Novel static sealed high-temperature superconductive excitation magnetic flux switching motor

A magnetic flux switching motor and high-temperature superconducting technology, which is applied to synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of stator space shortage, limitation of superconducting motor power density, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

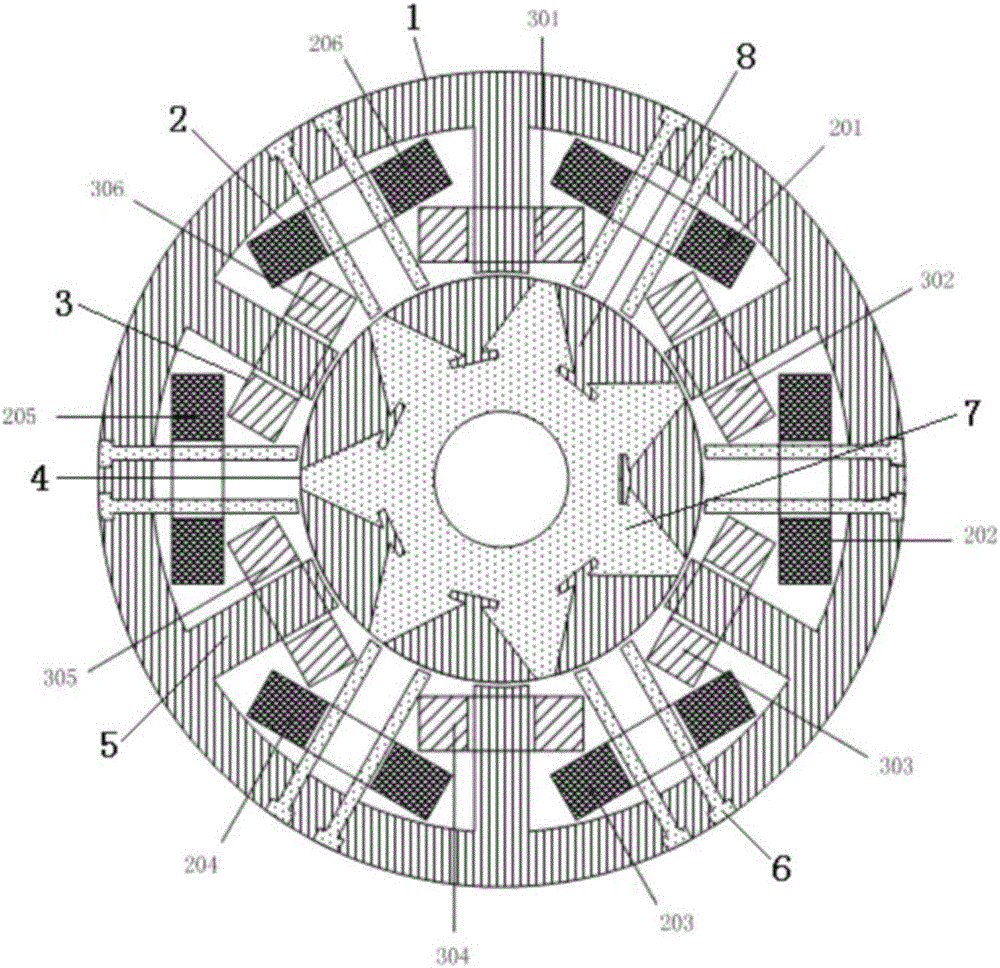

[0011] Such as figure 1 As described above, a new type of statically sealed high-temperature superconducting field flux switching motor includes a stator 1 and a rotor 4 from outside to inside, the stator 1 is formed by laminating silicon steel sheets, the rotor 4 is located inside the stator 1, and the inside of the stator 1 is There are six stator teeth 5 and six stator non-ferromagnetic supports 6 evenly and alternately around the circumferential direction, and the stator teeth 5 and the stator non-ferromagnetic supports 6 are respectively arranged in radial pairs, and the stator teeth 5 are wound with armature windings 3. The high temperature superconducting excitation winding 2 is wound on the stator non-ferromagnetic support 6; the rotor 4 is separated by the rotor non-ferromagnetic support 7 to form segmented rotor cores 8 that evenly and alternately surround along the circumferential direction.

[0012] The armature winding 3 is a concentrated winding, which is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com