Photocatalysis composite material of graphene coated titanium dioxide with twice growth

A graphene encapsulation and secondary growth technology, which is applied in the direction of physical/chemical process catalysts, special compound water treatment, chemical instruments and methods, etc., can solve the problem of inability to make full use of graphene electron mobility, and cannot effectively improve composite fast, graphite The problem of small surface area contact with alkene can avoid agglomeration growth, improve photocatalytic efficiency, and improve photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

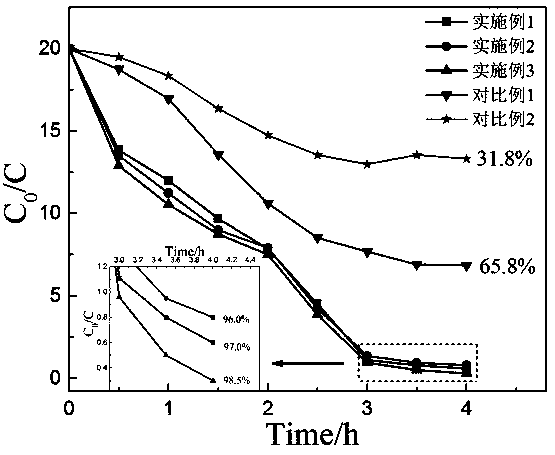

Embodiment 1

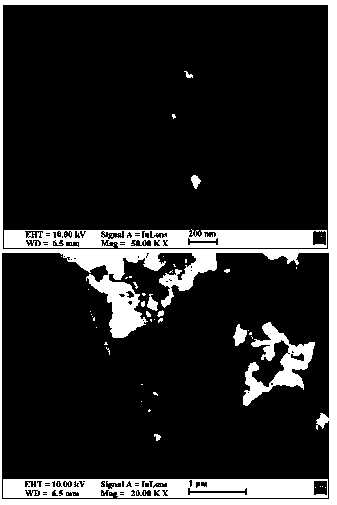

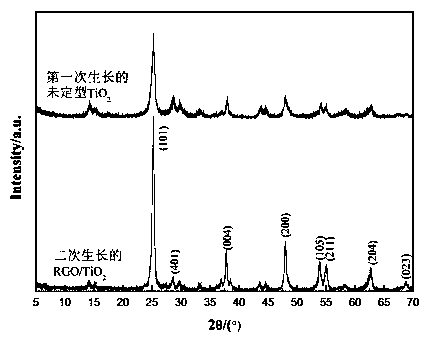

[0025](1) At room temperature, measure 5ml of titanium isopropoxide and 25ml of ethylene glycol, mix them with magnetic force for 3 hours, then slowly drop the solution into 5mol / L sulfuric acid, add 13ml of ethanol, and move to a PTFE-lined React in a hydrothermal reactor at 120°C for 4h, cool to room temperature, wash with ethanol and deionized water to neutrality, and dry at 60°C for 24h to obtain unshaped TiO 2 ,spare;

[0026] (2) Weigh 1g flake graphite, slowly add 23ml98wt% concentrated H 2 SO 4 , and slowly add 4gKMNO 4 During the period, magnetic stirring was kept and the reaction system was below 10°C. After 2 hours of reaction, the temperature was raised to 35°C and the reaction was continued for 2 hours. Then, the temperature was raised to 98°C and 44ml of deionized water was added to dilute the reaction solution. After 5 minutes, 5vol%H was added dropwise. 2 o 2 Until the mixture is completely golden yellow and no bubbles are generated. Finally, the mixture...

Embodiment 2

[0029] (1) At room temperature, measure 5ml of titanium isopropoxide and 30ml of ethylene glycol, and mix with magnetic force for 3 hours to obtain TiO2 coordinated by ethylene glycol and centered on Ti 6 octahedron, the solution was slowly dropped into 3mol / L hydrochloric acid solution, and 13ml of ethanol was added, moved to a polytetrafluoroethylene-lined hydrothermal reaction kettle at 150°C for 8 hours, cooled to room temperature, and then respectively added with ethanol, Centrifugal washing with ion water until neutral, drying at 60°C for 24 hours to obtain unshaped TiO after one growth 2 ,spare;

[0030] (2) Weigh 1g flake graphite, slowly add 23ml98wt% concentrated H 2 SO 4 , and slowly add 4gKMNO 4 During the period, magnetic stirring was kept and the reaction system was below 10°C. After 2 hours of reaction, the temperature was raised to 35°C and the reaction was continued for 2 hours. Then, the temperature was raised to 98°C and 44ml of deionized water was adde...

Embodiment 3

[0033] (1) At room temperature, measure 5ml of titanium isopropoxide and 22ml of ethylene glycol, mix magnetically for 3 hours, then slowly drop the solution into 5mol / L hydrochloric acid solution, add 13ml of ethanol, and transfer to the React in a lined hydrothermal reactor at 150°C for 10 hours, cool to room temperature, wash with ethanol and deionized water to neutrality, and dry at 60°C for 24 hours to obtain unshaped TiO 2 ,spare;

[0034] (2) Weigh 1g flake graphite, slowly add 23ml98wt% concentrated H 2 SO 4 , and slowly add 4gKMNO 4 During the period, magnetic stirring was kept and the reaction system was below 10°C. After 2 hours of reaction, the temperature was raised to 35°C and the reaction was continued for 2 hours. Then, the temperature was raised to 98°C and 44ml of deionized water was added to dilute the reaction solution. After 5 minutes, 5vol%H was added dropwise. 2 o 2 Until the mixture is completely golden yellow and no bubbles are generated. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com