Electric motor for washing machine and washing machine having the electric motor

A washing machine and electric motor technology, applied in the field of electric motors, can solve problems such as rusted electric motor performance, terminal short circuit, short circuit, etc., and achieve the effect of preventing performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

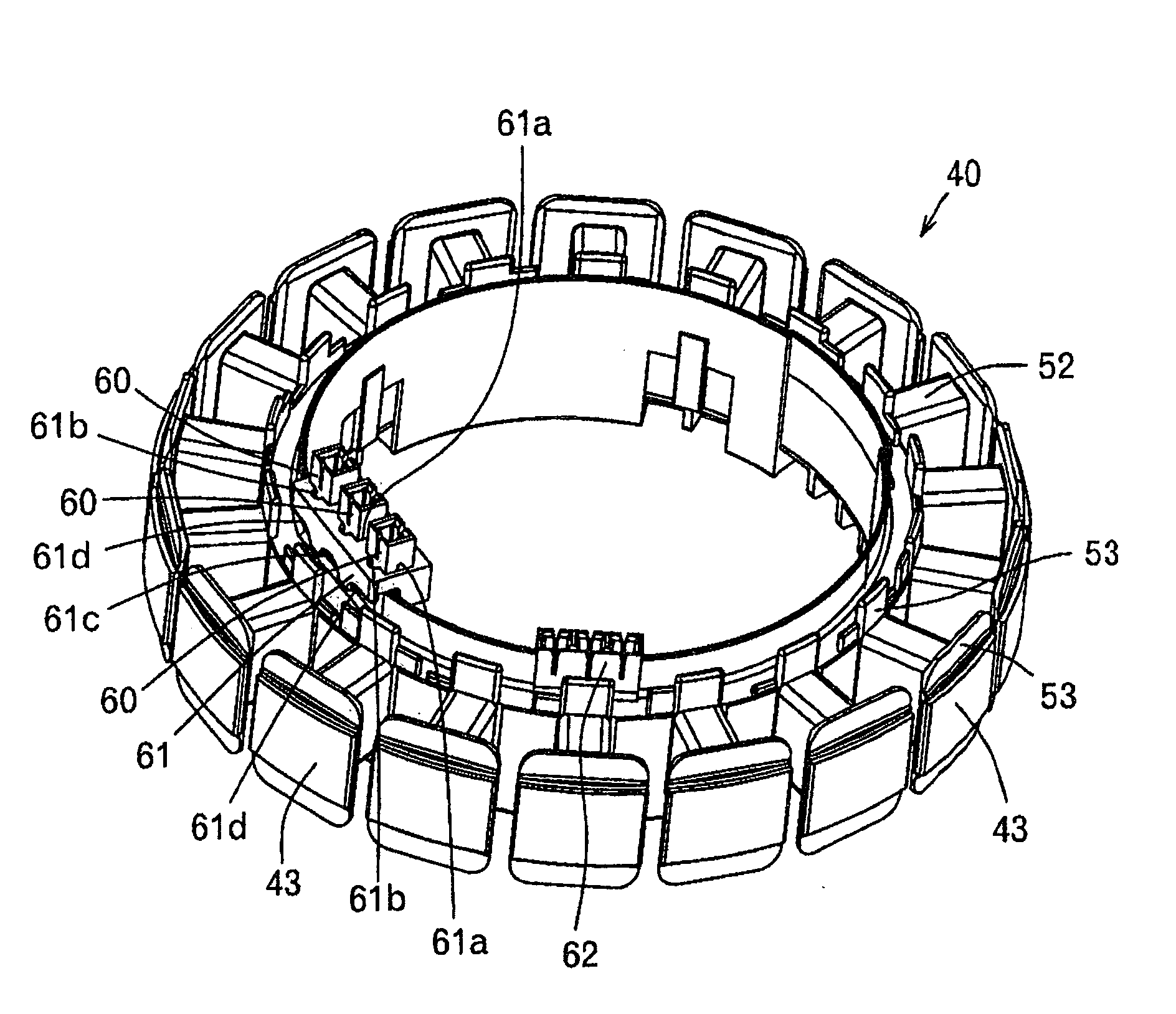

Image

Examples

Embodiment Construction

[0030] A washing machine 10 equipped with a washing machine motor 30 according to the present invention will be described with reference to the drawings.

[0031] figure 1 It is a cross-sectional view of a washing machine 10 equipped with a washing machine motor 30 according to the present invention, figure 2 is an enlarged sectional view of the drive mechanism. The washing machine 10 is constituted as a bottomed circular tank with a plurality of dehydration holes (not shown) on the peripheral wall that is freely rotatably supported inside a bottomed cylindrical outer tank 12 (water storage tank) that is suspended and supported by a casing 11. Cylindrical inner tank 13 (dehydration tank). On the inner bottom surface of the inner tank 13, an agitator 15 (agitator blade) for agitating the laundry is rotatably supported.

[0032] The inner tank 13 extends from a hollow main shaft 14 on the bottom side, and an impeller shaft 16 serving as an agitator 15 is fitted to the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com