Preparation method of positive electrode material for lithium-ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of lithium carbonate residue, reduce gram capacity, reduce NCM ion conductance and electron conductance, etc., to prevent agglomeration growth, improve Operability and the effect of improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

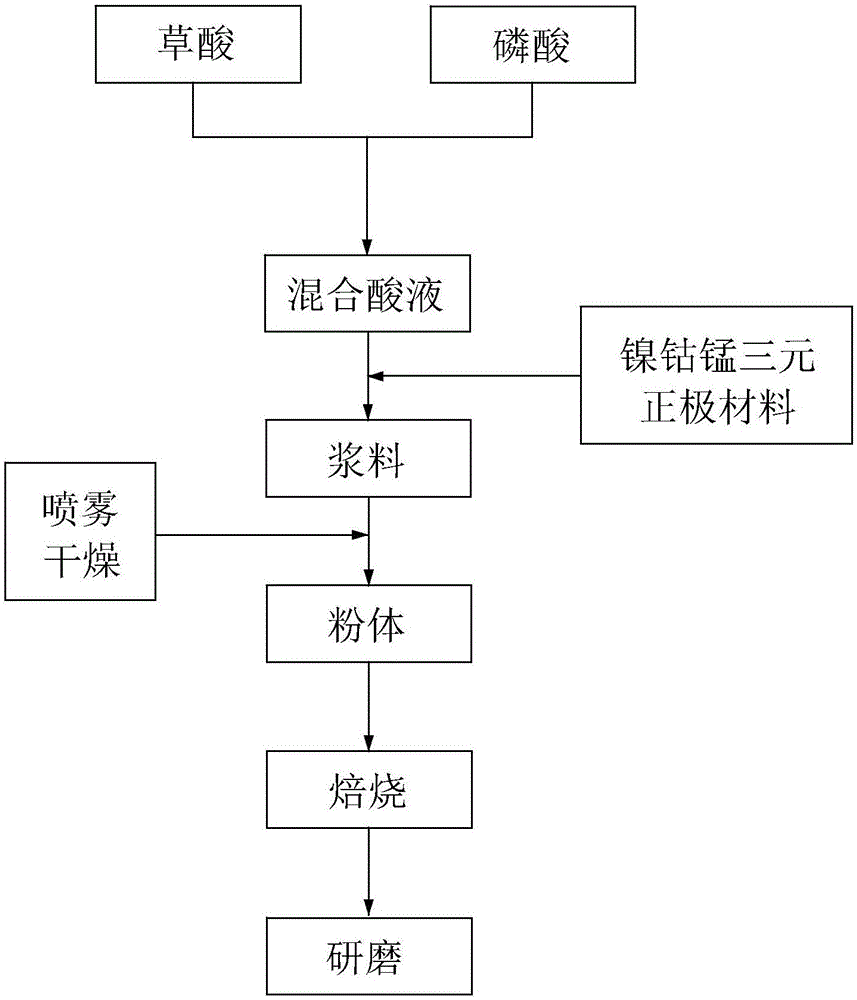

[0027] Please refer to figure 1 , the invention provides a kind of preparation method of lithium-ion battery cathode material, comprises the following steps:

[0028] 1) configuring an oxalic acid solution with a molar concentration of 0.3-0.9mol / L, adding a certain amount of phosphoric acid to obtain a mixed acid solution, the molar ratio of the oxalic acid to the phosphoric acid in the mixed acid solution is 1.5-90;

[0029] 2) Add a certain amount of nickel-cobalt-manganese ternary positive electrode material to the mixed acid solution obtained in step 1), and the quality of the nickel-cobalt-manganese ternary positive electrode material is 5-30 times of the mass of the oxalic acid, at room temperature Stir for 10-60min to form a slurry;

[0030] 3) The slurry obtained in step 2) is spray-dried according to an inlet temperature of 150±50°C, an outlet temperature of 100±50°C, and a spray speed of 500-1000mL / h to obtain a dried powder;

[0031] 4) The powder obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com