Magnetic ZnFe2O4/graphene nanometer composite photocatalyst as well as preparation method and application thereof

A nanocomposite and photocatalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low utilization rate of visible light and non-recyclability, and achieve The effect of low equipment requirements and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

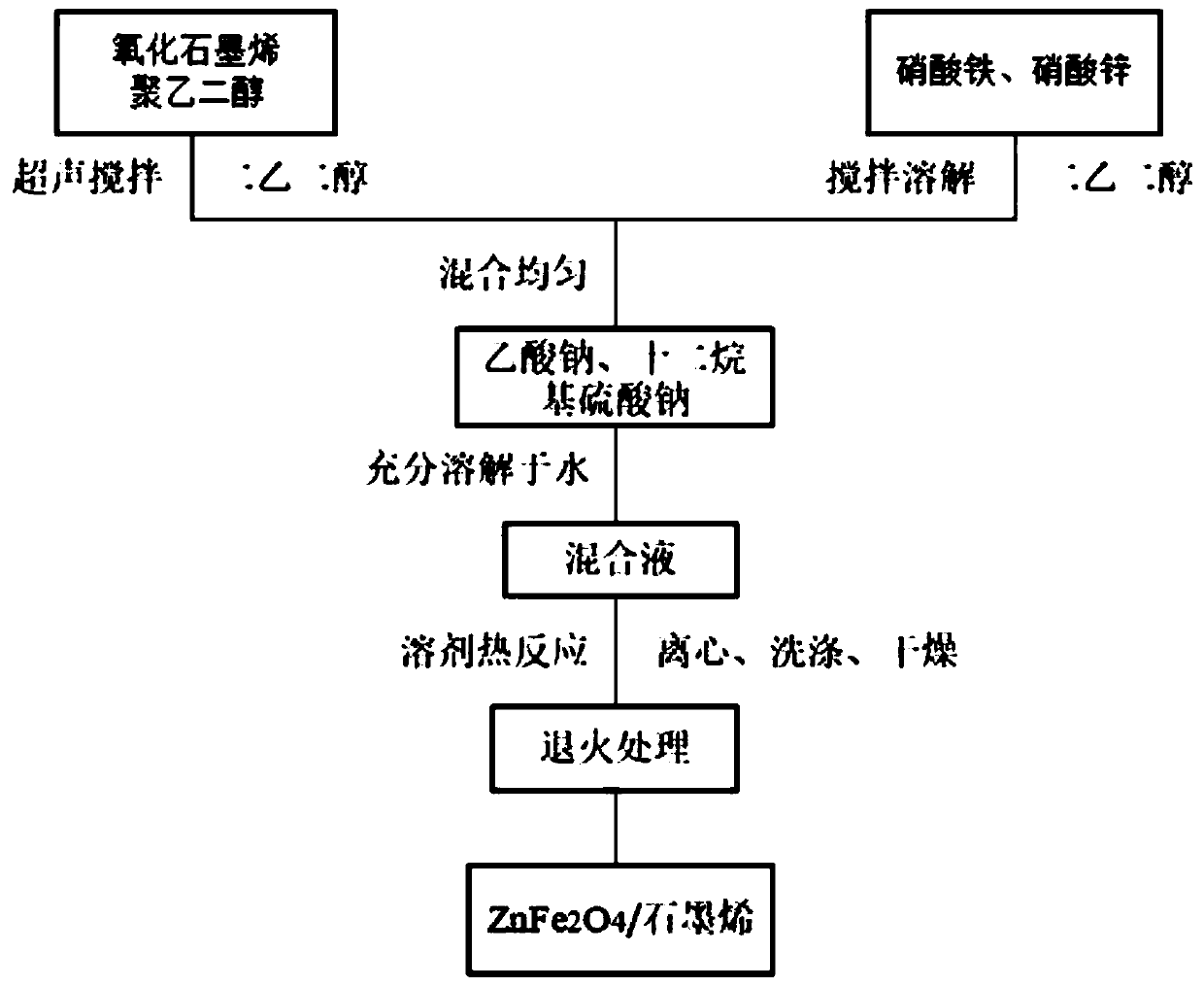

[0042] (1) Weigh 60 mg of graphene oxide and add it to 60 mL of diethylene glycol, and ultrasonically stir for 30 min to obtain a uniform dispersion;

[0043] (2) Add 2mL polyethylene glycol to the graphene oxide dispersion to obtain mixed solution A;

[0044] (3) Weigh 0.808gFe(NO 3 ) 3 and 0.297gZn(NO 3 ) 2 Dissolve in 20mL diethylene glycol, fully dissolve to obtain a uniform metal salt solution B;

[0045] (4) Metal salt solution B is slowly added dropwise in graphene oxide mixed solution A, fully stirred for 30min, and mixed solution C is obtained;

[0046] (5) Weigh 3.5g of sodium acetate and 0.58g of sodium lauryl sulfate, dissolve them in 10mL of deionized water, and add them dropwise to the above mixed solution C, and transfer the mixed solution to an autoclave at 180°C for 10 hours;

[0047] (6) After centrifugation, washing and vacuum drying, the product was annealed at 200°C for 2 hours under a nitrogen atmosphere to obtain magnetic ZnFe 2 o 4 / Graphene nano...

Embodiment 2

[0051] (1) Weigh 53.5 mg of graphene oxide and disperse it in 40 mL of diethylene glycol, and ultrasonically stir for 20 min to obtain a uniform dispersion;

[0052] (2) Add 2mL polyethylene glycol to the graphene oxide dispersion to obtain mixed solution A;

[0053] (3) Weigh 1.616g Fe(NO 3 ) 3 9H 2 O with 0.594g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 20mL diethylene glycol to obtain a uniform metal salt solution B;

[0054] (4) The metal salt solution is slowly added dropwise to the graphene oxide mixed solution A obtained in step (2), and fully stirred for 60 min to obtain a mixed solution C;

[0055] (5) Weigh 6.56g of sodium acetate and 0.3456g of sodium lauryl sulfate, dissolve them in 15mL of deionized water, and add them dropwise to the above mixed solution C, transfer the mixed solution to an autoclave, and react at 200°C for 8h;

[0056] (6) After centrifugation, washing and vacuum drying, the product is annealed at 500°C for 0.5h under nitrogen atmosphere to ob...

Embodiment 3

[0058] (1) Weigh 60 mg of graphene oxide and disperse it in 20 mL of diethylene glycol, and ultrasonically stir for 60 min to obtain a uniform dispersion;

[0059] (2) Add 1.33mL polyethylene glycol to the graphene oxide dispersion to obtain mixed solution A;

[0060] (3) Weigh 0.604gFe(NO 3 ) 3 9H 2 O and 0.222gZn(NO 3 ) 2 ·6H 2 O was dissolved in 20mL diethylene glycol to obtain a uniform metal salt solution B;

[0061] (4) The metal salt solution is slowly added dropwise to the graphene oxide mixed solution A obtained in step (2), and fully stirred for 20 min to obtain a mixed solution C;

[0062] (5) Weigh 6.12g of sodium acetate and 0.538g of sodium lauryl sulfate, dissolve them in 12.24mL of deionized water, and add them dropwise to the above mixed solution C, transfer the mixed solution to an autoclave, and react at 130°C for 72h ;

[0063] (6) After centrifugation, washing and vacuum drying, the product is annealed at 250°C for 3 hours under nitrogen atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com