Silicon-aluminum bicontinuous composite material and preparation method thereof

A composite material, bi-continuous technology, applied in the field of preparation of silicon-aluminum composite materials, can solve the problems of bi-continuous composite materials without any reports, and achieve good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

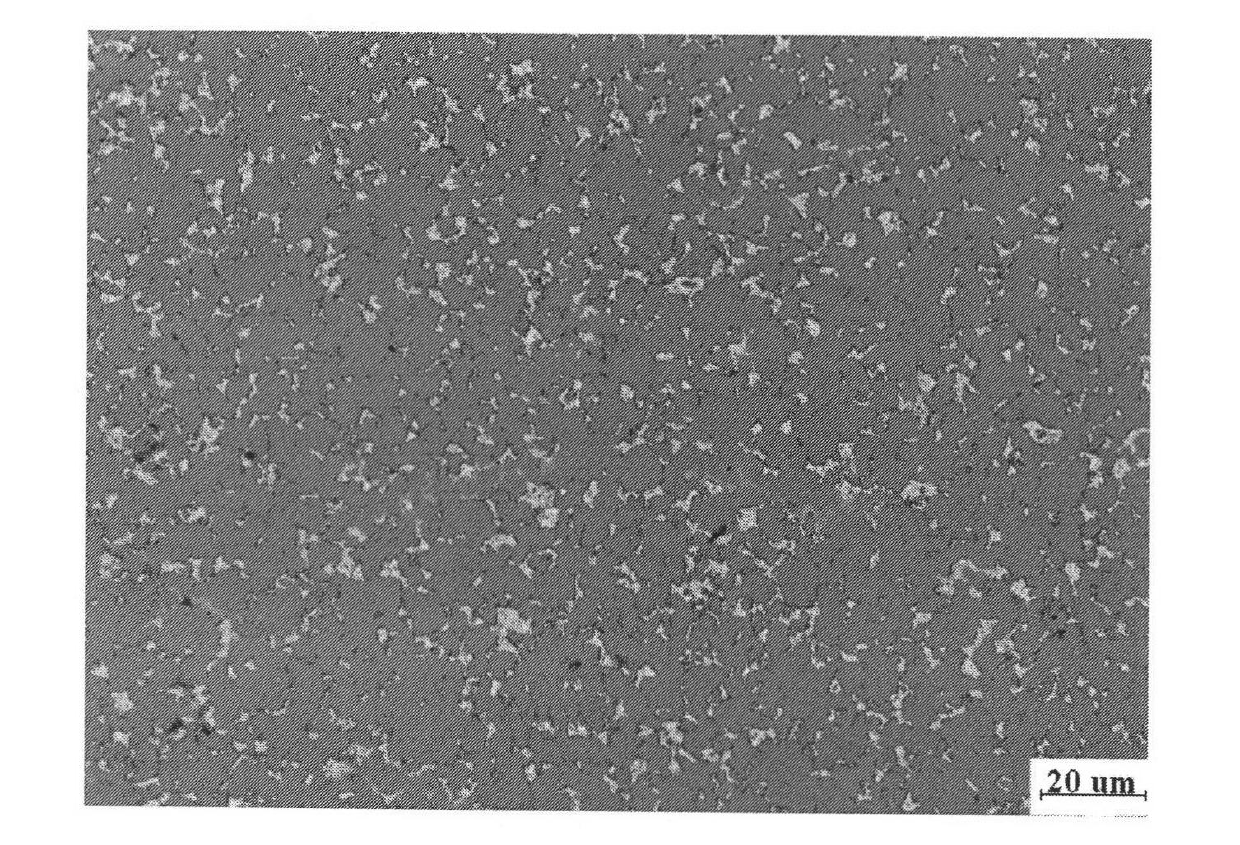

[0043] The bicontinuous composite material prepared in this embodiment is 65vol.%Si / Al, that is, the content of silicon is 65vol.%; the content of aluminum alloy is 35vol.%, and the composition of aluminum alloy is Al-4.5Cu-0.5Mg (4.5 and 0.5 Indicates that the mass fractions of copper and magnesium are 4.5% and 0.5%, respectively). Its preparation method adopts following technical scheme:

[0044] (1) Pure aluminum powder, pure copper powder and pure magnesium powder account for 4.5wt.% and 0.5wt.% of the mass fraction of mixed powder according to pure copper powder and pure magnesium powder and evenly mix and make aluminum-copper-magnesium mixed powder, then The aluminum-copper-magnesium mixed powder and the surface-treated silicon powder are evenly mixed according to the mass ratio of 1:1.57 to prepare the aluminum-copper-magnesium-silicon mixed powder, so that the volume fraction of silicon is 65 vol.%. The average particle size of pure aluminum powder, pure copper powder...

Embodiment 2

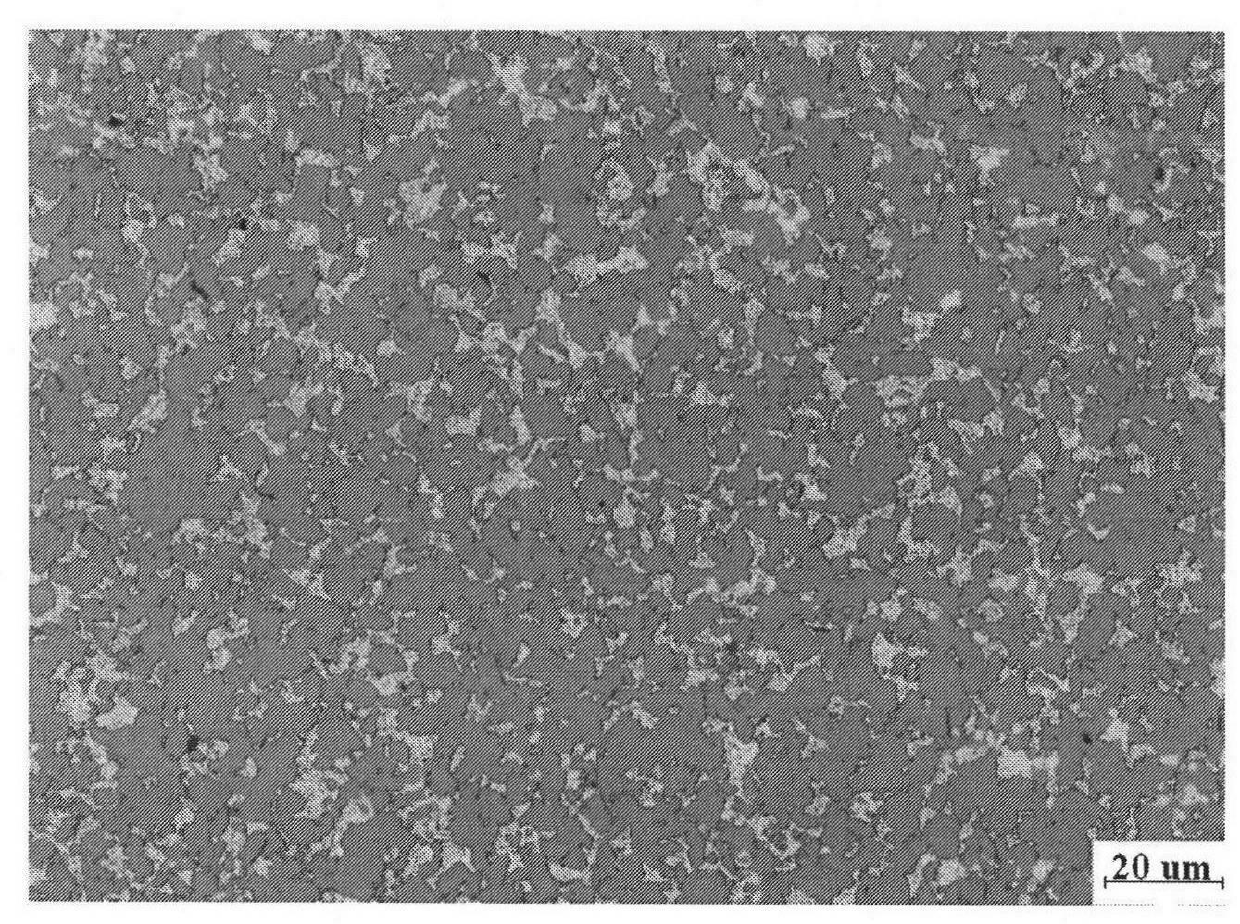

[0056] The bicontinuous composite material prepared in this embodiment is 75vol.% Si / Al, that is, the silicon content is 75vol.%; the aluminum alloy content is 25vol.%, and the aluminum alloy composition is Al-4.5Cu. Its preparation method adopts following technical scheme:

[0057] (1) Pure aluminum powder and pure copper powder are uniformly mixed according to the mass fraction of pure copper powder accounting for 4.5wt.% of the mixed powder to make aluminum-copper mixed powder, and then the aluminum-copper mixed powder and the silicon powder after surface treatment are mixed according to the mass ratio Mix 1:2.5 evenly to make aluminum-copper-silicon mixed powder, so that the volume fraction of silicon is 75vol.%. Due to the increase of the silicon content, in order to enable the silicon powder to be uniformly dispersed in the aluminum-copper mixed powder, the particle size of the silicon powder is increased. The average particle sizes of the silicon powder, pure aluminum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com