Loofah complex oil absorb material

An oil-absorbing material and porous composite material technology, applied in the field of loofah composite oil-absorbing materials, can solve the problems of poor binding force and easy blockage of graphene oil-absorbing materials, and achieve the effect of high reuse effect, large pore structure, and high oil absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) slice the loofah, at 200 ℃, N 2 Carbonization under atmosphere for 4h to obtain carbonized loofah;

[0037] (2) Weigh 0.05g cetyltrimethylammonium bromide, add it to 100ml water and stir to mix, weigh 0.5g carbonized loofah, add carbonized loofah to the solution, stir at 80°C to change After curing for 2 hours, take out the loofah solid and wash it, dry the loofah solid at 100°C for 1 hour to obtain the modified loofah;

[0038] (3) Take 50mg of graphene and add it to 50ml of water, stir and mix for 10min under ultrasonic to obtain graphene suspension;

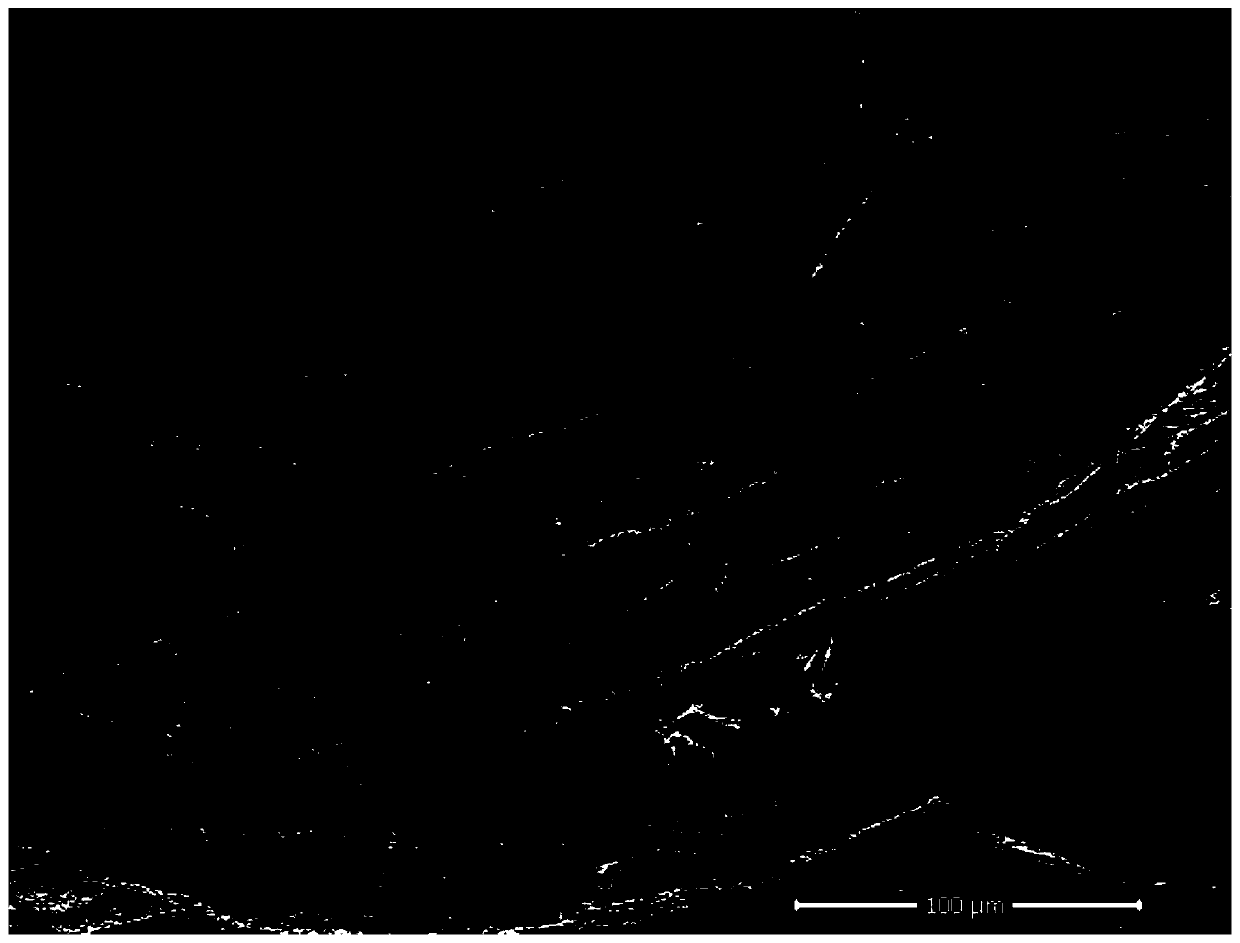

[0039] (4) Mix the graphene suspension with the modified loofah, put it in a hydrothermal reaction at 140°C for 10 hours to obtain a porous solid, and then dry the obtained porous solid at 90°C for 4 hours to obtain a loofah composite Oil absorbent material. The SEM photo of the loofah composite oil-absorbing material is shown in figure 1 .

Embodiment 2

[0041] (1) Slice the loofah, at 450°C, N 2 Carbonization under atmosphere for 2h to obtain carbonized loofah;

[0042] (2) Weigh 0.05g of cetyltrimethylammonium bromide, add it to 300ml of water and stir to mix, weigh 1g of carbonized loofah, add carbonized loofah into the solution, and stir at 100°C for modification 1.5h, take out the loofah solid and wash it, dry the loofah solid at 105°C for 2h to obtain the modified loofah;

[0043] (3) Take 300mg graphene and join in 75ml water, stir and mix 35min under ultrasonic, obtain graphene suspension;

[0044] (4) Mix the graphene suspension with the modified loofah, put it in a hydrothermal reaction at 160°C for 18 hours to obtain a porous solid, and then dry the obtained porous solid at 40°C for 48 hours to obtain a loofah composite Oil absorbent material.

Embodiment 3

[0046] (1) Slice the loofah and carbonize it under vacuum at 280°C for 6 hours to obtain carbonized loofah;

[0047] (2) Weigh 0.1g of cetyltrimethylammonium bromide, add it to 400ml of water and stir to mix, weigh 2g of carbonized loofah, add the carbonized loofah into the solution, stir and modify at 95°C 2.5h, take out the loofah solid and wash it, dry the loofah solid at 95°C for 1 hour to obtain the modified loofah;

[0048] (3) Take by weighing 330mg graphene and join in 105ml water, stir and mix 30min under ultrasonic, obtain graphene suspension;

[0049] (4) Mix the graphene suspension with the modified loofah and place it in a hydrothermal reaction at 180°C for 12 hours to obtain a porous solid, then dry the obtained porous solid at 50°C for 30 hours to obtain a loofah compound Oil absorbent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com