Method for operating a ring spinning machine

A technology of ring spinning machine and spinning machine, which is applied in the direction of spinning machine, textile and papermaking, jointing device, etc. It can solve irreparable problems, reduce downtime, reduce total downtime, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The foregoing Summary, together with the following Detailed Description of the Preferred Embodiments, will be better understood when read in conjunction with the accompanying drawings. For purposes of describing the present invention, embodiments are presently preferred, in which like reference numerals refer to like parts throughout the several views of the drawings, it being understood that the invention is not limited specific methods and structures disclosed.

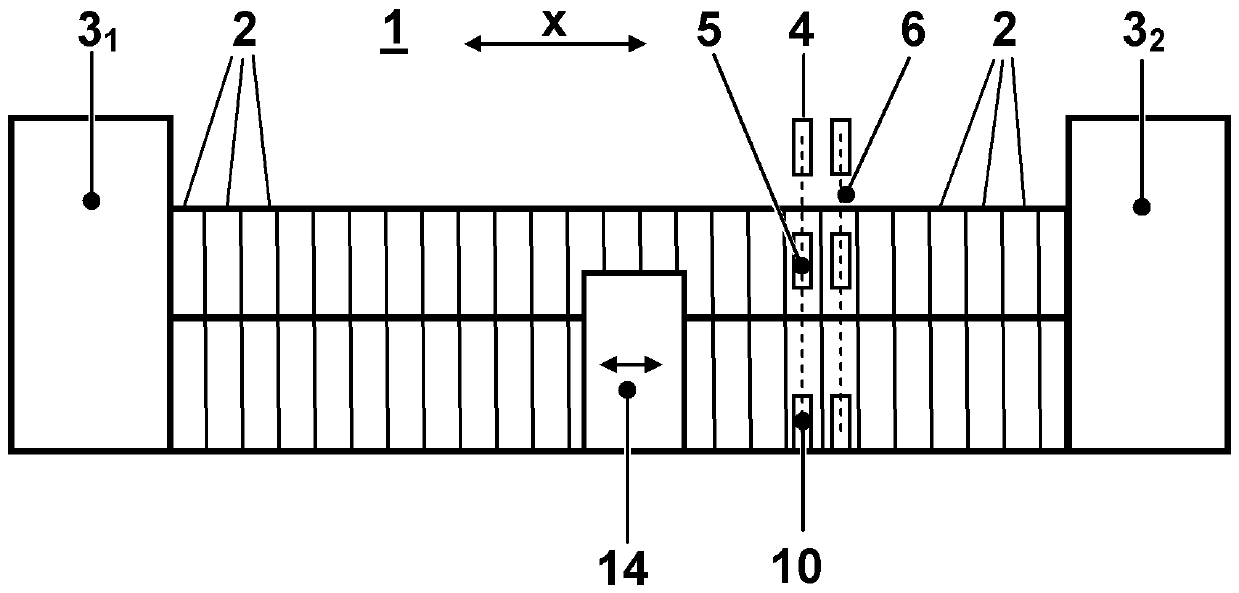

[0051] figure 1 A ring spinning machine 1 according to the invention is shown schematically with a plurality of adjacently positioned spinning stations 2 . The spinning station 2 is located at the head 3 along the longitudinal direction x of the ring spinning machine 1 1 and tail 3 2 between. Head 3 of ring spinning machine 1 1 and tail 3 2 May contain bearings, drives, controllers etc. necessary for operating the spinning machine. For example, as further apparent, in figure 1 with 2 At two spinning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com