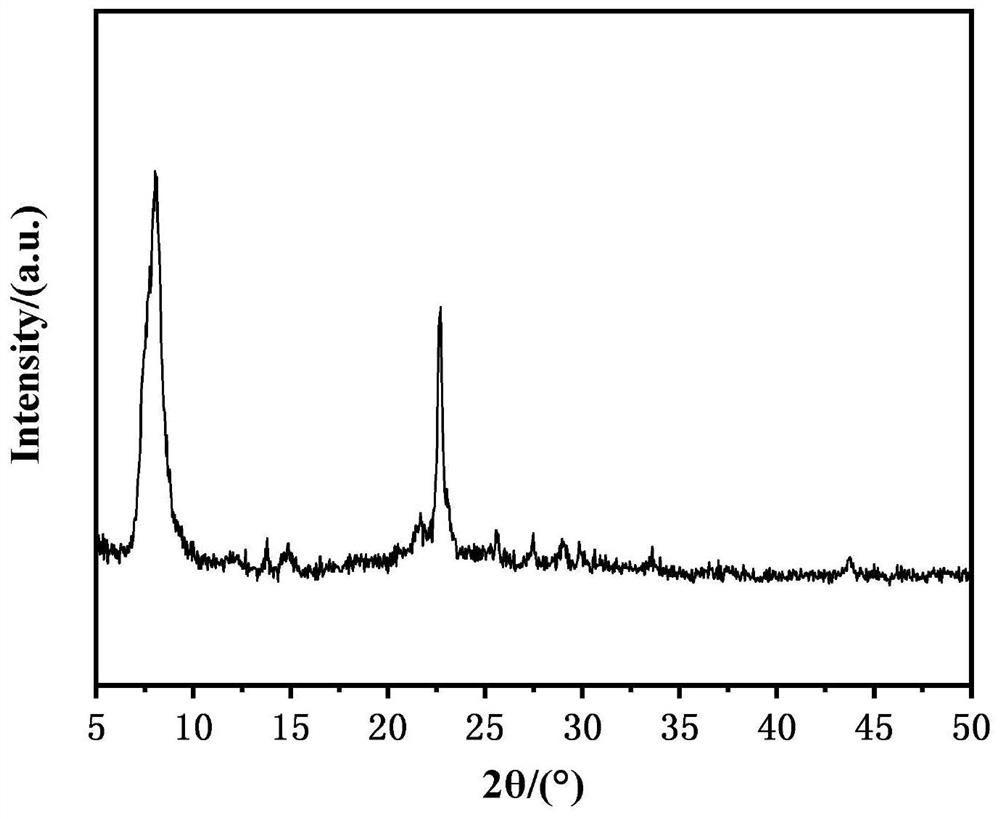

Nano hierarchical pore BEA structure molecular sieve catalyst and preparation method and application thereof

A molecular sieve, multi-level pore technology, applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali exchange compounds, etc., can solve the problems of short pore channel length, high mesopore pore volume, etc. Conducive to the effect of industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The embodiment of the present invention discloses a preparation method of a molecular sieve catalyst with a nanoscale hierarchical porous BEA structure, which specifically includes the following steps:

[0058] (1) Add aluminum source, organic template agent and alkali source to deionized water and stir to dissolve, then add silicon source drop by drop under stirring condition, and then continue to stir to obtain sol;

[0059] Among them, the silicon source is one or more mixtures of white carbon black, tetraethyl orthosilicate, and silica sol; the aluminum source is one of aluminum chloride, sodium metaaluminate, and aluminum nitrate; the alkali source is hydroxide Sodium; the organic template is one of tetraethylammonium hydroxide (TEAOH), tetraethylammonium bromide (TEABr), tetraethylammonium chloride (TEACl), tetraethylammonium iodide (TEAI) or A variety of mixtures, more preferably TEAOH; the mass ratio of aluminum source, organic template, alkali source and silico...

Embodiment 1

[0076] Embodiment 1 of the present invention discloses a preparation method of a molecular sieve catalyst with a nanoscale hierarchical porous BEA structure, which specifically includes the following steps:

[0077] (1) In a 250mL three-necked flask, 0.63g of NaAlO 2 Dissolve in 22.09g of TEAOH, and react for 1h at a stirring speed of 1000rpm to obtain a transparent aluminate solution, then add 10.5g of deionized water and 0.43g of NaOH, continue stirring for 0.5h, then add 17.56 g of TEOS, and the stirring speed is 1800rpm during the dropwise addition. After the dropwise addition, stir at room temperature at a rotation speed of 2400rpm for 2h, add 0.80g of polyvinylpyrrolidone, continue to stir for 1h, and finally put the above mixed solution in a water bath at 65°C Evaporate the excess water in the pot to make it reach H 2 O / SiO 2 The mass ratio of is 2.1, thus obtaining a concentrated sol.

[0078] (2) Then transfer the concentrated sol to a polytetrafluoroethylene-lined...

Embodiment 2

[0082] Embodiment 2 of the present invention discloses a preparation method of a molecular sieve catalyst with a nanoscale hierarchical porous BEA structure, which specifically includes the following steps:

[0083] (1) In a 250mL three-necked flask, 0.63g of NaAlO 2 Dissolve in 22.09g of TEAOH, and react for 1h at a stirring speed of 1000rpm to obtain a transparent aluminate solution, then add 10.5g of deionized water and 0.43g of NaOH, continue stirring for 0.5h, then add 17.56 g of TEOS, and the stirring speed is 1800rpm during the dropping process. After the dropping is completed, stir at room temperature at a rotating speed of 2400rpm for 2h, add 1.24g of lysine, and continue stirring for 1h. Finally, put the above mixed solution in a water bath at 65°C Evaporate the excess water in the pot to make it reach H 2 O / SiO 2 The mass ratio of is 2.1, thus obtaining a concentrated sol.

[0084] (2) Then transfer the concentrated sol to a polytetrafluoroethylene-lined stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com