Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Eliminate disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

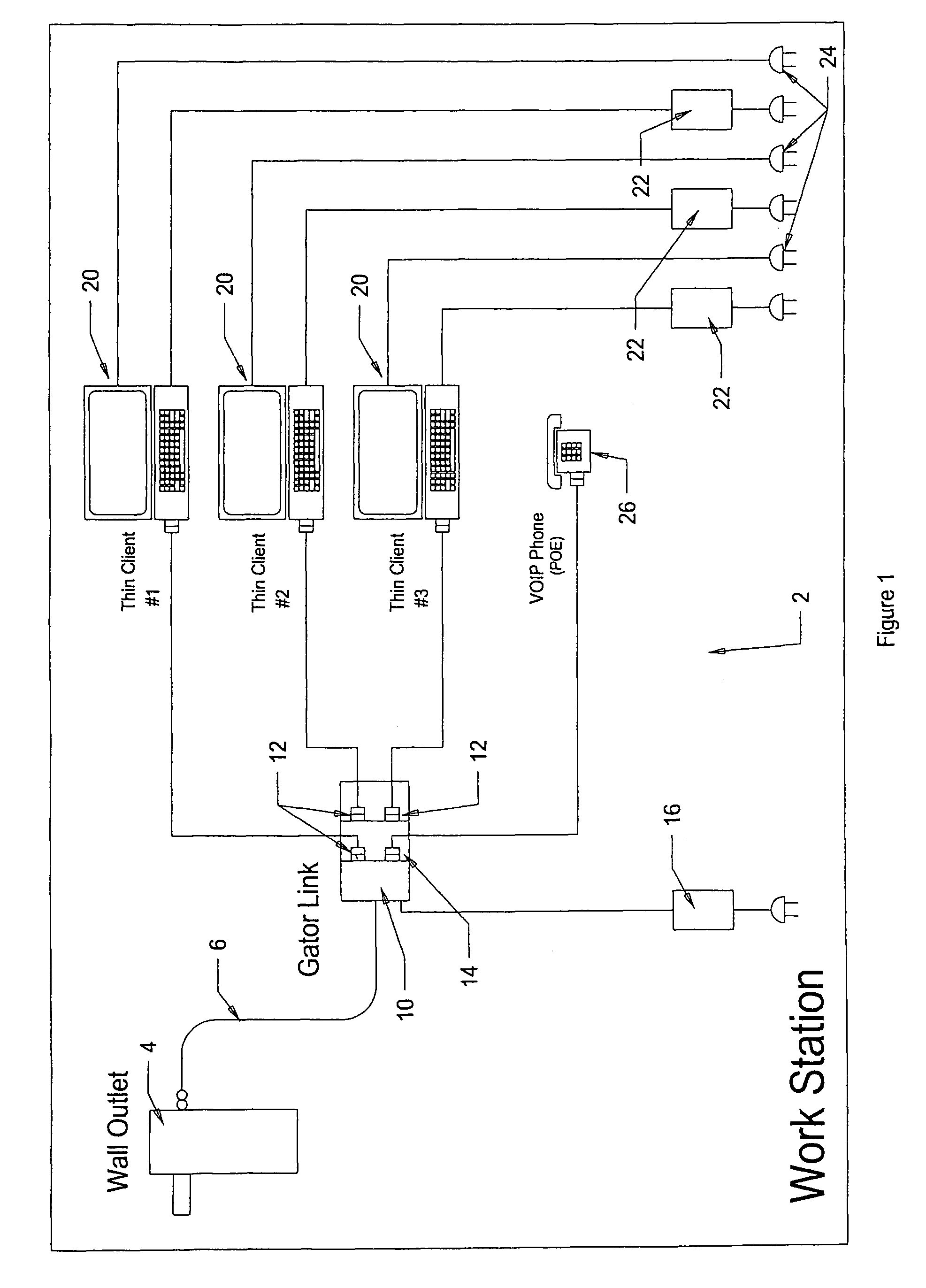

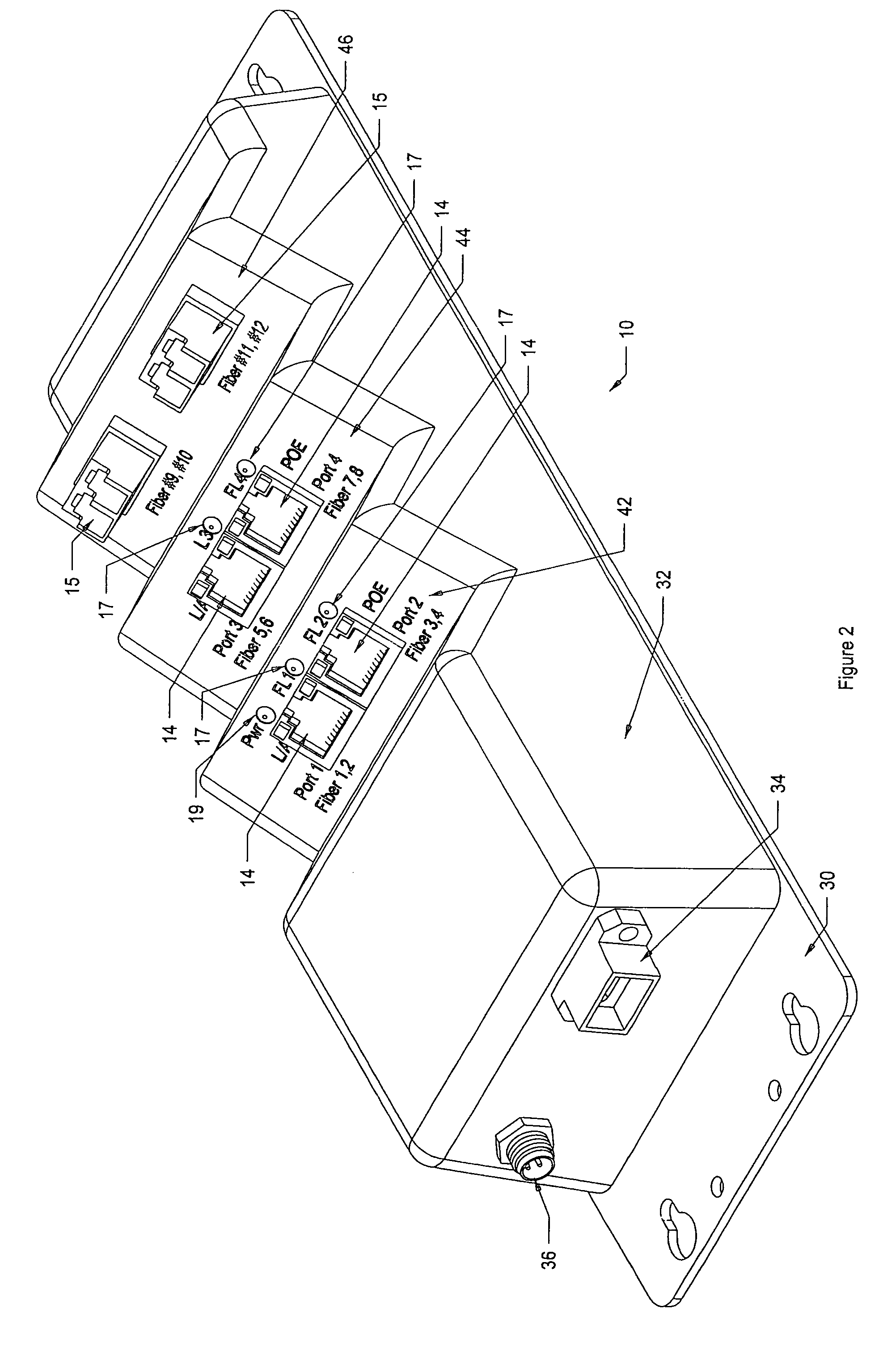

Digital signal media conversion panel

InactiveUS20090226181A1Eliminate disconnectionData switching current supplyCoupling light guidesFiberEngineering

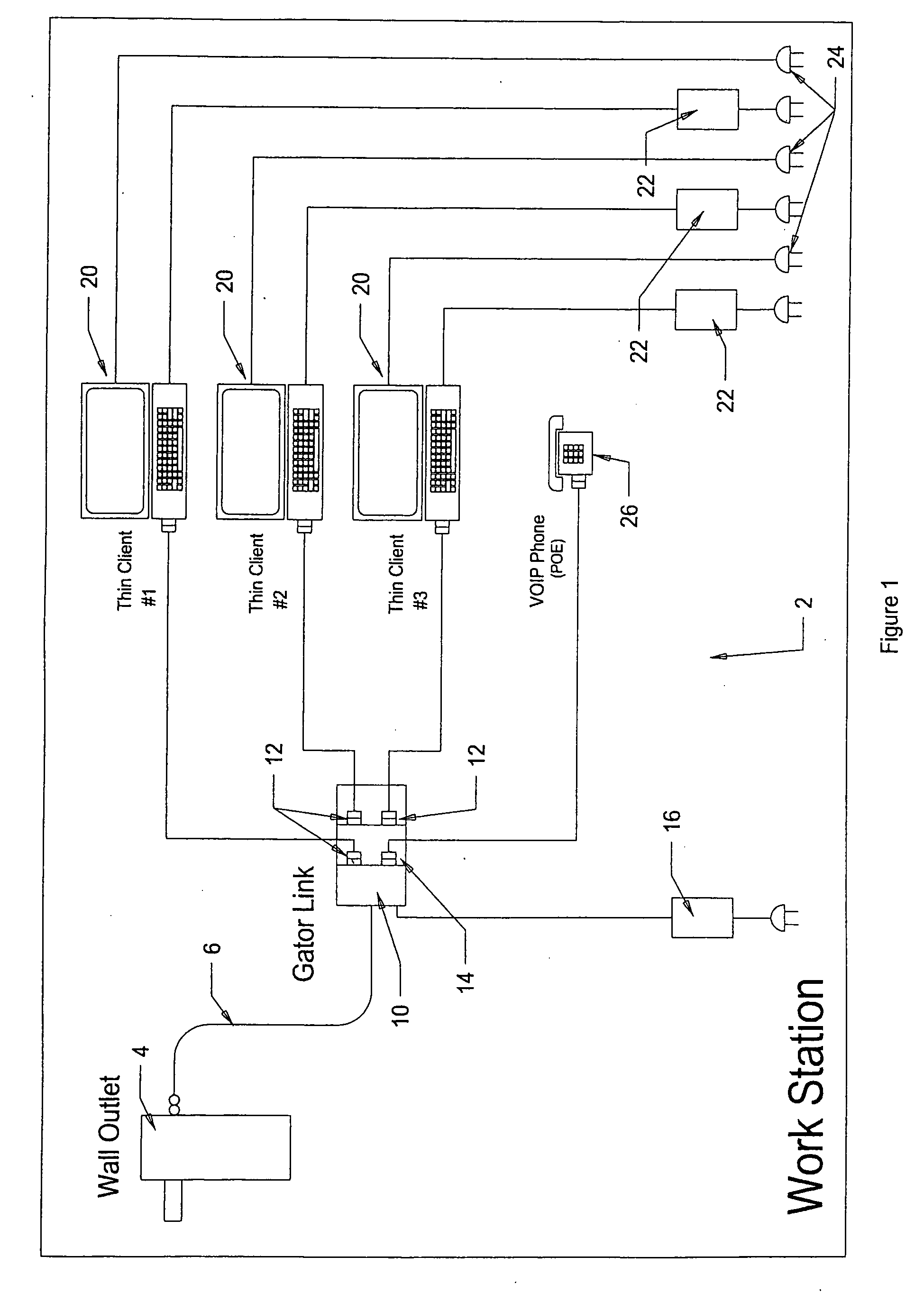

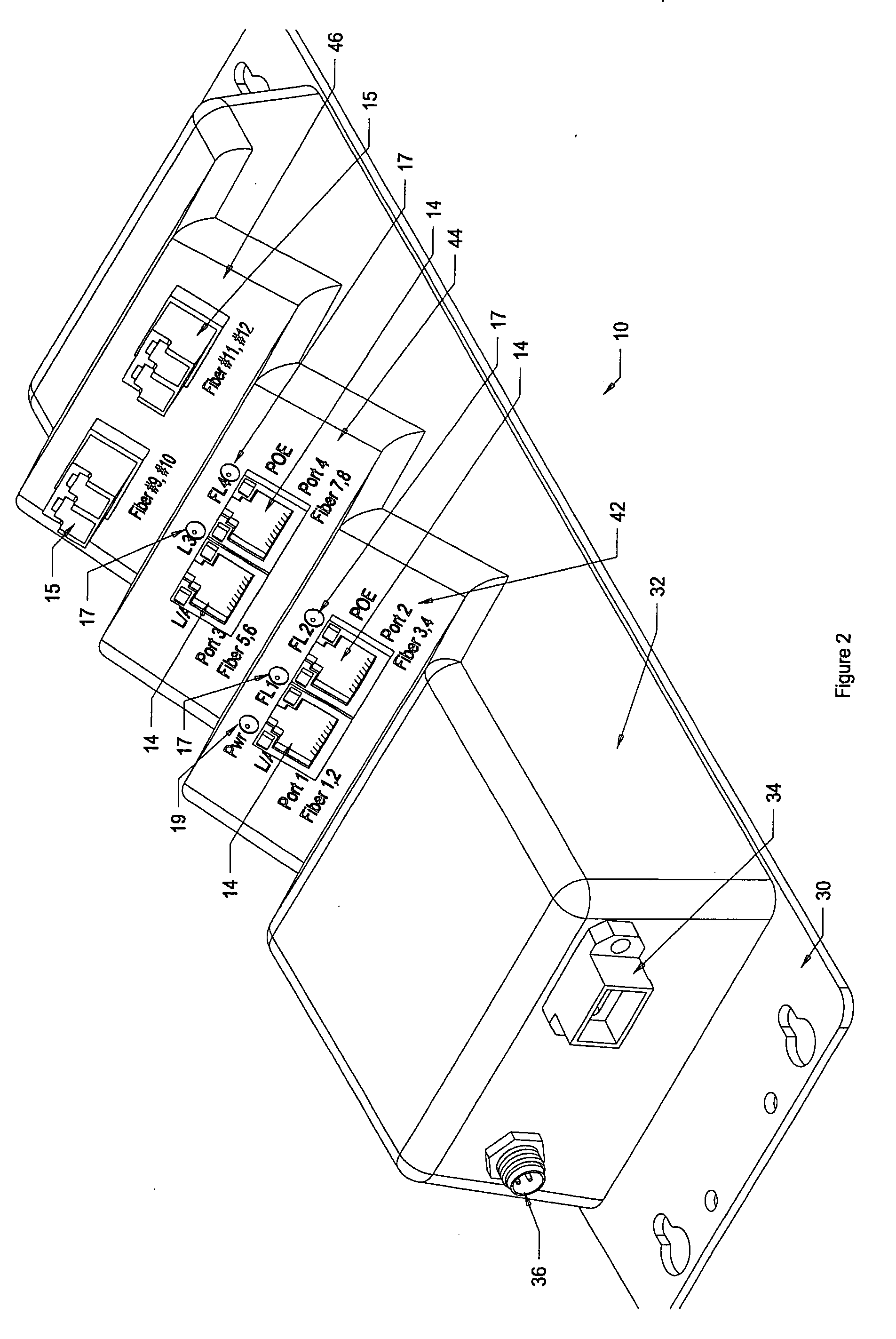

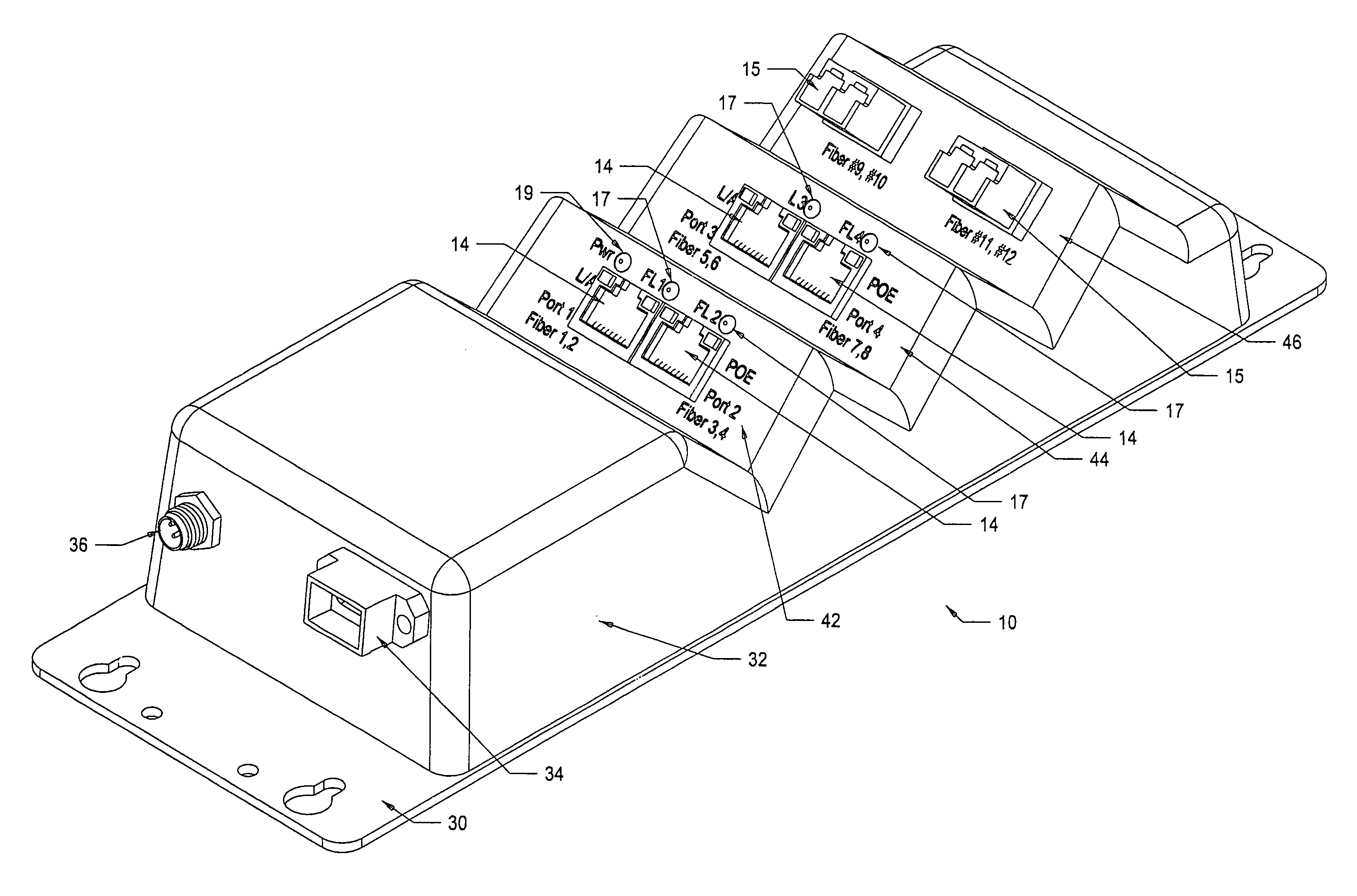

A digital signal media conversion panel has a series of media converters for converting between electrical signals and fiber optic signals. The conversion panel includes a power feed for the media converters. Preferably the conversion panel includes some Power Over Ethernet receptacles thereby simplifying connection of devices such as Voice Over Internet Protocol telephones and security cameras. In this embodiment, a separate power adapter provides two voltages to the patent panel using the power feed. The use of a separate adaptor with two voltages simplifies the design and avoids heat problems.

Owner:FIBER CONNECTIONS

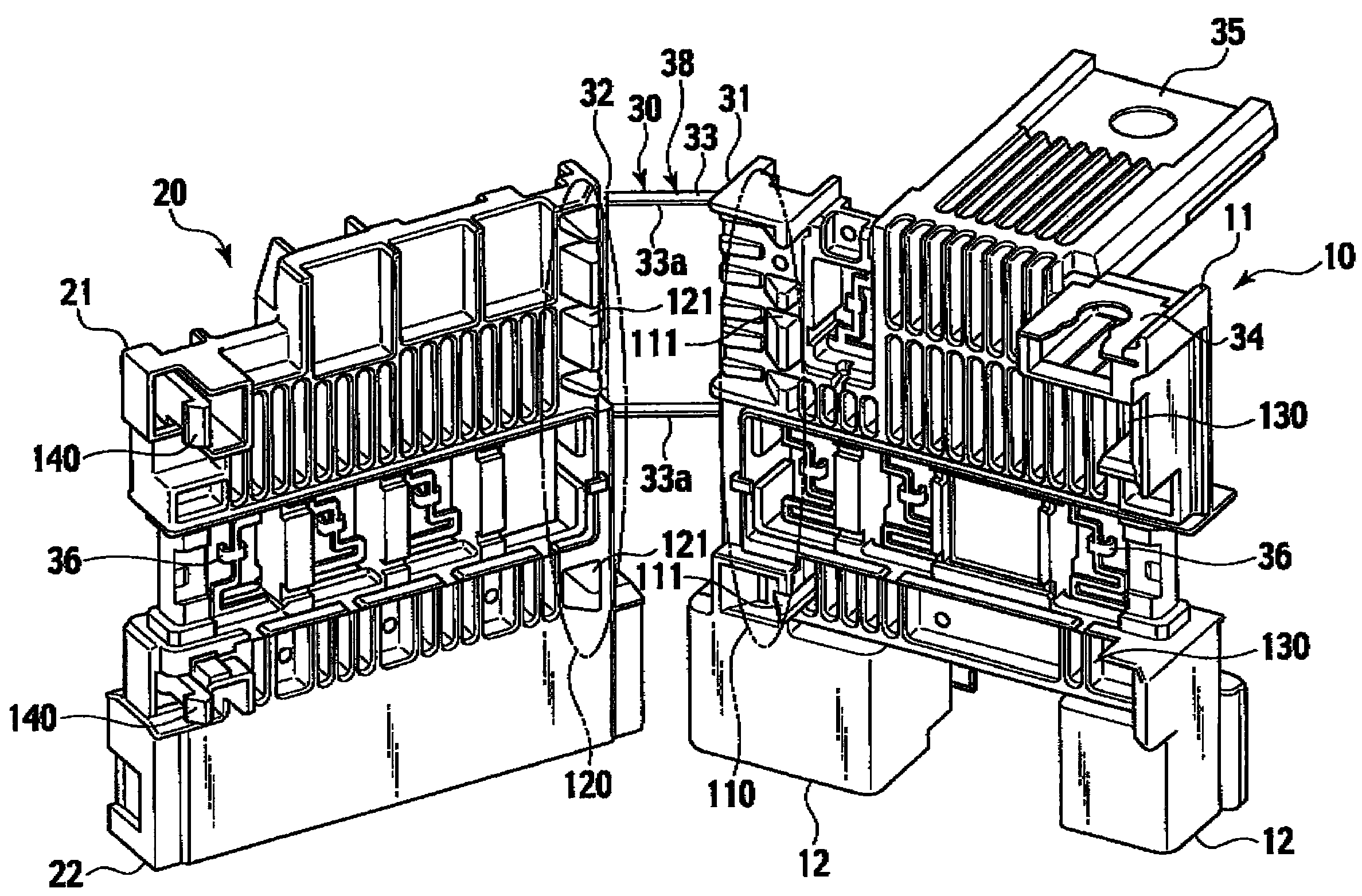

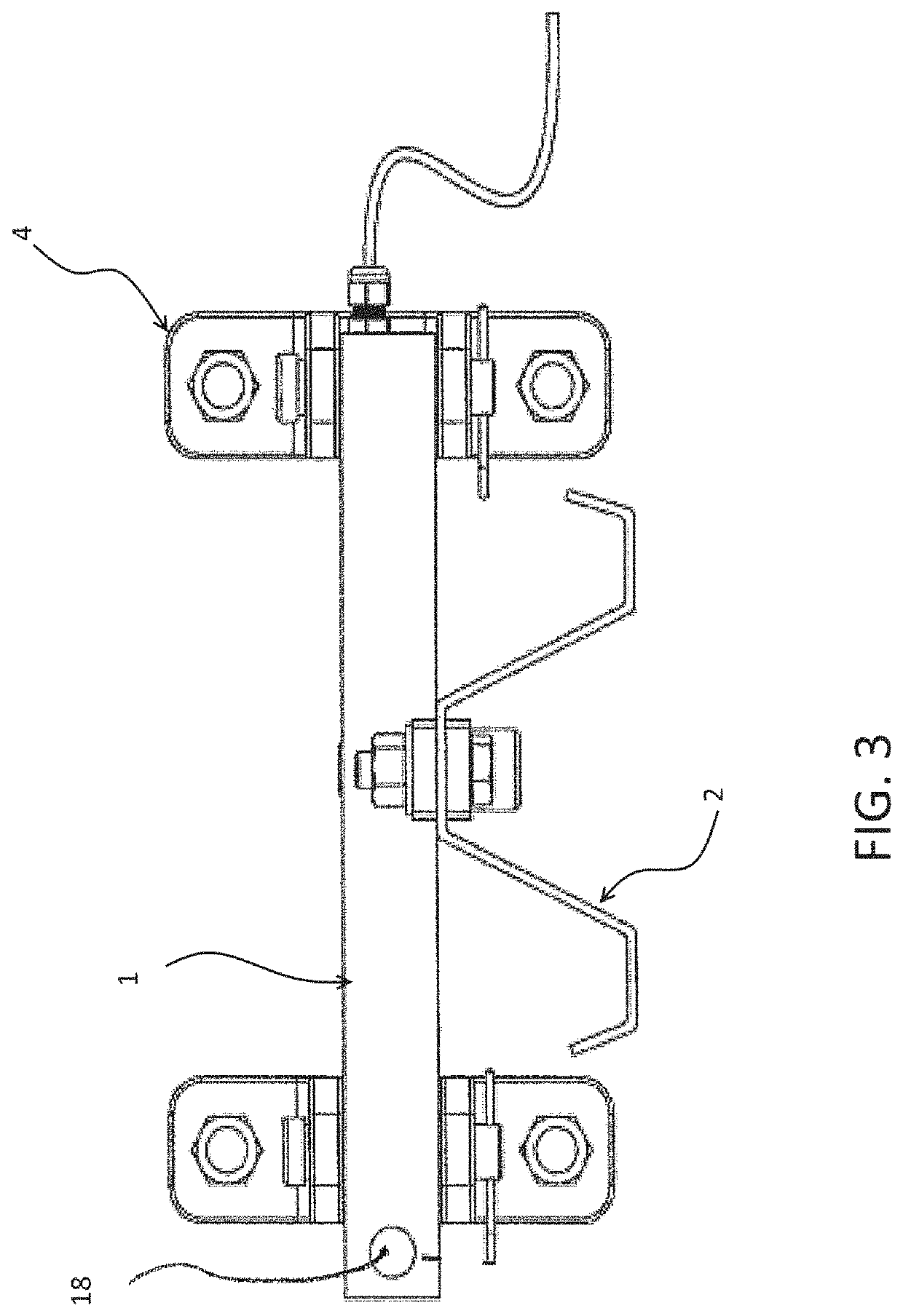

Fusible Link Unit with Hinge Section

ActiveUS20090111316A1Improve vibration resistanceAvoid noiseIncorrect coupling preventionEmergency protective devicesBusbarEngineering

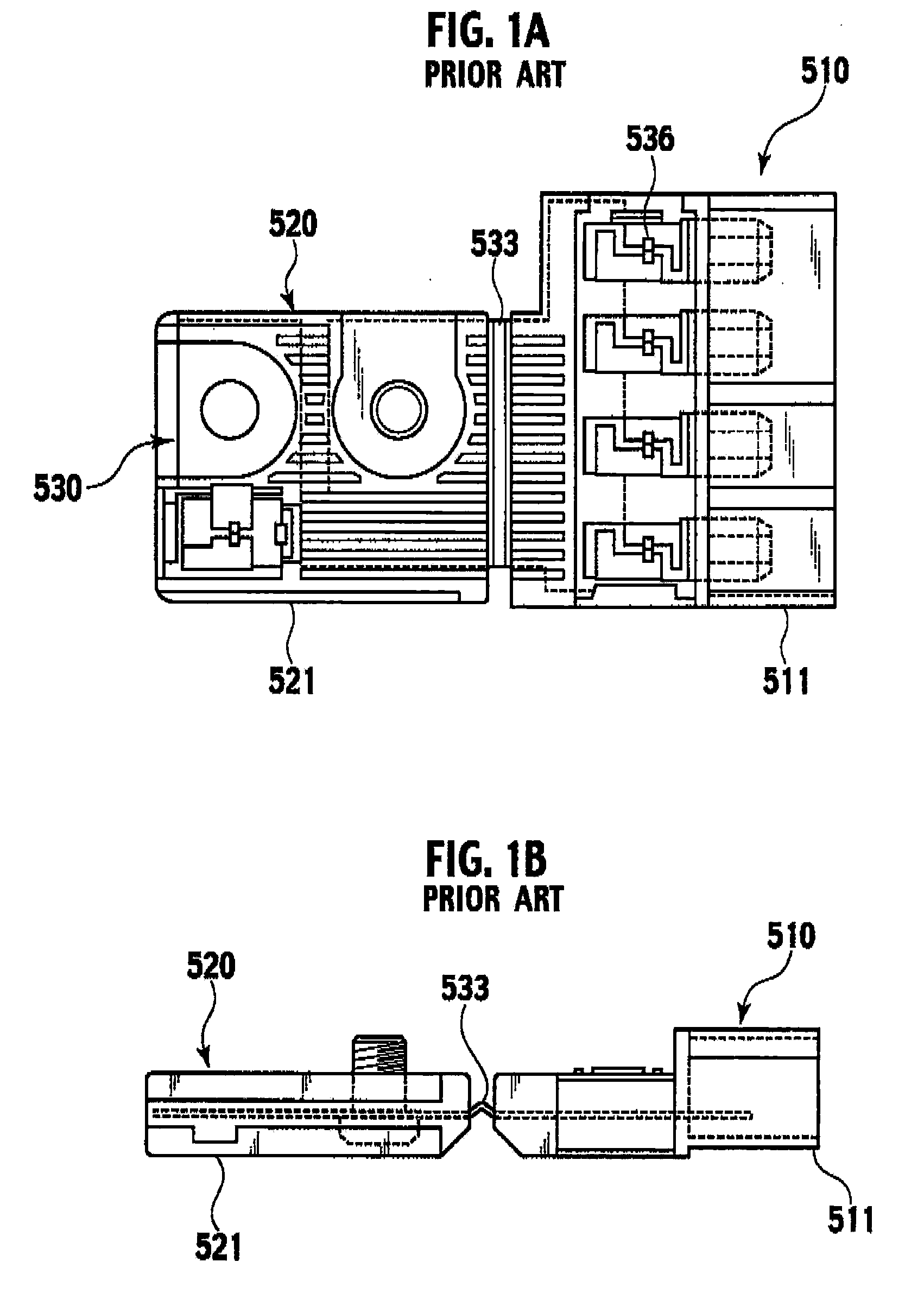

A hinge section including bending sections at both side edges of a band plate section is provided in center of a busbar. On both sides of the hinge section, two fuse circuit constituting plate sections are integrally formed to be linked thereto. Two resin housings are assembled by insert molding to the respective fuse circuit constituting plate sections, thus forming two bodies. The two bodies are pivoted in the same direction at the bending sections, and engagement units are locked, thus constituting a fusible link unit having a U-shaped plan view. The two bodies are engaged with each other in vicinity areas of the hinge section in the opposed surfaces of the opposed resin housing when the two bodies are pivoted. The fusible link unit also includes recessed and projected guides guiding the two resin housings to proper positions.

Owner:YAZAKI CORP

Digital signal media conversion panel

InactiveUS7837397B2Eliminate disconnectionData switching current supplyCoupling light guidesEngineeringElectric signal

Owner:FIBER CONNECTIONS

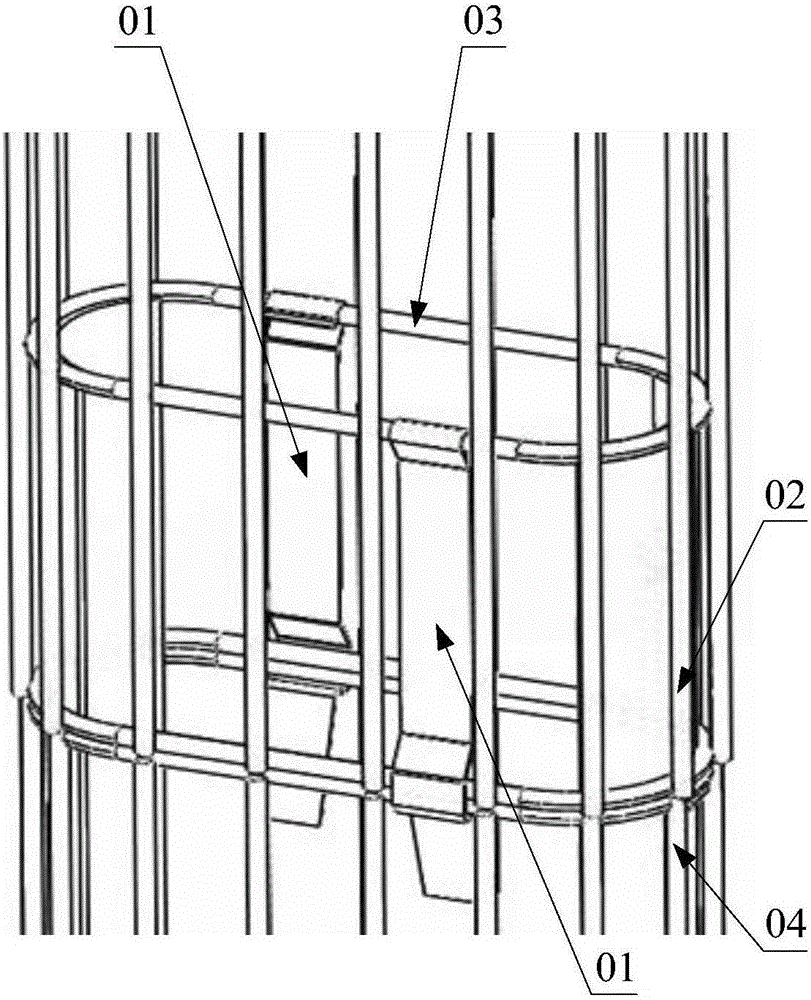

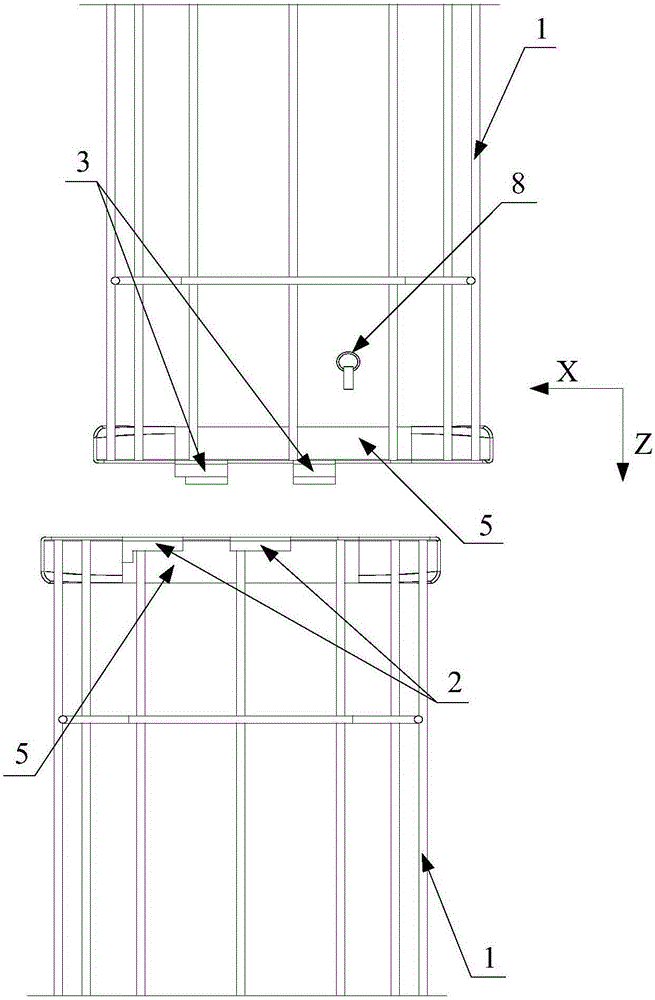

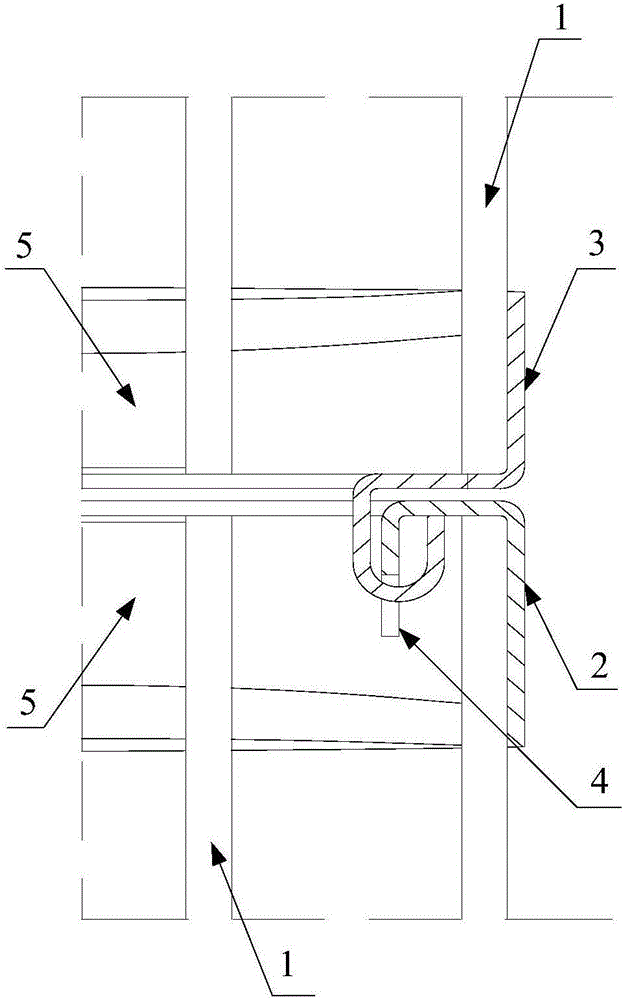

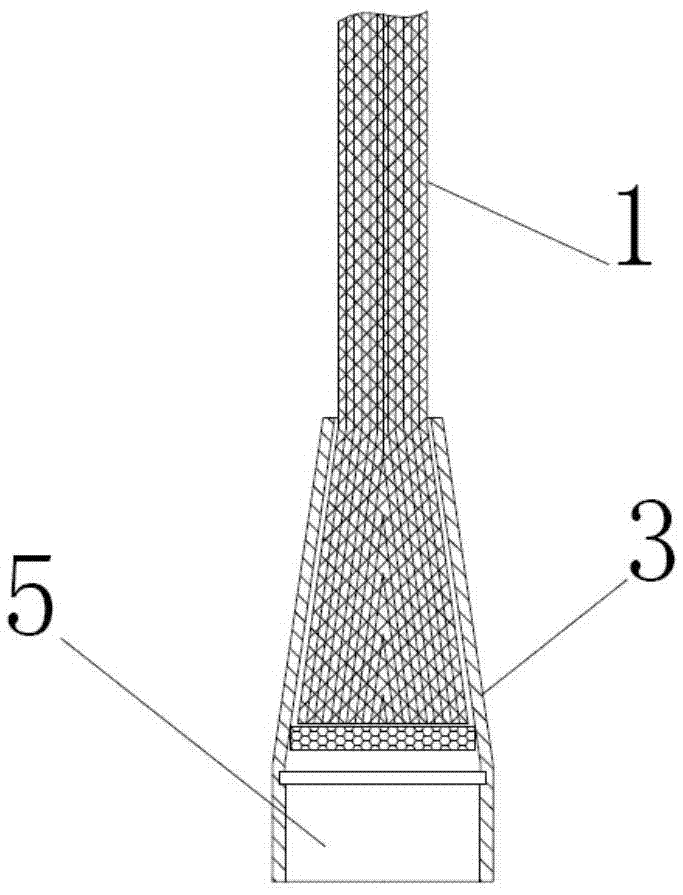

Bag type dust collector and sectioned bag cage thereof

InactiveCN105214398AGuaranteed to workNormal work relaxationDispersed particle filtrationEngineeringDust collector

The invention discloses a sectioned bag cage which comprises multiple connected bag cage sections. A clamping groove is formed in one of any two adjacent bag cage sections, and a clamping hook which can extend into the clamping groove to be clamped with the clamping groove so as to achieve connection of the two bag cage sections is arranged on the other of the two adjacent bag cage sections. In the sectioned bag cage, hook-groove structures are adopted replace elastic clamps so as to achieve connection of the bag cage sections, the phenomenon of filter bag puncture caused by drop of the elastic clamps is fundamentally avoided, and normal work of the sectioned bag cage is ensured. In addition, in the mode that the bag cage sections are connected by adopting the hook-groove structures, the accuracy requirement for matching sizes of the connecting positions of the upper and lower bag cage sections is greatly loosened, the manufacturing accuracy of connecting members is also reduced, the clamping grooves and the clamping hooks are both fixed to the bag cage sections, integration of the bag cage sections and the connecting members is achieved, and the connecting stability can be better. Furthermore, free-hand installation can be also achieved without special installing tools, and mounting and dismounting operation are more convenient. The invention further provides a bag type dust collector provided with the sectioned bag cage.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

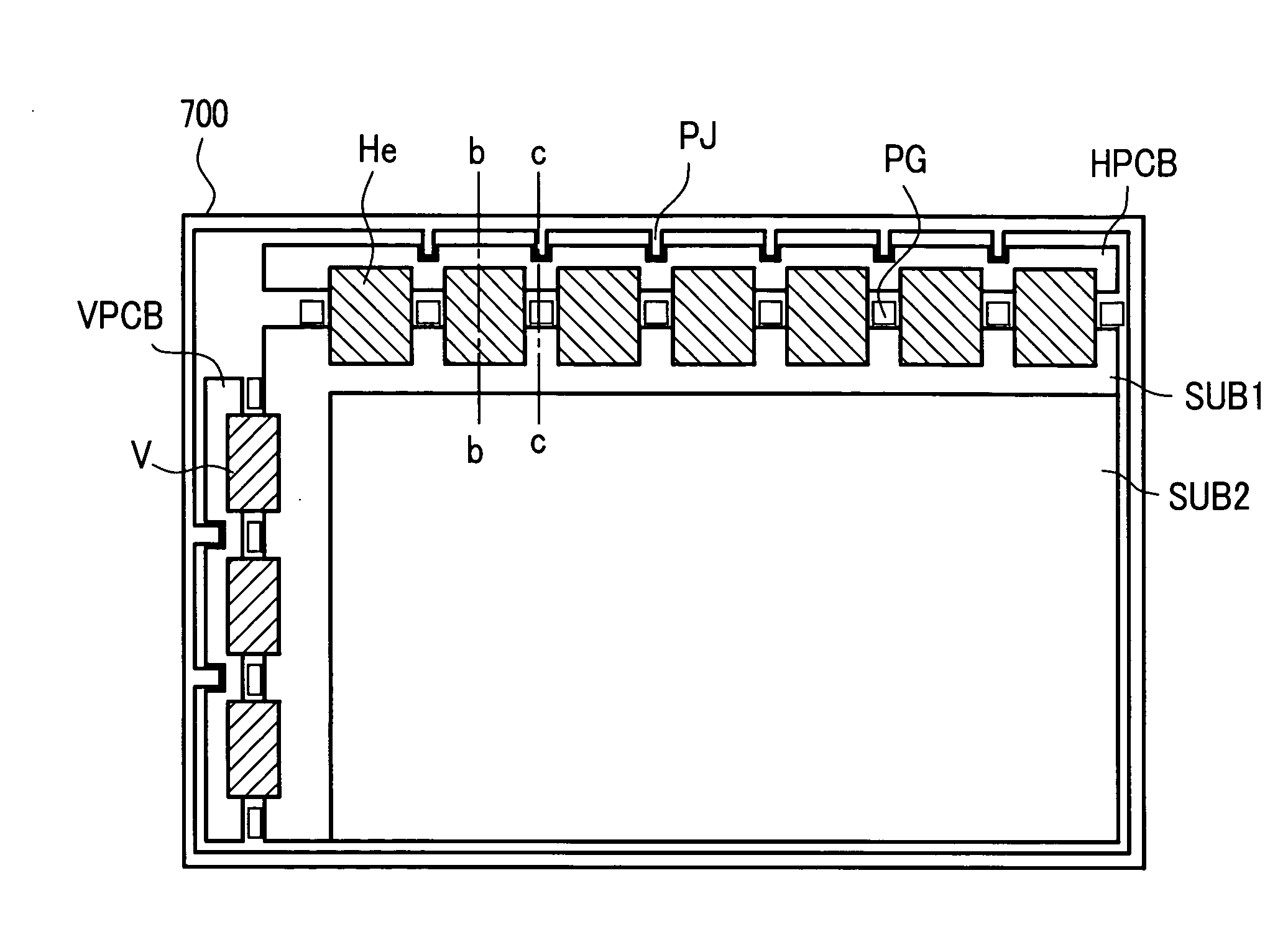

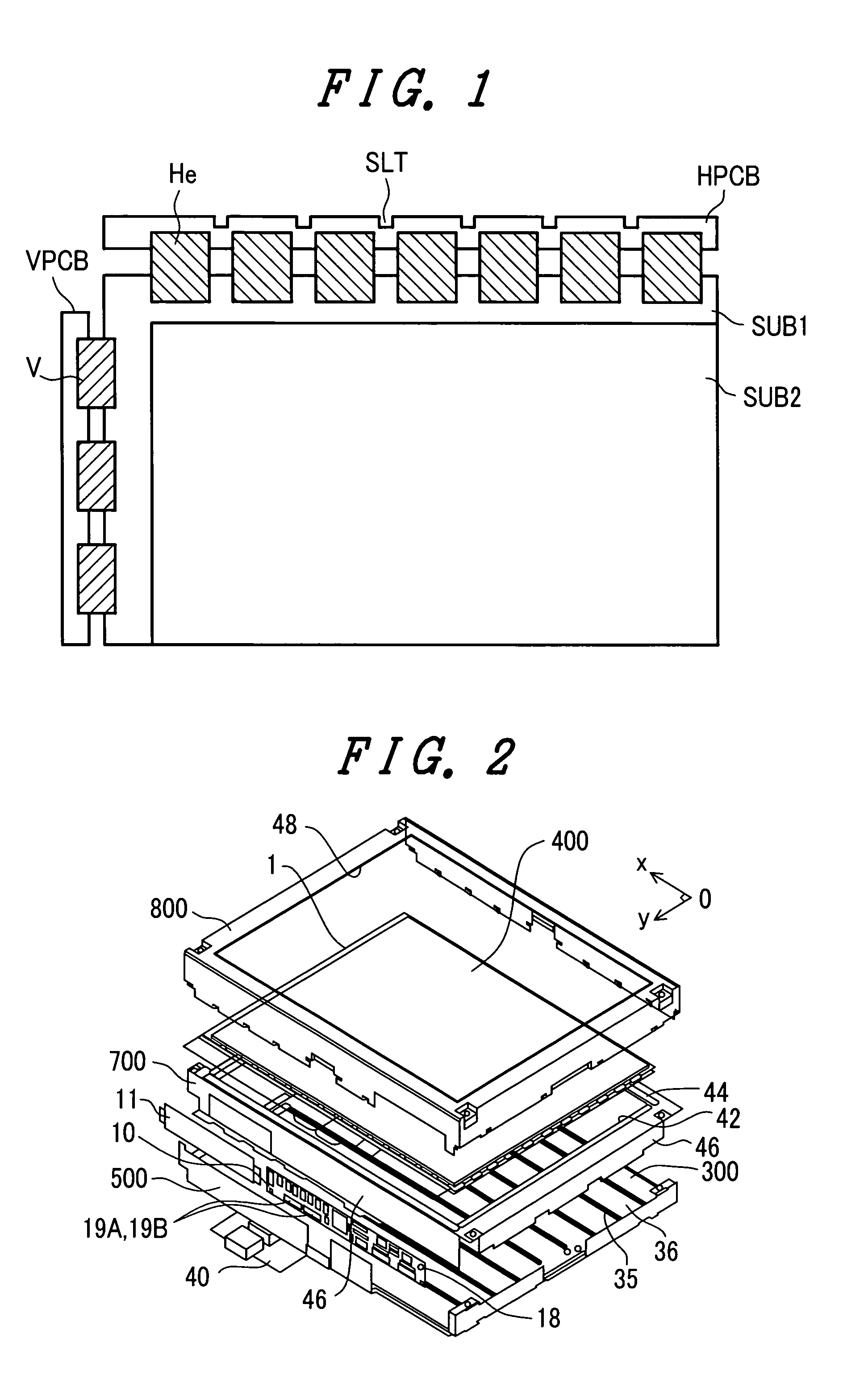

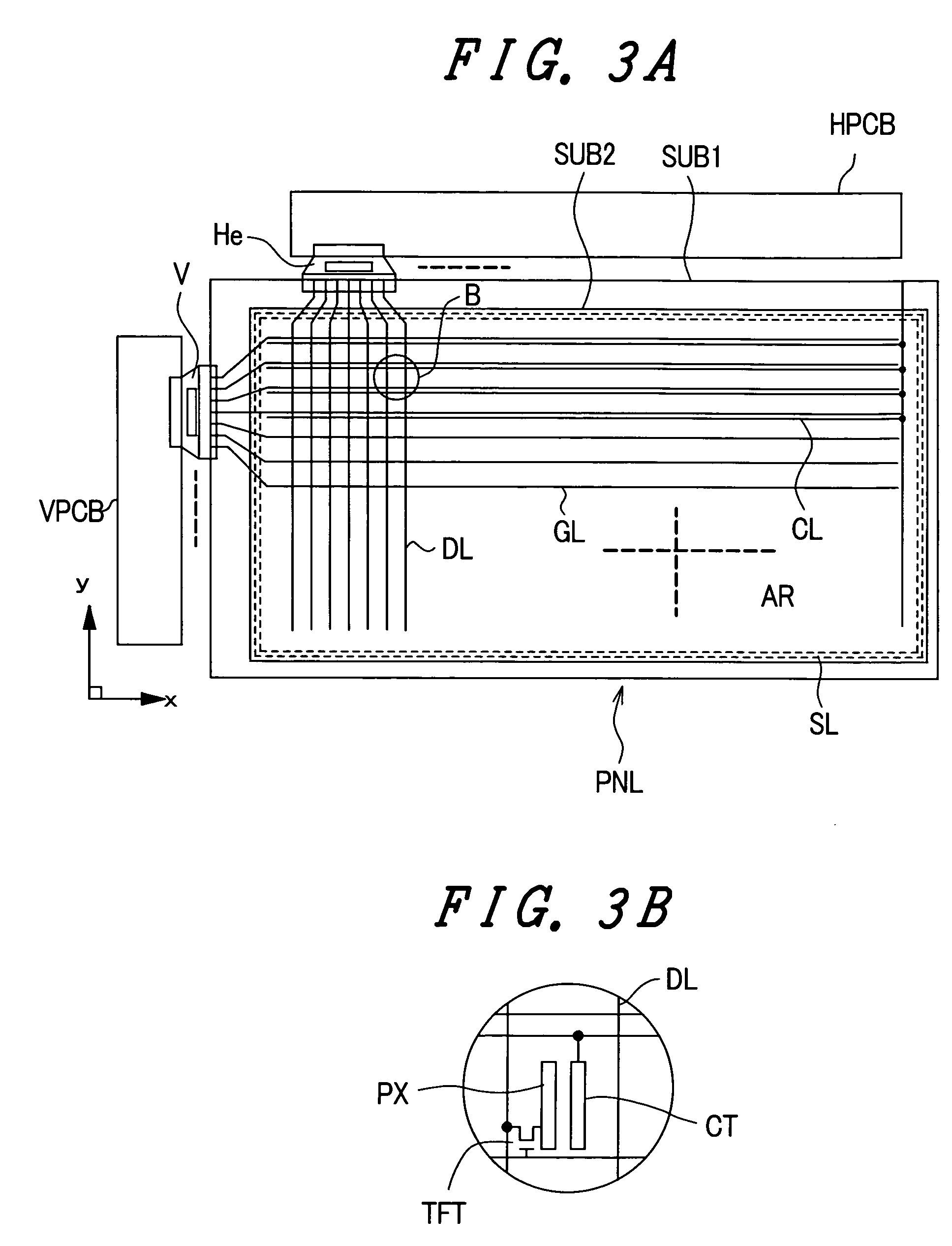

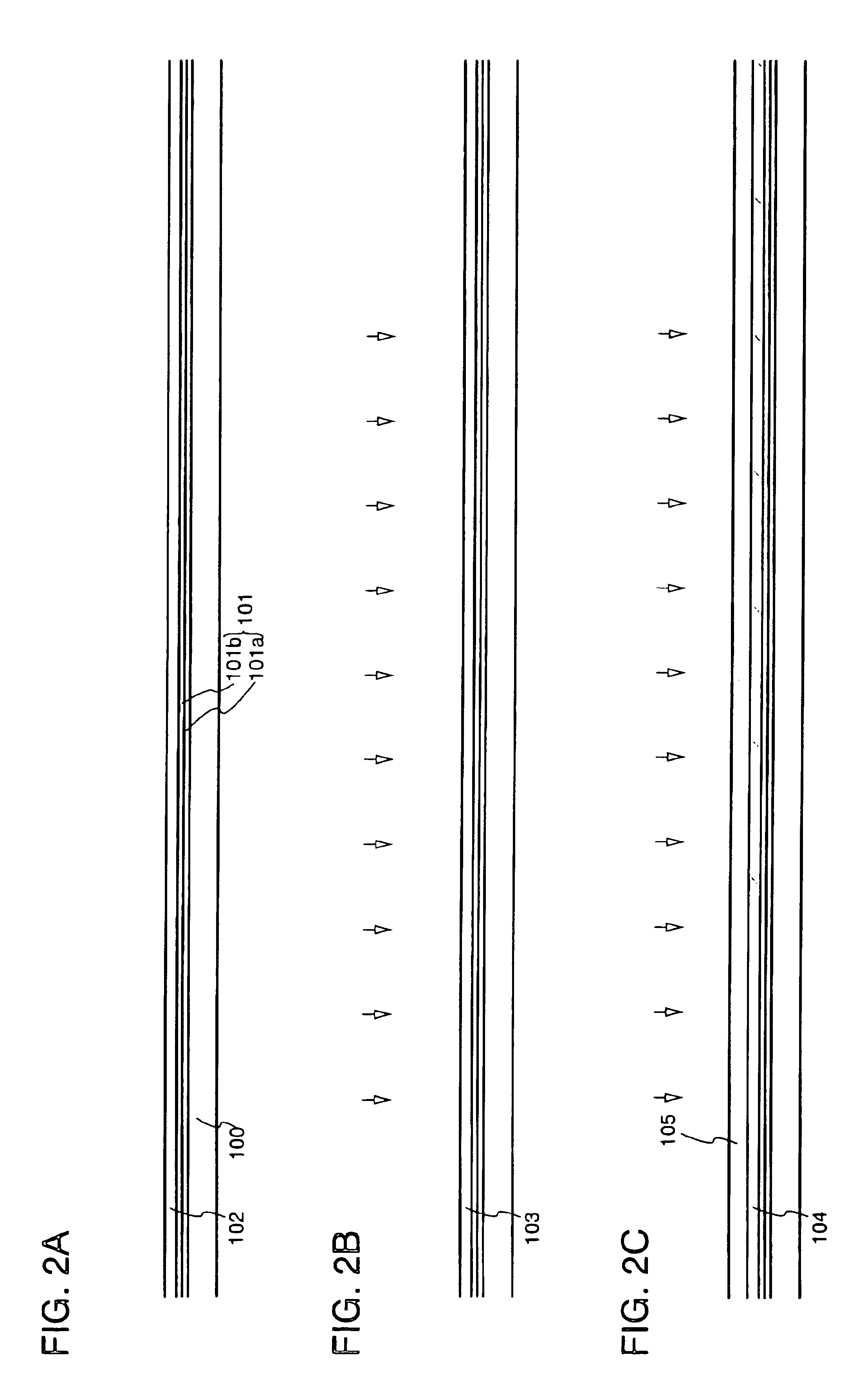

Image display device

ActiveUS7259822B2Improvement factorEliminate disconnectionStatic indicating devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An image display device includes an image display panel, a first wiring printed circuit board which is arranged in spaced relationship close to the image display panel, and a second wiring printed circuit board which is arranged to extend between the image display panel and the first wiring printed circuit board. The second wiring printed circuit board is constituted such that at least a wiring layer which allows inputting of signals thereto from the first wiring printed circuit board side and outputting of signals therefrom to the image display panel side is formed on a surface of a flexible printed circuit board. The first wiring printed circuit board includes a portion having, a width smaller than the width of the first wiring printed circuit board, disposed at a side thereof opposite to the image display panel.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

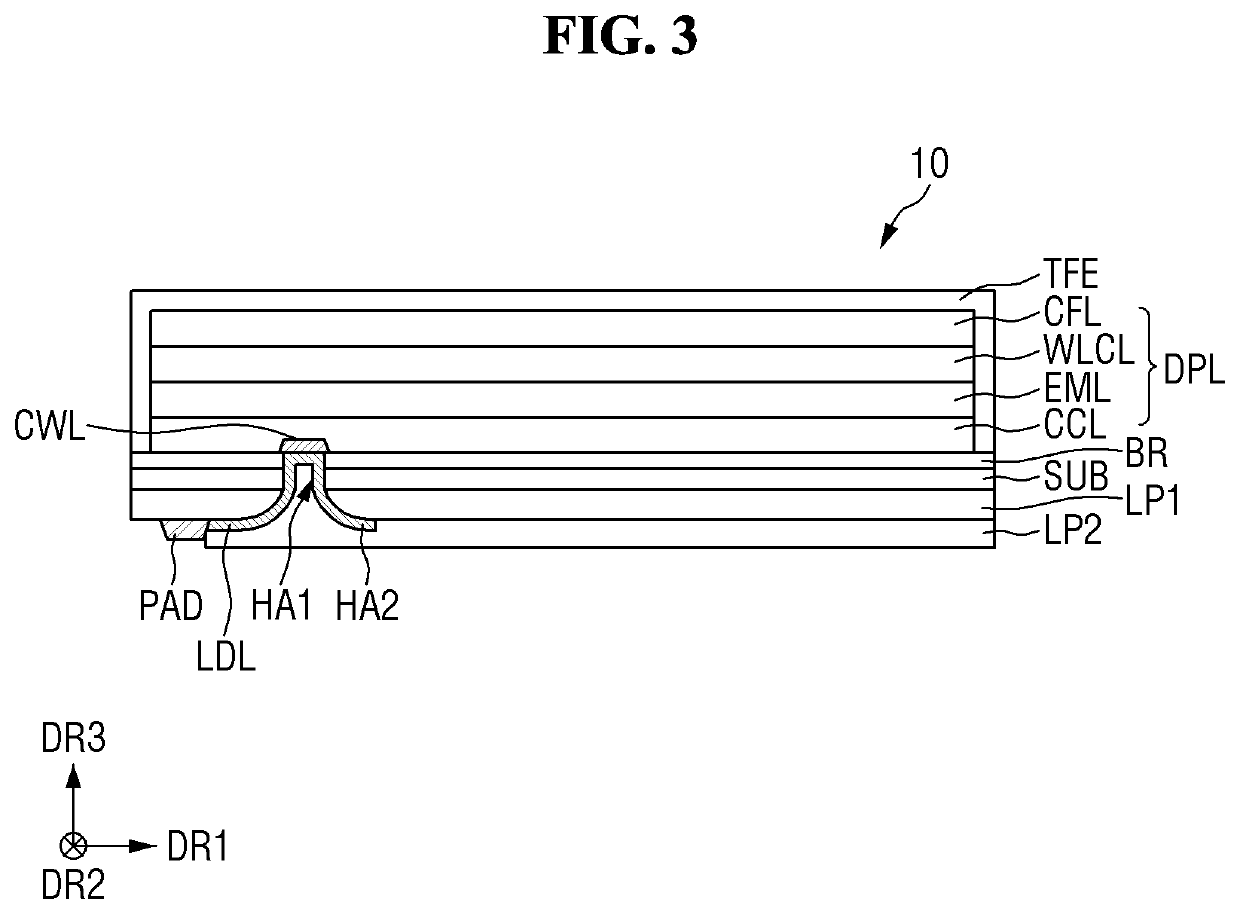

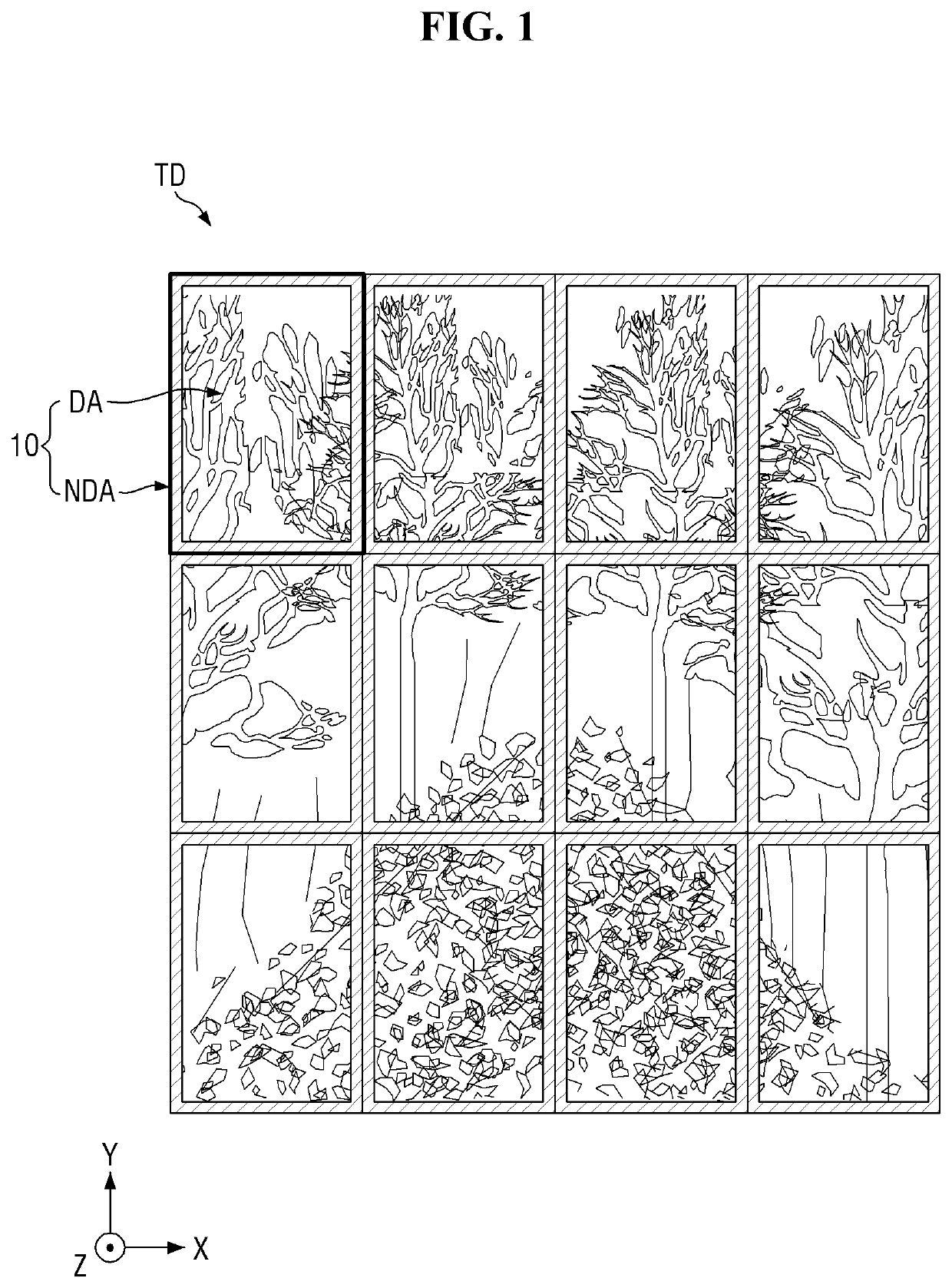

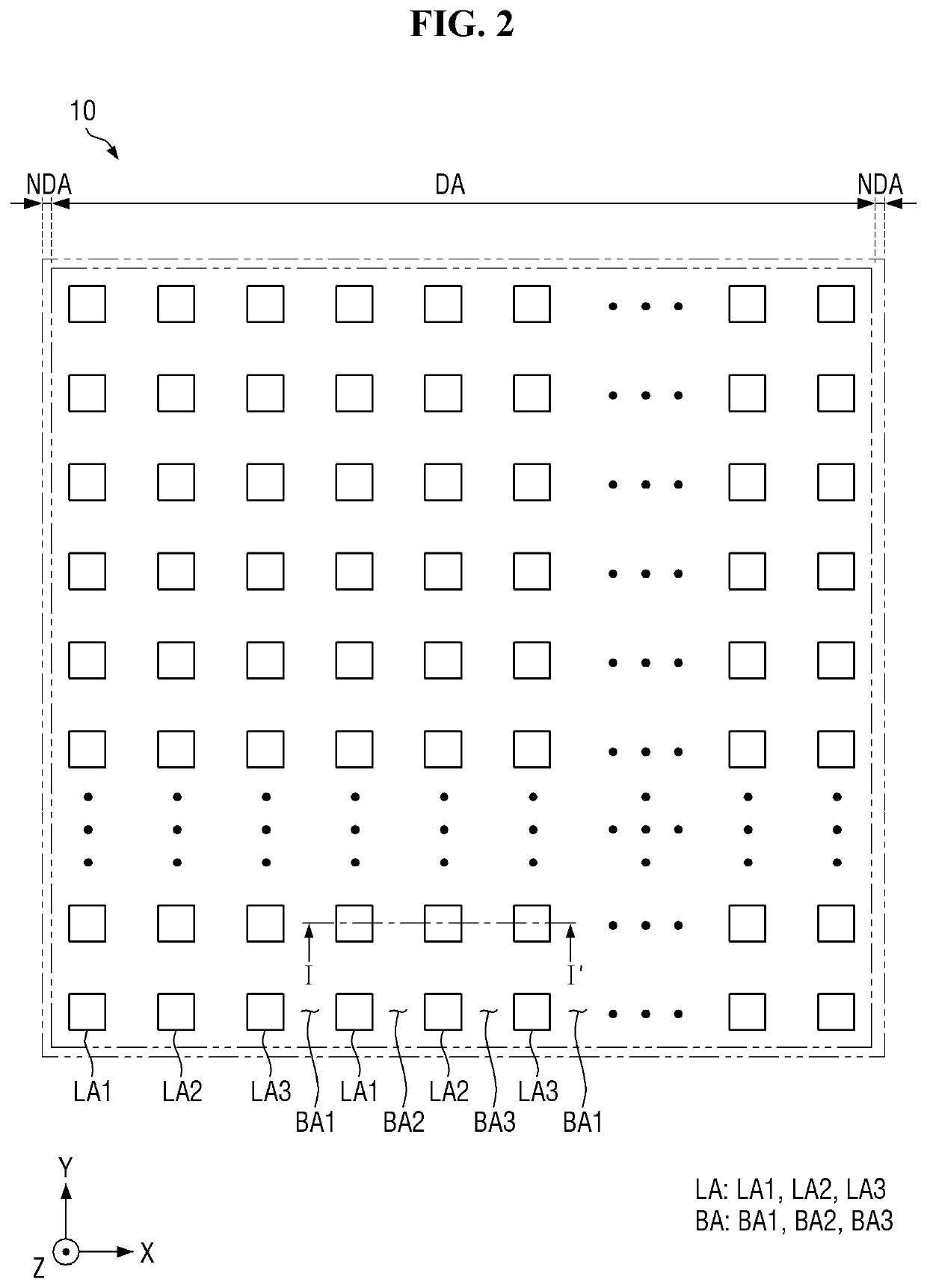

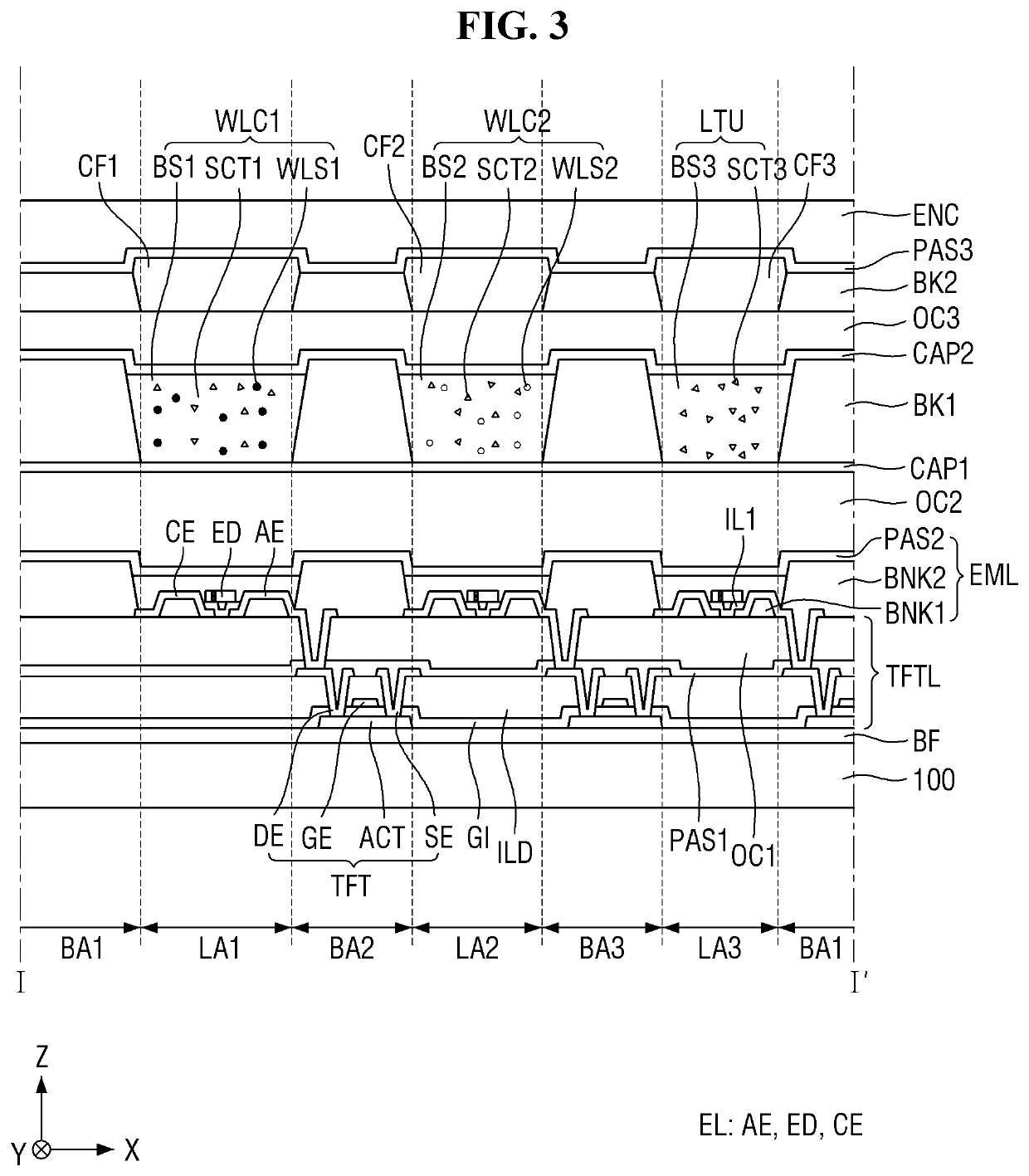

Display device and tiled display device including the same

PendingUS20220093677A1Removing a disconnection sensationImprove image qualitySolid-state devicesIdentification meansDisplay deviceMaterials science

A display device includes a display layer including pixels each including at least one transistor, a connection wiring electrically connected to the at least one transistor and exposed to a lower surface of the display layer through a first contact hole in the display layer, a base member disposed under the display layer and including a first hole exposing the connection wiring exposed to the lower surface of the display layer, a first lower protective layer disposed on a lower surface of the base member and including a second hole overlapping the first hole, a pad portion disposed on a lower surface of the first lower protective layer, and a lead line disposed on the lower surface of the first lower protective layer and electrically connecting the pad portion and the connection wiring. A tiled display device includes multiple display devices.

Owner:SAMSUNG DISPLAY CO LTD

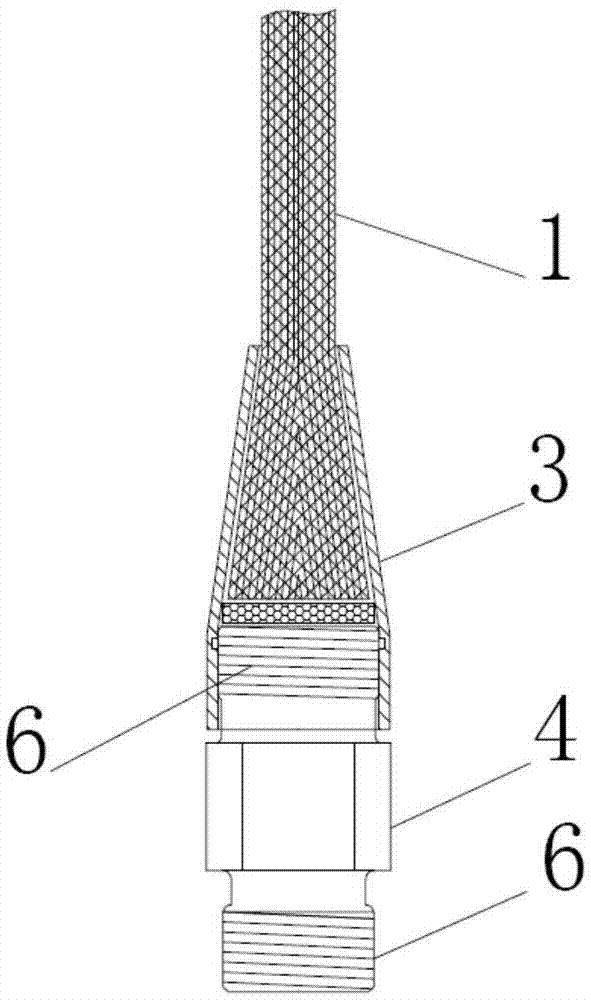

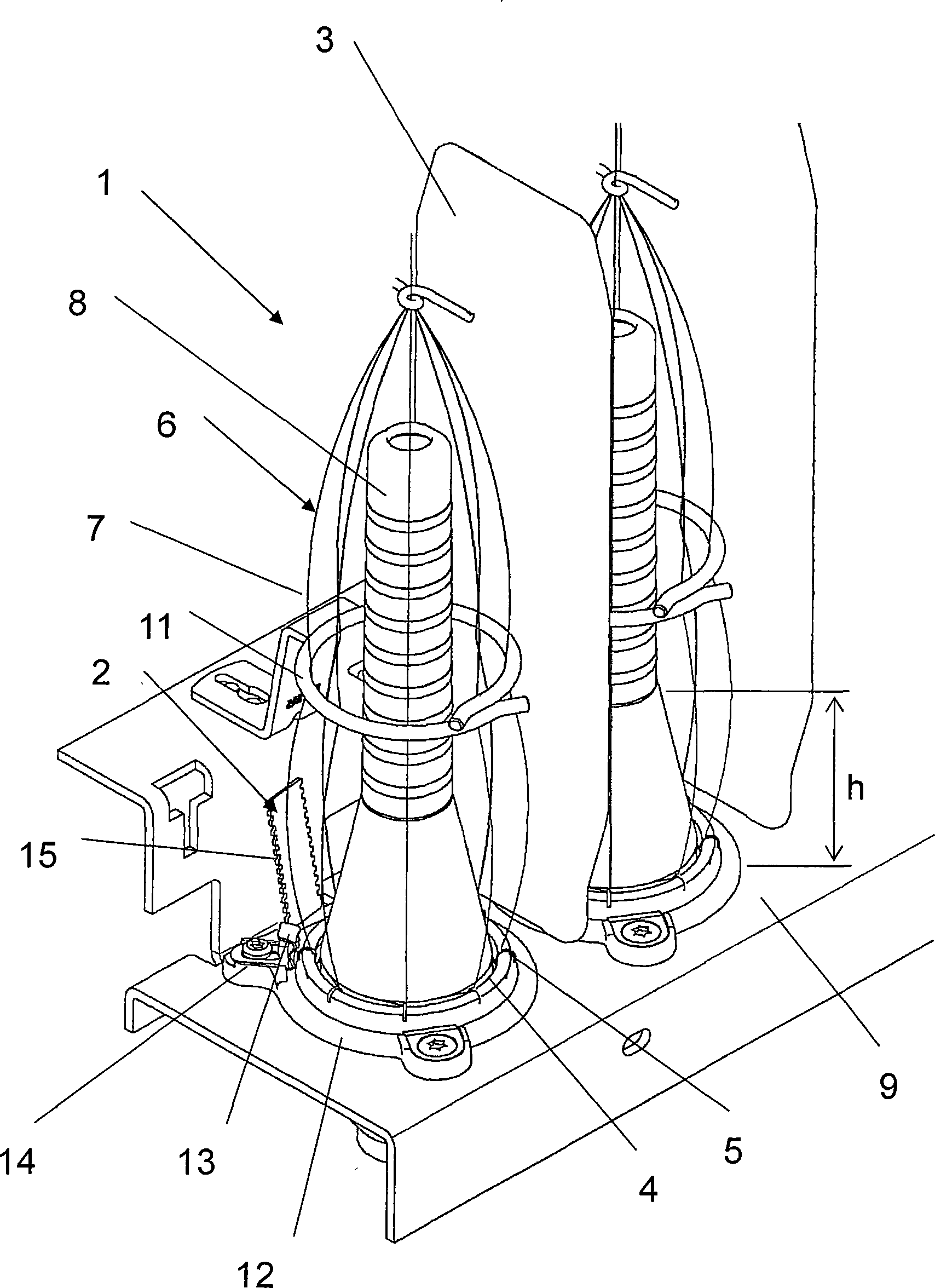

Device to protect edges from separators on a ring spinning machine and ring spinning machine

The present invention provides a device to protect edges of a spinning bench from separators on a ring spinning machine. Each bench has a steel collar part, a steel wire ring arranged on the steel collar part and a steel ring cleaning device arranged outside the steel ring tracks. The device for protecting edges is designed to be a cutting device, which cuts off yarn ends relieved from spindle sides in condition that the yarn is broken. The invention also provides a ring spinning machine with a plurality of spinning benchs, on which corresponding devices are provided to protect edges of the separators.

Owner:MASCHINENFABRIK RIETER AG

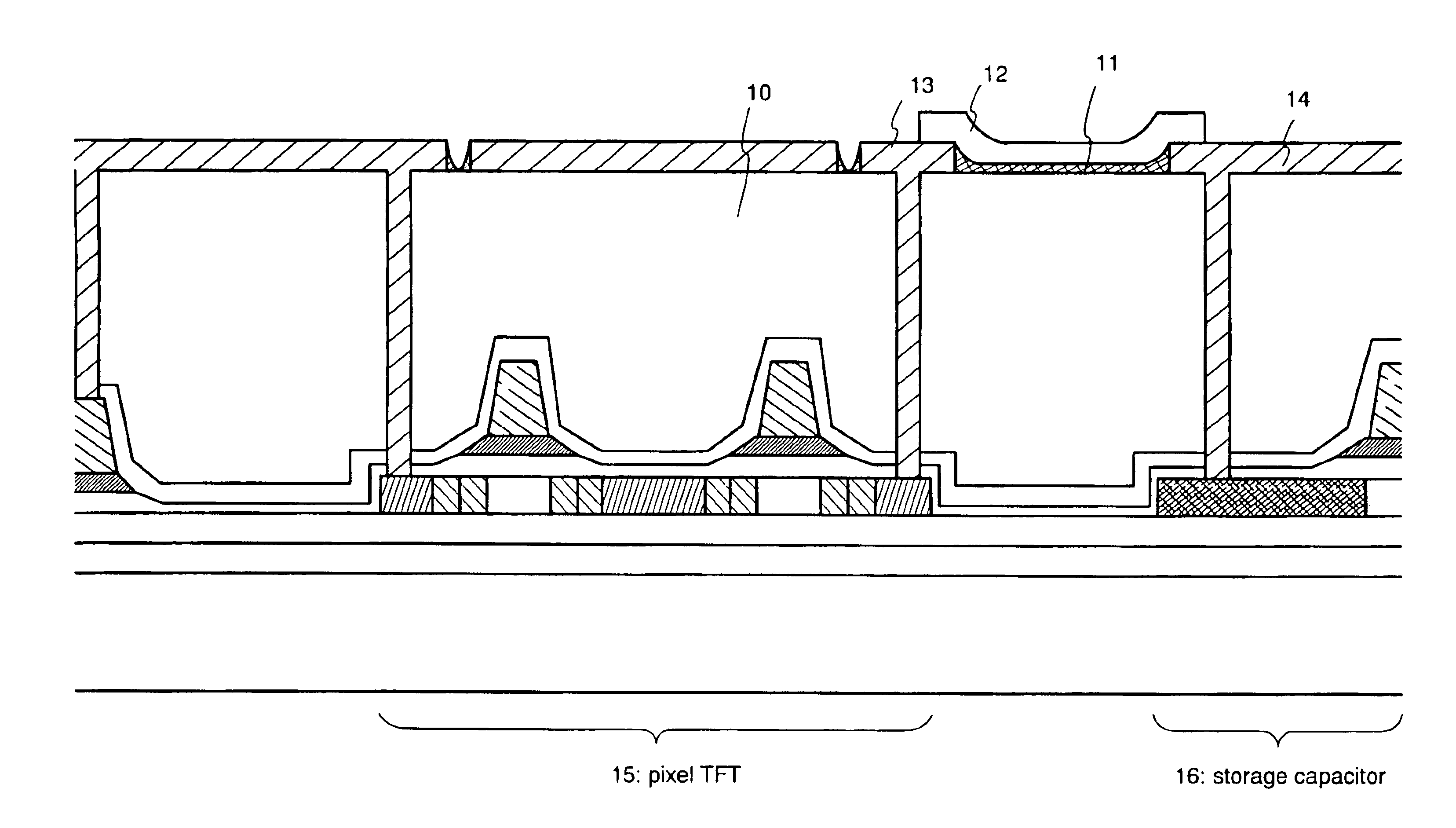

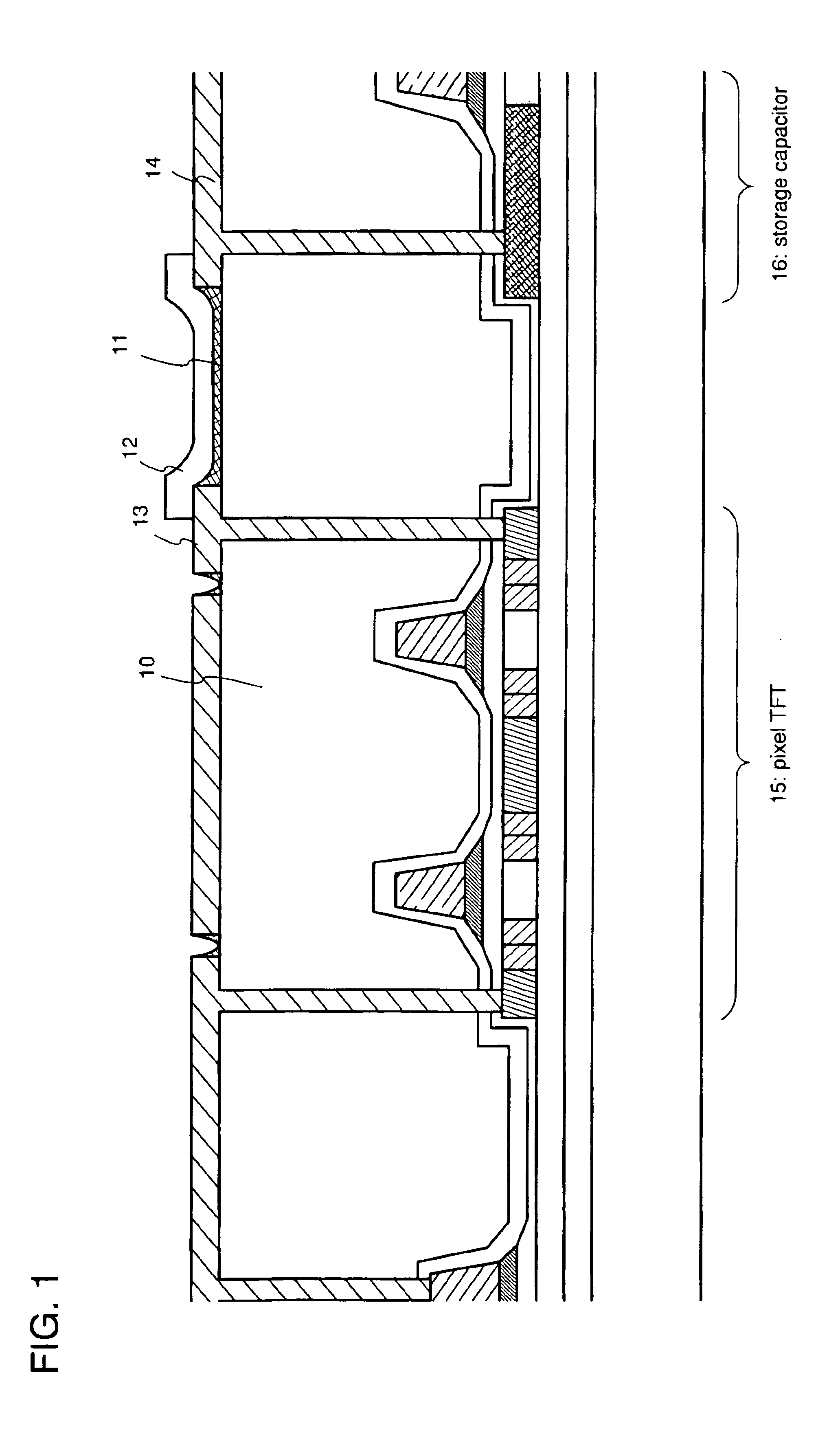

Semiconductor device, display device, and method of manufacturing the same

InactiveUS6929986B2Eliminate disconnectionIncrease productivityTransistorSolid-state devicesDisplay deviceEngineering

In order to eliminate the disconnection of a pixel electrode caused by a change in shape of an interlayer insulating film at the ends of metal wiring, a resin film is formed at the ends of the metal wiring. Because of the resin film at the ends of the metal wiring, the step difference of the ends of the metal wiring is alleviated, and even if the interlayer insulating film is changed in shape, the ends of the metal wiring is prevented from peeling, whereby the disconnection of the pixel electrode can be prevented. Furthermore, the resin film flattens the surface of the interlayer insulating film, and prevents an alignment defect of liquid crystal molecules and a non-uniform electric field, thereby suppressing a minute defect of a light-emitting device caused by the roughness of the surface of the pixel electrode.

Owner:SEMICON ENERGY LAB CO LTD

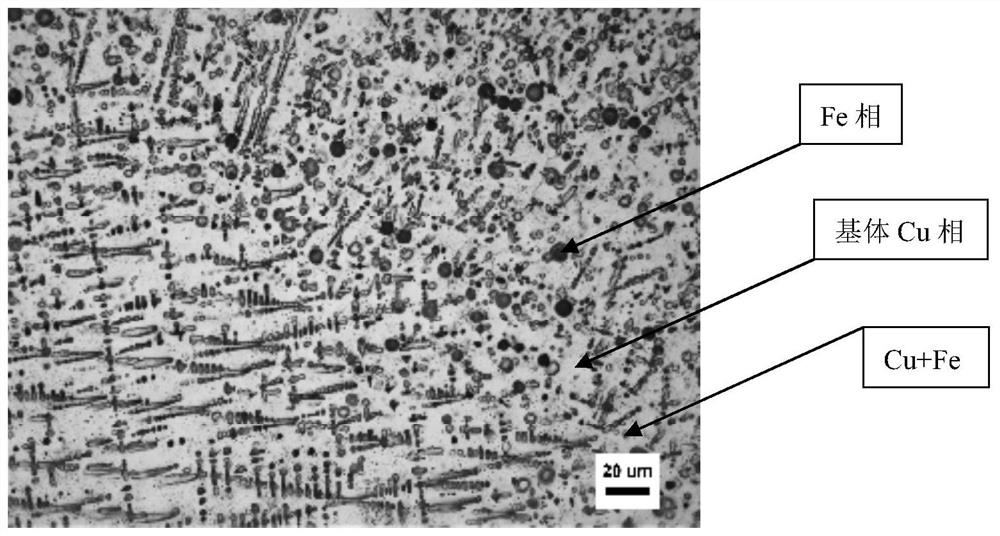

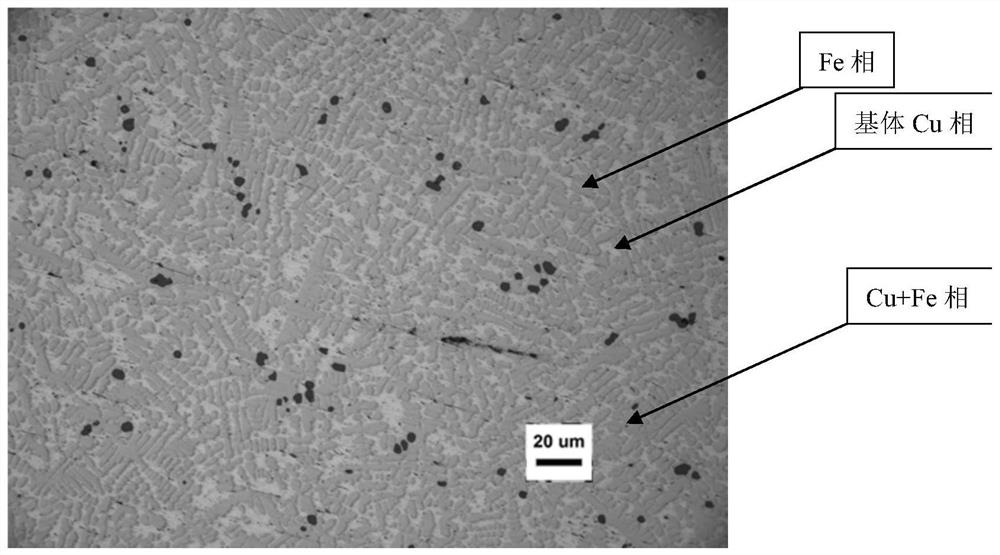

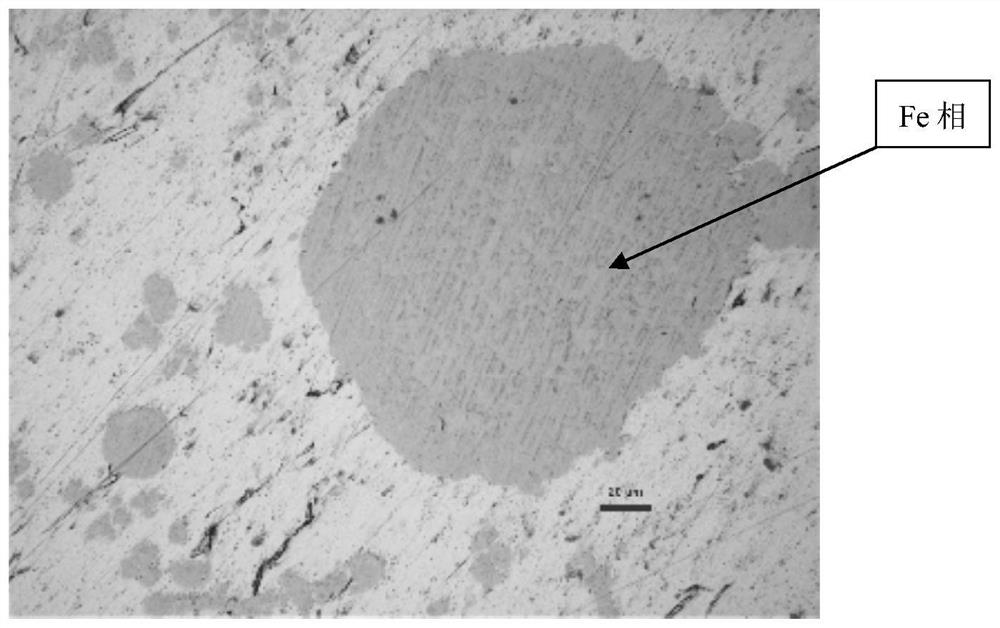

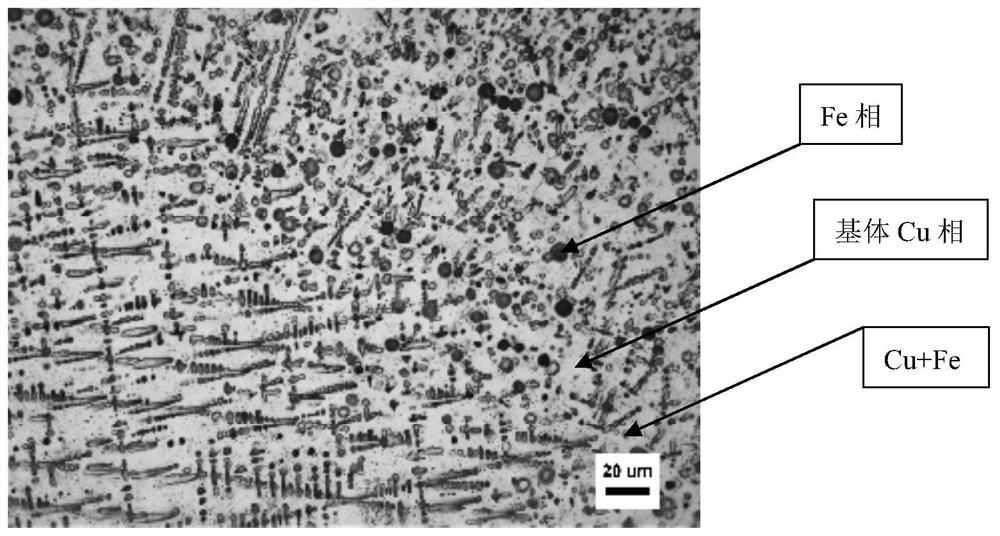

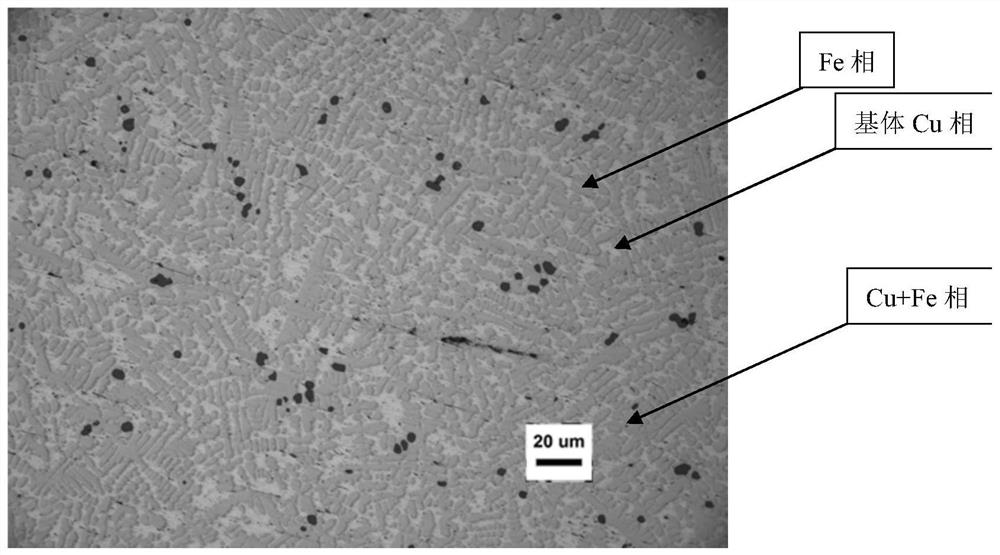

Copper-iron alloy modifier as well as preparation method and use method thereof

ActiveCN113481394AImprove refinementGood spherical effectProcess efficiency improvementIron powderAlloy

The invention discloses a copper-iron alloy modifier which is characterized by comprising a modifier A which comprises, in percentage by mass, 15-25wt% of one or more of copper powder, iron powder and yttrium powder, and the balance copper-calcium alloy powder and inevitable impurities; the content of calcium in the copper-calcium alloy powder is 50wt% or above; and the copper-iron alloy modifier further comprises a modifier B which comprises, in percentage by mass: 10-30wt% of Cu, 20-30wt% of one or more of Te, Mg, Ca, Si and La, and the balance of Fe and inevitable impurities. The modifier B and the modifier A can mutually promote the refinement and spheroidization of crystal grains, a copper-iron alloy phase structure with evenly distributed iron phases can be obtained, the copper-iron alloy with Fe smaller than or equal to 90 wt% can be prepared, ultra-fine wires can be conveniently machined, and the problem of iron phase breaking is solved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

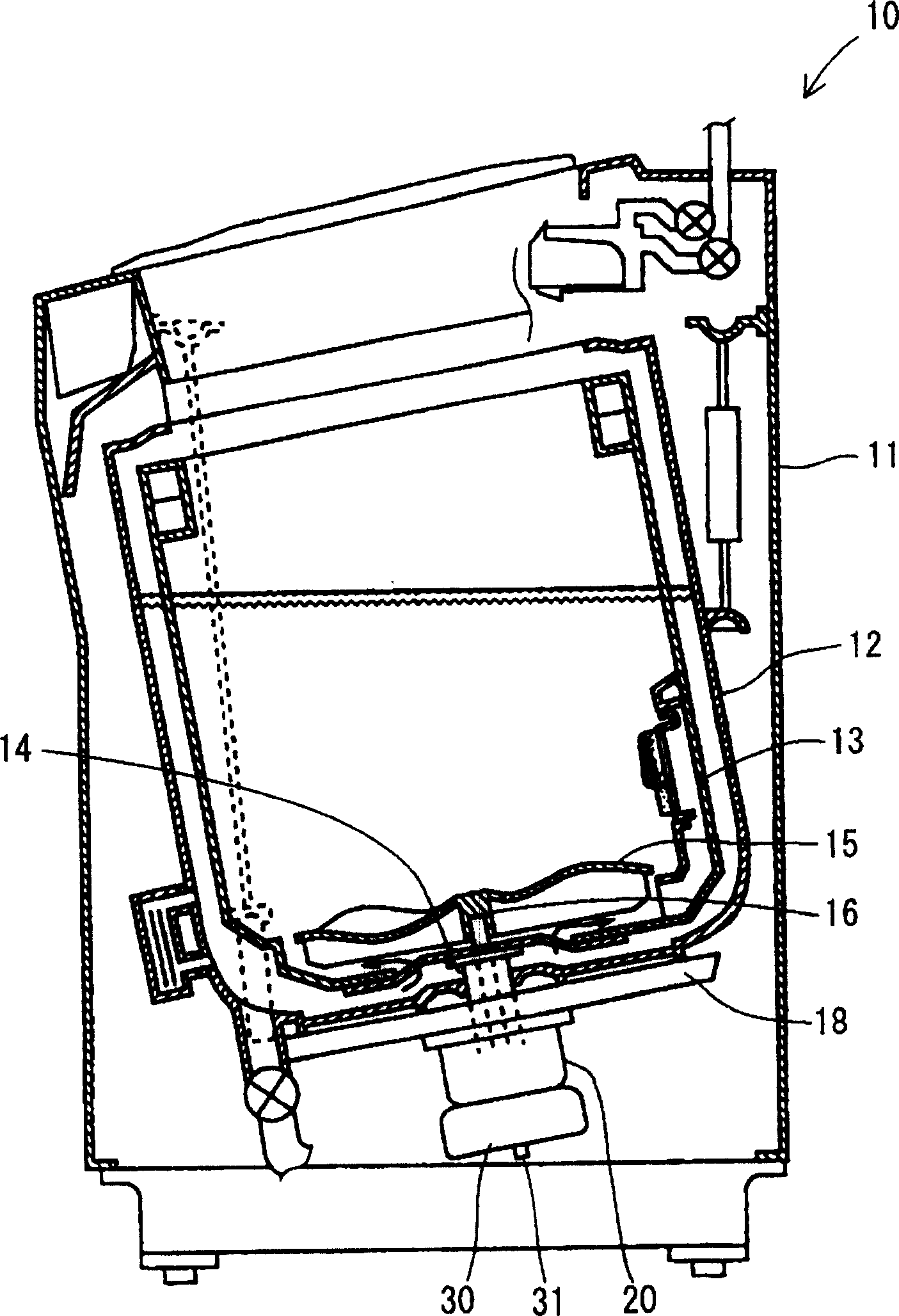

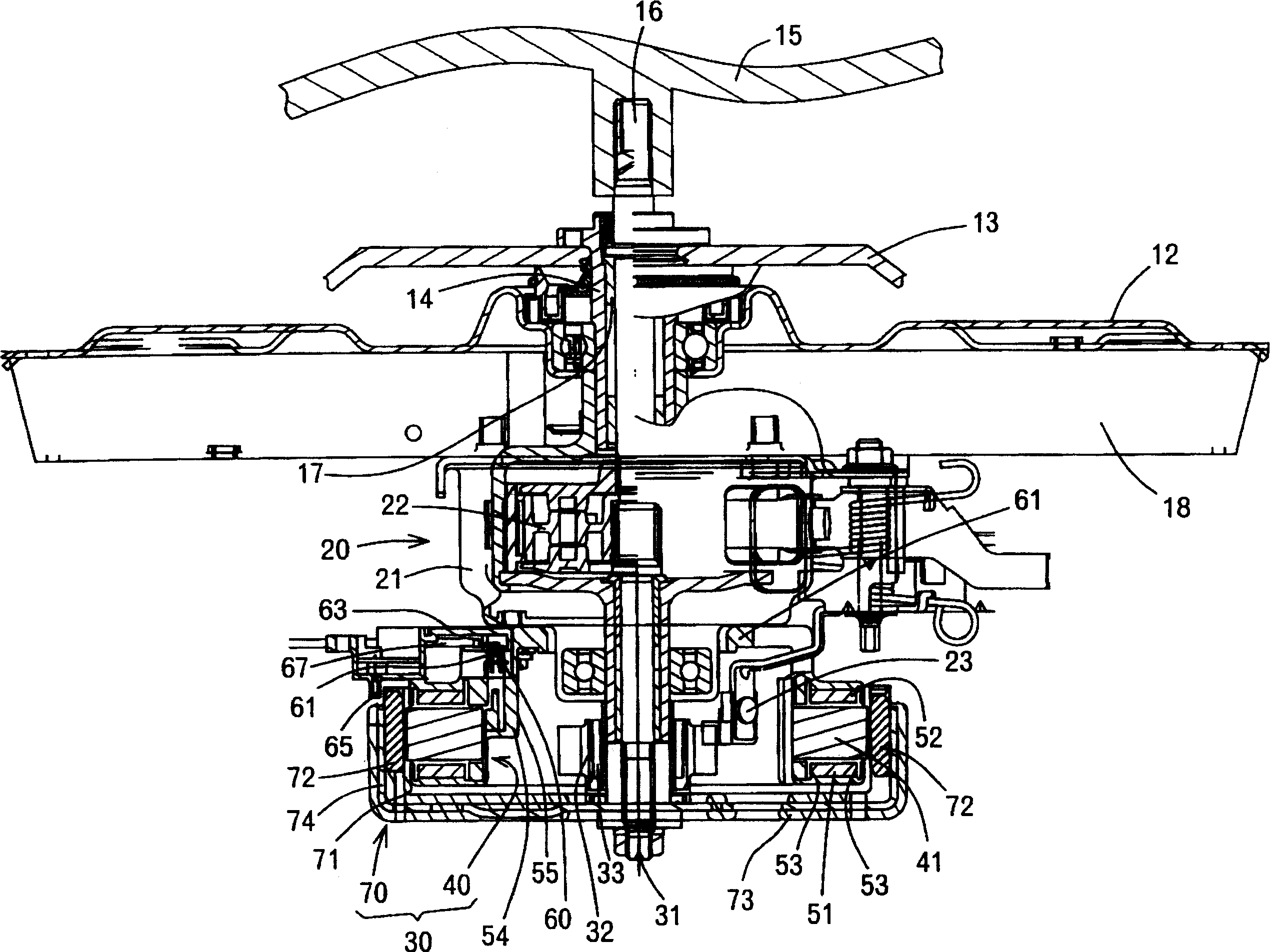

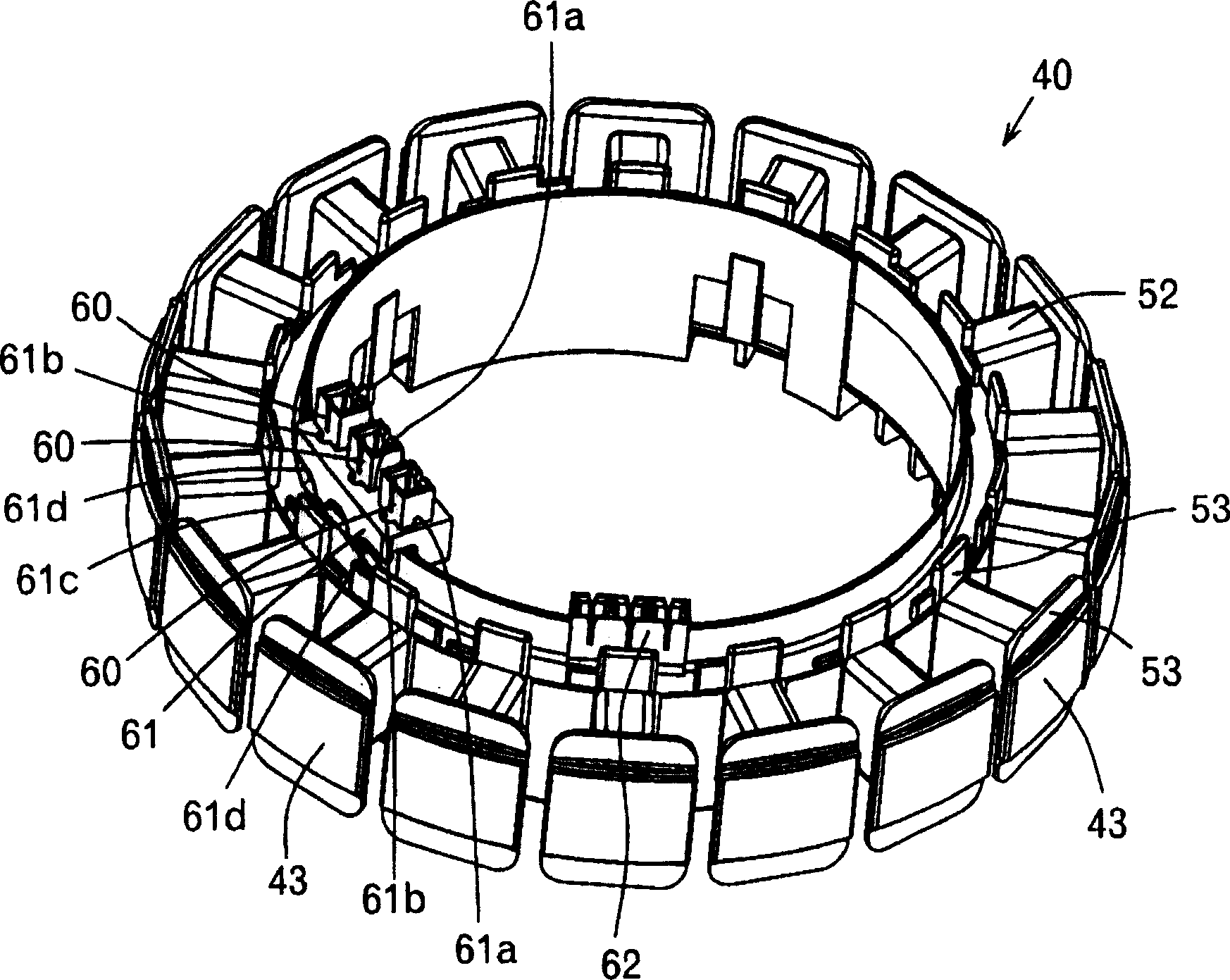

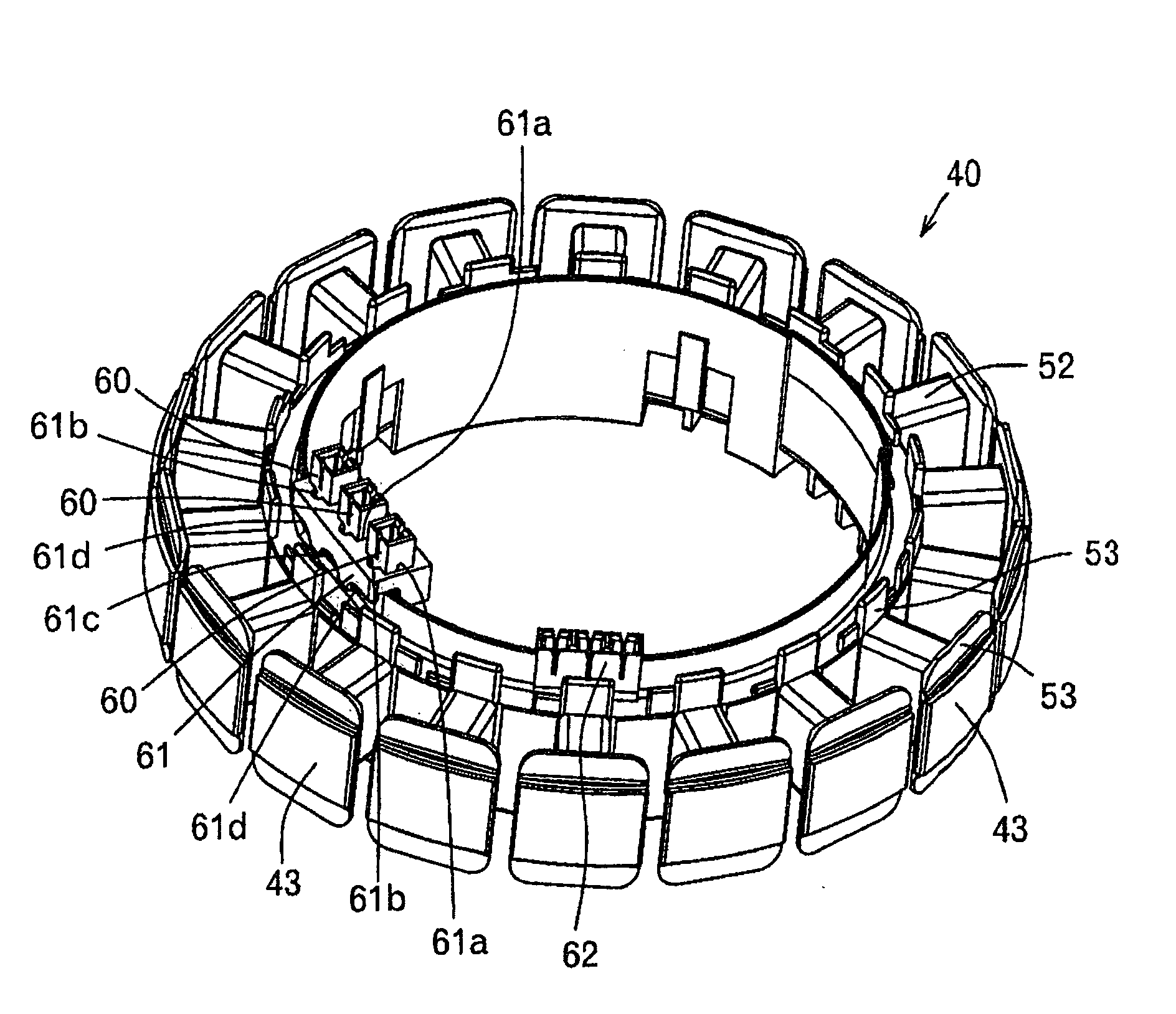

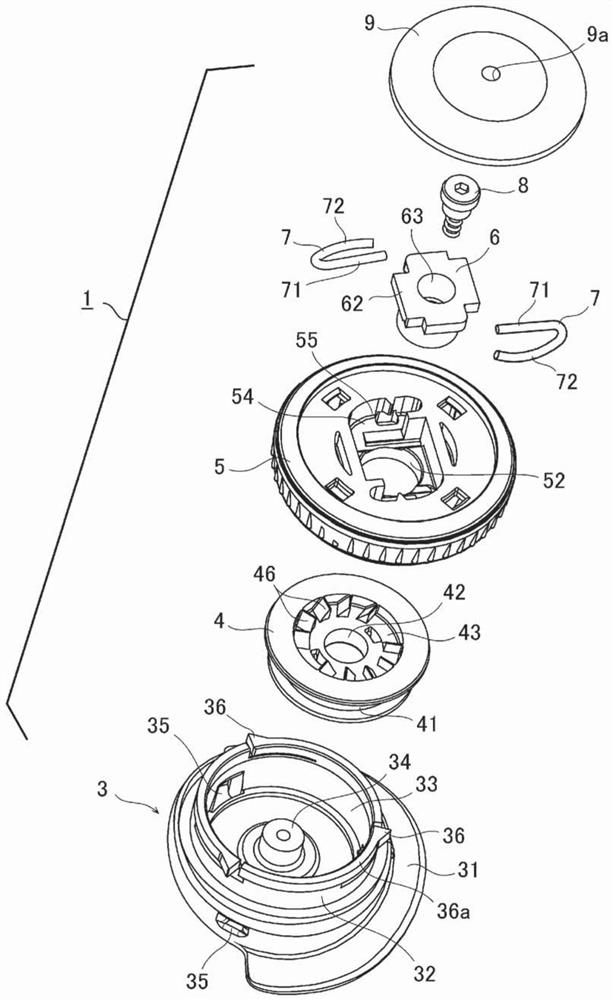

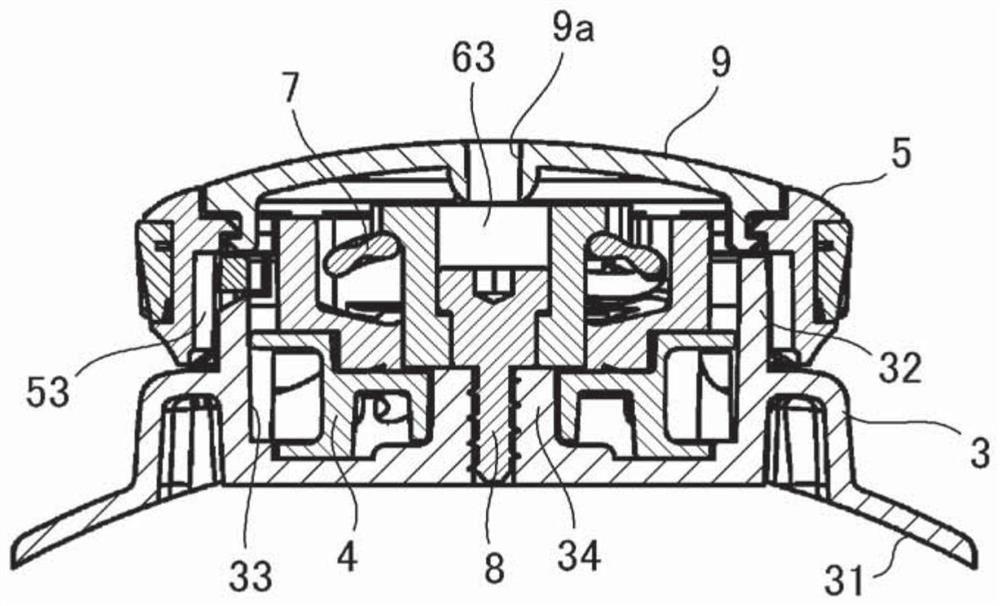

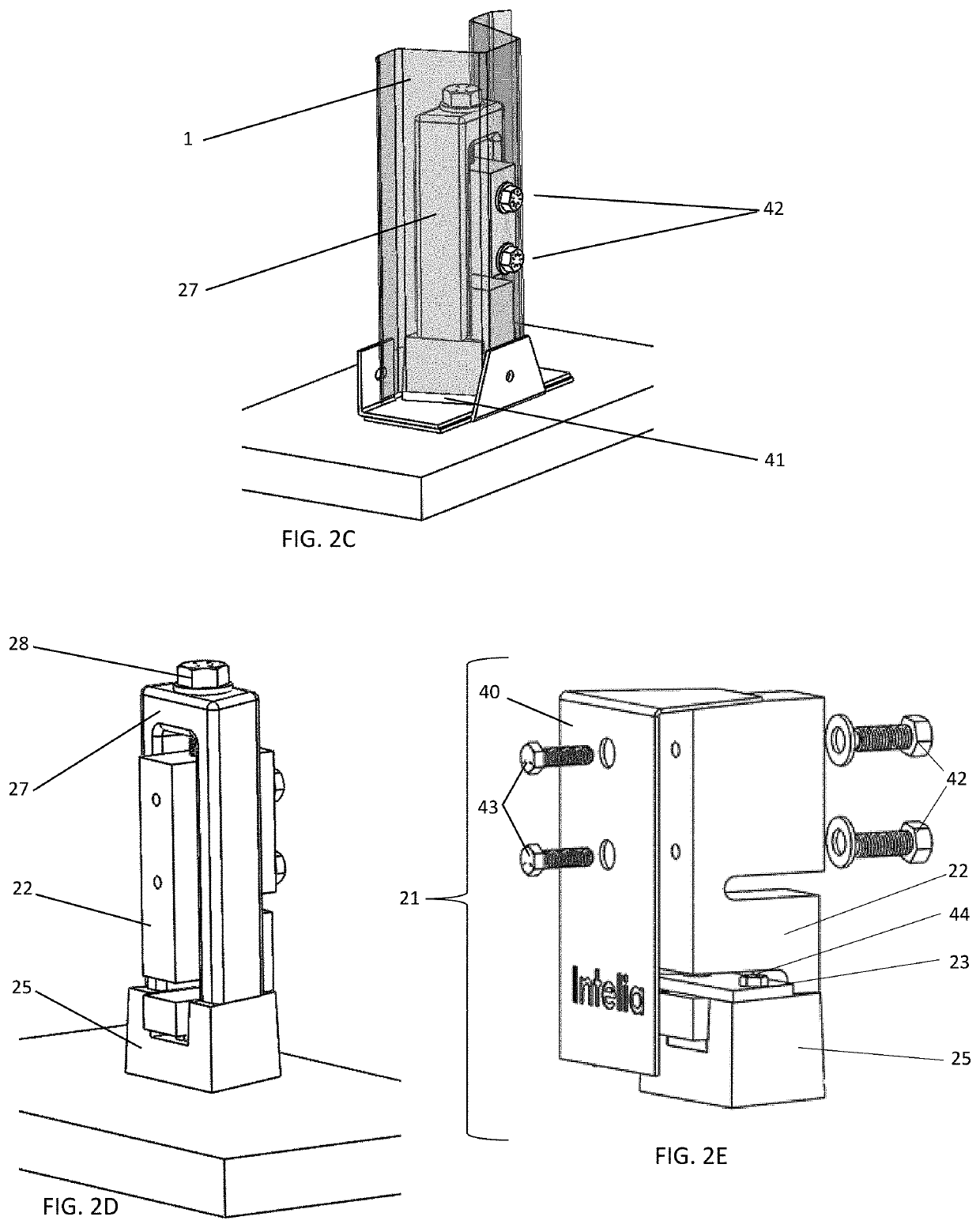

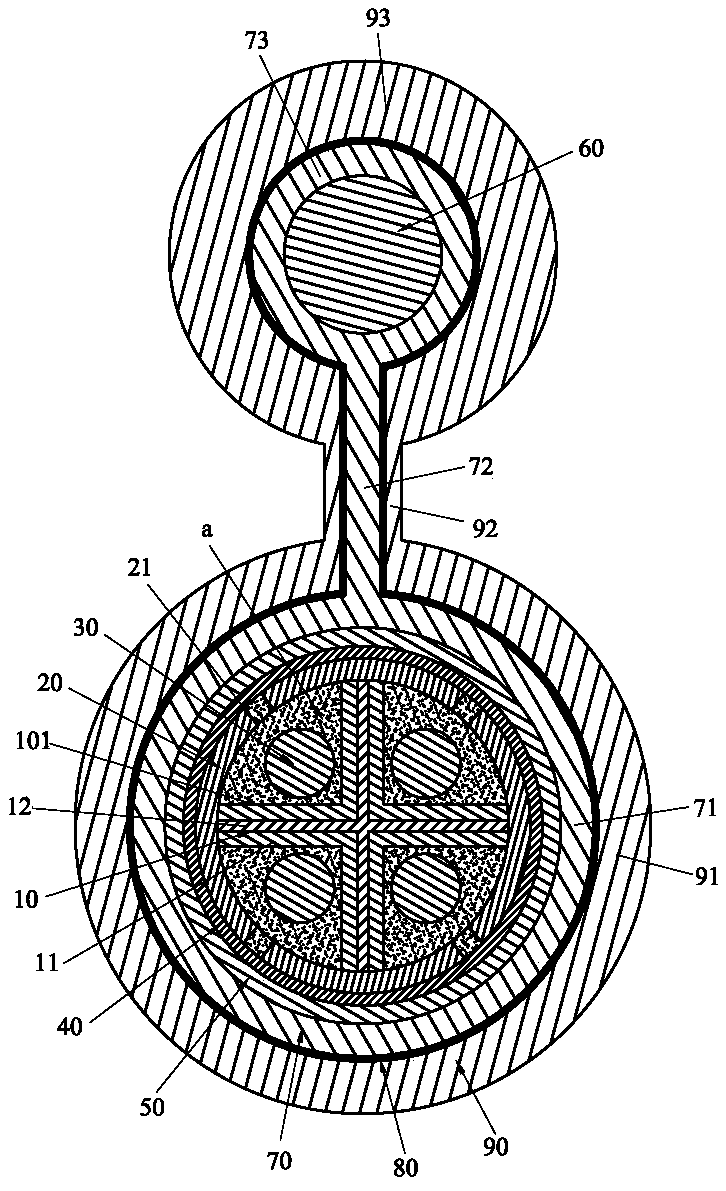

Electric motor for washing machine and washing machine having the electric motor

ActiveCN1913285AReduce performanceGuaranteed waterproof performanceMagnetic circuit stationary partsEngineeringMagnet

The invention provides a motor for washing machine which can be used over a long term without deteriorating the performance by enhancing waterproofness of the coil and the terminal of a stator. The motor for washing machine comprises a stator 40 formed by laminating a plurality of cores 41 having a plurality of teeth 43 projected from an annular yoke 42 toward the outer circumference, molding the core with insulating resin and then winding a coil 51 around the teeth 43 from above the insulating resin mold 52, and a rotor 70 located coaxially with the stator 40 and having a plurality of magnets 72 arranged at positions opposing the teeth 43 wherein the stator 40 is molded of waterproof resin.

Owner:HAIER GRP CORP +1

Fusible link unit with hinge section

ActiveUS7637781B2Easy to engageLow sectionIncorrect coupling preventionEmergency protective devicesBusbarEngineering

A hinge section including bending sections at both side edges of a band plate section is provided in center of a busbar. On both sides of the hinge section, two fuse circuit constituting plate sections are integrally formed to be linked thereto. Two resin housings are assembled by insert molding to the respective fuse circuit constituting plate sections, thus forming two bodies. The two bodies are pivoted in the same direction at the bending sections, and engagement units are locked, thus constituting a fusible link unit having a U-shaped plan view. The two bodies are engaged with each other in vicinity areas of the hinge section in the opposed surfaces of the opposed resin housing when the two bodies are pivoted. The fusible link unit also includes recessed and projected guides guiding the two resin housings to proper positions.

Owner:YAZAKI CORP

Electric motor for washing machine and washing machine having the electric motor

ActiveCN100557920CReduce performanceGuaranteed waterproof performanceMagnetic circuit stationary partsEngineeringMagnet

Provided is a washing machine motor capable of improving the waterproofness of a coil and a terminal portion of a stator and enabling long-term use without deteriorating performance. An outer rotor type washing machine motor comprising: a stator (40) insulated by laminating a plurality of iron cores (41) protruding from an annular yoke portion (42) toward a plurality of teeth (43) on the outer periphery; Plastic resin is molded, starting from the insulating resin mold (52) on the tooth (43) to wind the coil (51) to form; ) are provided with a plurality of magnets (72) at opposing positions, wherein the stator (40) is made into a mold (54) with waterproof resin.

Owner:HAIER GRP CORP +1

Display device and tiled display device including the same

PendingUS20220052240A1Remove and substantially remove sense of disconnectionImprove immersionSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceMaterials science

A display device includes: a substrate including a display area and a non-display area, the substrate having a first portion of a through hole penetrating in a thickness direction thereof in the display area, an etching stopper on one surface of the substrate, the etching stopper having a second portion of the through hole connected to one end of the first portion of the through hole, a display layer on one surface of the etching stopper, and the display layer including a connection line on the second portion of the through hole, an insulating layer on other surface opposite to the one surface of the substrate, the insulating layer having a third portion of the through hole connected to the other end of the first portion of the through hole, and a pad unit on an other surface of the insulating layer and connected to the connection line.

Owner:SAMSUNG DISPLAY CO LTD

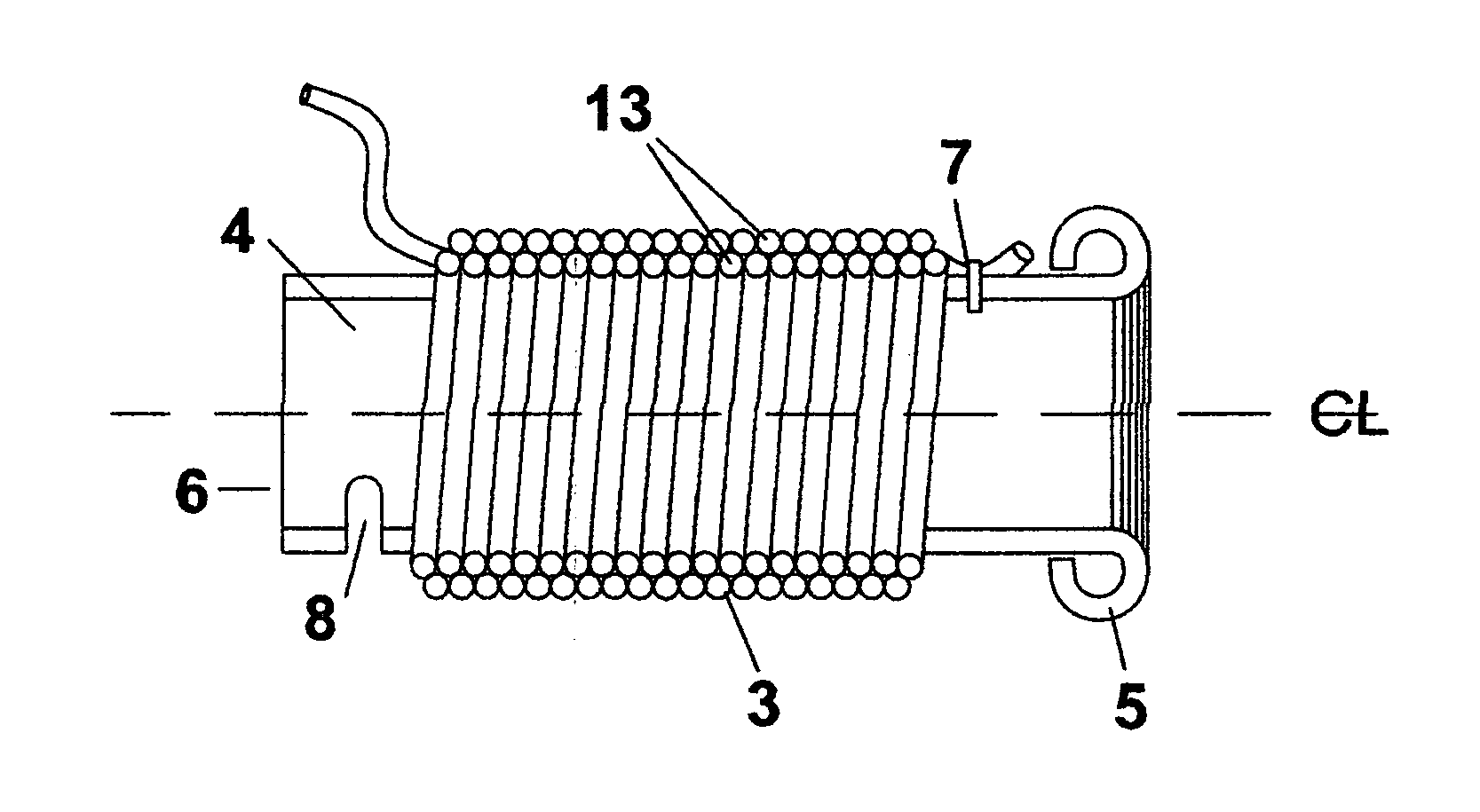

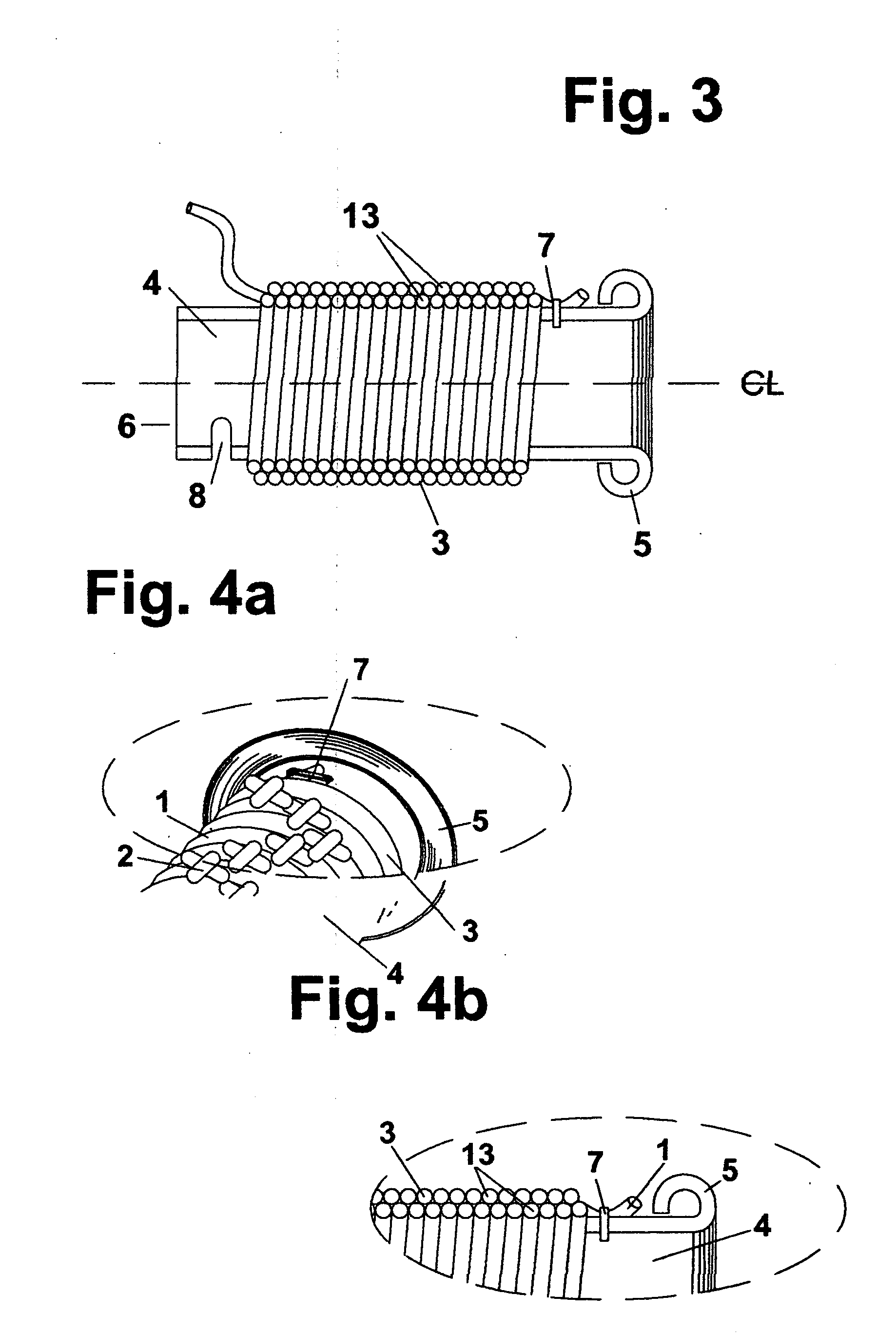

Backlight device and liquid crystal display device incorporating the same

InactiveCN1928665AEliminate disconnectionImprove reliabilityElongate light sourcesTransformers/inductances coils/windings/connectionsBobbinLiquid-crystal display

A backlight device includes a frame, at least one lamp unit each comprising a transformer and a discharge lamp structured into an integral and rigid unit, and also includes a circuit board for lighting the discharge lamp, which is disposed at the back surface of the frame and at which the transformer is mounted at. The transformer of the lamp unit includes: two terminal blocks having terminal pins; a bobbin having a primary winding and first and second secondary windings wound around an outer circumference of the winding core member; a magnetic core; and two lamp connecting terminals attached respectively to the terminal blocks and connected respectively to the first and second secondary windings, wherein the discharge lamp is attached to the transformer with electrodes of the discharge lamp connected directly to the lamp connecting terminals of the transformer, thus forming the lamp unit into an integral structure.

Owner:MINEBEA CO LTD

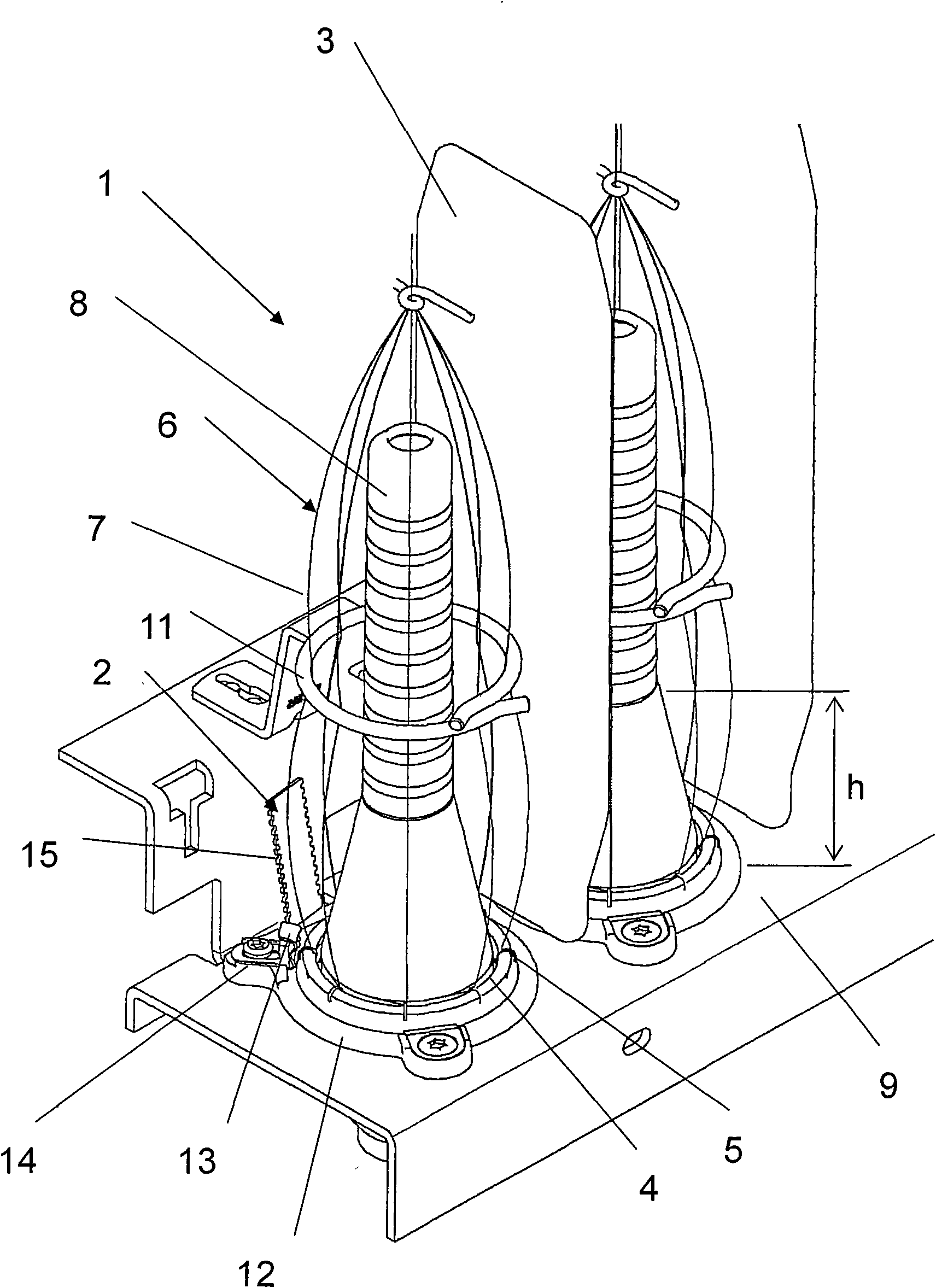

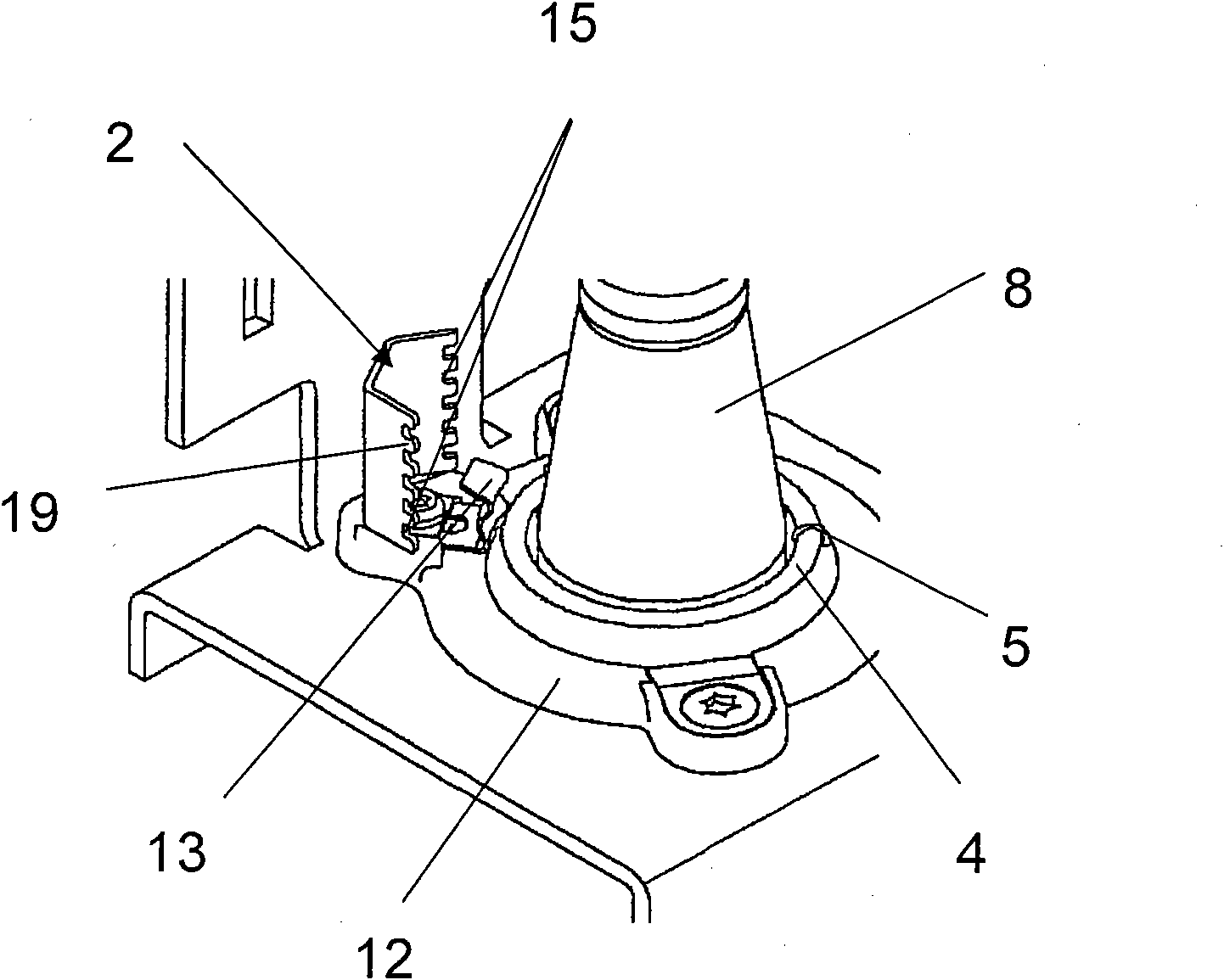

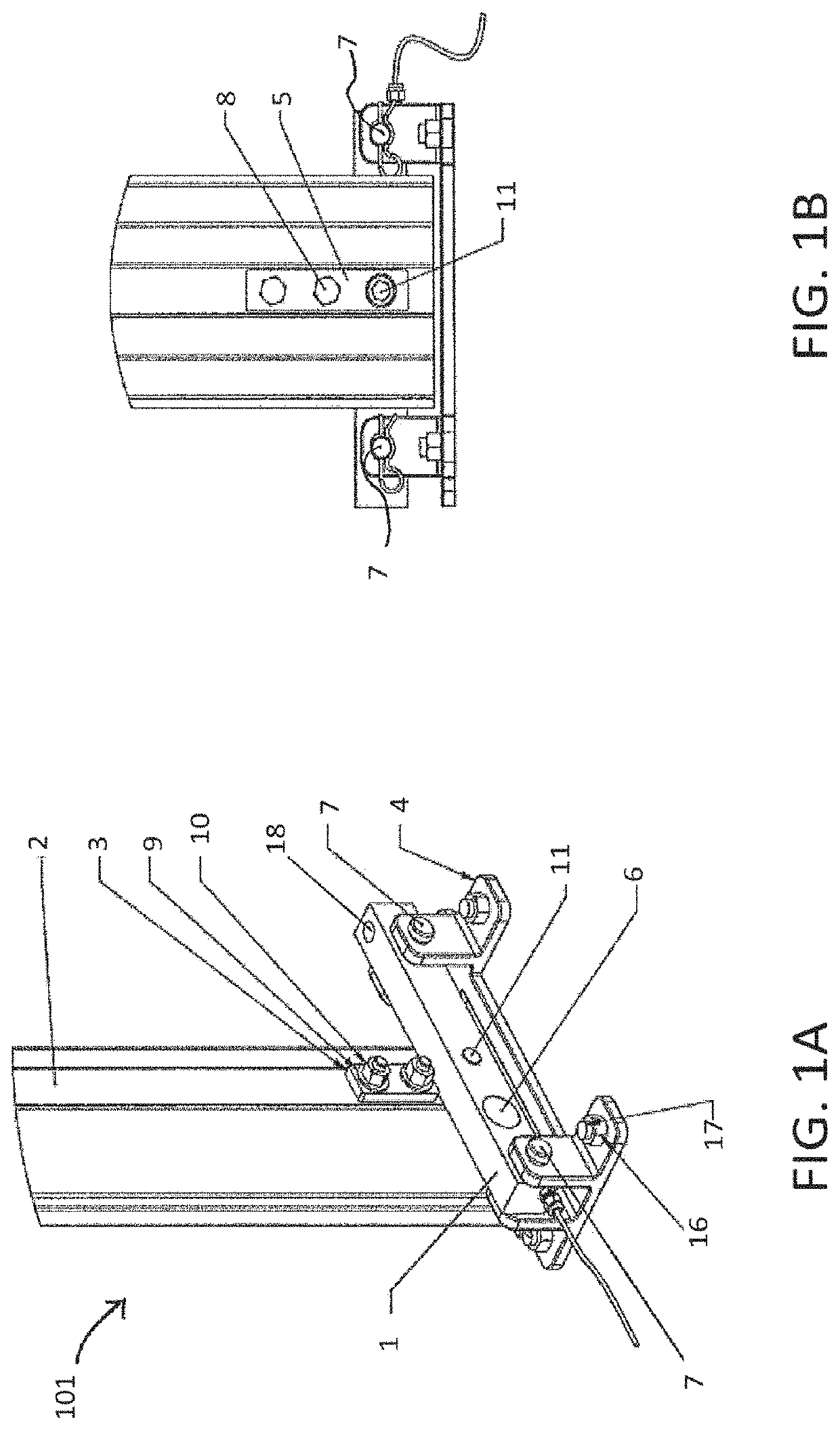

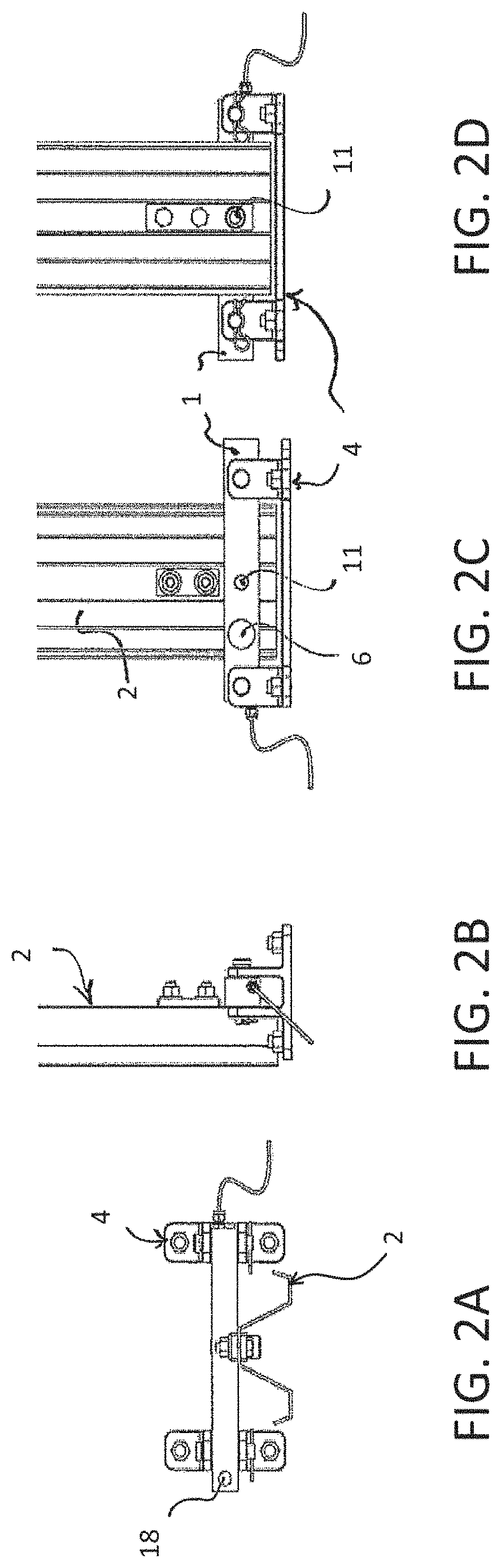

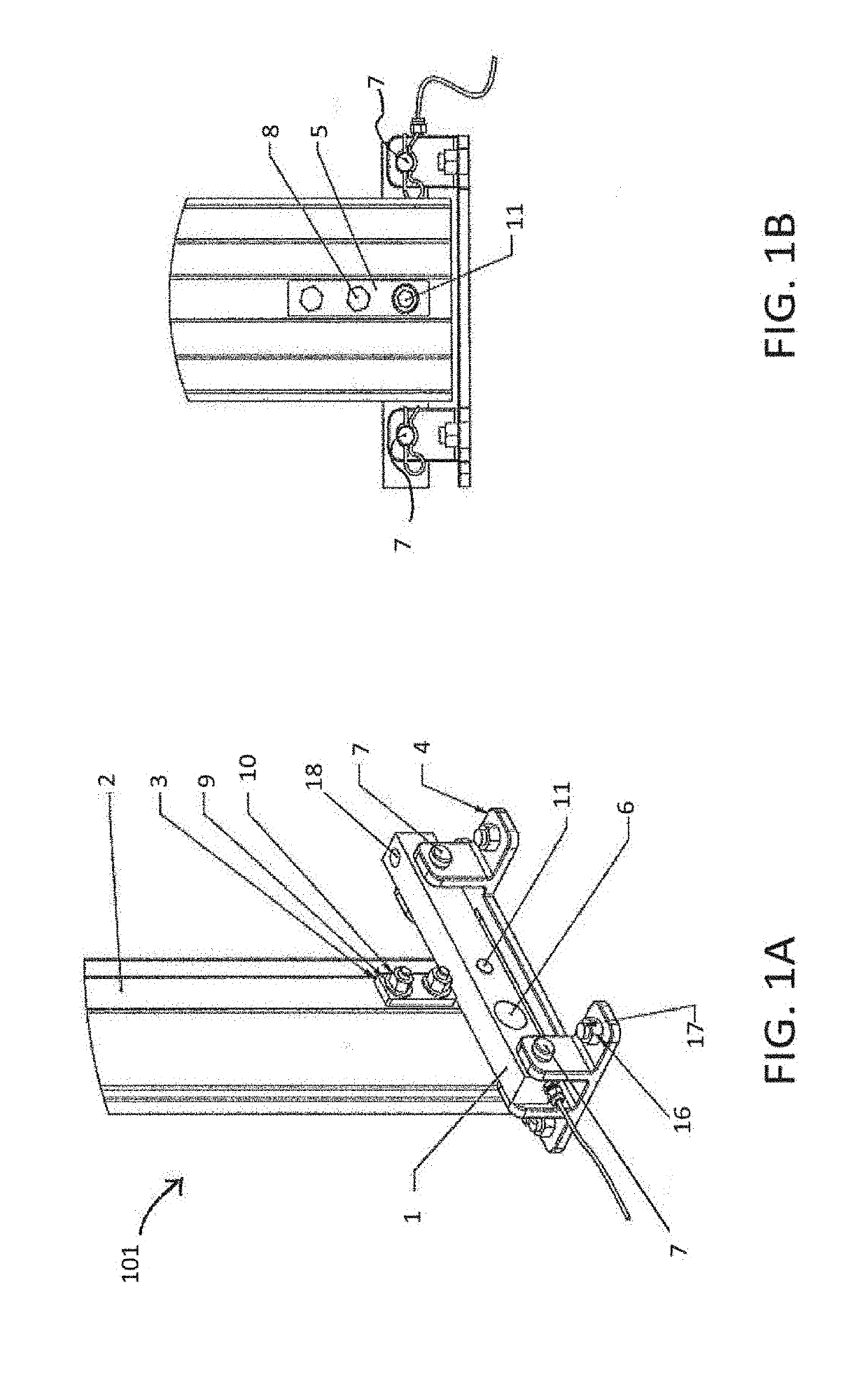

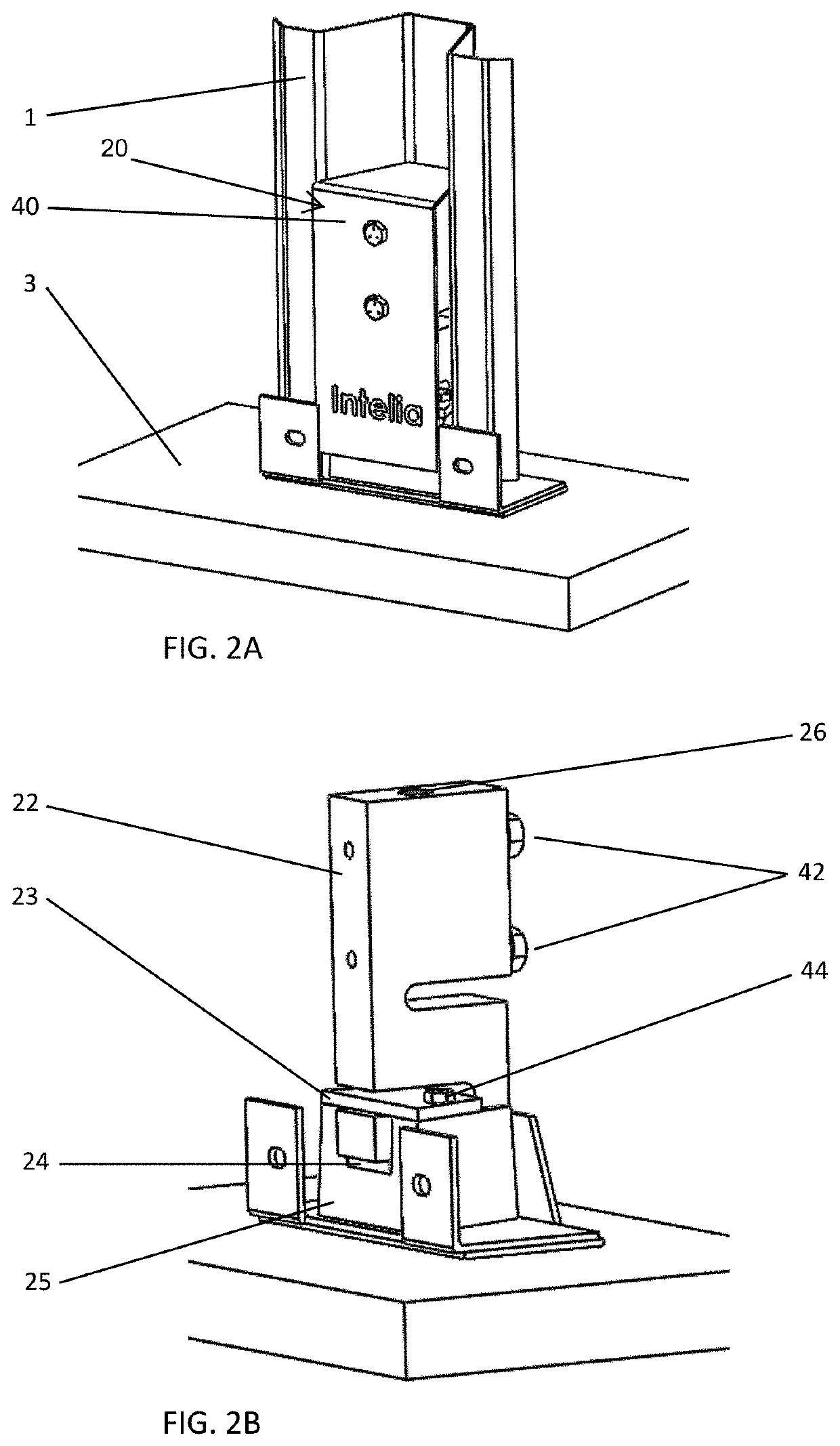

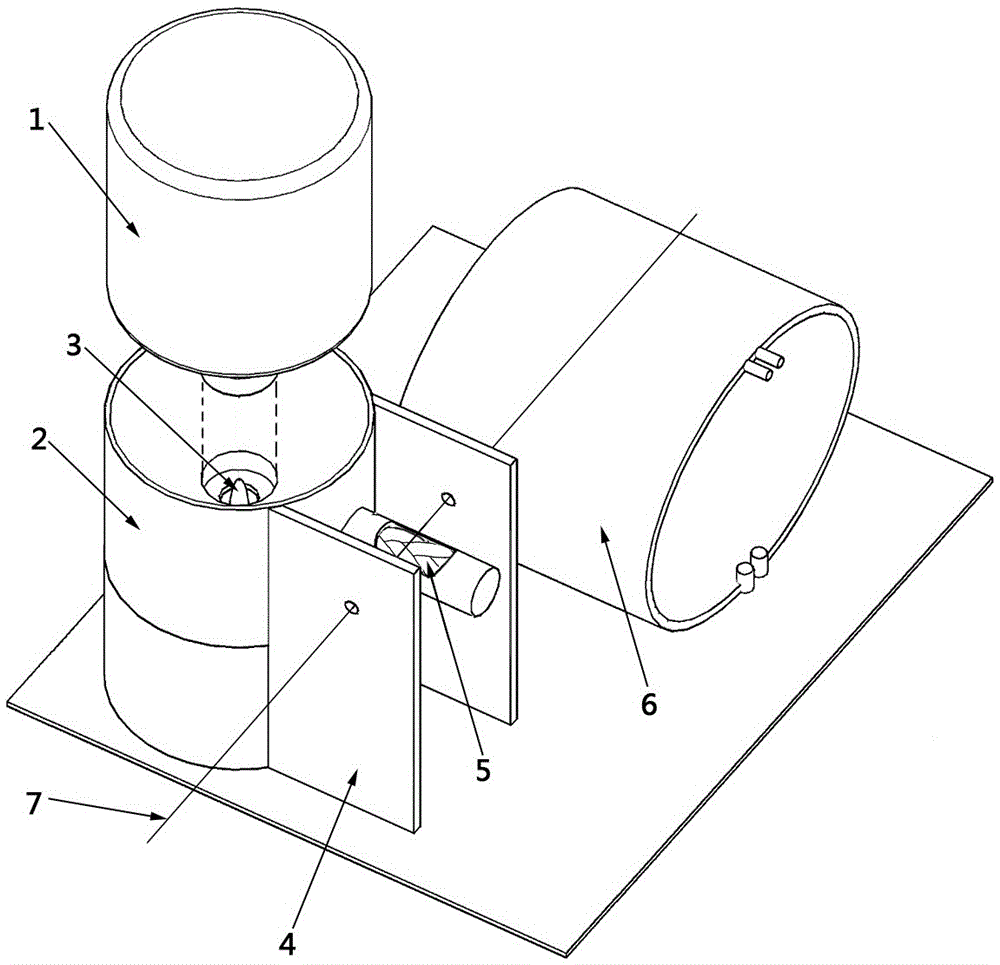

Method and apparatus to monitor a reservoir or a structure

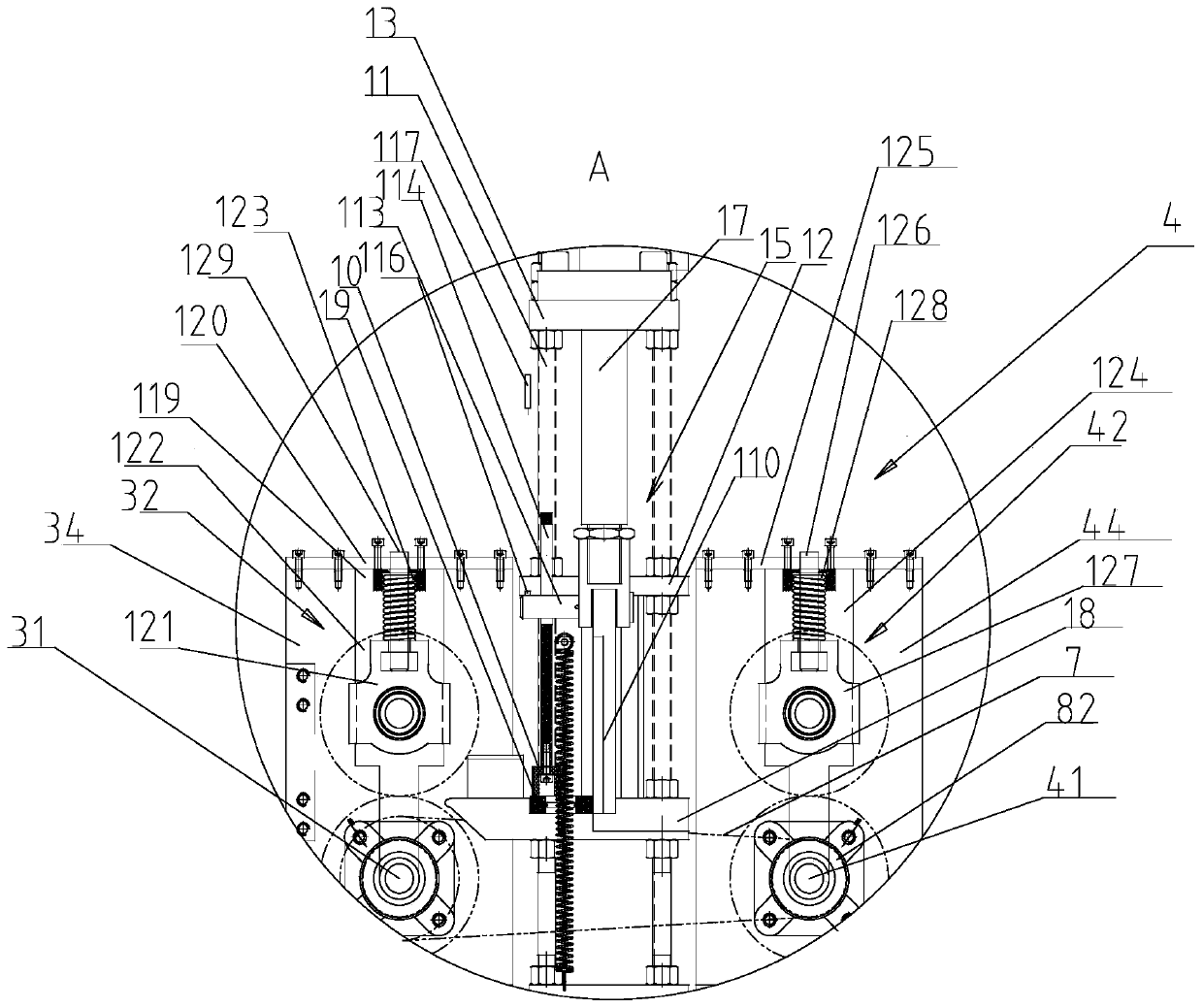

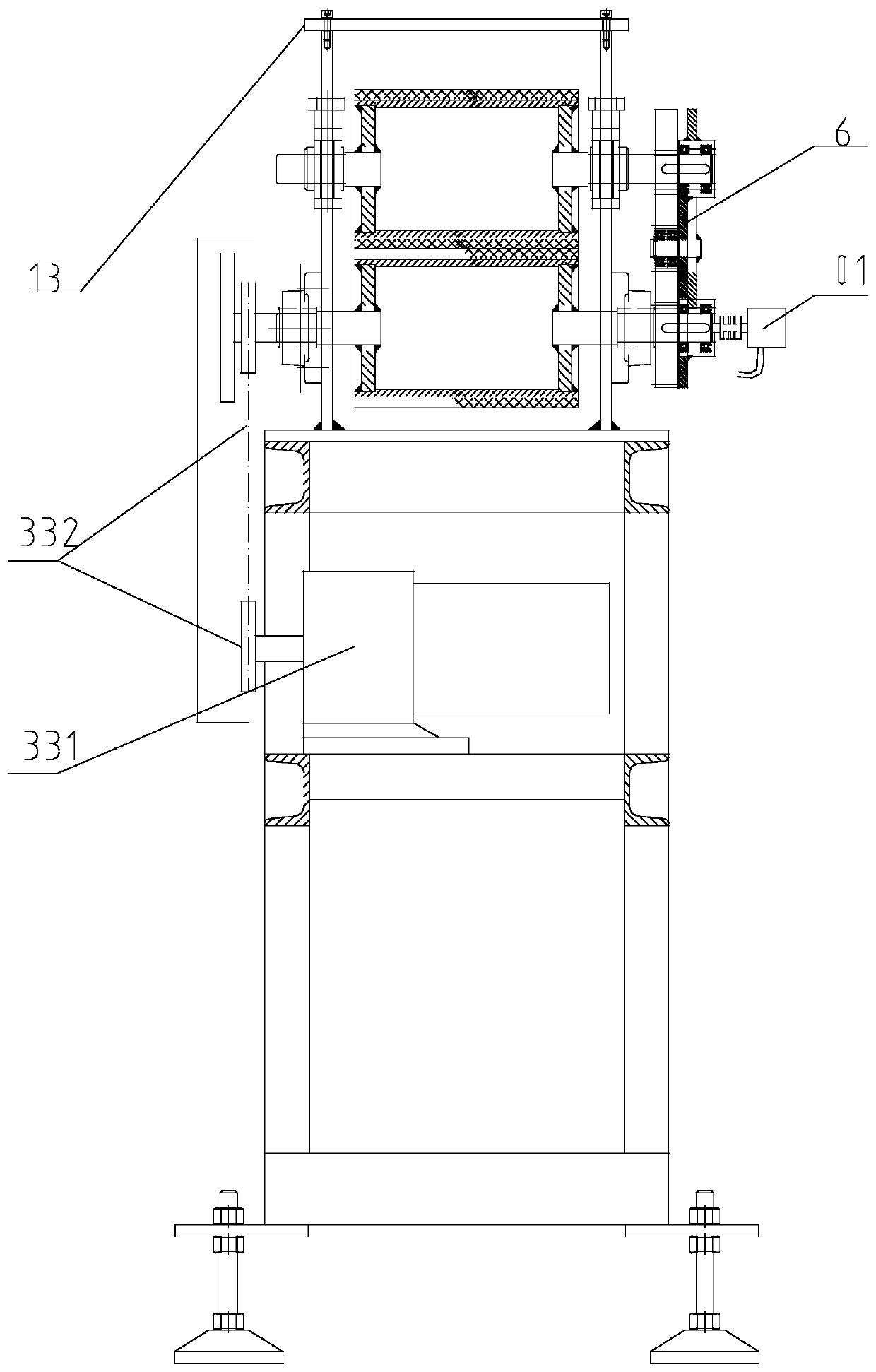

ActiveUS10921178B2Eliminate disconnectionMinimizing installation procedureWeighing relieving/arrestment mechanismsWeighing apparatus with automatic feed/dischargeClassical mechanicsMonitor equipment

A method and apparatus to monitor the weight of a silo or tank is disclosed. The system is adapted to be attached to a leg of the silo and comprises a load cell, a support member anchored to the ground and a lifting device attached to the load cell and to the support member. The load cell comprises two extremities that are attached to the silo leg and comprises an aperture there between. The aperture is preferably threaded to receive the lifting device, such as a bolt. The bolt is rotated using a tool as to induce a movement of the load cell along the axis of the bolt thereby lifting the load cell and the attached silo leg. Strain gauges are attached to the load cell to measure the variation in an electric or optical signal that is translated in human readable data using a monitoring device.

Owner:TECH INTELIA INC

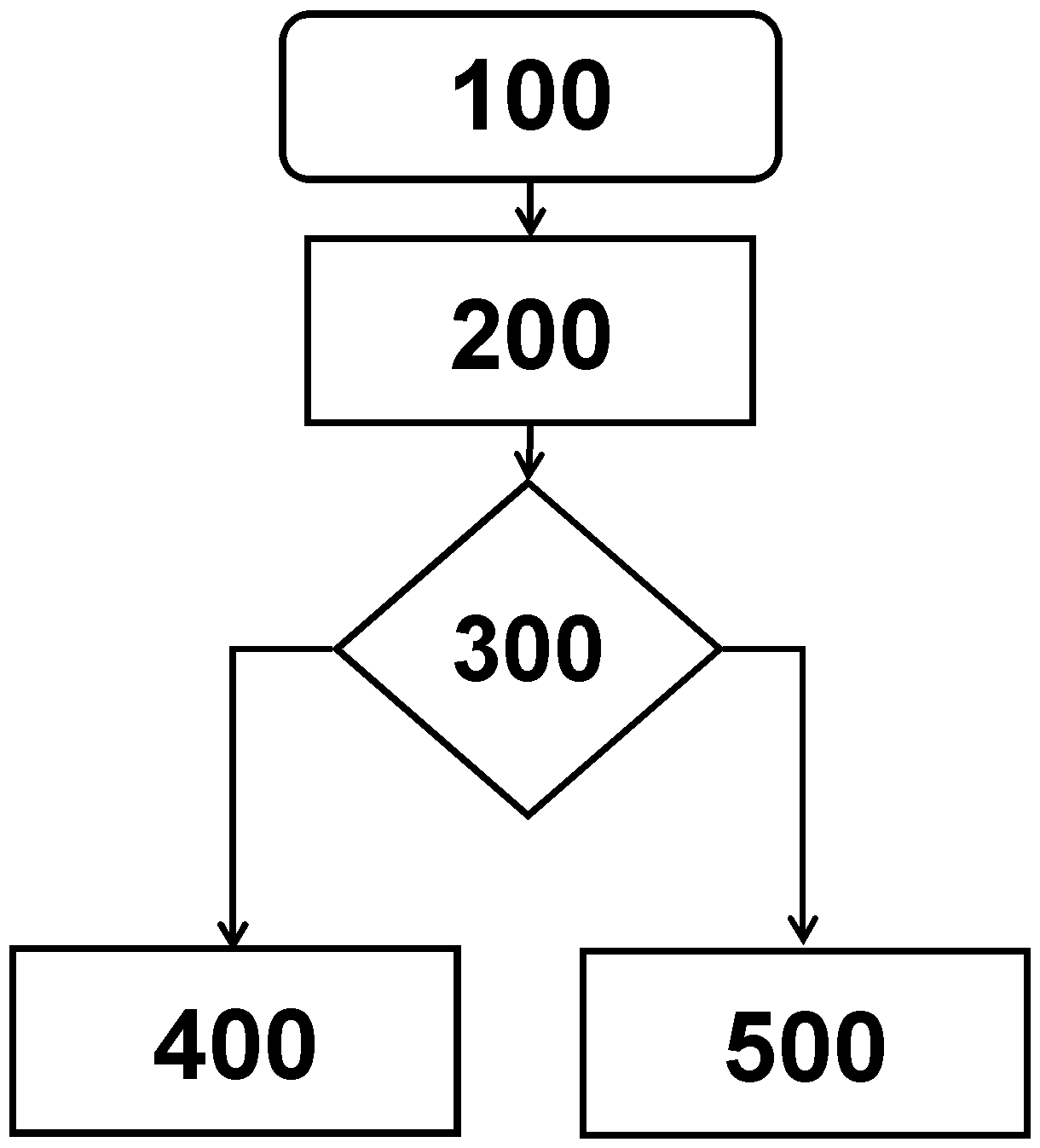

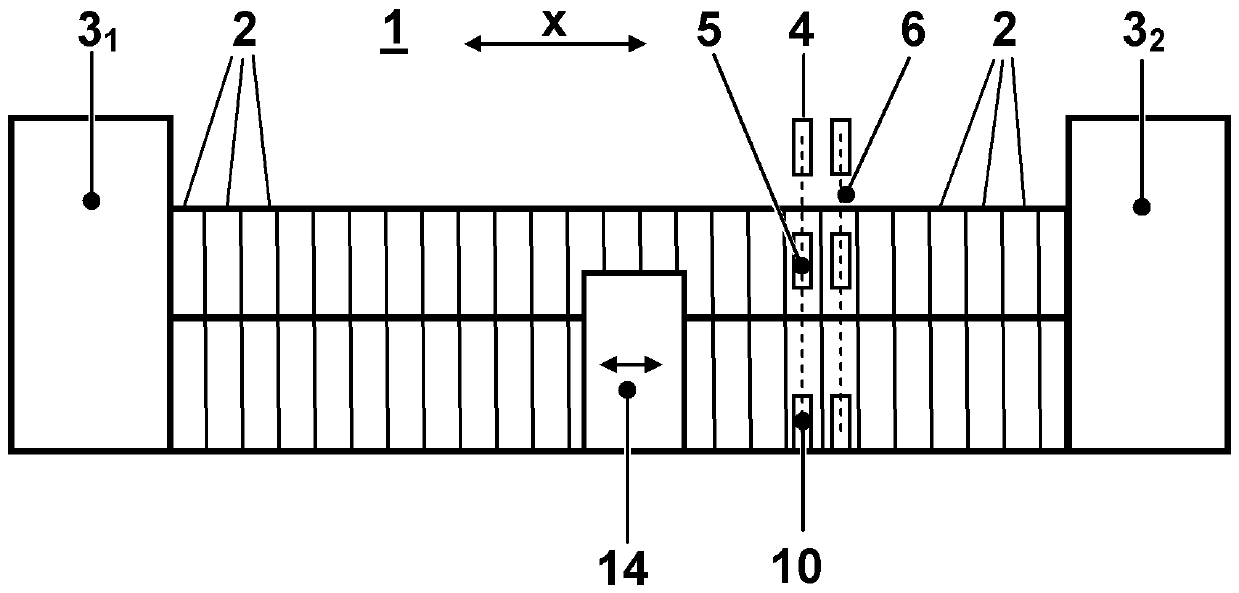

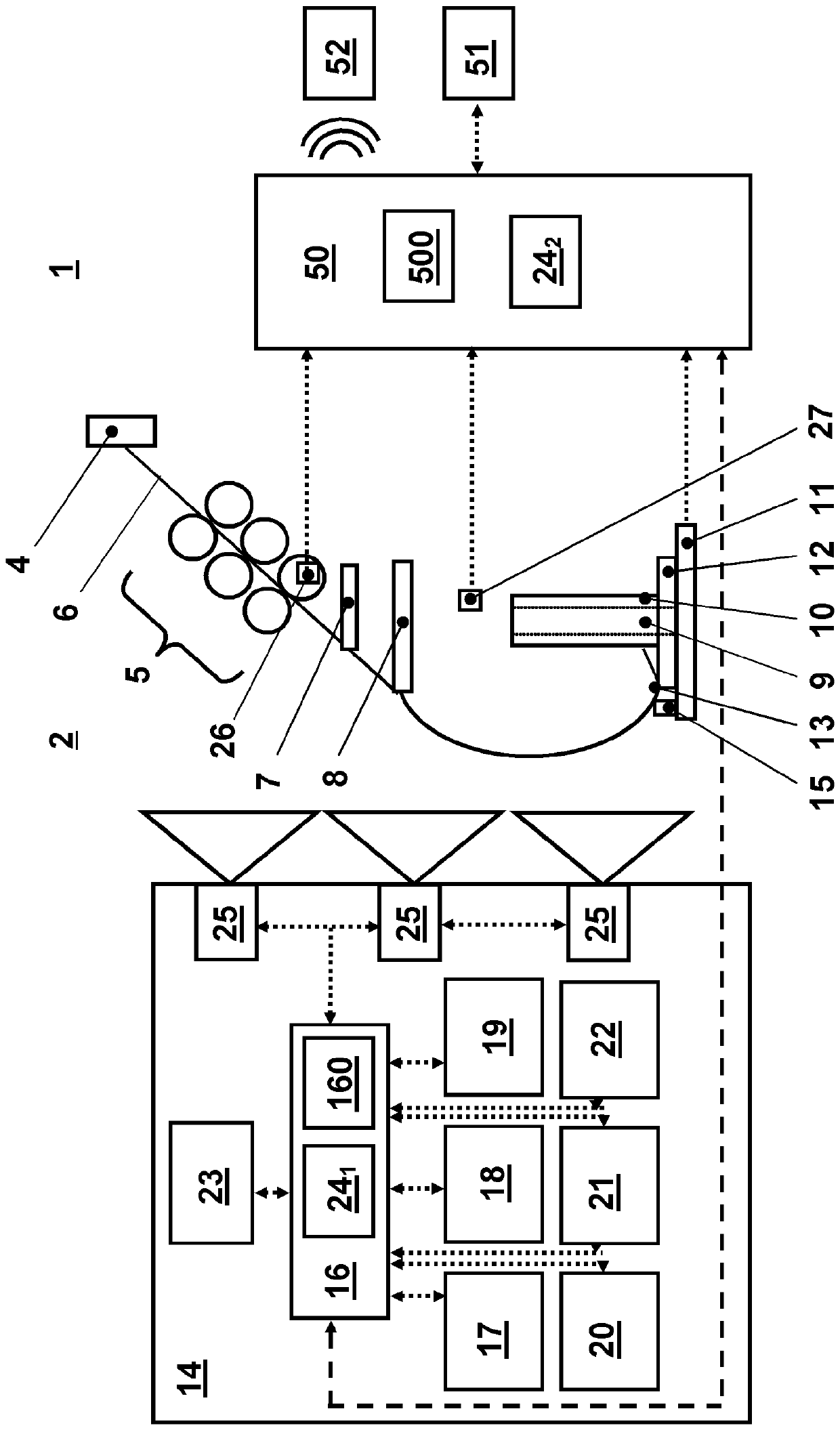

Method for operating a ring spinning machine

A method for operating a ring spinning machine (1) having a service carriage (14) is disclosed, wherein the ring spinning machine (1) has a plurality of spinning stations (2), wherein the spinning stations (2) include a drafting system (5) having a discharge cylinder, a thread guide (7), a balloon control ring (8), a spindle (8), a ring traveller (13), and a spindle monitor (15), and wherein the service carriage (14) moves along the spinning stations (2) on one side of the ring spinning machine (1) and eliminates thread breaks at the spinning stations (2) by means of a standard program. When athread break is detected at a spinning station (2), a status of the spinning station (2) having the thread break is determined in a module (241, 242), and based on the determined status a decision ismade as to whether the thread break can be eliminated by the standard program of the service carriage (14). The invention further relates to a corresponding ring spinning machine (1).

Owner:MASCHINENFABRIK RIETER AG

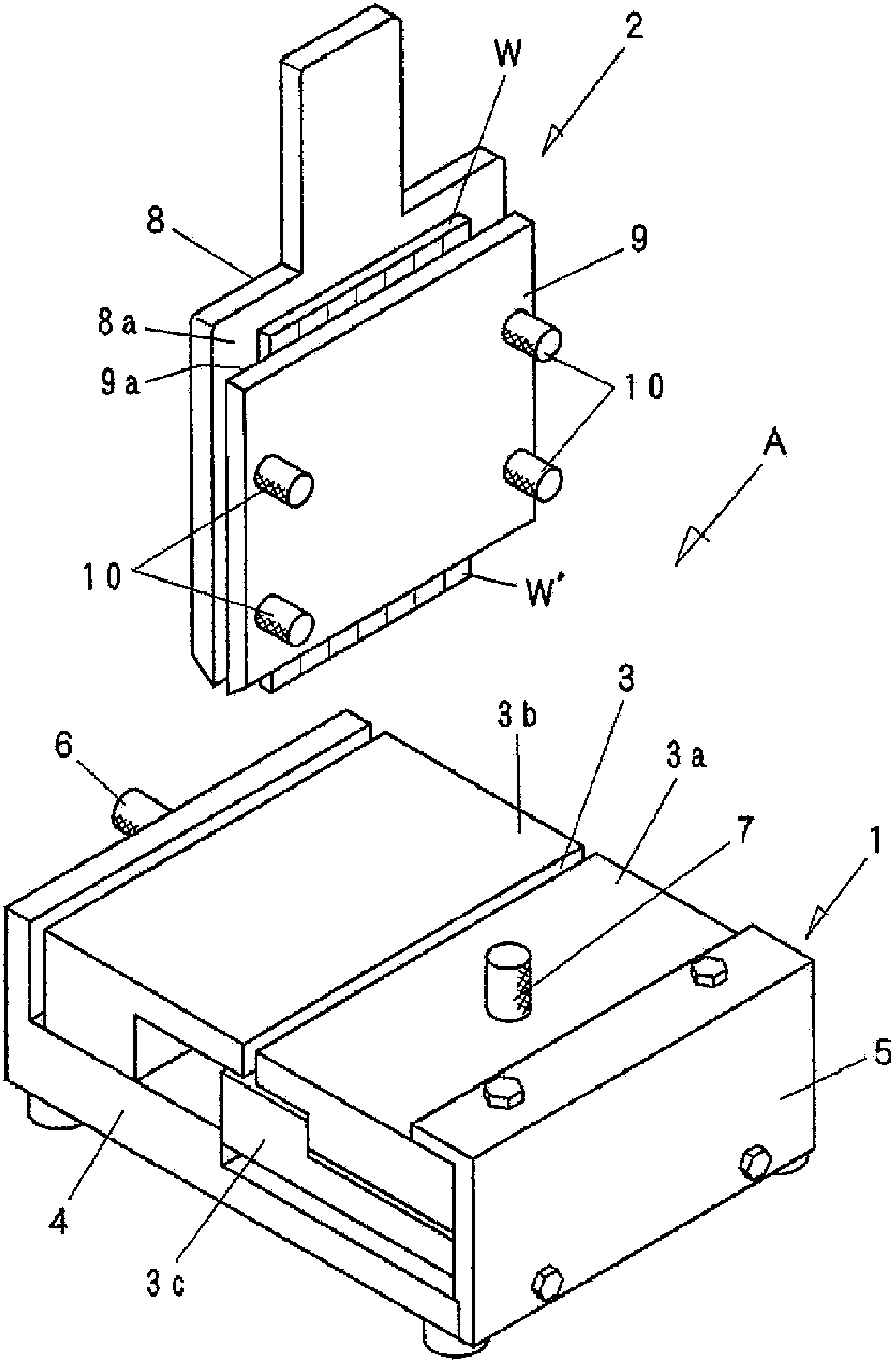

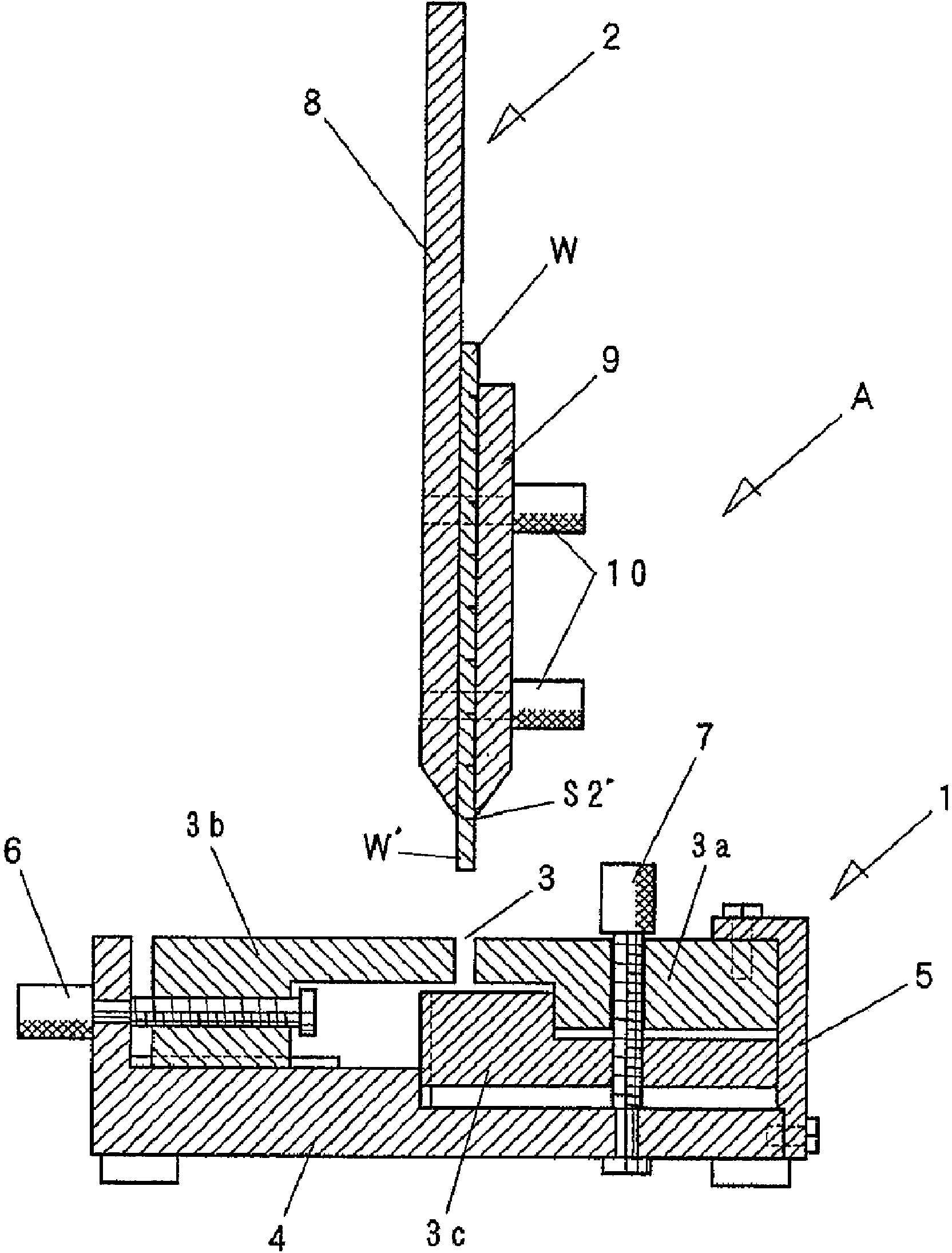

Brittle material base board parting tool and brittle material base board supporting fixture

InactiveCN104249412AEasy to fixEliminate disconnectionWorking accessoriesFine working devicesEngineeringMechanical engineering

Owner:MITSUBOSHI DIAMOND IND CO LTD

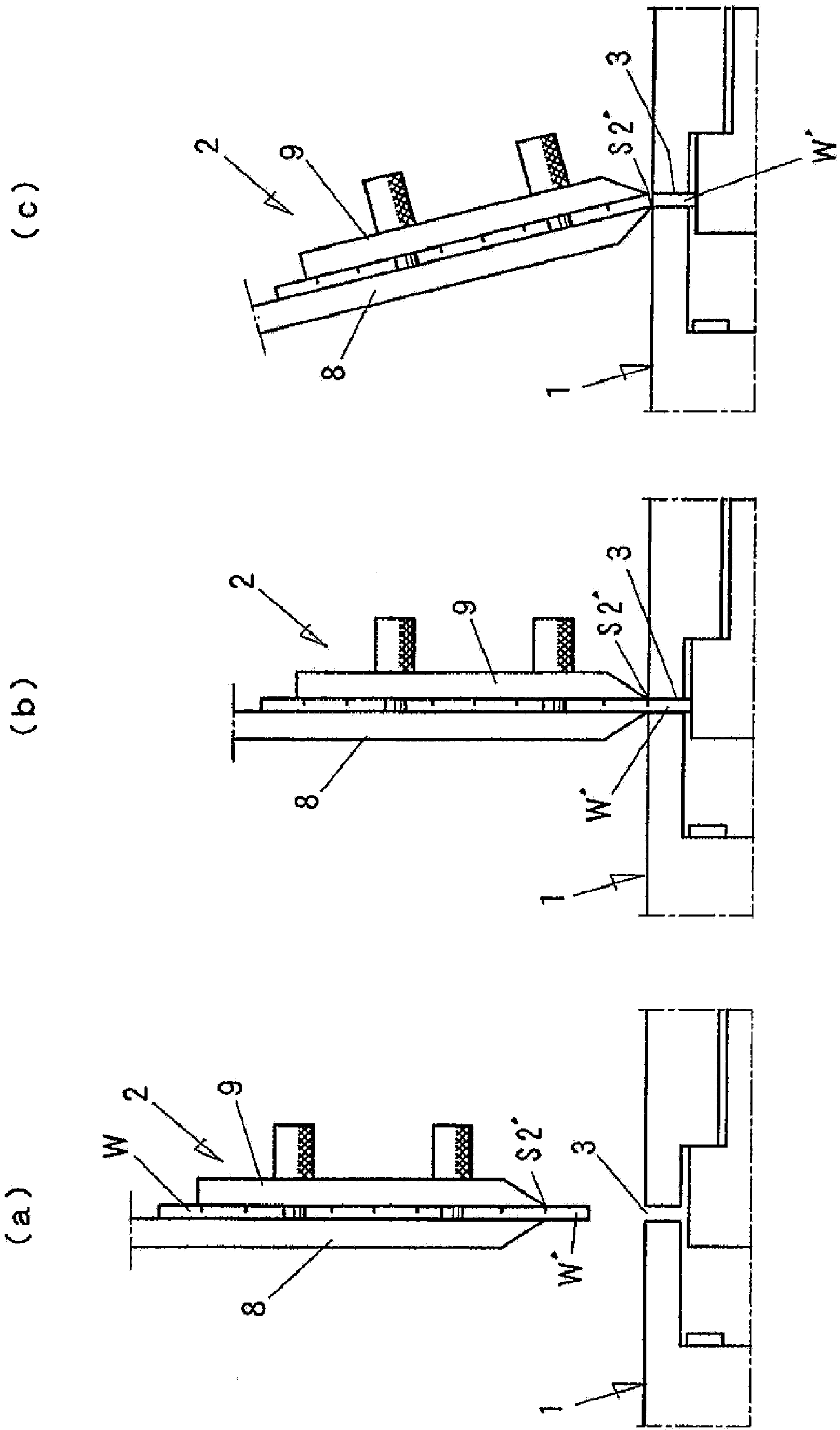

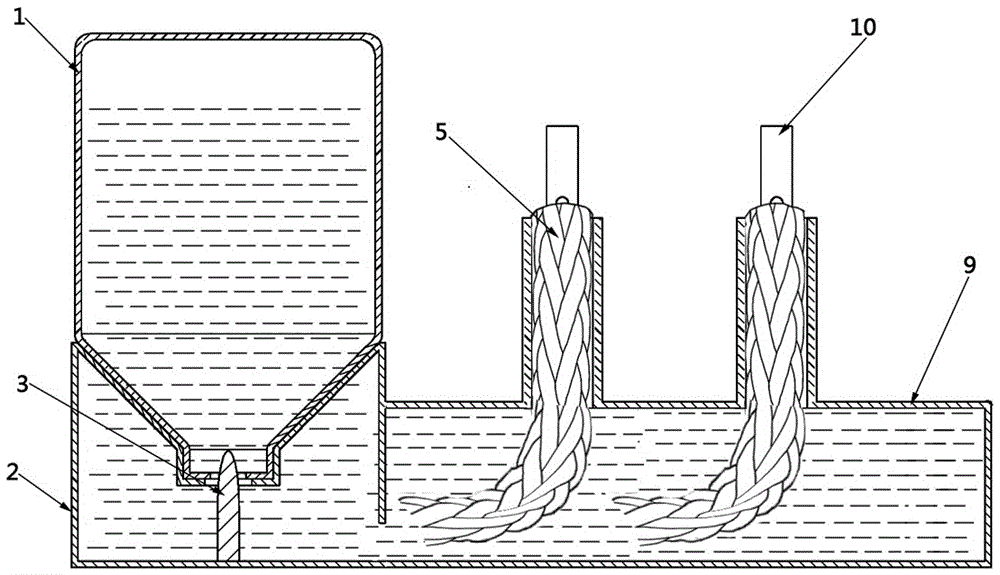

Flexible continuous sucker rod made of synthetic fiber

ActiveCN105443046AHigh tensile strengthHigh elastic modulusDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention provides a flexible continuous sucker rod made of synthetic fiber and relates to the technical field of oil exploitation. The flexible continuous sucker rod made of the synthetic fiber comprises a sucker rod body and a connector in sequence from top to bottom. The sucker rod body is connected with an underground oil pumping device through the connector. The sucker rod body is made of the synthetic fiber. The flexible continuous sucker rod is made of the synthetic fiber, and multiple strength and chemical performance tests verify that equipment loads are reduced greatly, and strength, toughness and various chemical properties of the sucker rod body are improved; moreover, the working procedure of manufacturing the sucker rod is simplified, time is saved, and efficiency is improved.

Owner:青岛新胜石油机械有限公司

Method and apparatus to monitor a reservoir or a structure

ActiveUS20190293479A1Reduce disadvantagesEliminate disconnectionWeighing relieving/arrestment mechanismsWeighing apparatus with automatic feed/dischargeEngineeringStrain gauge

A method and apparatus to monitor the weight of a silo or tank is disclosed. The system is adapted to be attached to a leg of the silo and comprises a load cell, a support member anchored to the ground and a lifting device attached to the load cell and to the support member. The load cell comprises two extremities that are attached to the silo leg and comprises an aperture there between. The aperture is preferably threaded to receive the lifting device, such as a bolt. The bolt is rotated using a tool as to induce a movement of the load cell along the axis of the bolt thereby lifting the load cell and the attached silo leg. Strain gauges are attached to the load cell to measure the variation in an electric or optical signal that is translated in human readable data using a monitoring device.

Owner:TECH INTELIA INC

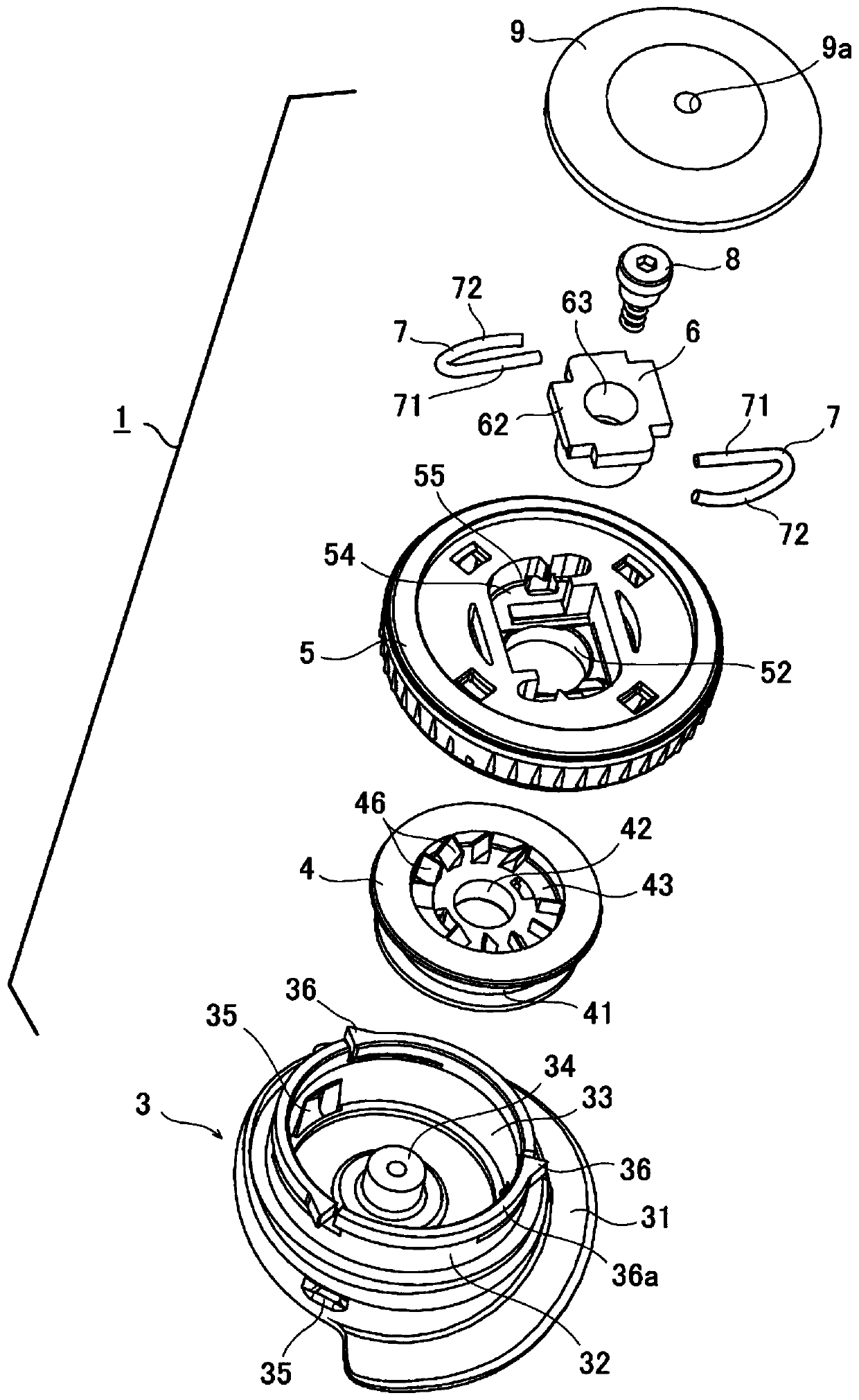

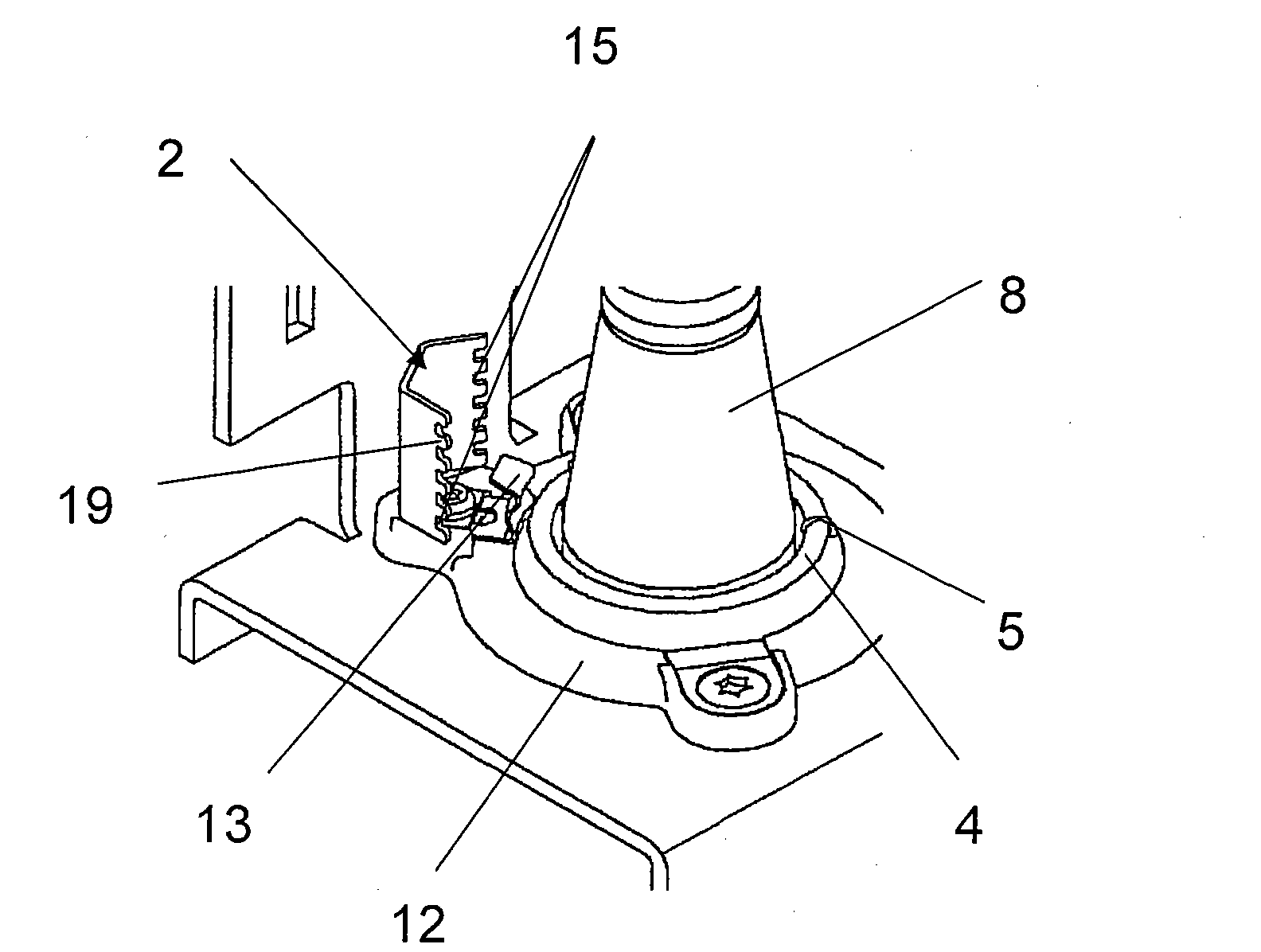

Article equipped with cord wind-up device

ActiveCN110234247AEliminate disconnectionIncreased durabilityShoe lace fasteningsBucklesEngineeringWind direction

The present invention provides an article equipped with a cord wind-up device that provides excellent durability due to being able to prevent a cord from snapping. This article S equipped with a cordand a cord wind-up device 1 is provided with: a drum 4 having a wind-up part 41 around which the cord 2 is wound; a drum housing part 33 in which the drum 4 is rotatably housed; two cord exits 35 which are formed at two locations in a peripheral wall 32 constituting the drum housing part 33 and through which the cord 2 is drawn out from an inner surface of the peripheral wall 32 toward the outsideof the cord wind-up device 1, wherein the cord wind-up device 1 is configured such that, when constriction of the cord 2 is relaxed in a case where the central portion of the drum housing part 33 isnot aligned with the two positions where the cord exits 35 are formed, even if the cord 2 is drawn out of one of the cord exits 35 to a maximum extent, no kink that reverses the winding direction of the cord 2 or no fatigue that results from repeated bending of the cord 2 occurs at a link fix part P between the wind-up part 41 and the cord 2 and corresponding to the other cord exit 35.

Owner:JAPANA CO LTD

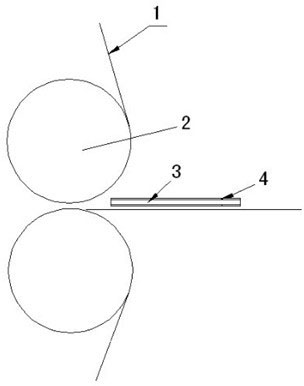

Pressing film method of flexible printed circuit

InactiveCN102256446AEliminate disconnectionEliminate Bubble ProblemsPrinted circuit manufactureThin layerMechanical engineering

The invention provides a pressing film method of a flexible printed circuit. The method comprises the following steps: smearing a thin layer of water with a wet cloth on a material to be pressed with a film, sending the material into a pressing film device, and pressing a photosensitive film on the material by an upper roller and a lower roller. Since a surface of the material has a thin layer of water before pressing film, the thin layer of water just fills uneven points of the material surface, there is no air bubbles between the material and the film, thus after pressing the film, a line made of the material will not be disconnected. Technical effect of the invention is that: a bubble problem in a pressing film process caused by an uneven surface of a material is eliminated, and a line disconnection problem of a produced line caused by the above problem is eliminated too, thus a rate of good product is greatly raised.

Owner:江西鑫力华数码科技有限公司

Device to protect edges from separators on a ring spinning machine and ring spinning machine

InactiveCN101603215BAvoid collisionEliminate disconnectionContinuous wound-up machinesYarnEngineering

Owner:MASCHINENFABRIK RIETER AG

Items equipped with a rope reel

ActiveCN110234247BEliminate disconnectionIncreased durabilityShoe lace fasteningsBucklesWinchIndustrial engineering

The present invention provides an article including a rope winding device capable of preventing the rope from breaking and having excellent durability. The article (S) has a rope (2) and a rope winding device (1), and the rope winding device (1) has: a winch (4) having a take-up part (41) around which the rope (2) is wound; a housing portion (33) for housing the winch (4) rotatably; and a rope outlet (35) for facing the rope coil from the inner surface of the peripheral wall (32) constituting the winch housing portion (33) The rope (2) is led out from the outside of the device (1), and is formed on two parts of the peripheral wall (32), at the formation position of the rope outlet (35) of the two parts and the winch storage part (33) In the case that the central part of the rope (2) is not on a straight line, when the fastening of the rope (2) is released, even if the rope (2) is pulled out from the rope outlet (35) of the one side to the maximum, it will not be connected with the other side. The connection and fixing part (P) of the said rope (2) corresponding to the rope outlet (35) and the said take-up part (41) will not have a kink in which the winding direction of the rope (2) is reversed, or because the rope (2) Fatigue caused by repeated bending.

Owner:JAPANA CO LTD

Method and Apparatus to Monitor a Reservoir or a Structure

PendingUS20220214206A1Reduced footprintSimple structureWeighing apparatus using elastically-deformable membersWeighing relieving/arrestment mechanismsElectrical batteryOptical transducers

A system to monitor weight of a reservoir or a structure comprises a load cell which comprises an electrical or optical transducer to provide a proportional signal of the deformation, a load cell base support for holding the load cell on the ground substantially about the axis of the support element of the reservoir, a load cell support adapter to attach the loadcell to the support member of the reservoir. The cell support adapter may comprise an opening or a shouldering anchor aiming at facilitating attachment to a temporary lifting device.

Owner:TECH INTELIA INC

Optical element and its manufacturing method

InactiveUS20070054437A1Reduce leakage currentReduce outputLaser detailsSemiconductor/solid-state device manufacturingInsulation layerLaser light

An optical element includes a substrate, a surface-emitting type semiconductor laser that emits laser light in a direction vertical to a surface of the substrate, and a light-receiving element formed above or below the surface-emitting type semiconductor laser provided above the substrate. The optical element includes a first insulation layer that covers a side surface and a part of an upper surface of a first columnar section that includes at least a part of the surface-emitting type semiconductor laser, and a second insulation layer that covers a side surface and a part of an upper surface of a second columnar section that includes at least a part of the light-receiving element.

Owner:SEIKO EPSON CORP

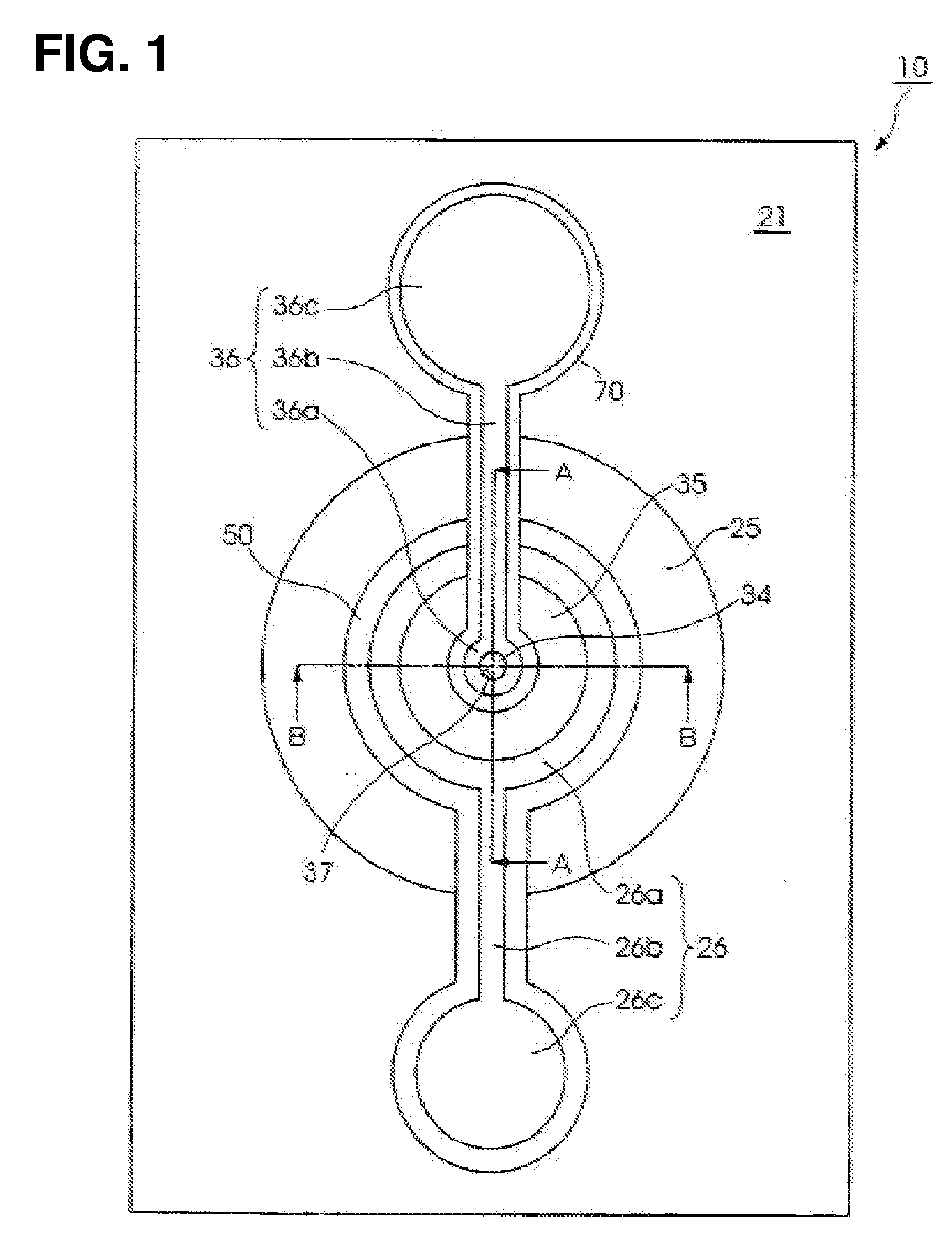

Composite material cutting machine

PendingCN111390269AEliminate disconnectionShearing machinesShearing machine accessoriesComposite materialManufacturing engineering

The invention discloses a composite material cutting machine. The composite material cutting machine comprises an underframe, a material guide frame, a feeding mechanism and a material cutting mechanism. The feeding mechanism comprises a front feeding set located upstream relative to the material cutting mechanism, and a rear feeding set located downstream relative to the material cutting mechanism. The material conveying speed of the rear feeding set is greater than that of the front feeding set. According to the composite material cutting machine, a material cutting structure is utilized tocomplete basic cutting of materials; and after the cutting is completed, because the feeding speed of the front feeding set is lower than that of the rear feeding set, broken materials and unbroken materials drag each other to achieve complete material breaking, thereby eliminating the problem that the materials are not completely broken.

Owner:SUZHOU MORE V COMPOSITE MATERIAL

Device for the Elastic Foreshortening of Cable, Rope or other Flexible Linear Structures

InactiveUS20110167593A1Easy to removePromote fragmentationSnap fastenersRopes and cables for vehicles/pulleyStructural deformationEngineering

Improvements to a device as previously disclosed in U.S. Pat. No. 7,219,397 wherein an elastic cord is attached to a pre-existing flexible linear structure such as a wire, tube, or rope to deform the structure and impart elastic handling properties. The improvements include features necessary for the effective manufacture and use of the device.

Owner:BISHOP TODD NICHOLAS

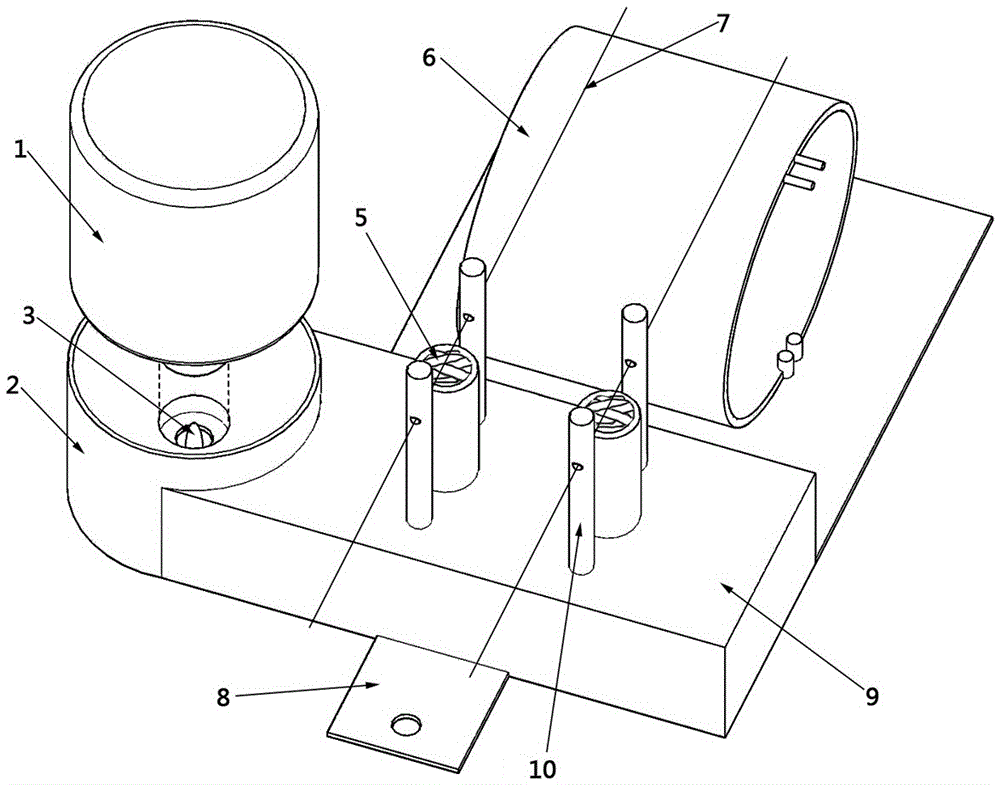

Random oiling device for sewing thread/seaming thread

ActiveCN104805606BMeet the characteristics of useSimultaneous drying operationSewing-machine elementsYarnEconomic benefits

The invention relates to a sewing thread / serging thread random oil immersion device. The structure of the device comprises an oil bottle for accommodating oil solutions, a bottle holder, oil smearing nozzles, thread penetrating plates and a bottom plate. The bottle holder is used for bearing the bottle opening of the oil bottle and piercing an opening seal layer of the bottle opening, the oil smearing nozzles are formed by tube casings and oil rope cores plugged in the tube casings tightly. The thread penetrating plates are arranged on the front and rear sides of the oil smearing nozzles, and the bottom plate is fixedly connected with the bottle holder. After the oil immersion device is arranged on a sewing machine / serging machine, thread breaking of the sewing machine and the serging machine is eliminated fundamentally, and a good thread breaking resistant effect is provided. Moreover, manufacturers using the sewing machine and the serging machine can purchase and use ordinary yarns directly to perform machine production, and purchase and use of special oil immersion yarns are saved, accordingly, the sewing thread and serging thread purchasing cost of sewing product manufacturers can be reduced greatly, and the enterprise economic benefit is improved.

Owner:苏州驰行智能科技有限公司

A copper-iron alloy modifier, preparation method and application method thereof

ActiveCN113481394BImprove refinementGood spherical effectProcess efficiency improvementIron powderPhysical chemistry

The invention discloses a copper-iron alloy modifier, which is characterized in that it includes a modifier A, and the mass percentage of the modifier A is composed of: 15-25 wt% of one or more of copper powder, iron powder, and yttrium powder The balance is copper-calcium alloy powder and unavoidable impurities; the calcium content in the copper-calcium alloy powder is more than 50wt%; modifier B is also included, and the mass percentage of the modifier B is composed of: 10-30wt % Cu, 20-30 wt% one or more of Te, Mg, Ca, Si, La, and the balance is Fe and unavoidable impurities. In the present invention, modifier B and modifier A can mutually promote the refinement and spheroidization of crystal grains, can obtain a copper-iron alloy phase structure with uniform distribution of iron phases, and can prepare copper-iron alloys with Fe≤90wt%, which is convenient for ultra-fine Wire processing to eliminate the problem of iron phase disconnection.

Owner:JINTIAN COPPER GROUP CORP NINGBO

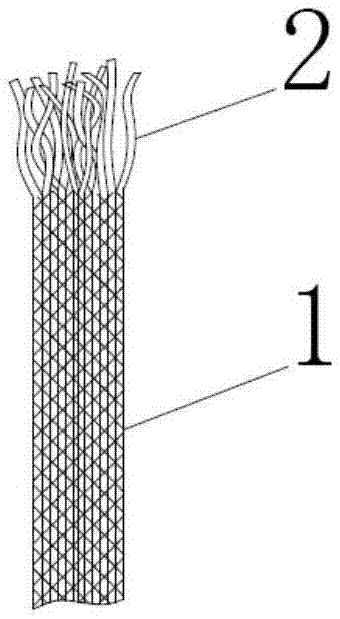

Self-supporting light-emitting optical cable and manufacturing method thereof

ActiveCN109254366BIncreased load-bearing capacityEliminate disconnectionFibre mechanical structuresFiberEngineering

The invention discloses a self-supporting light-emitting optical cable and a manufacturing method thereof. The self-supporting light-emitting optical cable includes a reinforced inner frame, a heat-shrinkable sleeve, a plurality of optical fibers, a waterproof layer, a metal shielding layer, a steel strand, A bulletproof silk braiding layer, a luminescent layer and a flame-retardant transparent sheath layer; the surrounding side of the reinforced inner frame is formed with a plurality of placement positions arranged at intervals, and the reinforced inner frame includes an outer carbon fiber frame and an inner metal frame , the inner metal frame is embedded in the formed outer carbon fiber frame; through the use of heat-shrinkable sleeves and foam materials, multiple optical fibers can be firmly fixed on the reinforced inner frame, effectively preventing the occurrence of disconnection , and by setting waterproof layer, metal shielding layer, steel strand, bulletproof wire braided layer, luminous layer and flame-retardant transparent sheath layer, this product has waterproof, shielding, tensile resistance, strong load-bearing, self-illumination and resistance Combustion and other characteristics, the overall performance of the product is better.

Owner:DONGGUAN TW SCIE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com