Technique for producing high-purity antimonous oxide by processing stibnite concentrate through wet method

A technology of antimony trioxide and wet treatment, which is applied in the direction of inorganic chemistry, antimony compounds, chemical instruments and methods, etc. It can solve the problems of large antimony loss, high production cost, and large dosage, and achieve good arsenic removal effect , Uniform particle size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

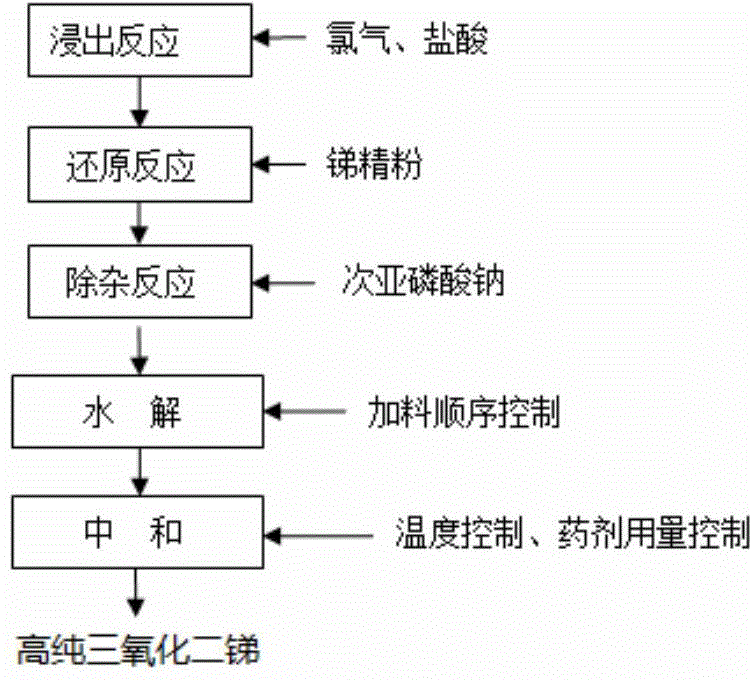

Method used

Image

Examples

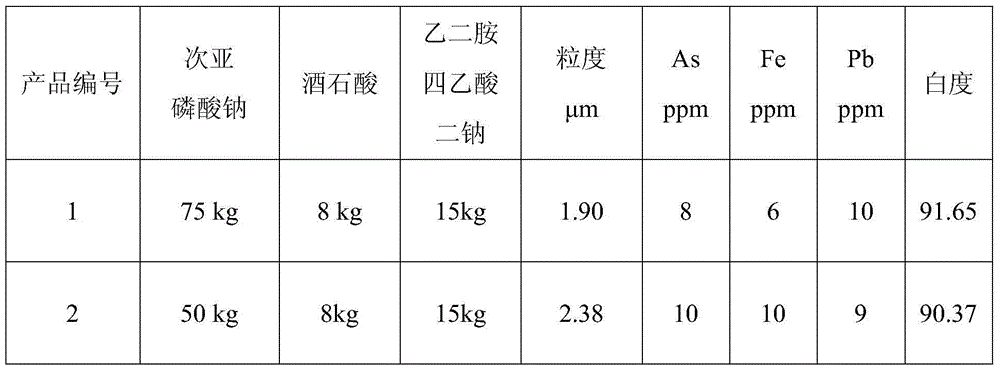

Embodiment 1

[0043] The antimony sulfide concentrate (with a particle size of -80 mesh) having the composition in Table 1 is chlorinated and leached, and antimony fine powder is added to the chlorinated leaching solution, stirred, and reduced. The amount of antimony fine powder is Sb in the antimony liquid 5+ 5 times the mass content, the particle size of antimony fine powder is less than 80 mesh, the reaction time is 3 hours, and the solution is filtered after the reaction is in place; the filtered antimony solution is added with sodium hypophosphite to remove impurities, and the added quality of sodium hypophosphite is 2 to 4 times the mass content (sodium hypophosphite is industrial grade, the main content is 99.95%), the acidity of the antimony solution is controlled at about 5mol / L, the reaction temperature is controlled at about 100°C, the stirring time is 4 hours, and the filtrate precipitates after filtration for 7 About hours; the precipitated antimony solution is filtered again, a...

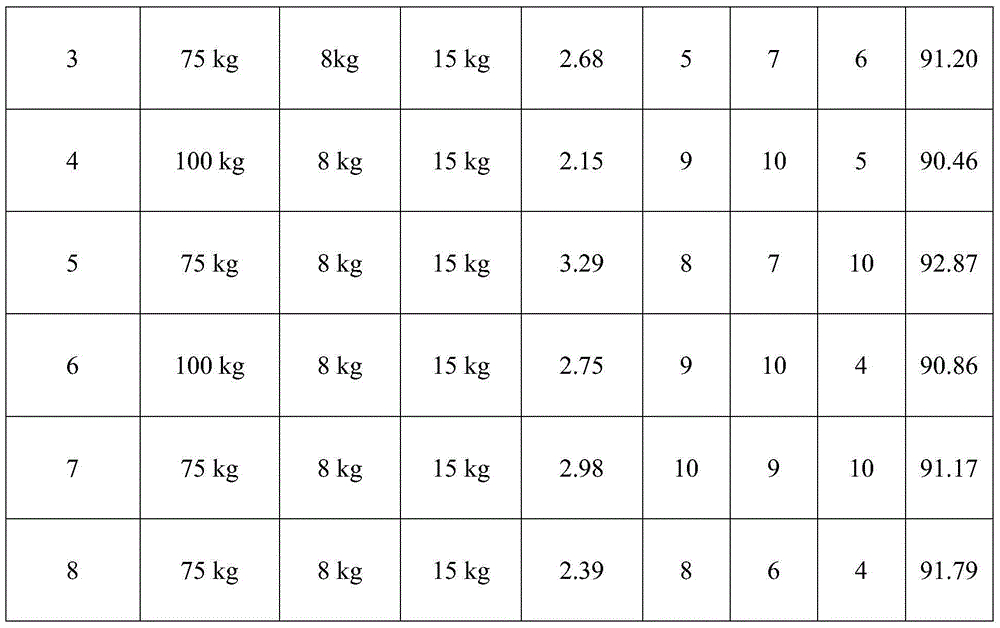

Embodiment 2

[0049] The antimony sulfide concentrate (with a particle size of -80 mesh) having the composition in Table 1 is chlorinated and leached, and antimony fine powder is added to the chlorinated leaching solution, stirred, and reduced. The amount of antimony fine powder is Sb in the antimony liquid 5+ 6 times the mass content, the particle size of antimony fine powder is less than 80 mesh, and the reaction time is 4 hours. After the reaction is in place, filter the solution; add sodium hypophosphite to the filtered antimony solution to remove impurities. 2 to 4 times the mass content (sodium hypophosphite is industrial grade, the main content is 99.95%), the acidity of the antimony solution is controlled at about 4.5mol / L, the reaction temperature is controlled at about 95°C, the stirring time is 3 hours, and the filtrate precipitates after filtration Not less than 6 hours; filter the precipitated antimony solution again, carry out hydrolysis reaction at room temperature, and the vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com