Solid solution catalyst for acetic acid self-heating hydrogen production by reforming and preparation method

An autothermal reforming and catalyst technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve problems such as catalyst deactivation, and achieve higher ratio Surface area, enhanced activity and stability, inhibition of formation and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

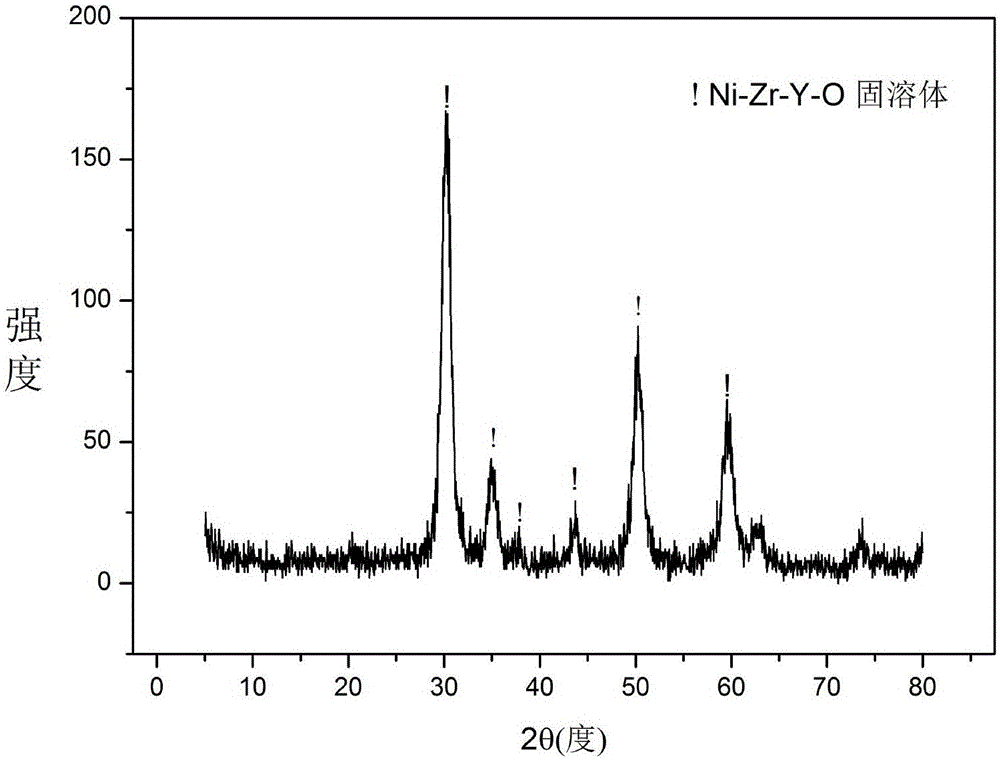

Embodiment 1

[0028] Weigh 1.0000g of P123, add it to 20ml of absolute ethanol, cover with plastic wrap, and stir magnetically at room temperature for 1h to obtain solution #1. Weigh 0.4362g of Ni(NO 3 ) 2 ·6H 2 O, 2.0045g of ZrO(NO 3 ) 2 2H 2 O and 0.3830g of Y (NO 3 ) 3 ·6H 2 O, join solution #1, continue to stir at room temperature for 5h, follow-up steps are the same as reference example 1, obtain the figure 1 Catalyst CUT-NZY10 with the solid solution structure shown. The weight percent composition of the catalyst is as follows: 9.7% of nickel oxide, 80.5% of zirconia, and 9.8% of yttrium oxide.

[0029] The catalyst CUT-NZY10 was investigated by the autothermal reforming activity of acetic acid. The reaction conditions were normal pressure, space velocity 30000mL / (g-catalyst.h), reaction temperature 700°C, raw material gas acetic acid / water / oxygen = 1 / 4.0 / 0.28 , the acetic acid conversion rate of the catalyst was stable at 100%, and the hydrogen production rate was initially...

Embodiment 2

[0031] Weigh 1.0000g of P123, add it to 20ml of absolute ethanol, cover with plastic wrap, and stir magnetically at room temperature for 1h to obtain solution #1. Weigh 0.4362g of Ni(NO 3 ) 2 ·6H 2 O, 1.7373g of ZrO(NO 3 ) 2 2H 2 O and 0.7661g of Y (NO 3 ) 3 ·6H 2 O, join solution #1, continue to stir at room temperature for 5h, follow-up steps are the same as reference example 1, obtain the figure 1 The catalyst CUT-NZY20 with the solid solution structure shown. The weight percent composition of the catalyst is as follows: 9.8% of nickel oxide, 70.4% of zirconium oxide and 19.8% of yttrium oxide.

[0032] The catalyst CUT-NZY20 was investigated by the autothermal reforming activity of acetic acid. The space velocity was 30000mL / (gcatalyst·h), the reaction temperature was 700℃, and the feed ratio was AC / H 2 O / O 2 / N 2 Under the condition of =1 / 4 / 0.28 / 4.2, the acetic acid conversion rate of this catalyst is 100%, and the productive rate of hydrogen is 3.05mol-H 2 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com