Method for preparing lithium-rich positive electrode material through adjustable low temperature combustion method

A lithium-rich cathode material, low-temperature combustion technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of irreversible capacity loss, high price, poor rate discharge performance, etc., to save equipment investment costs, improve The rate of crystallization, the effect of high specific surface area and pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

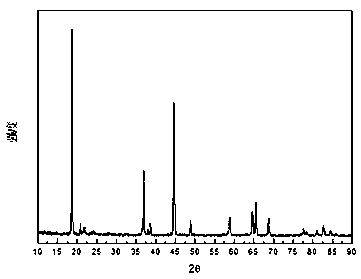

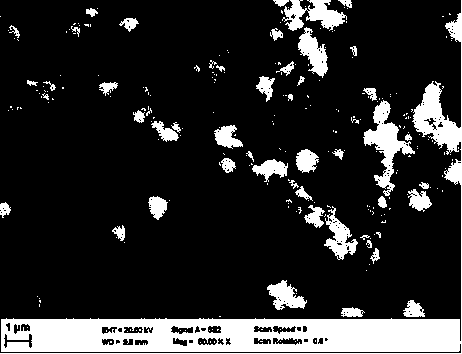

Embodiment 1

[0025] In this example, carbonamide is used as a reducing agent, and an appropriate amount of polyethylene glycol is added to a mixed solvent of deionized water and ethanol to prepare a lithium-rich positive electrode material 0.4Li 2 MnO 3 0.4Li[Ni 1 / 3 co 1 / 3 mn 1 / 3 ]O 2 . Prepare 100ml of ethanol solution with a volume fraction of 50%, and prepare 0.5mol / L LiNO according to the stoichiometric ratio 3、 Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) metal salt mixed solution A, add 0.14mol carbonamide, 5ml polyethylene glycol, stir evenly, add ammonia water dropwise to adjust the pH to 8, and obtain solution B. Put solution B in a 100-degree oil bath and stir the reaction until the solution is concentrated to 50ml, pour it into a crucible, burn it at 600 degrees, keep it warm for 1 hour and take it out to obtain powder C, collect and grind C, and place it under a muffle furnace at high temperature Calcined at 900°C for 12 hours, c...

Embodiment 2

[0028] In this example, carbonamide and citric acid were used as reducing agents, and an appropriate amount of Tween 20 was added to deionized water to prepare a lithium-rich cathode material 0.5 / 3Li 2 MnO 30.5Li[Ni 1 / 3 co 1 / 3 mn 1 / 3 ]O 2 . Prepare 100ml of propanol solution with a volume fraction of 50%, and prepare 0.5mol / L LiNO according to the stoichiometric ratio 3 , Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) metal salt mixed solution A, add 0.1mol carbonamide and 0.5mol citric acid, 2ml Tween 20, stir evenly, add ammonia water dropwise to adjust the pH to 8, and obtain solution B. Put solution B in a 90-degree oil bath and stir the reaction until the solution is concentrated to 65ml, pour it into a crucible, burn it at 550 degrees, keep it warm for 0.5h, take it out to obtain powder C, collect and grind C, and place it under a muffle furnace Calcined at a high temperature of 900 degrees for 12 hours, cooled and sieved b...

Embodiment 3

[0031] In this example, carbohydrazide was used as a reducing agent, and an appropriate amount of PVDF was added to a mixed solvent of deionized water and ethylene glycol to prepare a lithium-rich cathode material 0.2 / 3Li 2 MnO 3 0.9Li[Ni 0.4 co 0.2 mn 0.2 ]O 2 . Prepare 100ml of ethylene glycol solution with a volume fraction of 20%, and prepare 0.5mol / L CH 3 COOLi·2H 2 O 、Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O and Mn(CH 3 COO) 2 4H 2 O metal salt mixed solution A, add 0.08mol carbohydrazide, 2g PVDF powder, stir evenly, add ammonia water dropwise to adjust the pH to 7, and obtain solution B. Put solution B in a 100-degree oil bath and stir the reaction until the solution is concentrated to 60ml, pour it into a crucible, burn it at 500 degrees, keep it warm for 2 hours and take it out to obtain powder C, collect and grind C, and place it under a muffle furnace at high temperature Calcined at 900°C for 12 hours, cooled and sieved by a ball mill to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com