Load type nickel phosphide catalyst and pre-phosphating preparation method thereof

A catalyst, nickel phosphide technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor purity and dispersion, improve purity, avoid oxidative deactivation, and high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

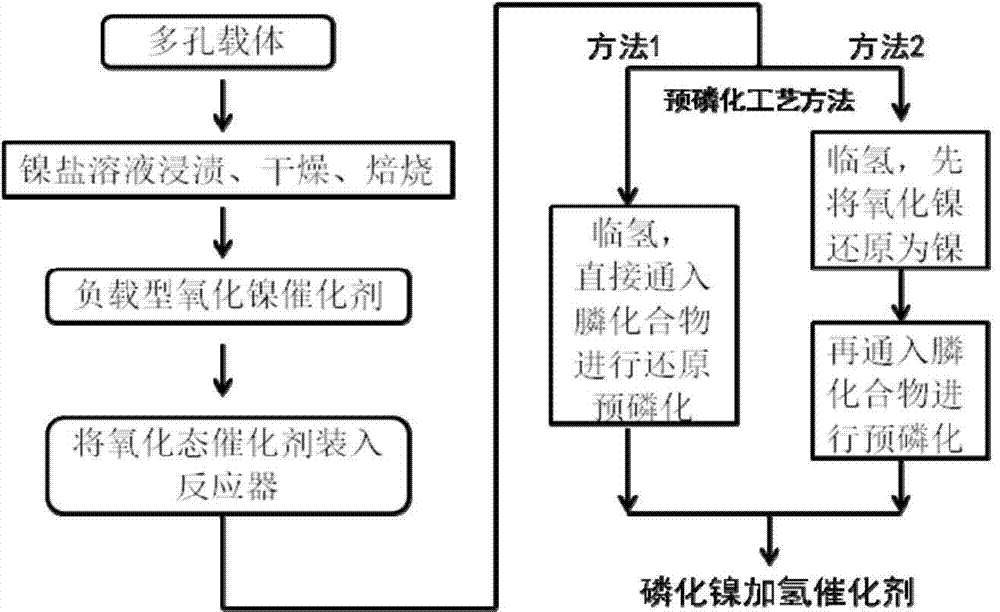

Method used

Image

Examples

Embodiment 1

[0059] Take 42.5g of alumina as a carrier. The water absorption rate of the alumina support was 1.0 ml / g. Weigh 25g of nickel acetate, 10ml of ammonia water, the concentration of ammonia water is 25%~28wt.%, and the density is 0.87g / cm 3 . Dissolve nickel acetate in ammonia water to prepare nickel acetate ammonia solution, that is, impregnation solution. The catalyst was impregnated by equal volume impregnation. Dry at room temperature for 8 hours, and dry at 120°C for 6 hours to prepare a nickel oxide-supported catalyst, sample number S-1.

Embodiment 2

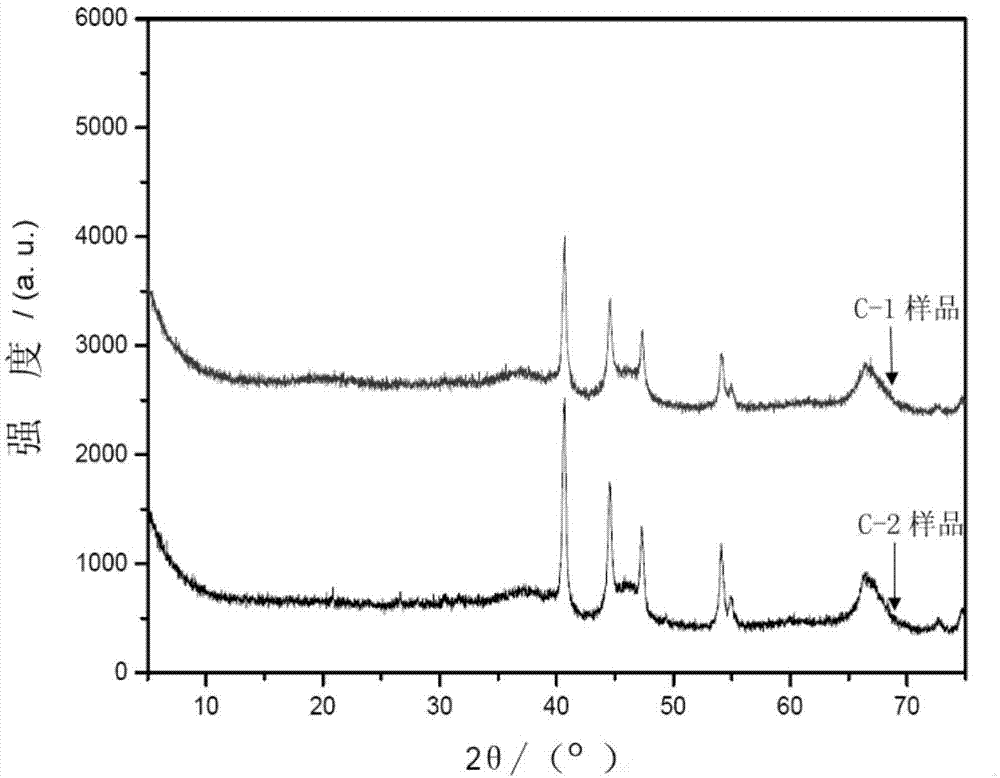

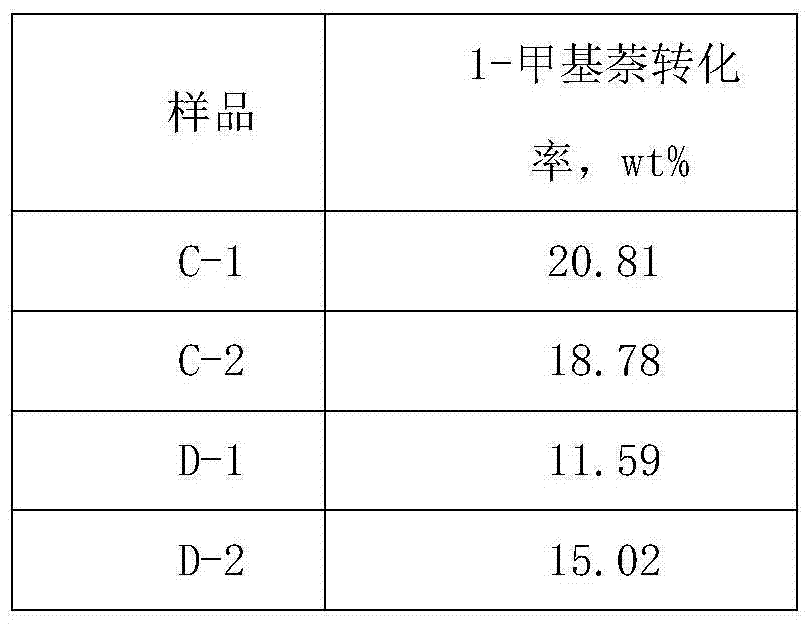

[0061] Take 10ml of catalyst S-1 loaded with nickel oxide and place it in the reactor, and feed H 2 , H 2 The pressure is 2MPa and the space velocity is 2h -1 . 1°C / min to raise the temperature to 120°C, and feed 3wt% triphenylphosphine (PPH 3 ) in cyclohexane solution, the temperature was programmed to 400°C, and pre-phosphating was performed for 12 hours. Obtain supported nickel phosphide catalyst, sample number C-1.

[0062] The Ni prepared in this example 2 P catalyst specific surface area is 253m 2 / g, the average pore diameter is 6.3nm, and the pore volume is 0.53cm 3 / g, the loading of Ni is 15.2%wt, and Ni / P is 1.98 (molar ratio).

Embodiment 3

[0064] Take 10ml of catalyst S-1 loaded with nickel oxide and place it in the reactor, and feed H 2 , H 2 The pressure is 2MPa and the space velocity is 2h -1 , 1°C / min to raise the temperature to 400°C, reduce for 6h, and convert the nickel oxide into the reduced state of nickel. Then the temperature was lowered to 300°C, and 3wt% triphenylphosphine (PPh 3 ) toluene solution, pre-phosphating for 12h. Take out to obtain supported nickel phosphide catalyst, sample number C-2.

[0065] The Ni prepared in this example2 P catalyst specific surface area is 248m 2 / g, the pore diameter is 6.5nm, and the pore volume is 0.52cm 3 / g, the loading of Ni is 15.0%wt, and Ni / P is 2.11 (molar ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com