W-Cu composite material with high Cu content and preparation method of W-Cu composite material

A composite material and content technology, applied in the field of nanomaterials, can solve the problems of composite powder, material uniformity and compactness, the difficulty of sintering process, and the difficulty of meeting the requirements of high-performance drug-type covers, etc., to achieve good heat conduction performance, reduction of pores and channels, reduction of distortion and effects of tissue inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

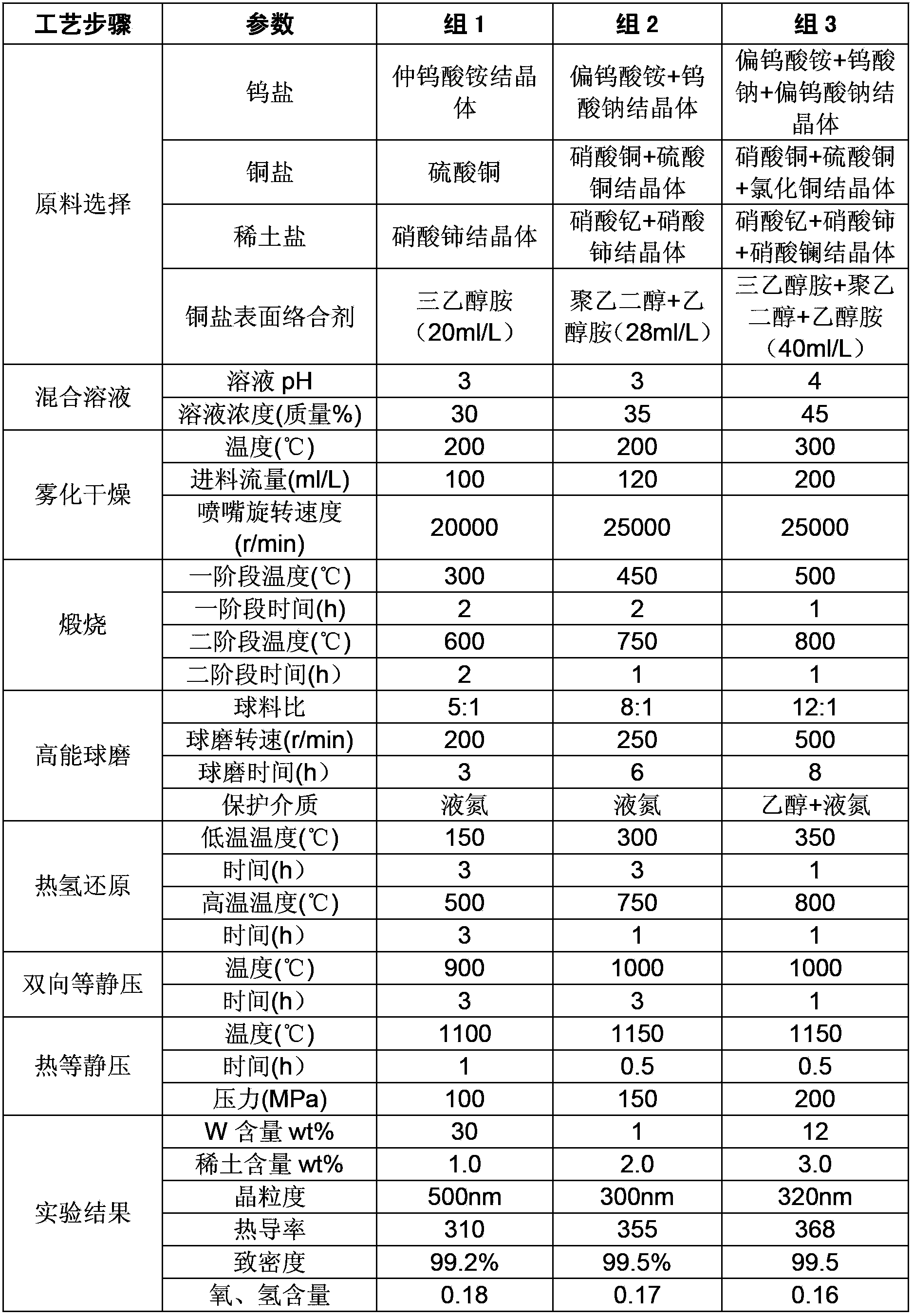

Examples

Embodiment 1

[0041] (1) The ultrafine / nanocrystalline W-70Cu composite powder is prepared by the two-step thermal hydrogen reduction method of mixed solution-atomization drying-calcination-high energy ball milling-(low temperature + high temperature); weigh 275g copper sulfate crystal (CuSO 4 ·5H 2 O), 43g ammonium metatungstate crystals {(NH4) 6 H 2 W 12 O 40 ·H 2 O}, 3g yttrium nitrate {Y(NO 3 ) 3 ·6H 2 O}, 3g polyethylene glycol, dissolved in 1200ml deionized water to prepare a solution with a concentration of 35%, and add a 25% nitric acid solution to adjust the pH of the above solution to 3, and let it stand for 20 minutes to obtain a stable Mixed salt solution; the mixed salt solution is atomized and dried, and the temperature is 250°C, the feed flow rate is 150ml / L, and the nozzle rotation speed is 22000r / min. Obtain the tungsten copper oxide mixed powder precursor, and then calcinate the powder precursor in the air. The calcining temperature is divided into two stages: low temperature...

Embodiment 2

[0044] (1) Prepare ultra-fine / nano W-80Cu composite powder by the two-step thermal hydrogen reduction method of mixed solution-atomization drying-calcination-high energy ball milling-(low temperature + high temperature); weigh 606g copper nitrate crystal {Cu(NO 3 ) 2 ·3H 2 O}, 54.8g ammonium metatungstate crystal {(NH4) 6 H 2 W 12 O 40 ·H 2 O}, 2g cerium nitrate {Ce(NO 3 ) 3 ·6H 2 O}, 3g of triethanolamine, dissolved in 1000ml of deionized water to prepare a solution with a concentration of 40%, add 25% nitric acid solution to adjust the pH of the above solution to 4, and stand for 30 minutes to obtain a stable mixed dissolved salt Solution: The dissolved salt solution is atomized and dried, the temperature is 280°C, the feed flow rate is 180ml / L, and the nozzle rotation speed is 23000r / min. The tungsten-copper oxide mixed powder precursor is obtained, and the powder precursor is calcined in the air. The calcining temperature is divided into two stages: low temperature 300℃+ high...

Embodiment 3

[0047] (1) The ultrafine / nano W-90Cu composite powder is prepared by the two-step thermal hydrogen reduction method of mixed solution-atomization drying-calcination-high energy ball milling-(low temperature + high temperature); weigh 241.6g of copper chloride crystal (CuCl 2 ·2H 2 O}, 14.5g ammonium metatungstate crystal {(NH4) 6 H 2 W 12 O 40 ·H 2 O}, 3g lanthanum nitrate {La(NO 3 ) 3 ·6H 2 O}, 6g of triethanolamine, dissolved in 1000ml of deionized water to prepare a solution with a concentration of 30%, add 25% nitric acid solution to adjust the pH of the above solution to 3, and stand for 30 minutes to obtain a stable mixed dissolved salt Solution: The dissolved salt solution is atomized and dried, the temperature is 220°C, the feed flow rate is 130ml / L, and the nozzle rotation speed is 21000r / min. The tungsten copper oxide mixed powder precursor is obtained, and the powder precursor is calcined in the air. The calcining temperature is divided into two stages of low temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com