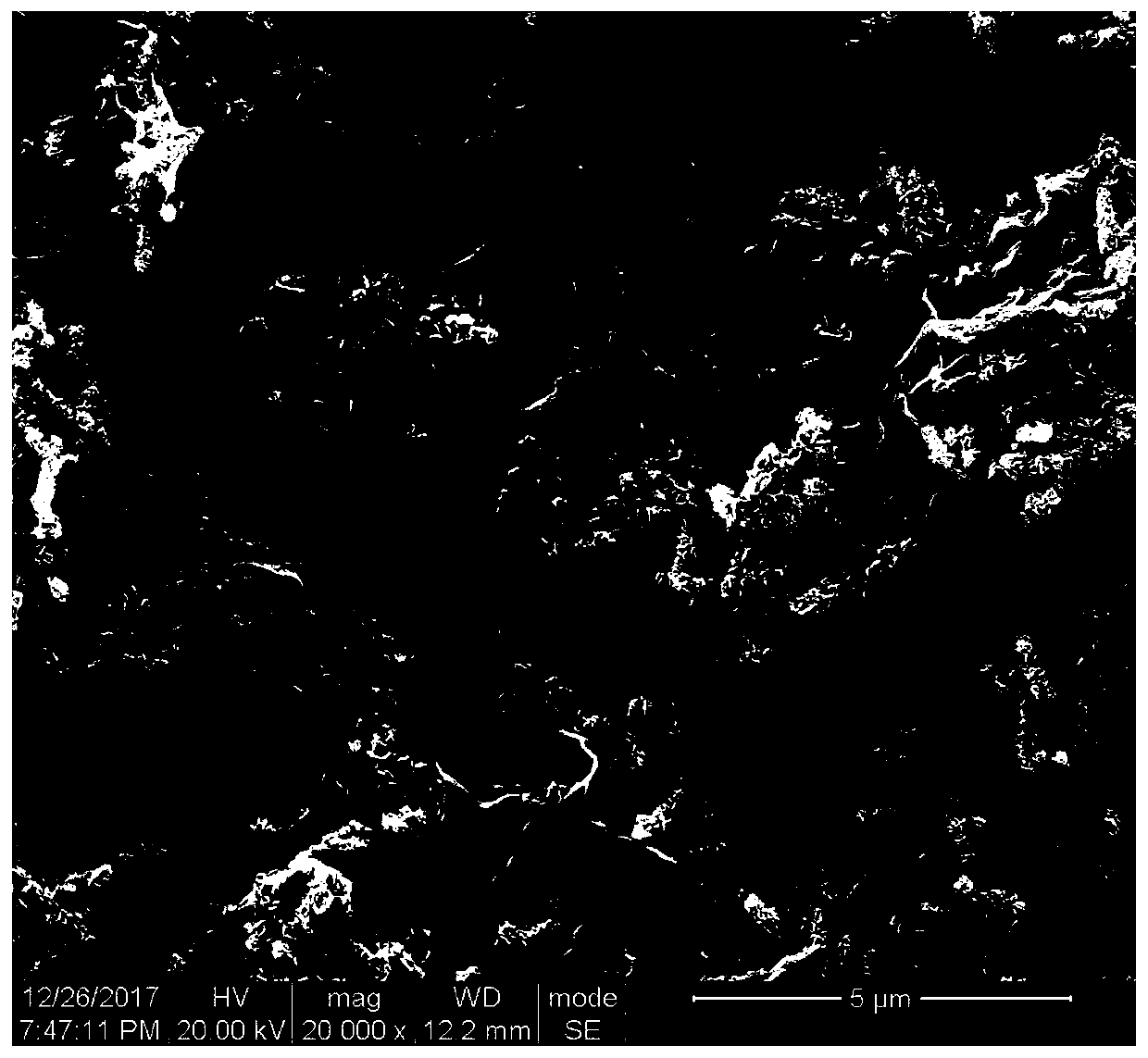

Lithium ion battery ternary cathode material modified by nanometer SnO2 and preparation method of lithium ion battery ternary cathode material

InactiveCN103441249AInhibit aggregate growthControl contentMaterial nanotechnologyCell electrodesParticle growthRepeatability

The invention discloses a lithium ion battery ternary cathode material modified by nanometer SnO2 and a preparation method of the lithium ion battery ternary cathode material. The chemical formula of the ternary cathode material is LiaNixCoyMnzO2, wherein a is not less than 0.9 and not greater than 1.2, and (x+y+z) is equal to 1; the particle dimension of the nanometer SiO2 is 5nm-100nm; the mass ratio of the nanometer SnO2 to the ternary cathode material is 0.01-0.08; nanocarbon is selected as a carrier for separately carrying out a particle growth process and a modification process of the nanometer SnO2. The preparation method disclosed by the invention can be used for precisely controlling the content of a modifier, and improving the material repeatability and consistence; moreover, the prepared lithium ion battery ternary cathode material modified by nanometer SnO2 has higher capacity, rate performance and cycle performance.

Owner:FUZHOU UNIV

Regulating method of nano layered MgFe hydrotalcite grain growth process

InactiveCN107879377ALarge specific surface areaInhibit aggregate growthNanotechnologyIron compoundsHydrotalciteHydrothermal synthesis

The invention relates to a regulating method of a nano layered MgFe hydrotalcite grain growth process. The regulating method of the nano layered MgFe hydrotalcite grain growth process comprises the steps as follows: (1) an Mg(NO3)2 solution and a Fe(NO3)3 solution are prepared and uniformly mixed, so that the molar ratio of Mg to Fe in the solution is (1:10)-(10:1); (2) a NaOH precipitant is dropwise added to the prepared solution in step (1), and the solution is continuously stirred, so that the pH of the solution is 8-12; (3) crystallization is performed at 40-220 DEG C for 0.5-6 h, crystallization is continuously performed at 70-120 DEG C for 12-36 h, the addition quantity of organic steric hindrance agents in a hydrothermal synthesis system is 0.1%-20.0% of the total mass of the solution, a solid product is obtained through separation after the reaction, washed and separated, the obtained solid product is dried, and nano layered MgFe hydrotalcite can be obtained. The nano MgFe hydrotalcite with the narrower crystal size distribution range can be prepared.

Owner:NORTHEAST GASOLINEEUM UNIV

Heat treatment process of low-alloying Al-Mg-Si alloy

ActiveCN108866463AMatch mechanicsMatch electrical propertiesIncreasing energy efficiencyThree levelManufacturing technology

The invention belongs to the technical field of nonferrous metal material manufacturing, and particularly relates to a heat treatment process of a low-alloying Al-Mg-Si alloy. The process is aimed atthe phenomenon that the low-alloying Al-Mg-Si alloy is used for extruding a product, the special heat treatment systems of high-temperature extrusion, three-level online quenching cooling and dual-stage aging high firstly and low at the later period are adopted, and the alloy obtains mechanical property and electrical property good matching. The heat treatment process is adopted, the low-alloyingAl-Mg-Si alloy can obtain the property matching with the tensile strength being 150 MPa, the elongation being 14%, and the specific conductance being 59% IACS or above, or the tensile strength being 180 MPa, the elongation being 12%, and the specific conductance being 57% IACS or above, and through the process, the application of the Al-Mg-Si alloy to the power industry is effectively promoted.

Owner:福建祥鑫股份有限公司

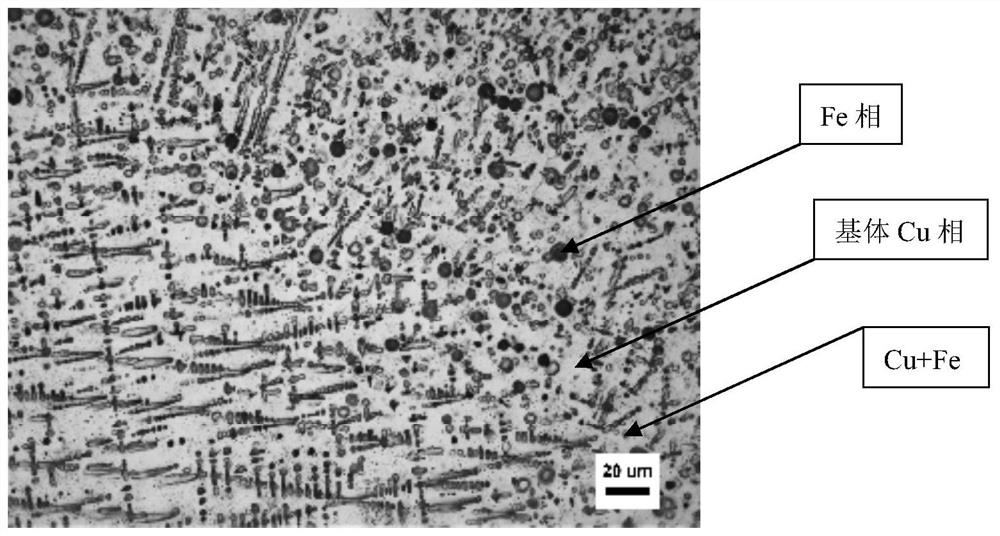

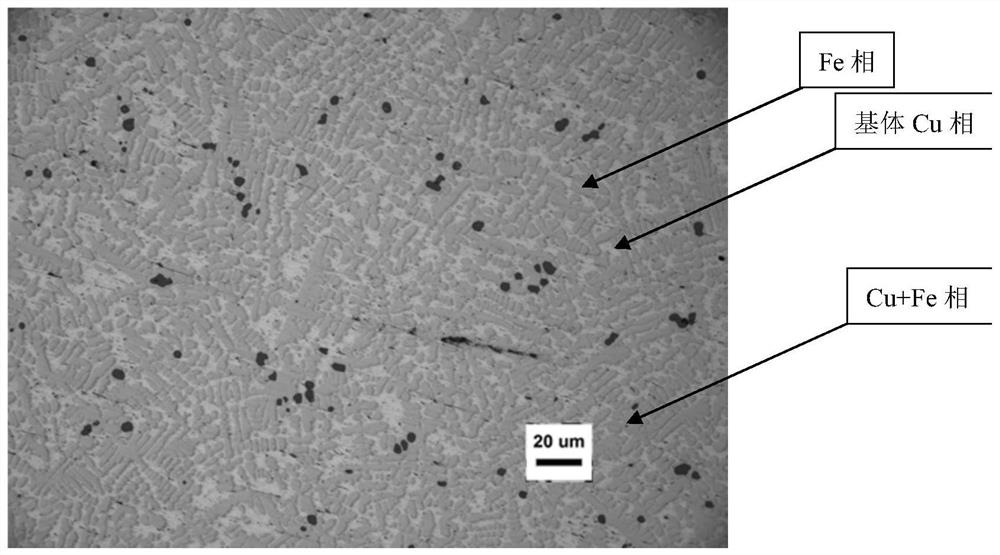

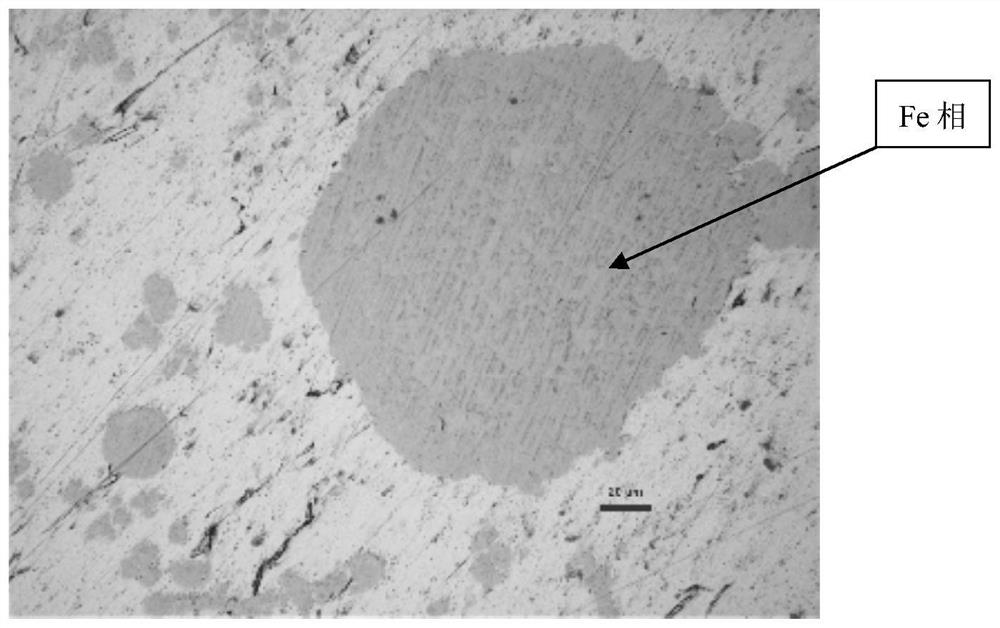

Copper-iron alloy modifier as well as preparation method and use method thereof

ActiveCN113481394AImprove refinementGood spherical effectProcess efficiency improvementIron powderAlloy

The invention discloses a copper-iron alloy modifier which is characterized by comprising a modifier A which comprises, in percentage by mass, 15-25wt% of one or more of copper powder, iron powder and yttrium powder, and the balance copper-calcium alloy powder and inevitable impurities; the content of calcium in the copper-calcium alloy powder is 50wt% or above; and the copper-iron alloy modifier further comprises a modifier B which comprises, in percentage by mass: 10-30wt% of Cu, 20-30wt% of one or more of Te, Mg, Ca, Si and La, and the balance of Fe and inevitable impurities. The modifier B and the modifier A can mutually promote the refinement and spheroidization of crystal grains, a copper-iron alloy phase structure with evenly distributed iron phases can be obtained, the copper-iron alloy with Fe smaller than or equal to 90 wt% can be prepared, ultra-fine wires can be conveniently machined, and the problem of iron phase breaking is solved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Production process method for reducing carbide mesh grade of GCr15 bearing steel bar

The invention discloses a production process method for reducing the carbide mesh grade of a GCr15 bearing steel bar, and relates to the field of metallurgical special steel production and manufacturing. According to the production process method for reducing the carbide mesh grade of the GCr15 bearing steel bar, in the produced bearing steel bar, the content range of C, Cr, Nb and Re meets the following formula: 1.7 < = 7.88 (% C) + 0.75 (% Nb) + 1.48 (% Re)-4.25 (% C) (% Cr) < = 1.8, and secondary cementite is promoted to be separated out to be finer, more dispersed and more uniform through the compounding and coordinating effect of all the elements; through component design, low-temperature rolling and rapid cooling after rolling, precipitation and aggregation growth of secondary carbides on a grain boundary are inhibited, so that the carbide mesh grade of the GCr15 bearing steel bar is controlled to be smaller than or equal to 1.0 grade, and the method is suitable for producing the bearing steel bar with the specification of phi 16-40 mm.

Owner:MAANSHAN IRON & STEEL CO LTD

Nano hierarchical pore BEA structure molecular sieve catalyst and preparation method and application thereof

PendingCN113694961ALarge specific surface areaShort channel lengthMolecular sieve catalystsMolecular sieve catalystPtru catalystPolyamide

The invention discloses a nano hierarchical pore BEA structure molecular sieve catalyst as well as a preparation method and application thereof, and relates to the technical field of a catalyst for a process of preparing ethylbenzene by alkylation. The preparation method specifically comprises the following steps: fully mixing a silicon source, an aluminum source, an inorganic alkali source, a template agent, a co-auxiliary agent and deionized water, slowly evaporating excessive water in an aging process to obtain concentrated sol, and performing low-temperature-high-temperature two-stage hydrothermal crystallization to obtain the molecular sieve catalyst. The used co-auxiliary agent is a binary co-auxiliary agent consisting of a water-soluble polyamide and a water-soluble small organic molecule containing amino and carboxyl. The molecular sieve catalyst disclosed by the invention has a BEA framework topological structure, a grain size of 50-200nm, a micropore-mesopore hierarchical pore channel and a core-shell structure, has a relatively high mesopore volume ratio, and shows excellent selectivity and catalytic stability in industrial production of ethylbenzene by liquid phase alkylation of benzene and ethylene.

Owner:JILIN INST OF CHEM TECH +1

Method for preparing lithium-rich positive electrode material through adjustable low temperature combustion method

InactiveCN108832085AImprove solubilityWell mixedCell electrodesSecondary cellsManganeseMolecular level

The invention belongs to the technical field of the preparation of positive materials for lithium-ion batteries, and specifically provides a method for preparing a lithium-rich positive electrode material 2x / 3Li2MnO3*(1-x)LiMO2 through an adjustable low temperature combustion method, wherein x is greater than 0 and smaller than 1, and M is Ni, Co and Mn. The method comprises the following steps: dissolving an Ni-Co-Mn metal salt into a solvent according to a stoichiometric proportion, adding a certain amount of a reducing agent and a certain amount of an additive, stirring uniformly, dropwiseadding an appropriate amount of ammonia water to adjust PH so as to obtain a solution A; After heating and evaporating the solution A for a certain period of time, putting the solution A in a heatingfurnace so that the heating furnace is combusted at the temperature of 300 to 700 DEG C to obtain powder B, collecting and grinding the B, putting the powder B in a muffle furnace for combustion for 5to 24 h at the high temperature of 700 to 1100 DEG C, and carrying out ball-milling sieving after cooling to obtain the lithium-rich positive electrode material. The preparation method is simple andquick, various elements in the solution can be mixed in a molecular level, the ultrafine nanoscale material can be prepared, the energy consumption is low, the reaction can be adjusted through parameters, the synthesizing cost of the lithium-rich positive electrode material is greatly reduced, and the rate capability and cycle performance of the lithium-rich positive electrode material are also obviously improved.

Owner:SHANDONG UNIV OF TECH

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

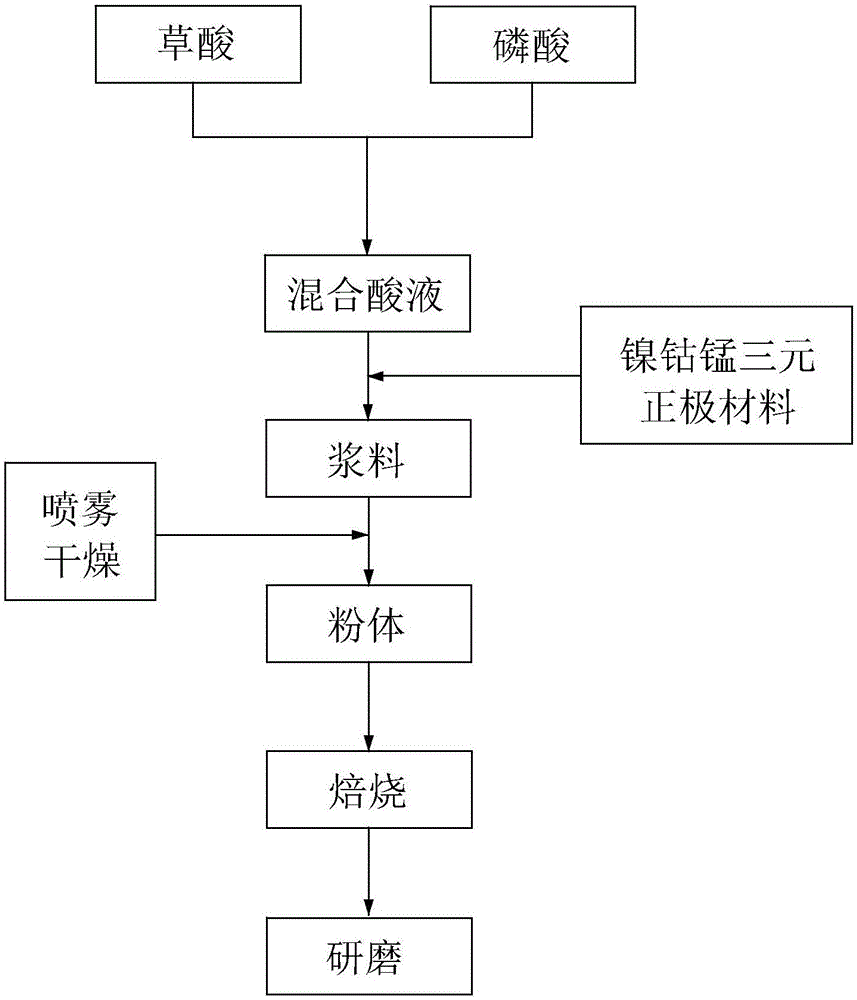

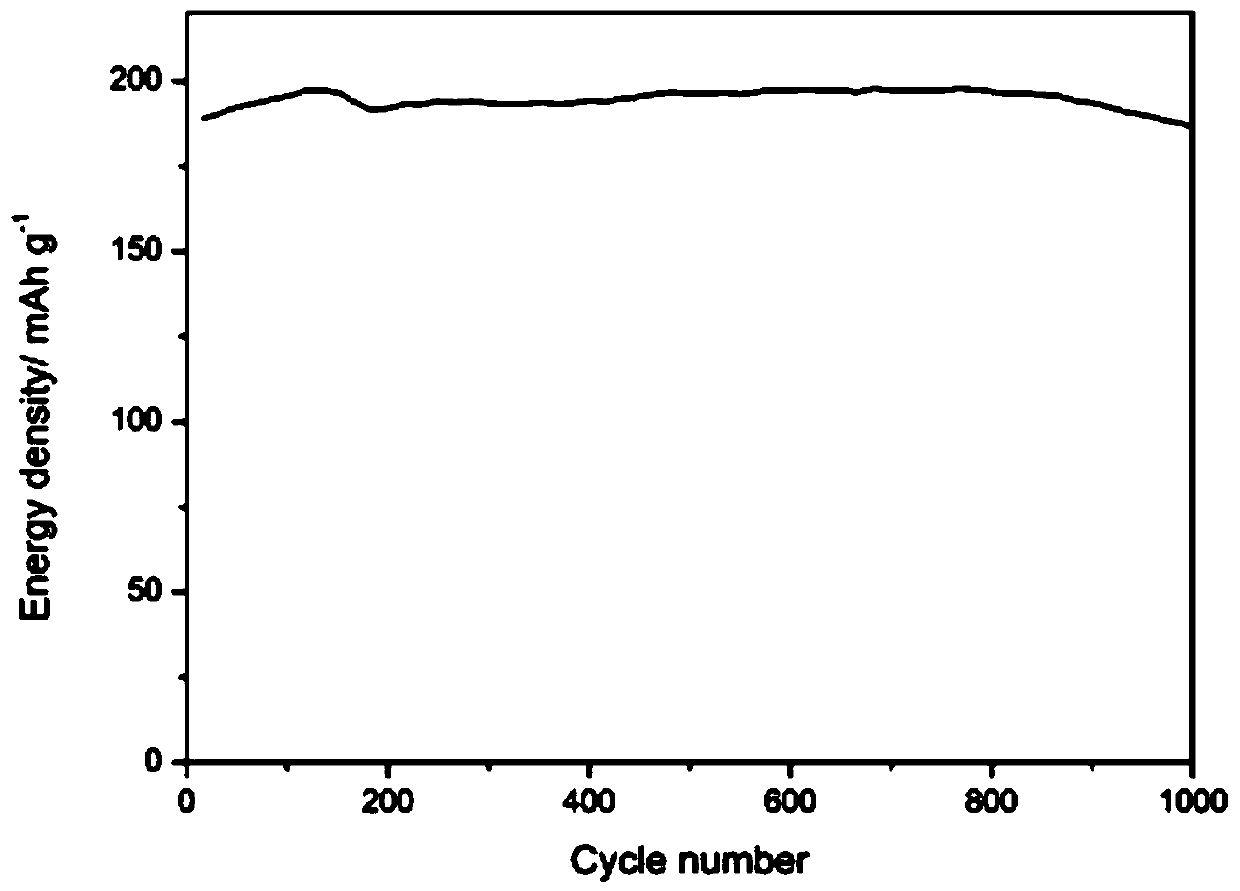

Preparation method of positive electrode material for lithium-ion battery

InactiveCN106654206AImprove conductivityFree from corrosionCell electrodesSecondary cellsPhosphoric acidManganese

The invention provides a preparation method of a positive electrode material for a lithium-ion battery. The method comprises the following steps of (1) preparing an oxalic acid solution of which the molar concentration is 0.3-0.9mol / L, and adding a certain amount of phosphoric acid to obtain a mixed acid liquid, wherein the molar ratio of an oxalic acid to the phosphoric acid in the mixed acid liquid is 1.5-90; (2) adding a certain amount of Ni-Co-Mn ternary positive electrode material to the mixed acid liquid obtained in the step (1), wherein the mass of the Ni-Co-Mn ternary positive electrode material is 5-30 times of that of the oxalic acid, and stirring at a room temperature to form slurry; (3) carrying out spray drying on the slurry obtained in the step (2) at an inlet speed of 150+ / -50 DEG C and the spray speed of 500-1000mL / h to obtain dry powder; and (4) putting the powder obtained in the step (3) in a muffle furnace, roasting the powder at 400-700 DEG C for 3-7 hours, naturally cooling and then carrying out grinding treatment.

Owner:OPTIMUM BATTERY CO LTD

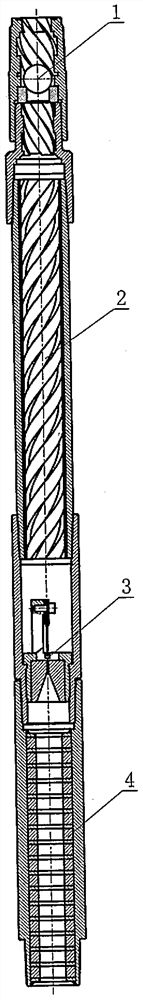

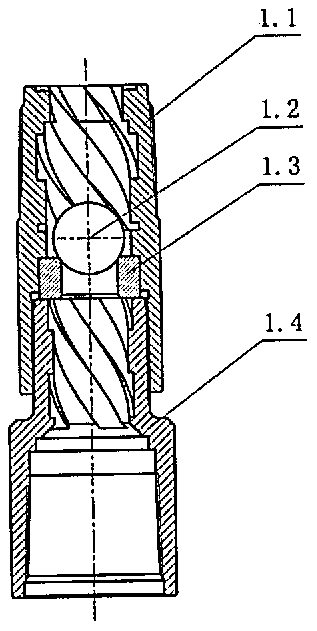

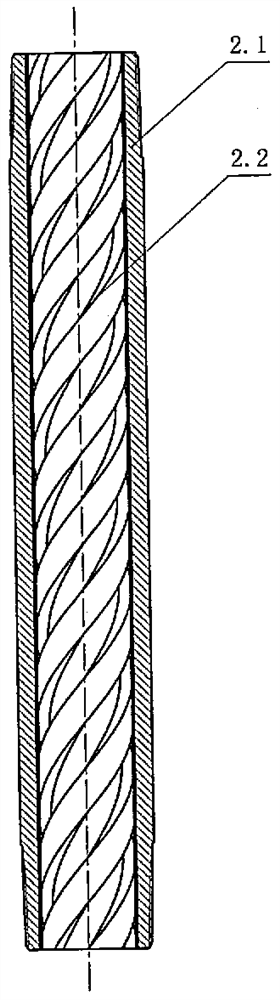

Super-strong viscosity-reducing paraffin control device

InactiveCN112211583AChange direction of motionAvoid depositionCleaning apparatusVibration devicesEngineeringSound wave

The invention discloses a super-strong viscosity-reducing paraffin control device. The device comprises a vortex generator, a special alloy coating pipe, a Palman sound wave generator, and a strong magnetic device. According to the super-strong viscosity-reducing paraffin control device, by means of the mechanical structure of the device, external power is not needed, and the formation of paraffincrystals of crude oil is prevented or reduced under the action of strong magnetism, oscillation sound waves and high-speed swirling, so that the viscosity of crude oil is reduced, paraffin depositionis prevented, the paraffin deposition period is prolonged, and the hot washing paraffin removal frequency is reduced.

Owner:陕西鼎和源瑞环境工程有限公司

Supported gold-PGM alloy catalyst with stable storage property and preparation method thereof

InactiveCN101698149BHigh activityInhibit migrationCatalyst carriersDispersed particle separationAmbient humidityActive component

The invention relates to a supported gold-PGM alloy catalyst with stable storage property and a preparation method thereof. An active component is Au, an accessory ingredient is Pd or Pt in PGM, and a carrier is a Al2O3 composite oxide modified by Al2O3 or MIOx and MIIOx, wherein the atomic ratio of Au to PGM is 1.0:1.0-1.0:1.0*10-2; the atomic ratio of Au to MI+MII is 1.0:1.0-1.0:10; the atomic ratio of MI to MII is 2.0:1.0-0.2:1.0; the atomic ratio of Au to Al is 1.0:1.0*103-1:0:10; MI is La; and MII is Fe, Co or Ni. The composite oxide carrier is prepared by an impregnation method or a coprecipitation method. After being supported with MIOx and MIIOx, Al2O3 is roasted at a temperature of between 800 and 1,000 DEG C to generate a spinelle or perovskite structure. The catalyst of the invention catalytically oxidizes micro CO (0.1 percent to 1.5 percent) in the air into CO2 at ambient temperature and in ambient humidity, and has the advantages of stable catalysis property, pressure drop meeting the requirements of a gas mask and a mining self-rescuer and low cost.

Owner:安立敦

A composite of ternary cobalt-nickel-molybdenum oxide grown in situ on graphene and its two-step synthesis method

ActiveCN108428562BLarge specific surface areaAvoid failureHybrid capacitor electrodesCapacitanceSynthesis methods

The invention provides a composite material of in-situ growth of ternary cobalt-nickel-molybdenum oxide on graphene and a two-step synthesis method thereof, and relates to the field of composite materials of graphene and metal oxides, and the composite material uses graphene as a substrate The cobalt oxide nanorods combined with the rod-like structure are grown in situ on the graphene substrate; the nickel-molybdenum oxide nanorods combined with the rod-like structure are grown in situ on the cobalt oxide nanorods. In the composite material provided by the present invention, the extremely thin graphene increases the specific surface area of the material and increases the utilization rate of the active material; the graphene connects the cobalt oxide materials together to make the material conduct as a whole, avoiding the problem caused by the electrical conductivity. The failure of the material caused by weakness; the well-defined structure avoids the agglomeration of the material, forms a three-dimensional loose and porous morphology, further increases the specific surface area of the material, and improves the capacitance of the material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Loofah complex oil absorb material

ActiveCN109847709AImprove pore structureImprove breathabilityOther chemical processesDispersed particle separationEngineeringPetroleum engineering

The invention relates to a loofah complex oil absorb material. The preparation process is free from harmful and toxic pollutant and has the advantages of simple operation and high efficiency. Loofah is combined with grapheme, so as to obtain the complex oil absorb material with large pore structure and good air permeability, and can be reused for many times. The loofah complex oil absorb materialprepared by the invention has high oil absorbing property and reuse effect, and can be applied to marine oil pollution treatment and oil fume exhaust gas purification.

Owner:ZHEJIANG UNIV OF TECH +1

Silicon-aluminum bicontinuous composite material and preparation method thereof

The invention relates to a bicontinuous composite material which has excellent comprehensive properties due to the special interpenetrating network structure. Aiming at the silicon aluminum material having wide application prospects, the invention implements a silicon-aluminum bicontinuous composite material and a powder metallurgy preparation technique thereof. The technique overcomes the defects of overgrowth of silicon, and material nonuniformity and noncompactness in the casting method and liquid phase impregnation method, and prepares the bicontinuous composite material with controllable composition, phase dimensions and microstructure. The invention implements uniform mixing of the two phases silicon and aluminum by selecting reasonable composition and powder size; and the alloy elements of the aluminum alloy are added by an element powder direct mixing method. The billet is completely compacted within a proper temperature range; and silicon atoms are diffused, so that the silicon powder particles are connected with each other and interpenetrate with the aluminum alloy to form the bicontinuous composite material. The silicon content in the composite material is 40-80 vol.%; and the composite material is completely compact and has a uniform structure. The composite material has excellent comprehensive properties, and is applicable to various conventional machining means.

Owner:有研金属复材技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com