2007 aluminum alloy rod manufacturing process

A production process and aluminum alloy technology, which is applied in the field of aluminum alloy manufacturing, can solve the problems such as the difficulty of online quenching of φ200-210mm aluminum alloy rods, and achieve the effect of solving the difficulty of online quenching, not easy to scratch, and easy to squeeze smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

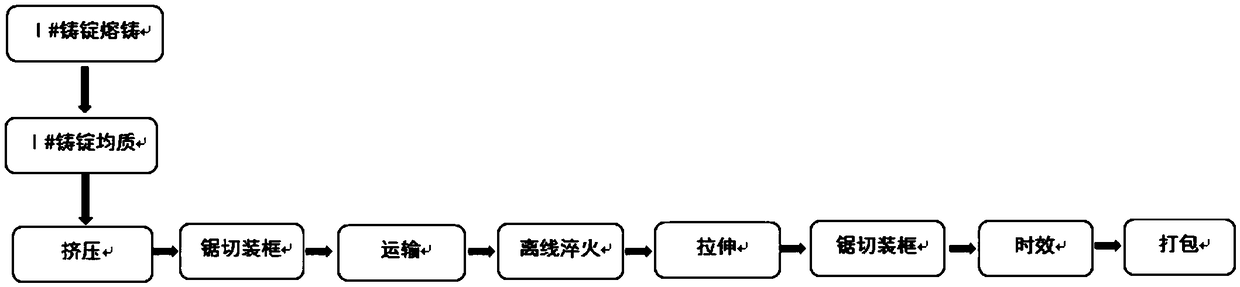

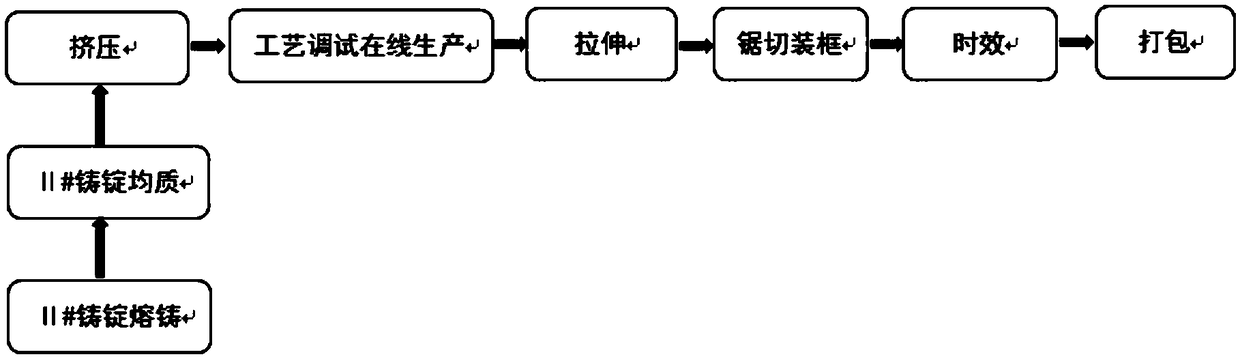

[0030] Such as figure 2 A kind of 2007 aluminum alloy bar production process shown, comprises the following steps:

[0031] A. Melting and casting: Prepare 2007 aluminum alloy raw materials according to the following weight ratio: Si: 0.50%, Mg: 0.60%, Fe: 0.80%, Cu: 4.2%, Mn: 0.45%, Cr: 0.03%, Ni: 0.02 %; Zn: 0.02%, Pb: 0.80%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the balance Al, put the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt into liquid aluminum alloy, and the liquid The aluminum alloy is melted and cast into an aluminum alloy ingot, and the melting temperature of the liquid aluminum alloy is 720°C;

[0032] B. Homogenization: heat the aluminum alloy ingot obtained by melting and casting to 480°C and keep it for 8 hours, then heat it to 510°C and keep it for 3 hours, and cool it to 420°C to obtain a homogeneous aluminum alloy ingot;

[0033] C. Extrusion: Send the homogenized aluminum alloy ingot into the ext...

Embodiment 2

[0040] Such as figure 2 A kind of 2007 aluminum alloy bar production process shown, comprises the following steps:

[0041] A. Melting and casting: prepare 2007 aluminum alloy raw materials according to the following weight ratio: Si: 0.60%, Mg: 0.40%, Fe: 0.60%, Cu: 4.0%, Mn: 0.55%, Cr: 0.03%, Ni: 0.02% ; Zn: 0.02%, Pb: 0.90%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the balance Al, put the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt into liquid aluminum alloy, and the liquid aluminum The alloy is melted and cast into an aluminum alloy ingot, and the melting temperature of the liquid aluminum alloy is 750°C;

[0042] B. Homogenization: heat the aluminum alloy ingot obtained by melting and casting to 480°C and keep it for 8 hours, then heat it to 510°C and keep it for 3 hours, and cool it to 360°C to obtain a homogeneous aluminum alloy ingot;

[0043] C. Extrusion: Send the homogenized aluminum alloy ingot into the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com