Motor stator and motor

A motor stator and stator slot technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of reducing motor efficiency, wasting copper space, and low iron utilization rate, so as to improve power density and motor efficiency and reduce power consumption. Iron content and the effect of improving iron utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

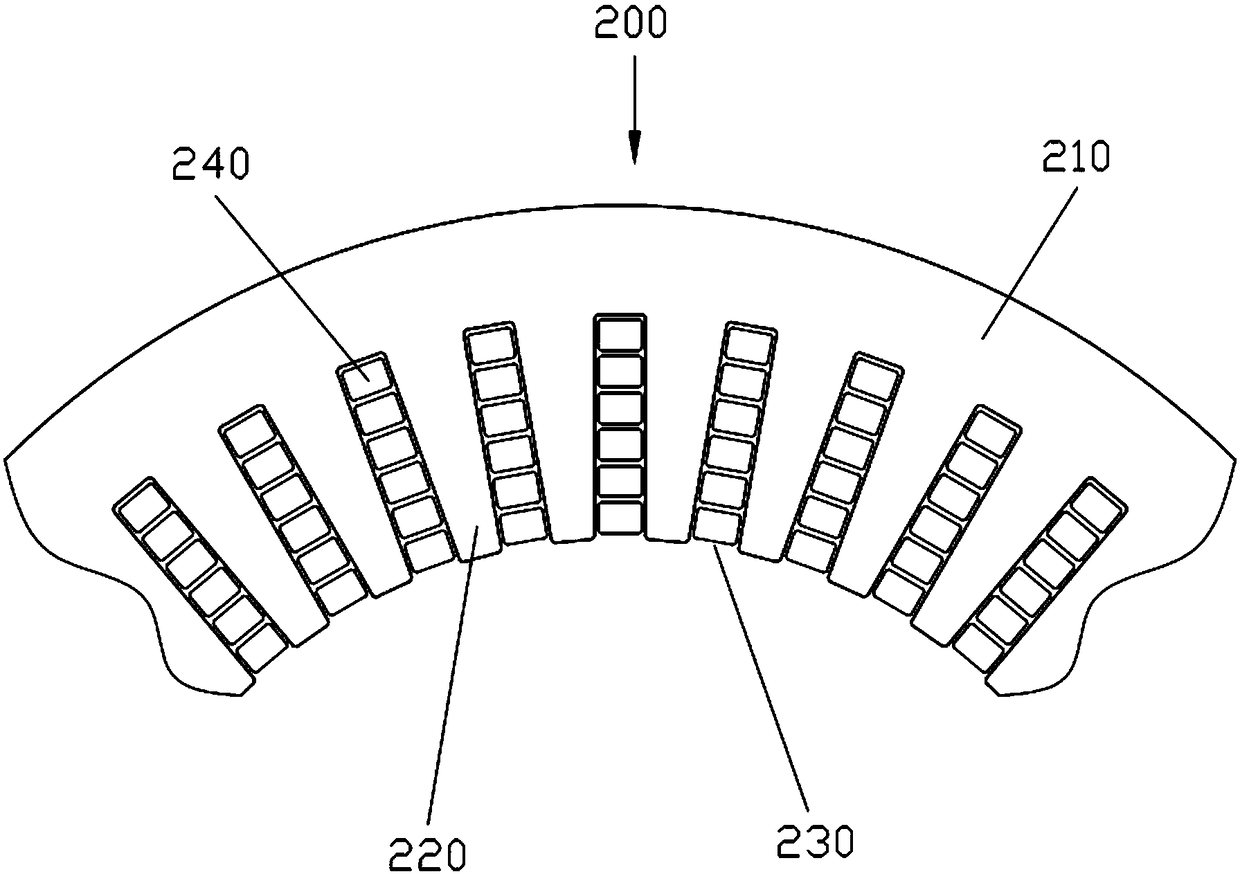

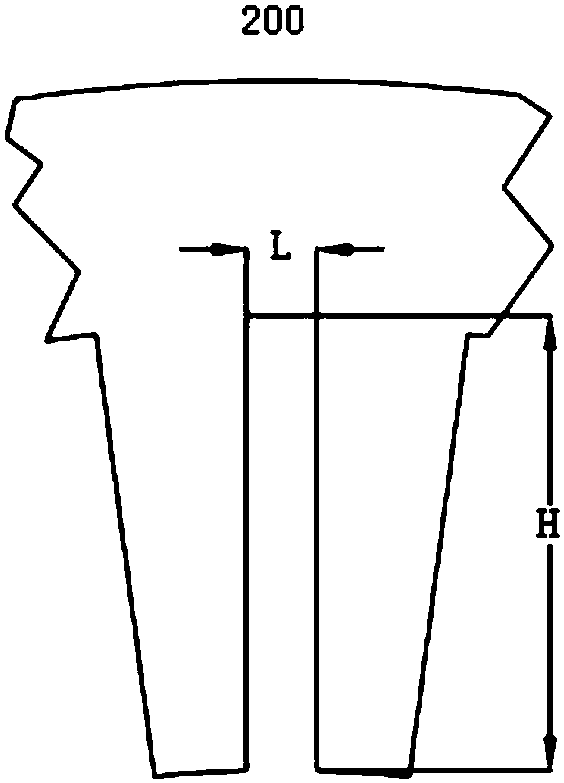

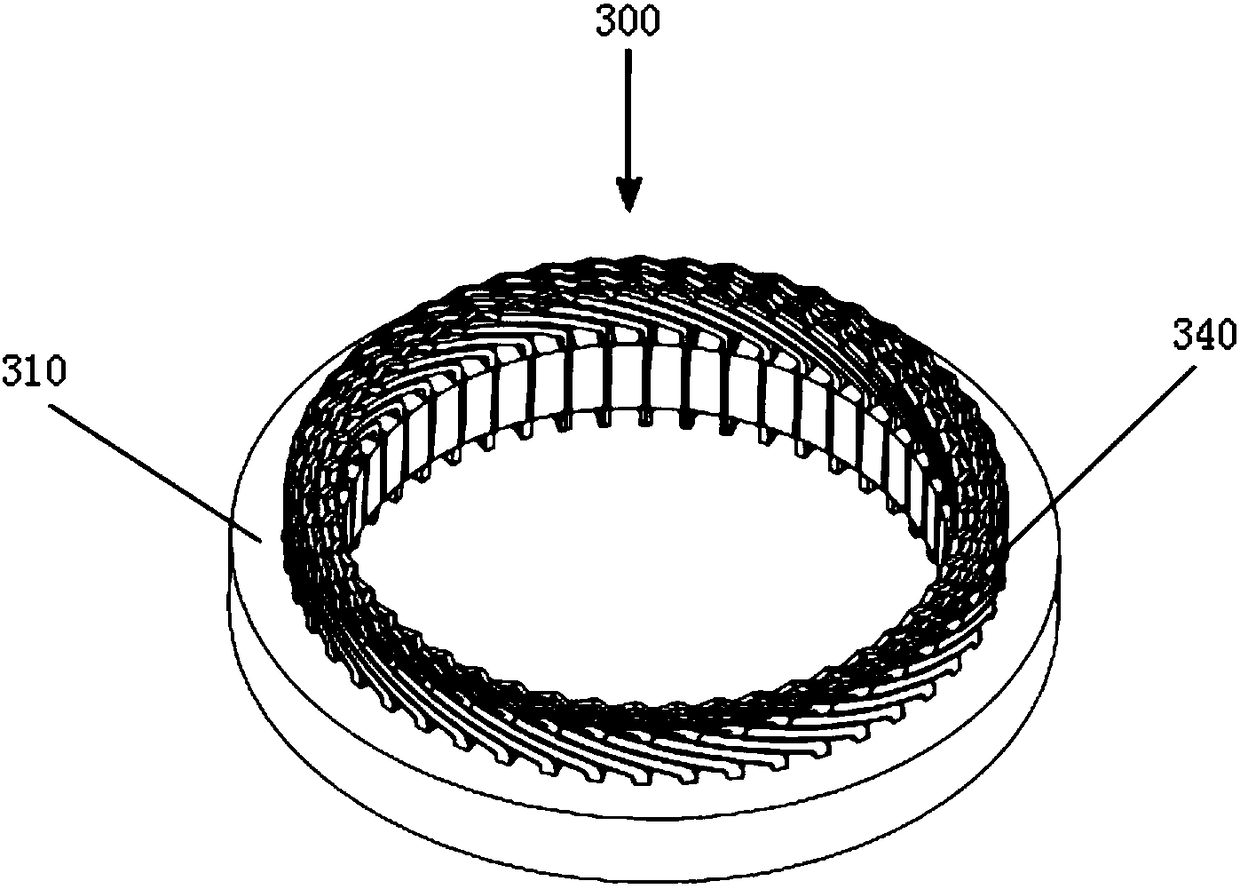

[0033] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only the technical solutions of the present invention. Some, but not all, embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative efforts fall within the protection scope of the present invention. It should be noted that the "width of the rectangular slot", "the width of the stator slot" and "the cross-sectional width of the copper wire" involved in the present invention all refer to the dimensions of the corresponding parts along the circumferential direction of the stator core. The "height of the rectangular slot", "the height of the stator slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com