U-shaped stator permanent magnet switched reluctance motor

A permanent magnet switch and reluctance motor technology, applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of reducing the power density and torque density of the motor, the long magnetic path of the working magnetic pole, and increasing the cost of the drive system , to achieve the effects of extremely small magnetic flux leakage, high performance to weight ratio, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] When the U-shaped stator permanent magnet switched reluctance motor provided by the present invention has three phases, the motor can be divided into a three-phase 6 / 5 structure and a three-phase 12 / 10 structure, and the working principle is the same.

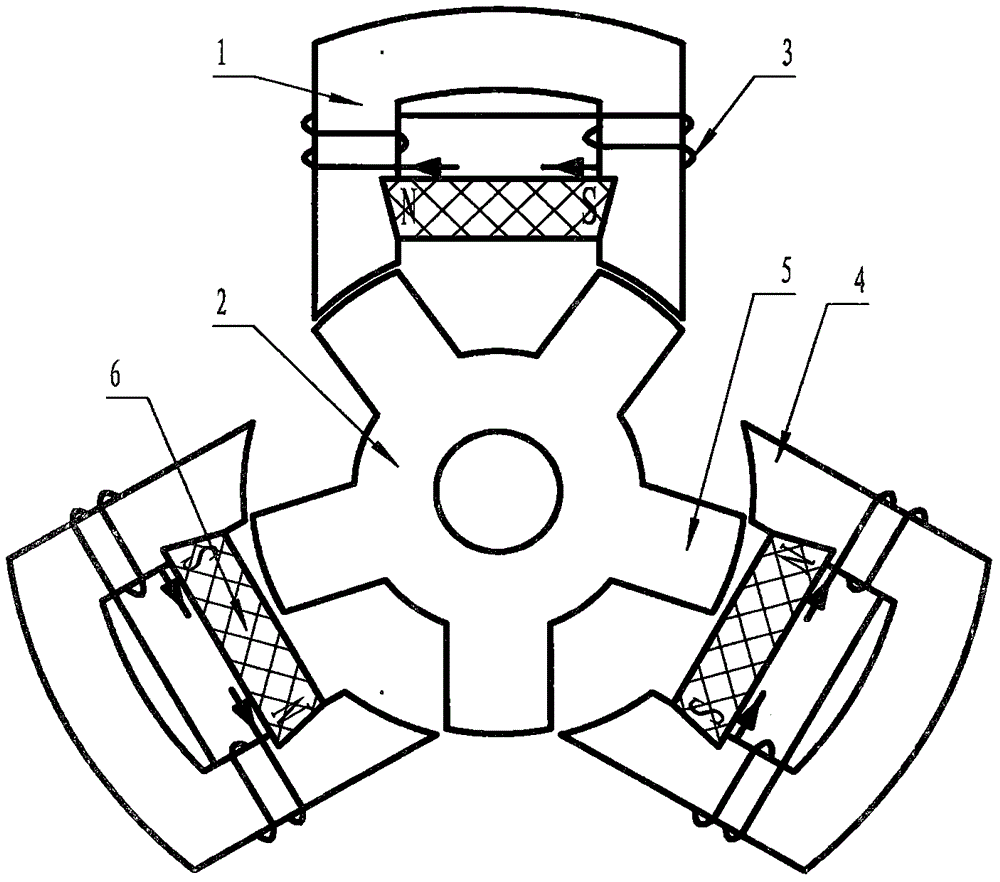

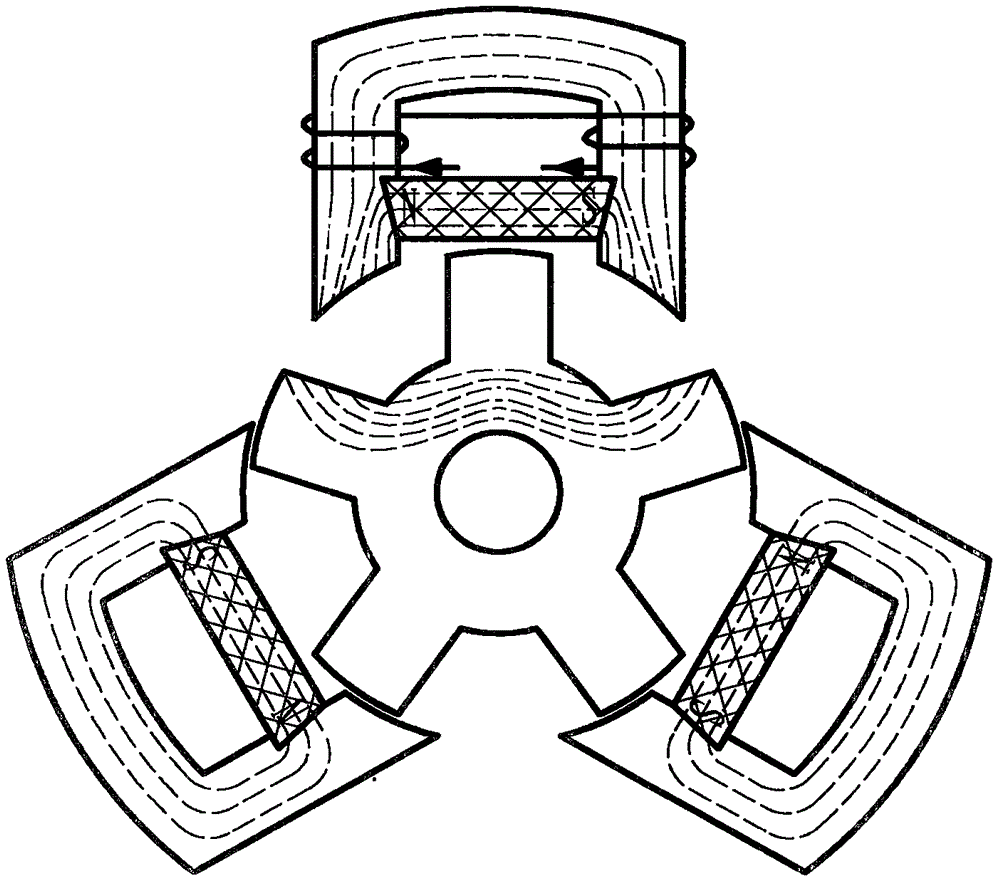

[0033] The cross-sectional structure of the U-shaped stator permanent magnet switched reluctance motor of the three-phase 6 / 5 structure of the present invention is as follows figure 1 As shown, it includes U-shaped stator block 1 , rotor 2 , field winding 3 and permanent magnet 6 . Three U-shaped stator blocks 1 are evenly distributed in the circumferential direction of the salient poles of the rotor 2. There is a permanent magnet installation slot 9 at the notch of each U-shaped stator block 1, and the permanent magnet 6 is placed on the permanent magnet of the U-shaped stator block 1. In the installation slot 9, the NS pole of the permanent magnet 6 is superimposed with the same polarity of the electromagnetic NS pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com