Super-strong viscosity-reducing paraffin control device

A wax-proof and super-strong technology, used in cleaning appliances, wellbore/well components, earth-moving drilling, etc., can solve problems such as high energy consumption and environmental pollution, and achieve the effect of preventing deposits from growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The invention consists of four parts: eddy current generator, special alloy coating tube, Perlman acoustic wave generator and strong magnetic device.

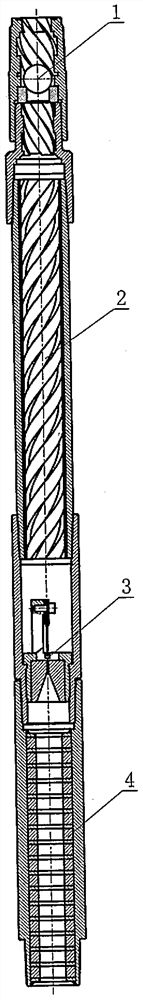

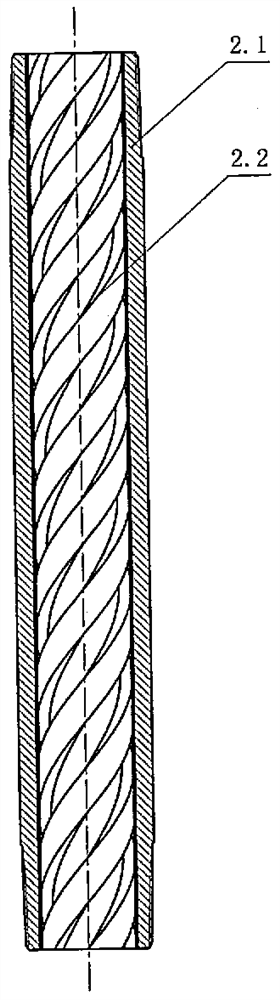

[0022] see figure 1 , a super-viscosity-reducing wax-preventing device, characterized in that it consists of 4 parts: a vortex generator, a special alloy coating tube, a Perlman acoustic wave generator, and a strong magnetic group; the lower end of the vortex generator and the special alloy coating Connection, the lower end of the special alloy coating is connected with the Pallman acoustic wave generator, and the lower end of the acoustic wave generator is connected with a strong magnetic device.

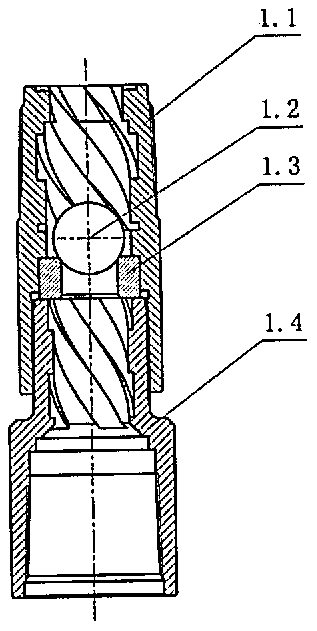

[0023] The vortex generator is composed of a vortex injector, a steel ball, a ball seat, and a vortex deflector; the inside of the vortex injector is a spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com