Method for preparing carbon-loading noble metal catalyst by solvothermal method

A technology of noble metal catalysts and solvothermal method, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems that carbon-supported noble metal catalysts are not involved, and achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

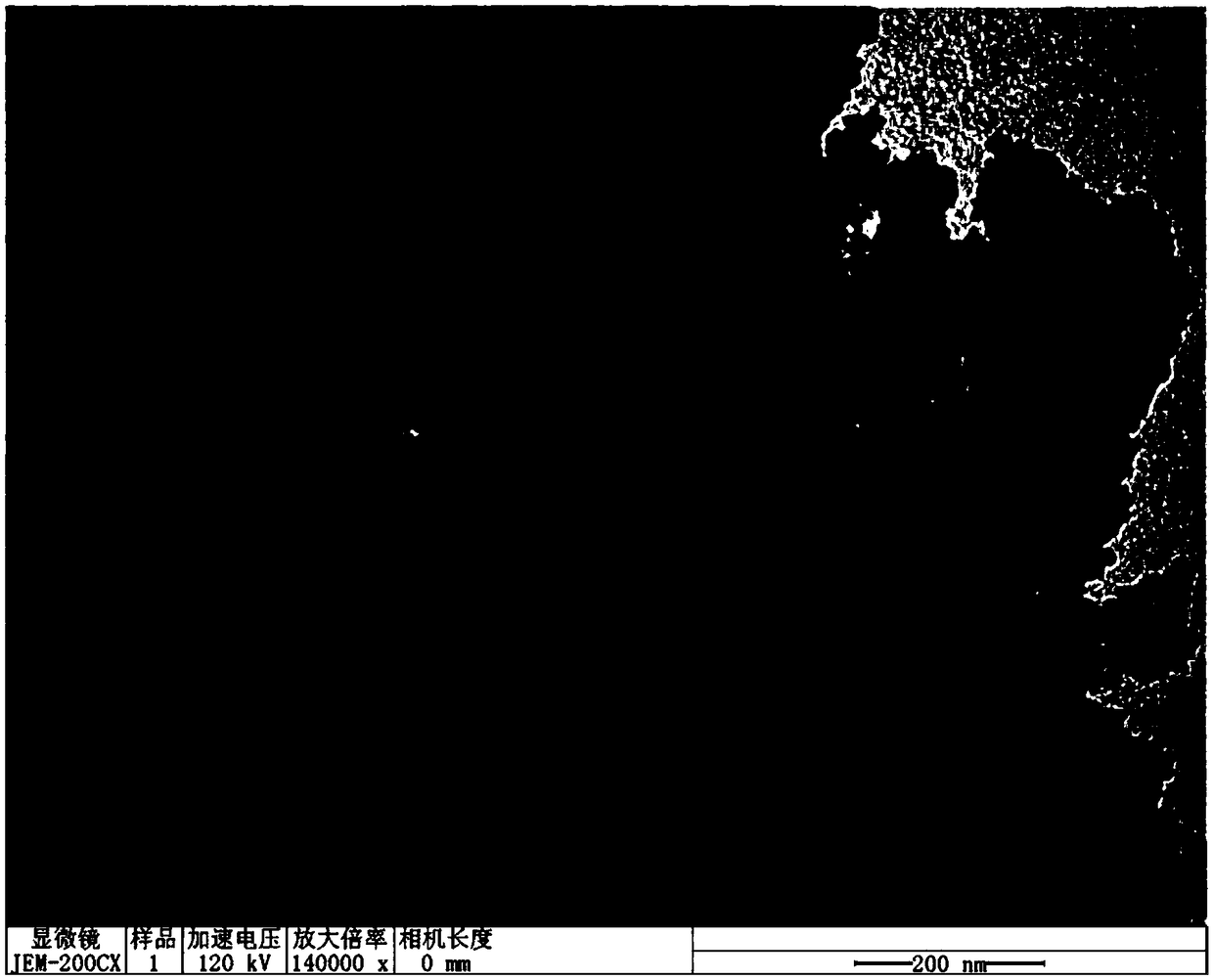

Image

Examples

Embodiment 1

[0026] In this embodiment, a Pd / C catalyst is prepared by a solvothermal method, and the specific methods include:

[0027] Step 1. Select a particle size distribution of 200 mesh to 400 mesh and a specific surface area of 950m 2 / g~1000m 2 / g of activated carbon, the activated carbon is added to the nitric acid solution with a mass concentration of 10%, soaked at 20°C for 24 hours, then washed with deionized water until neutral, then dried the washed activated carbon, The drying temperature is 120°C to obtain pretreated activated carbon with a moisture content not greater than 1%;

[0028] Step 2, the palladium chloride of metering ratio is dissolved in the mixed solvent of 1000mL ethylene glycol and water, and the volume percentage composition of ethylene glycol in the mixed solvent is 95%, then adds the gac of pretreatment in 50g step 1, stirs to The activated carbon is evenly dispersed to obtain a mixed slurry;

[0029] Step 3, placing the mixed slurry described in st...

Embodiment 2

[0033] This embodiment adopts solvothermal method to prepare Pt / C catalyst, and specific method comprises:

[0034] Step 1. Select a particle size distribution of 200 mesh to 400 mesh and a specific surface area of 1000m 2 / g~1300m 2 / g of activated carbon, add activated carbon to tartaric acid solution with a mass concentration of 20%, soak it at 30°C for 24 hours, then wash the soaked activated carbon with deionized water until neutral, then dry the washed activated carbon, The drying temperature is 100°C to obtain pretreated activated carbon with a moisture content not greater than 1%;

[0035] Step 2, dissolving the potassium chloroplatinate of the metered ratio in the mixed solvent of 1000mL formamide and water, the volume percentage of formamide in the mixed solvent is 95%, then add the activated carbon pretreated in 100g step 1, and stir until The activated carbon is evenly dispersed to obtain a mixed slurry;

[0036] Step 3, placing the mixed slurry described in s...

Embodiment 3

[0040] In this embodiment, a Pd / C catalyst is prepared by a solvothermal method, and the specific methods include:

[0041] Step 1. Select a particle size distribution of 200 mesh to 400 mesh and a specific surface area of 1300m 2 / g~1500m 2 / g of activated carbon, add the activated carbon into the nitric acid solution with a mass concentration of 1%, soak it at 100°C for 5 hours, then wash the soaked activated carbon with deionized water until neutral, then dry the washed activated carbon, The drying temperature is 100°C to obtain pretreated activated carbon with a moisture content not greater than 1%;

[0042] Step 2. Dissolve the palladium nitrate of the metered ratio in a mixed solvent of 1000mL formamide and water, the volume percentage of formamide in the mixed solvent is 80%, then add 200g of the pretreated activated carbon in step 1, and stir until the activated carbon is dispersed Uniformly, get mixed slurry;

[0043] Step 3, placing the mixed slurry described in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com