Hierarchical pore nanometer flower-like structure Ag catalyst of methyl glycolate prepared through oxalic ester hydrogenation

A technology of methyl glycolate and multi-level pores, which is applied in the direction of carboxylate preparation, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of low hydrogenation activity of silver-based catalysts and the selectivity of methyl glycolate Not high, low selectivity of methyl glycolate and other problems, to achieve the effect of increased conversion and selectivity, high hydrogenation activity and selectivity, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

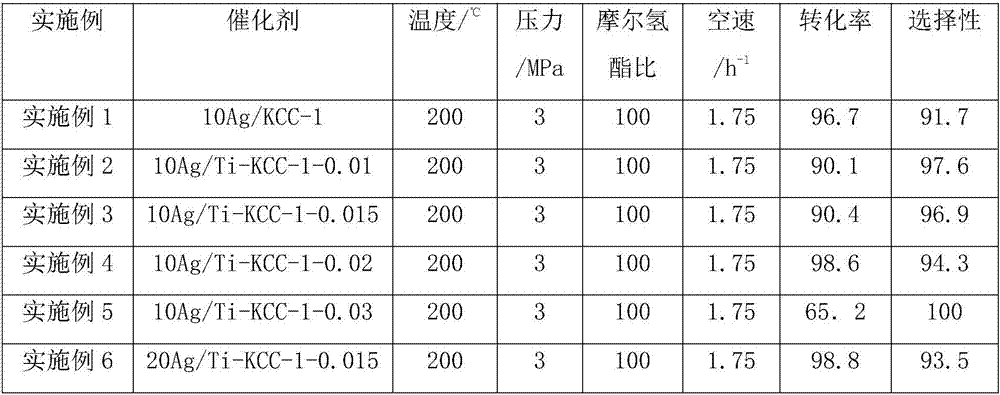

Embodiment 1

[0034] Catalyst preparation

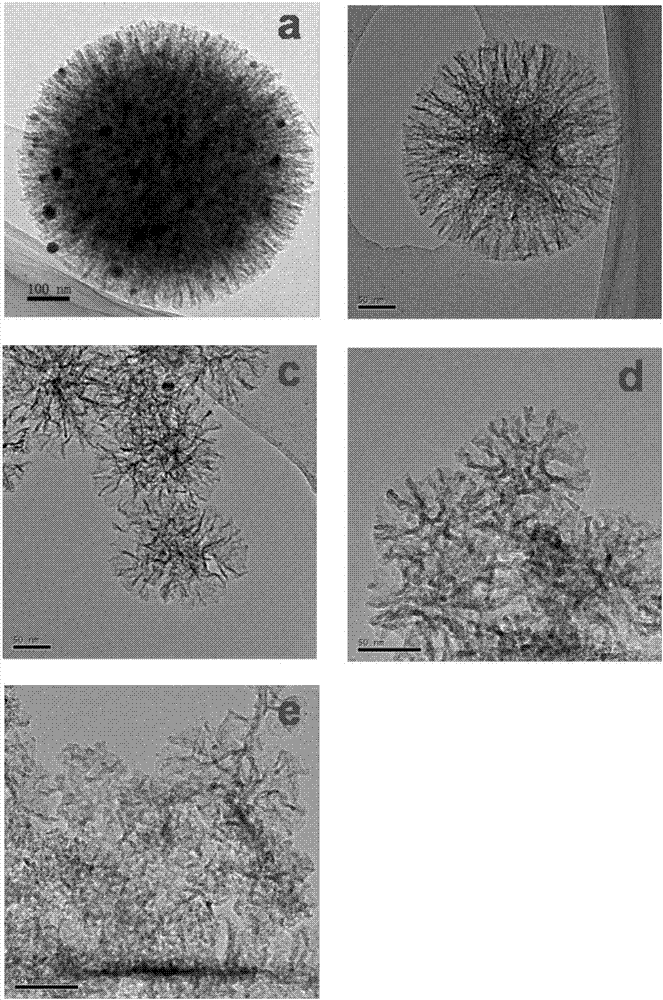

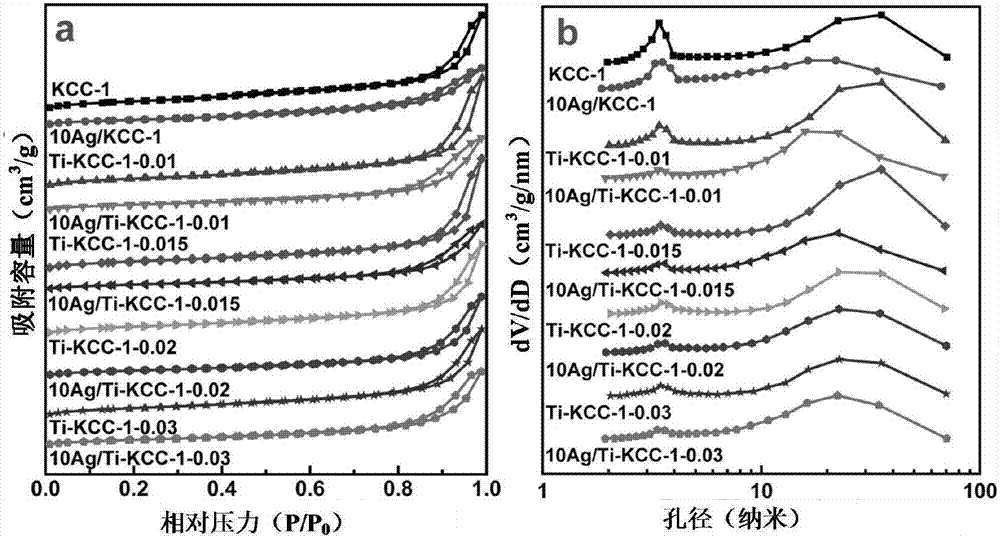

[0035] Add 5 g of cetylpyridinium bromide and 2 g of urea into the three-necked flask, then add 140 ml of deionized water and stir vigorously at room temperature. Measure 9ml of tetraethyl orthosilicate, 140ml of cyclohexane and 3ml of amyl alcohol, mix them, stir them evenly, then slowly add them dropwise into the three-necked flask, and stir for 1 hour. Then transfer the microemulsion in the three-neck flask to a crystallization kettle, and crystallize in an oven at 120° C. for 5 hours. After the product was cooled to room temperature, it was repeatedly centrifuged and washed with water and ethyl acetate, and the solid material was vacuum-dried at 60°C for 4 hours and calcined at 600°C for 4 hours in an air atmosphere to obtain the KCC-1 carrier. Weigh AgNO 3 0.52g, 5ml deionized water, to prepare AgNO 3 solution, the AgNO 3 The solution was added dropwise to 3 g of KCC-1 carrier and stirred evenly. The mixture was aged at room temperature i...

Embodiment 2

[0038] Catalyst preparation

[0039] Add 5 g of cetylpyridinium bromide and 2 g of urea into the three-necked flask, then add 140 ml of deionized water and stir vigorously at room temperature. Measure 9ml of ethyl orthosilicate, 140ml of cyclohexane and 3ml of amyl alcohol, mix them, stir them evenly, then slowly add them dropwise into the three-necked flask, stir for 30min, add 0.09g of tetrabutyl titanate, and continue stirring 30min. Then transfer the microemulsion in the three-neck flask to a crystallization kettle, and crystallize in an oven at 120° C. for 5 hours. After the product was cooled to room temperature, it was repeatedly centrifuged and washed with water and ethyl acetate, and the solid material was vacuum-dried at 60°C for 4 hours, and then calcined at 600°C for 4 hours in an air atmosphere to obtain Ti-KCC with a Ti weight content of 1%. -1-0.01 carrier. Weigh AgNO 3 0.52g, 4.5ml deionized water, to prepare AgNO 3 solution, the AgNO 3 The solution was a...

Embodiment 3

[0042] Catalyst preparation

[0043] Add 5 g of cetylpyridinium bromide and 2 g of urea into the three-necked flask, then add 140 ml of deionized water and stir vigorously at room temperature. Measure 9ml of ethyl orthosilicate, 140ml of cyclohexane and 3ml of amyl alcohol, mix them, stir them evenly, then slowly add them dropwise into the three-necked flask, stir for 30min, add 0.13g of tetrabutyl titanate, and continue stirring 30min. Then transfer the microemulsion in the three-neck flask to a crystallization kettle, and crystallize in an oven at 120° C. for 5 hours. After the product was cooled to room temperature, it was repeatedly centrifuged and washed with water and ethyl acetate, and the solid matter was vacuum-dried at 60°C for 4 hours, and then calcined at 600°C for 4 hours in an air atmosphere to obtain Ti-KCC with a Ti weight content of 1.5%. -1-0.015 vector. Weigh AgNO 3 0.52g, 4.5ml deionized water, to prepare AgNO 3 solution, the AgNO 3 The solution was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com