Copper-iron alloy modifier as well as preparation method and use method thereof

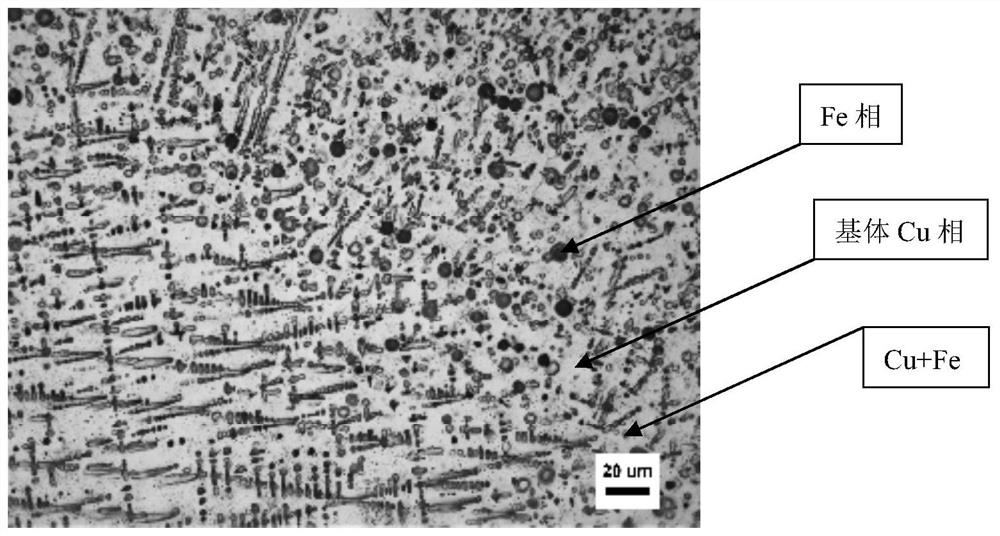

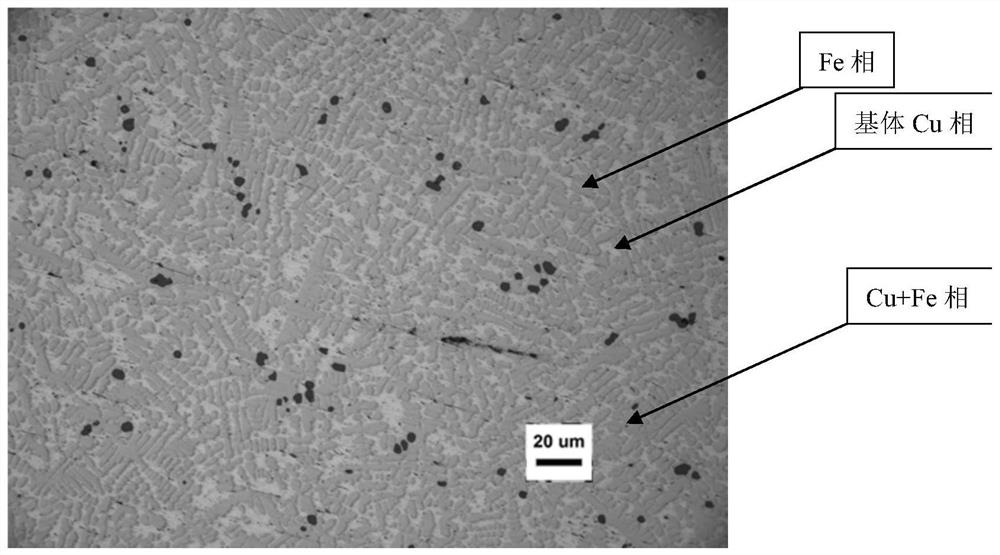

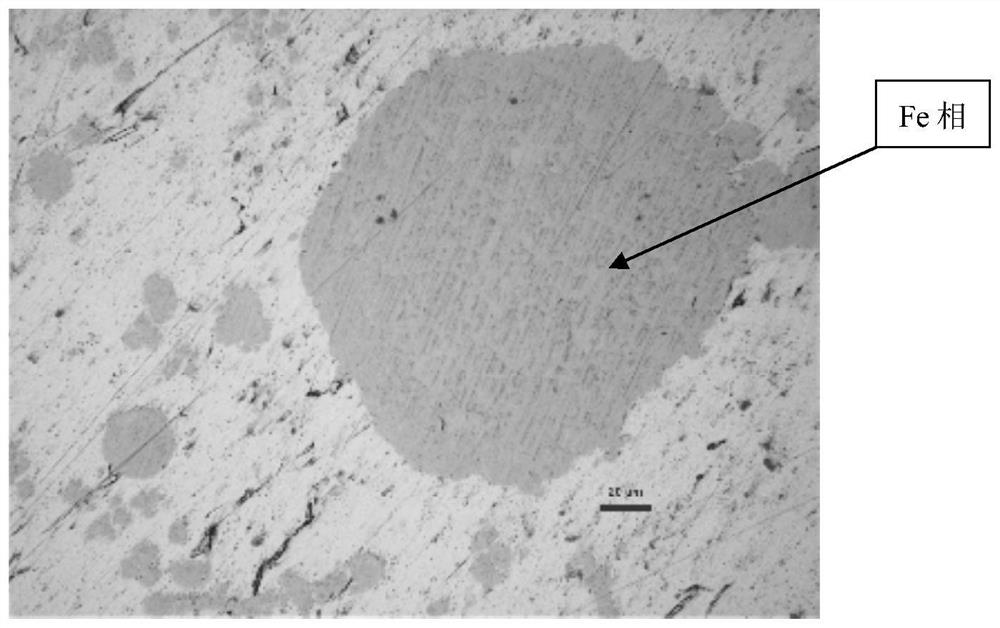

A copper-iron alloy and modifying agent technology, applied in the field of copper alloy, can solve the problems of poor control of iron phase morphology, large difference in specific gravity, iron phase segregation, etc., to eliminate the problem of iron phase disconnection, iron phase segregation, The effect of uniform distribution of iron phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The mass percent composition of modifier A is: 5wt% copper powder, 10wt% iron powder, 2wt% yttrium powder, and the balance is copper-calcium alloy powder; the calcium content in the copper-calcium alloy powder is 60wt%. The particle size of copper-calcium alloy powder is above 50 mesh, and the purity is above 99.9%; the particle size of copper powder is above 100 mesh, and the purity is above 99.9%; the particle size of iron powder is above 100 mesh, and the purity is above 99.9%; 99.9% or more.

[0029] The mass percent composition of modifier B is: 20wt% Cu, 5wt% Te, 5wt% Mg, 6wt% Ca, 5wt% Si, and the balance is Fe.

[0030] Modifier B comprises the following preparation steps:

[0031] 1) Raw material preparation: prepare raw materials according to the required ingredients;

[0032] 2) Melting: first put Cu into the heating furnace to melt, and the voltage is set to 450V. After melting, Fe block is put in, and the voltage is set to 800V. After both copper and iron ...

Embodiment 2

[0039] The mass percentage composition of the modifier A is: 15wt% iron powder, 5wt% yttrium powder, and the balance is copper-calcium alloy powder; the calcium content in the copper-calcium alloy powder is 60wt%. The particle size of copper-calcium alloy powder is above 50 mesh and the purity is above 99.9%; the particle size of iron powder is above 100 mesh and the purity is above 99.9%; the particle size of yttrium powder is above 100 mesh and the purity is above 99.9%.

[0040] The mass percent composition of modifier B is: 15wt% Cu, 5wt% Te, 5wt% Ca, 5wt% Si, 5wt% La and the balance being Fe.

[0041] Modifier B comprises the following preparation steps:

[0042] 1) Raw material preparation: prepare raw materials according to the required ingredients;

[0043] 2) Melting: first put Cu into the heating furnace to melt, and the voltage is set to 420V. After melting, Fe block is put into it, and the voltage is set to 780V. The temperature is lowered to 1120°C, and Te, Ca, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com