Composite material cutting machine

A composite material and material cutting machine technology, which is applied to the attachment of shearing machines, shearing machine equipment, shearing devices, etc., can solve the problems of broken and broken materials and cannot be completely cut at one time, and achieve the effect of eliminating broken and broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

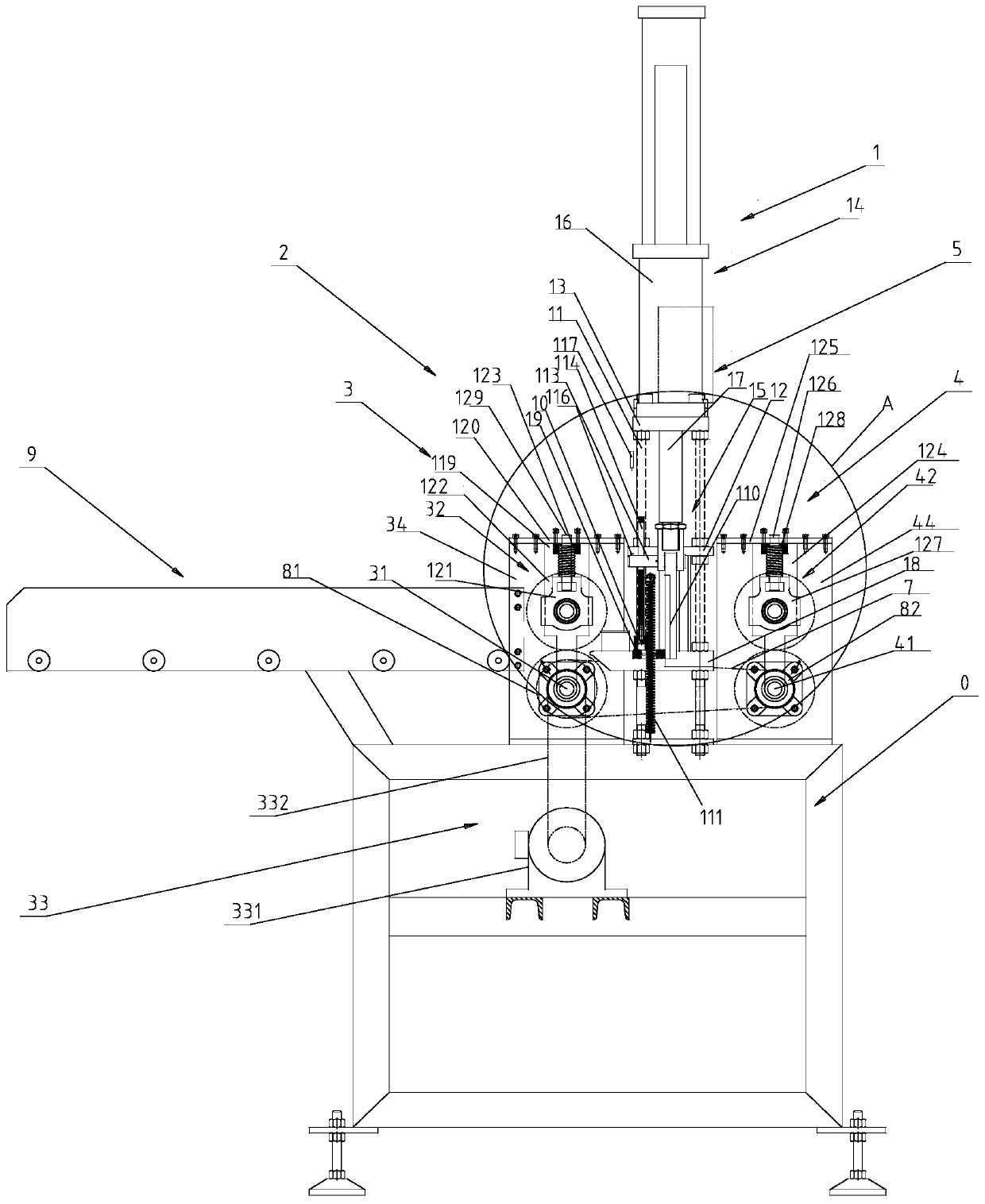

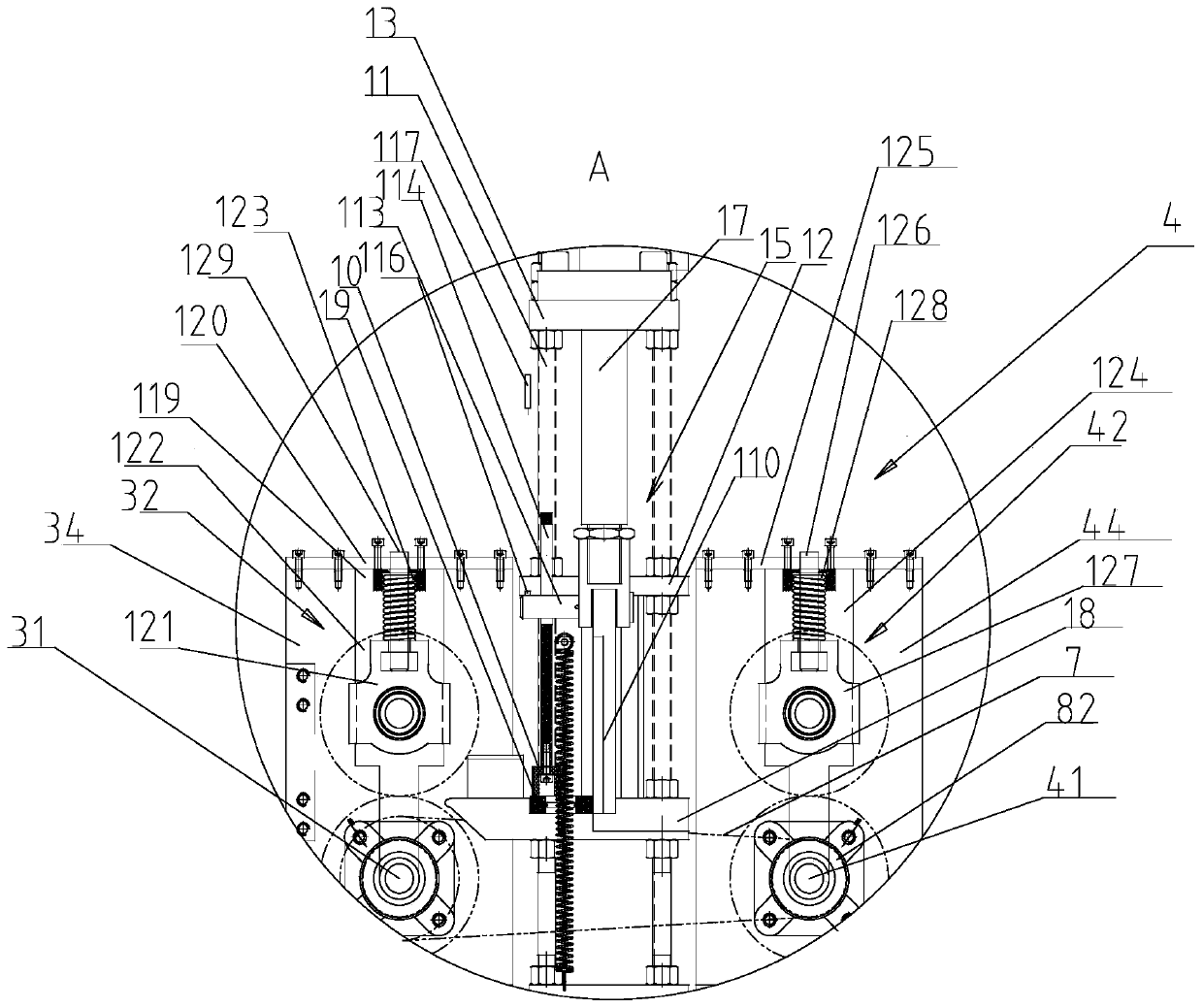

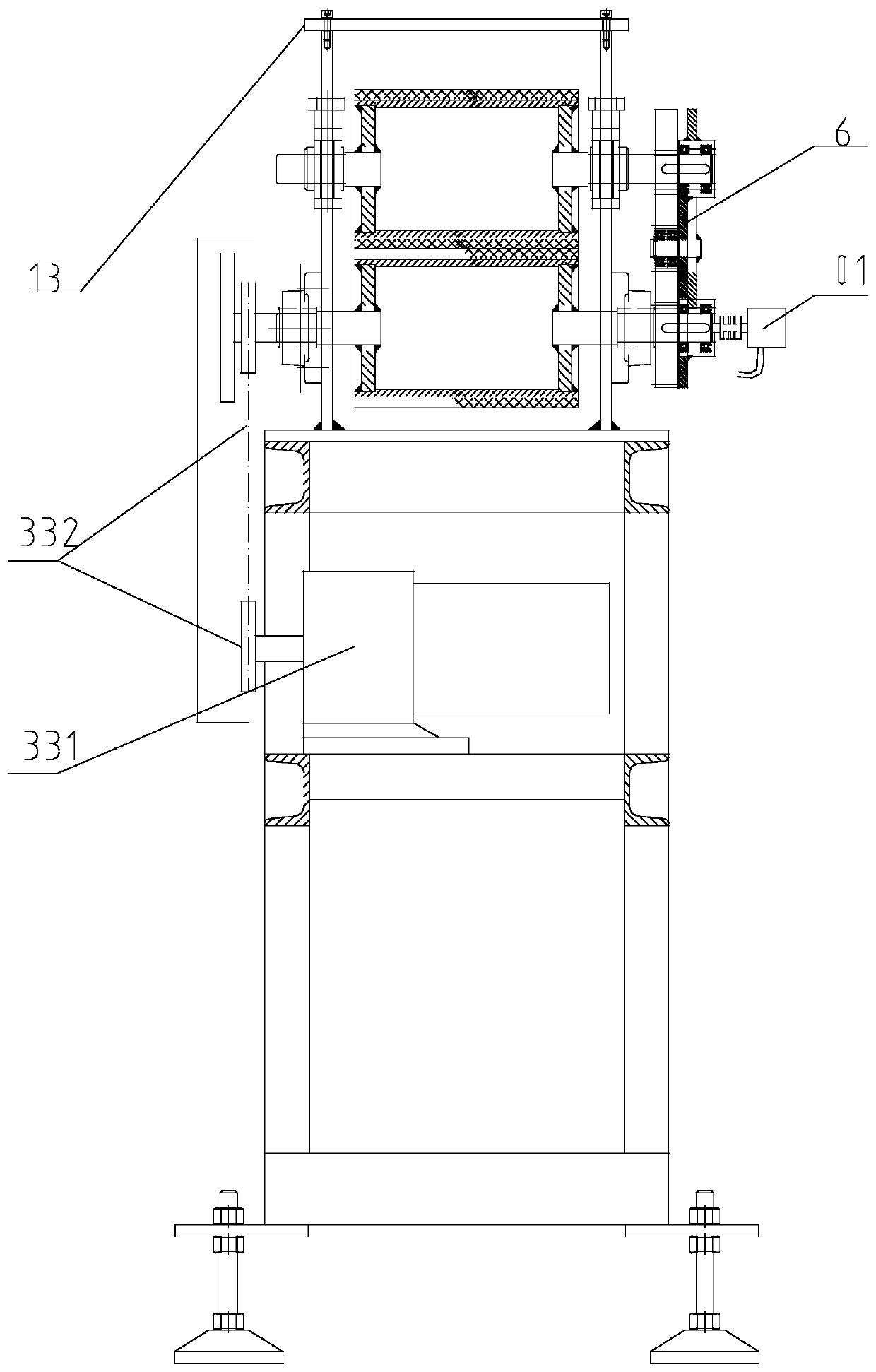

[0022] Such as Figure 1-5 As shown, the composite material cutting machine includes an underframe 0, a material guide frame 9, a feeding mechanism 2, and a cutting mechanism 1. The feeding mechanism 2 includes a front feeding group 3 located upstream of the cutting mechanism 1, and a Rear feeding group 4 and control cabinet 5;

[0023] The front feeding group 3 includes a front lower power roller 31, a front upper floating roller 32, a feeding drive member 33 and two oppositely arranged front vertical plates 34, and the front upper floating roller 32 can slide up and down and is rotatably arranged between the front vertical plates 34 , the front lower power roller 31 is rotatably located between the front vertical plates 34, the feeding drive member 33 is in transmission connection with the front lower power roller 31, and the rear feeding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com