Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

A gasoline hydrogenation and catalyst technology, applied in refining to remove heteroatoms, etc., can solve problems such as low total liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

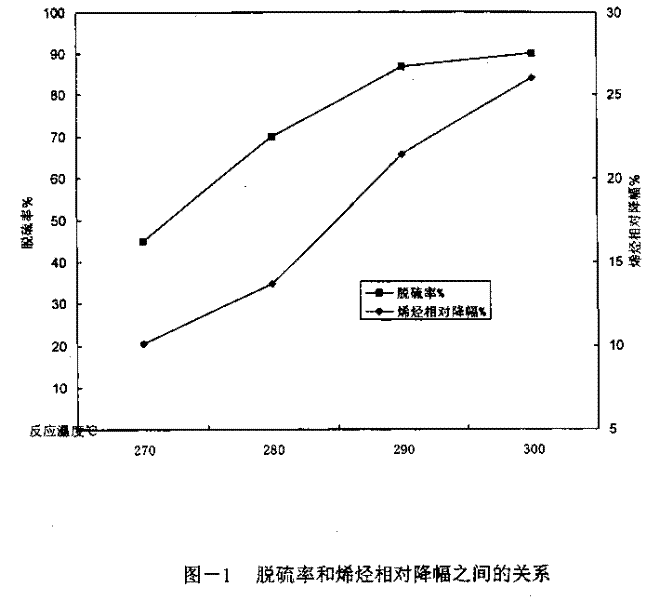

Image

Examples

Embodiment 1

[0041] The titanium dioxide dry rubber powder (containing TiO) produced by Beijing Haishunde Titanium Catalyst Co., Ltd. Deqing Branch 2 80%) 200g, add 10g Tianqing powder, and mix well. Add 120g of aluminum gel: silica sol (1:1) to the aforementioned materials, and after fully kneading, extrude it into a clover-like strip with an equivalent diameter of 1.4mm on a front extrusion twin-screw extruder. The resulting wet strip is 60% Dry for 2 hours at 120°C, 2 hours at 120°C, and roast at 500°C for 3 hours to obtain carrier A. Its properties are shown in Table 1. It is impregnated with Mo-Co solution, dried at 110°C for 5 hours, and calcined at 450°C for 2 hours. The properties of catalyst A1 are shown in Table 2.

Embodiment 2

[0043] The titanium dioxide dry rubber powder (containing TiO) produced by Beijing Haishunde Titanium Catalyst Co., Ltd. Deqing Branch 2 80%) 100g and titanium-zirconium dry rubber powder (containing ZrO 2 25%) 100g, add 10g Tianqing powder, and mix well. Add 120g of 1:1 aluminum gel and silica sol to the aforementioned materials, fully kneaded and extruded on a front extrusion twin-screw extruder into a clover-like strip with an equivalent diameter of 1.4mm, the resulting wet strip is dried at 60 degrees Drying at 120°C for 2 hours for 2 hours, and calcining at 500°C for 3 hours to obtain carrier B. The properties are shown in Table 1. After being impregnated with Mo-Co solution, dried at 110°C for 5 hours, and calcined at 450°C for 2 hours, catalyst B1 was obtained. The properties are shown in Table 2.

Embodiment 3

[0045] The titanium dioxide dry rubber powder (containing TiO) produced by Beijing Haishunde Titanium Catalyst Co., Ltd. Deqing Branch 2 80%) 100g and titanium-silicon dry rubber powder (containing SiO 2 25%) 100g, add 10g Tianqing powder, and mix well. Add 120g of aluminum gel to the aforementioned materials, after fully kneading, extrude it into a clover-like strip with an equivalent diameter of 1.4mm on a front extrusion twin-screw extruder. The resulting wet strip is dried at 60°C for 2 hours and at 120°C After drying for 2 hours and calcining at 500°C for 3 hours, carrier C was obtained. Its properties are shown in Table 1. After being impregnated with Mo-Co solution, dried at 110°C for 5 hours, and calcined at 450°C for 2 hours, catalyst C1 was obtained. Its properties are shown in Table 2. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com