Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

366results about How to "Reduce holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine anticorrosive coating

InactiveCN104087126AImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsHigh resistanceEpoxy

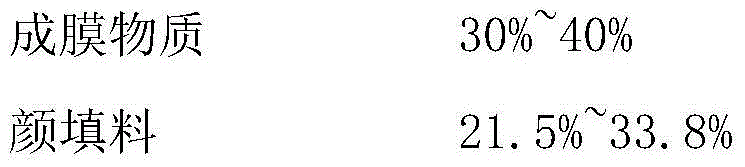

The invention discloses a marine anticorrosive coating. The marine anticorrosive coating consists of the following components in percentage by mass: 30-40 percent of film forming matter, 21.5-33.8 percent of pigment filler, 6.2-15.4 percent of aids and 30-42.3 percent of solvent, wherein the film forming matter consists of 16-23 mass percent of water-based phenolic epoxy resin and 14-16 mass percent of waterborne polyurethane; the pigment filler comprises graphene; the solvent is deionized water. The marine anticorrosive coating has high corrosion resistance, high flexibility, high wear resistance, high oil and aging resistance and good antirust performance. The film forming matter integrates high adhesion force, high strength, low shrinkage rate and high corrosion resistance of the water-based phenolic epoxy resin as well as high flexibility, wear resistance, oil and aging resistance and good film-forming performance of the waterborne polyurethane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

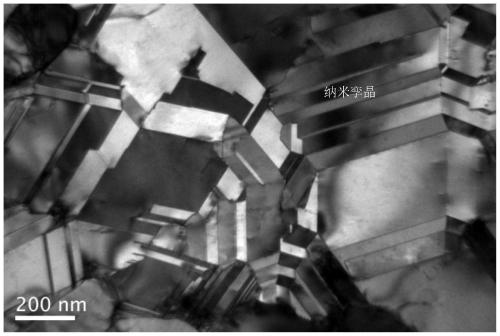

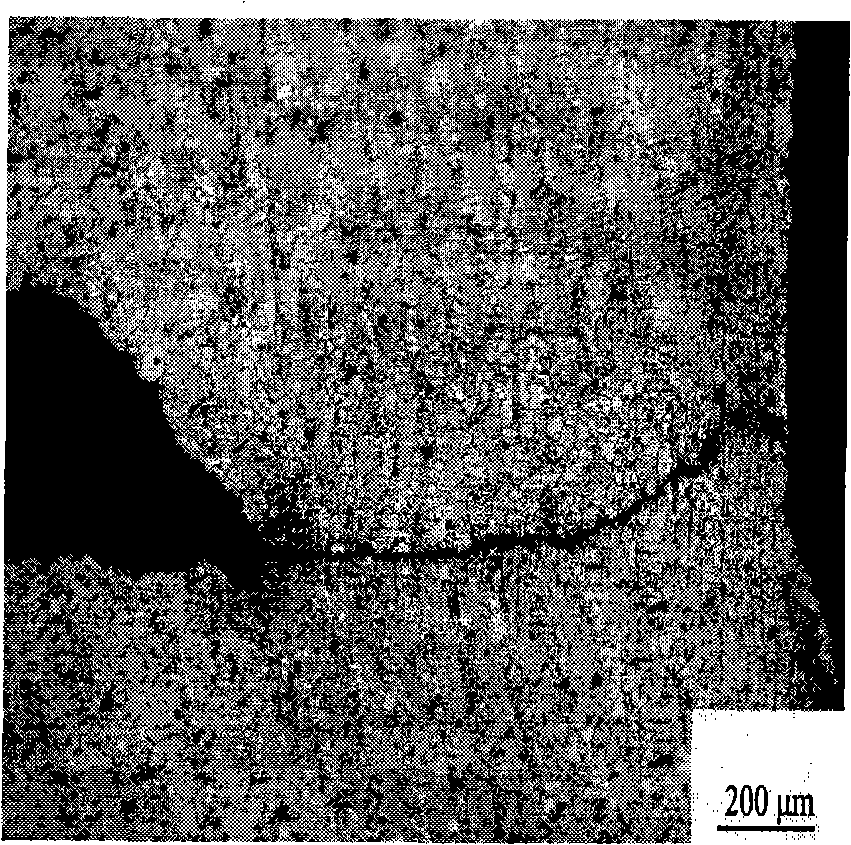

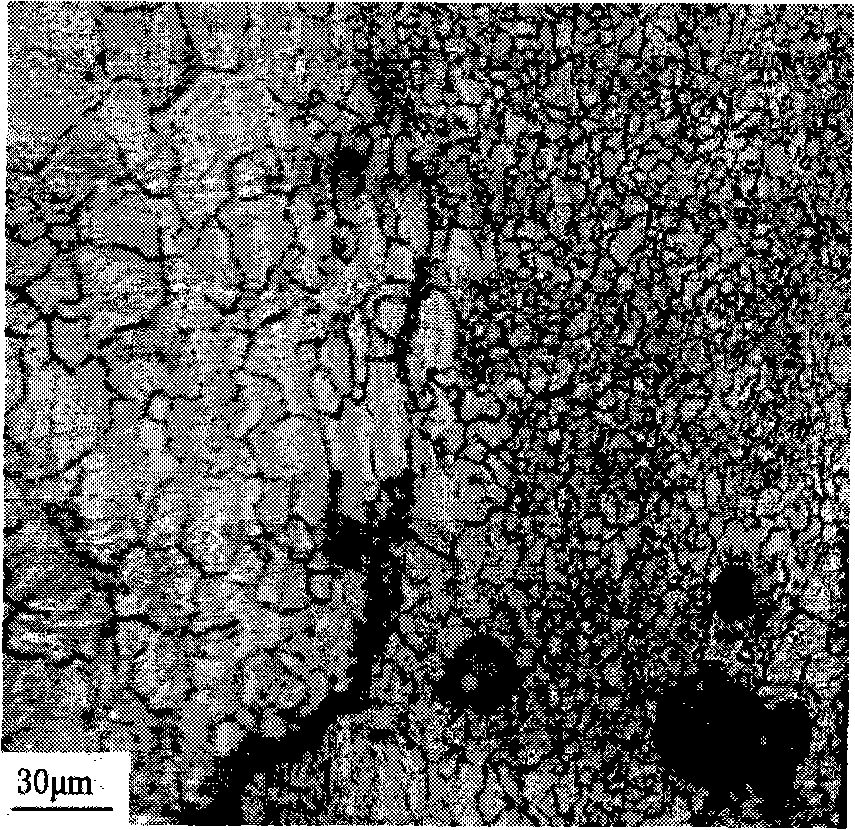

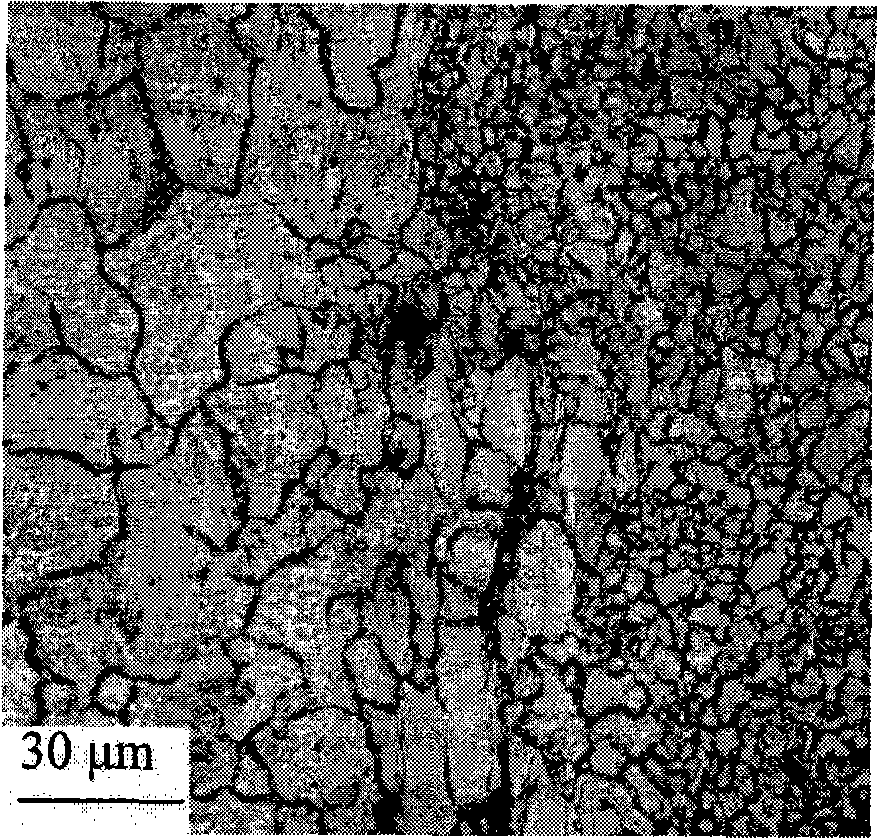

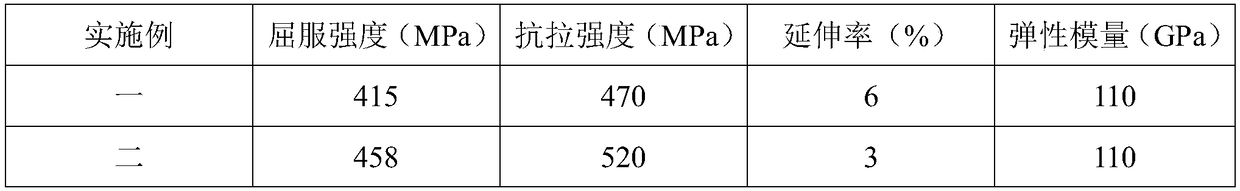

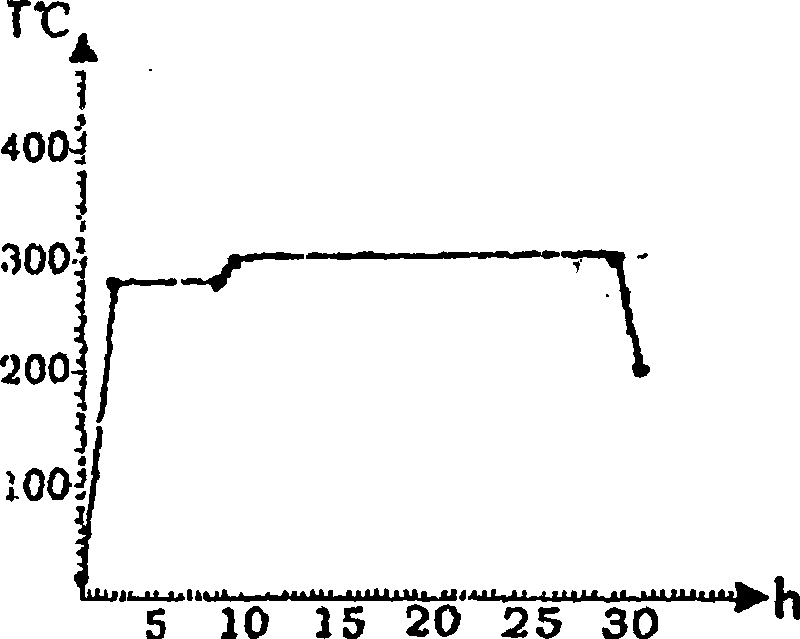

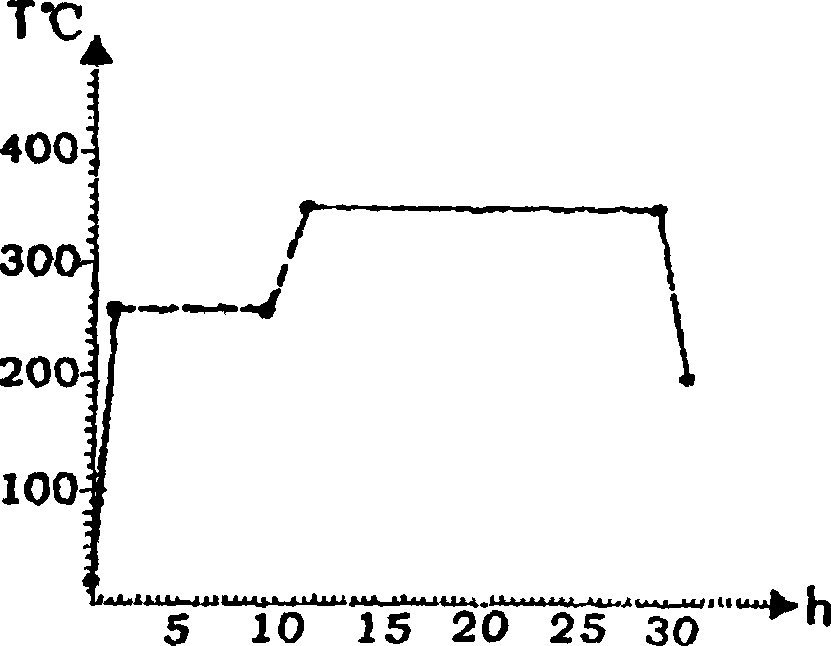

Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and preparation method for molding part

ActiveCN108486433AImprove performanceIncrease contentAdditive manufacturing apparatusIncreasing energy efficiencySolubilitySelective laser melting

The invention discloses an Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and a preparation method for a molding part. The composition comprises, by mass, 6-15% of Mg, 0.5-4% of Sc, 0.7-3% of Zr, 0.5-2% of Mn and the balance aluminum. An aluminum alloy molding part are prepared by smelting of master alloy, preparation of metal powder, preparation of aluminum alloy molding parts and heat treatment processes. According to the elective laser melting technology, the solubility of Mg, Sc and Zr alloy elements in aluminum matrix is greatly improved, the concentration of solid solution strengthening elements and dispersion strengthening particles in the aluminum alloy is increased, and the mechanical property of the aluminum alloy is improved. According to the aluminum alloy obtained by preparation of the selective laser melting technology, the highest density is 99.8%, the highest extension strength sigma b reaches 550 MPa, the yield strength sigma0.2 reaches 520 MPa, the plastic deformation rate of about 12 % is maintained, and the Al-Mg-Sc-Zr series aluminum alloy composition for the ctive laser melting technology and the preparation method for themolding part is applied to complicated structural parts with higher mechanical properties.

Owner:JIANGSU UNIV OF SCI & TECH

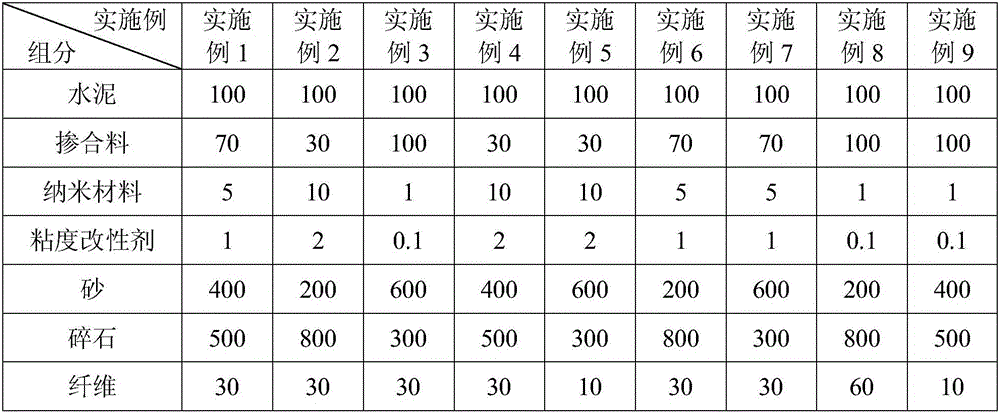

Concrete with common strength and high elastic modulus and preparation method thereof

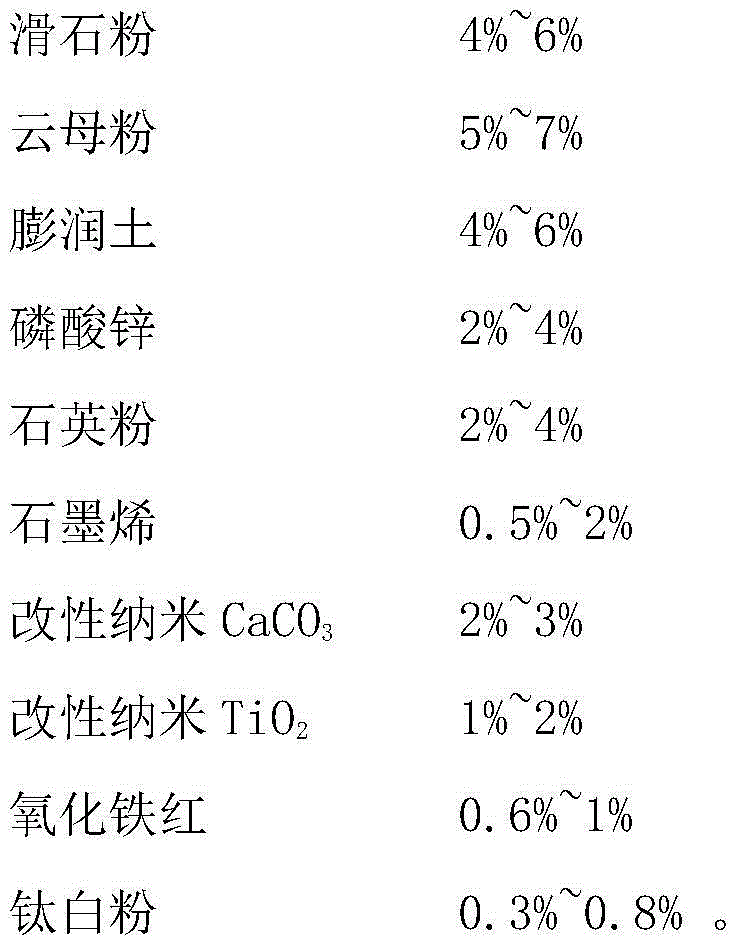

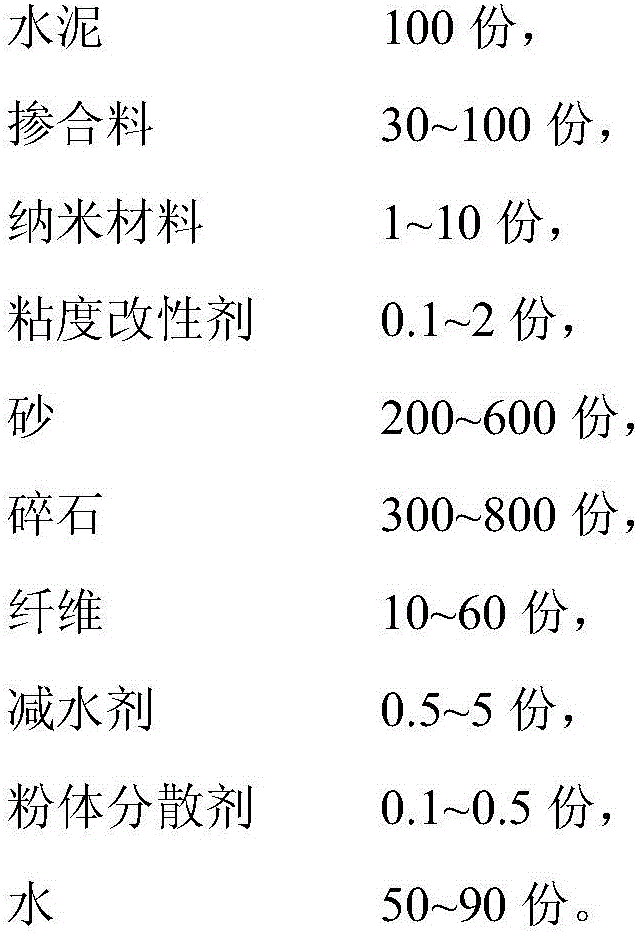

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

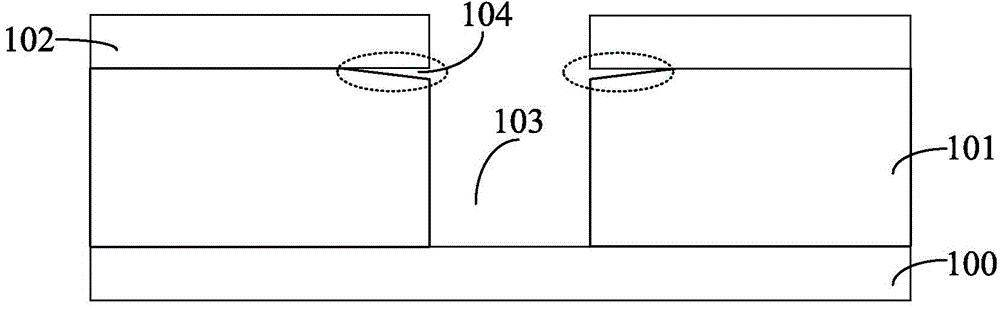

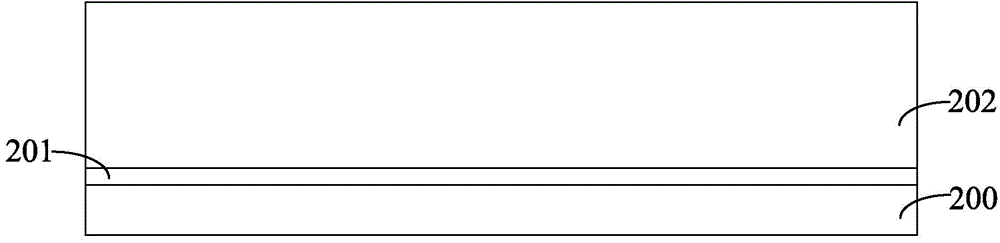

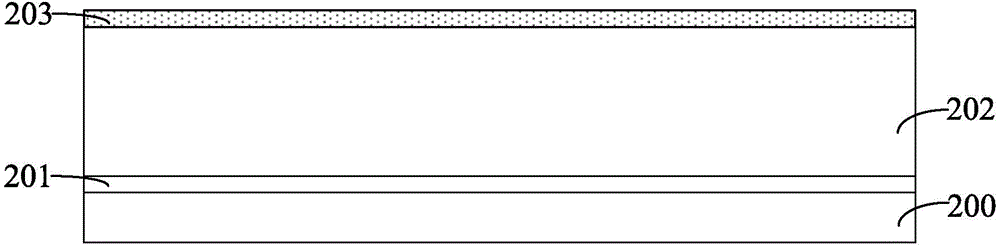

Semiconductor structure forming method

ActiveCN105097657AAvoid undercutInhibit sheddingSemiconductor/solid-state device manufacturingSemiconductor structureDielectric layer

The invention relates to a semiconductor structure. A semiconductor structure forming method comprises the following steps of providing a substrate; forming a carbon-containing dielectric layer on the surface of the substrate; forming a carbon-rich protecting layer on the surface of the carbon-containing dielectric layer, wherein the carbon atom concentration in the carbon-rich protecting layer material is greater than that in the carbon-containing dielectric layer material; forming a graphical hard mask layer on the surface of the carbon-rich protecting layer; and with the graphical hard mask layer as a mask, etching the carbon-rich protecting layer and the carbon-containing dielectric layer to form an opening, wherein the opening bottom makes the substrate surface exposed; and forming a metal layer filling the opening. An undercut phenomenon is prevented. The quality of the formed metal layer is improved. The performance of the semiconductor structure is further optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Hole sealing moisture-proof anticorrosive composite coating material and its prepn process

The pore sealing moisture-proof anticorrosive composite coating material includes pore sealing material and moisture-proof anticorrosive material. The pore sealing material includes gel with high solid phase content as the basic phase and filler(s) in the amount of 10-100 % of the solid phase component. The moisture-proof anticorrosive material is sol, hydrophobic organic matter or their mixture. The pore sealing moisture-proof anticorrosive composite coating material is prepared through the four steps of preparing pore sealing material, preparing moisture-proof anticorrosive material, preparing pore sealing coating and preparing moisture-proof anticorrosive coating. The pore sealing moisture-proof anticorrosive composite coating material has excellent water permeation arresting performance, high hydrophobicity and high corrosion resistance.

Owner:WUHAN UNIV OF TECH

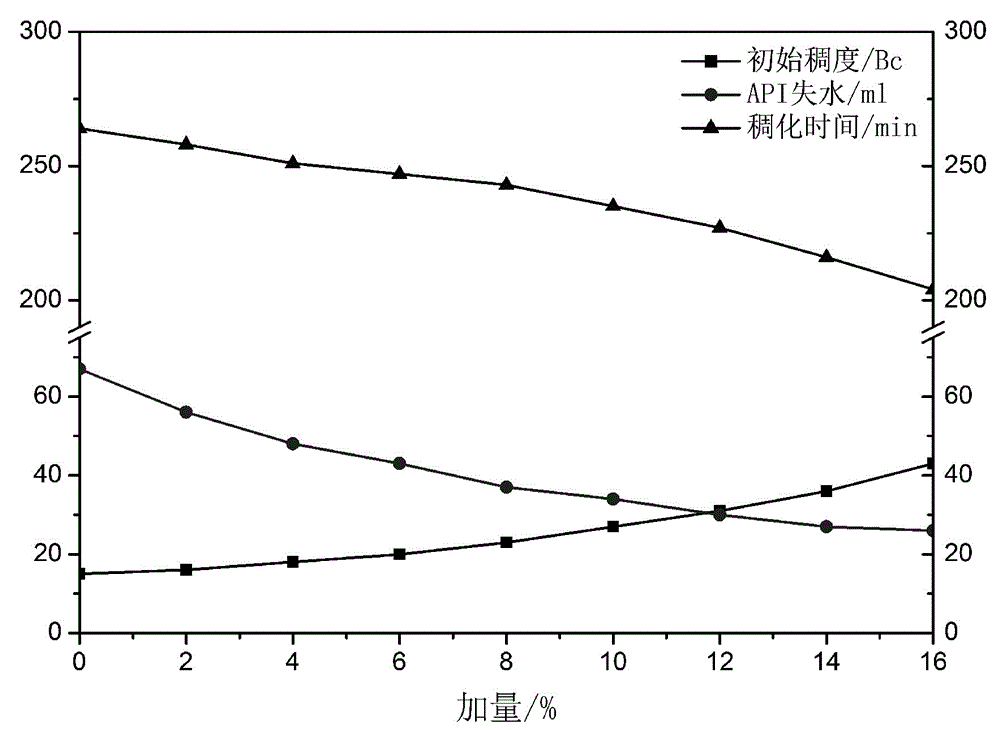

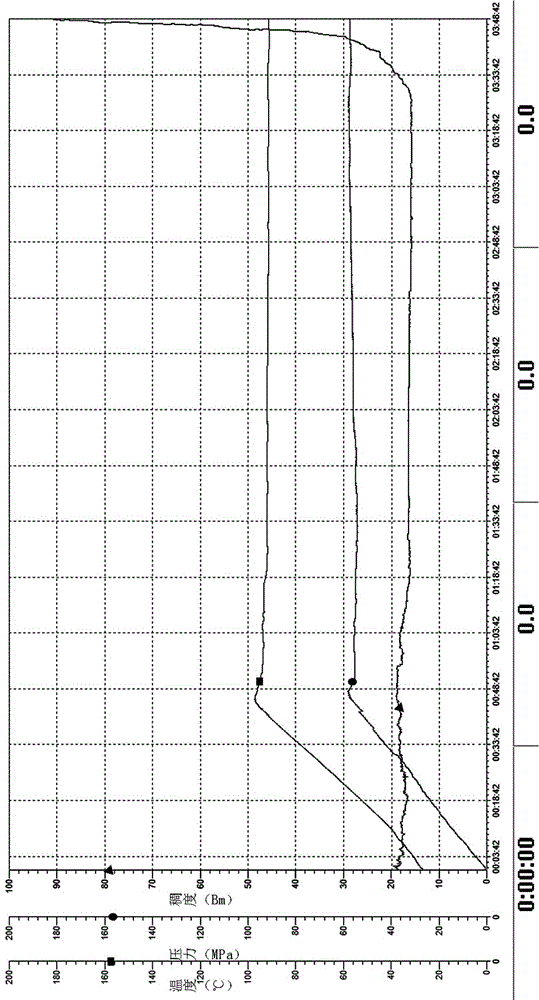

Novel liquid silicon anti-channeling cement slurry used in well cementation

InactiveCN105038745AApplicable temperature rangeHigh densityDrilling compositionPorosityWell cementing

The invention discloses a novel liquid silicon anti-channeling cement slurry used in well cementation, which includes following raw materials, by weight, 95-105 parts of G-grade cement, 10-35 parts of a strength stabilizer, 0.5-4 parts of a retarder, 0.1-0.2 parts of a defoaming agent, 5-15 parts of a filling agent, 0.5-2 parts of a dispersing agent, 100 parts of water, 5-15 parts of an anti-gas channeling agent, 5-10 parts of a fluid loss agent and also a density adjusting agent. The raw materials are mixed and stirred uniformly to prepare the novel liquid silicon anti-channeling cement slurry. The anti-channeling cement slurry is low in water loss, is good in stability, is short in static gelatinization transition time, is strong in anti-gas channeling performance, is quick in early strength development at a low temperature and resists corrosion of acidic mediums. Set cement slurry is slight in expansion, is less in porosity, is high in compactness and low in permeability, and can satisfy requirements in various well cementation situations.

Owner:成都欧美克石油科技股份有限公司

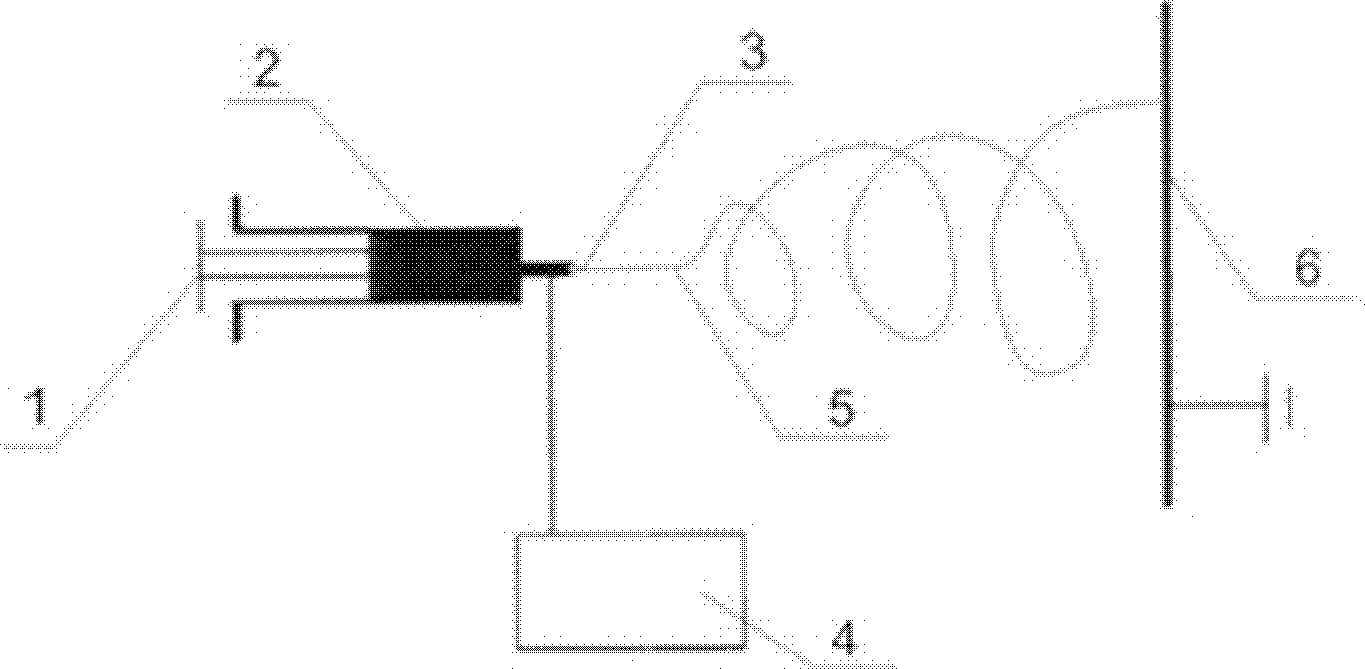

Preparation method for cigarette filter tip adopting electrostatically spun cellulose acetate membrane

InactiveCN102423141AEasy to cutEasy to sampleCigarette manufactureCellulose diacetateElectrospinning

The invention relates to a preparation method for a cigarette filter tip adopting an electrostatically spun cellulose acetate membrane, and the method includes the following steps: (1) cellulose diacetate is dissolved in the mixture of acetone and dimethylacetylamide, electrostatic spinning is carried out, and thereby the nano cellulose acetate membrane is obtained; (2) cellulose acetate tows in a cigarette are pulled out, the nano cellulose acetate membrane is laid between the filter tip and the cigarette along the cross-sectional direction of the filter tip, the cellulose acetate tows which are originally pulled out are then put into the cigarette, the part of the filter tip, which exceeds connecting paper, is cut off, and thereby the improved cigarette filter tip is fabricated. The preparation method uses the electrostatic spinning technology to fabricate the nano cellulose acetate membrane and adds the nano cellulose acetate membrane into the cigarette filter tip, the nano cellulose acetate membrane not only can be perfectly combined with the cigarette filter tip, but also can enhance the harmful gas-filtering performance of the cigarette filter tip, meanwhile, the preparation method is easy to operate, the efficiency is relatively high, and the cigarette filter tip can remarkably reduce the contents of various harmful components, and has a good market prospect.

Owner:DONGHUA UNIV +1

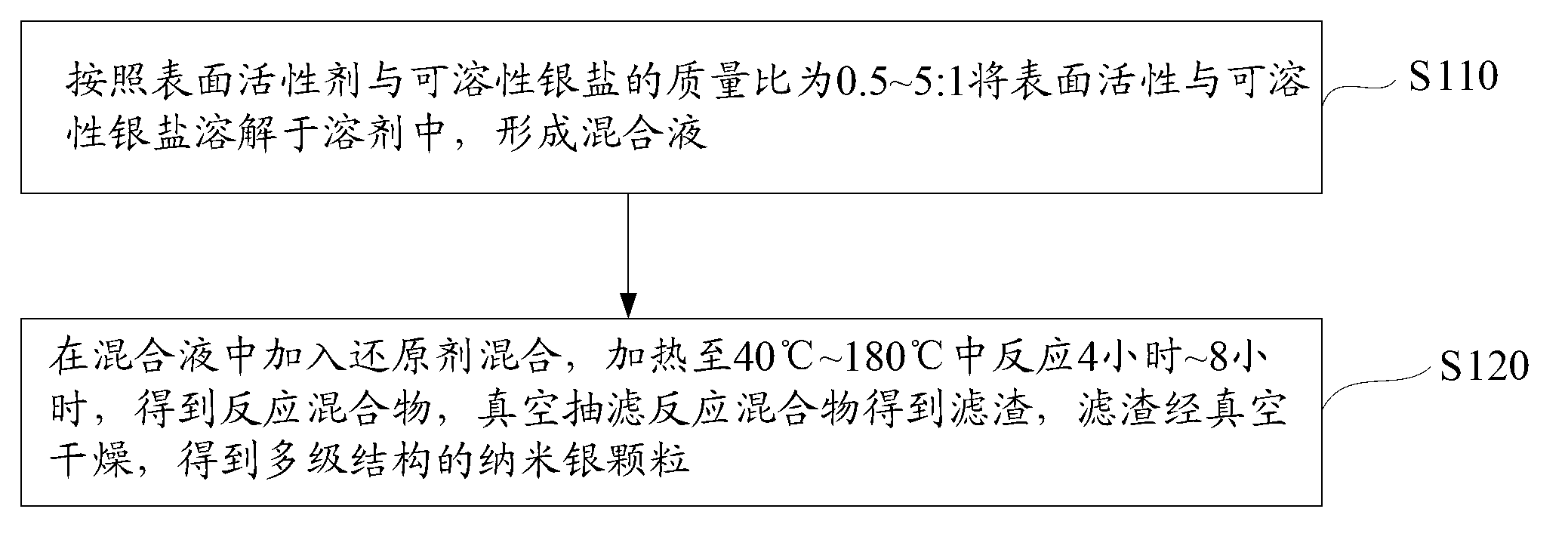

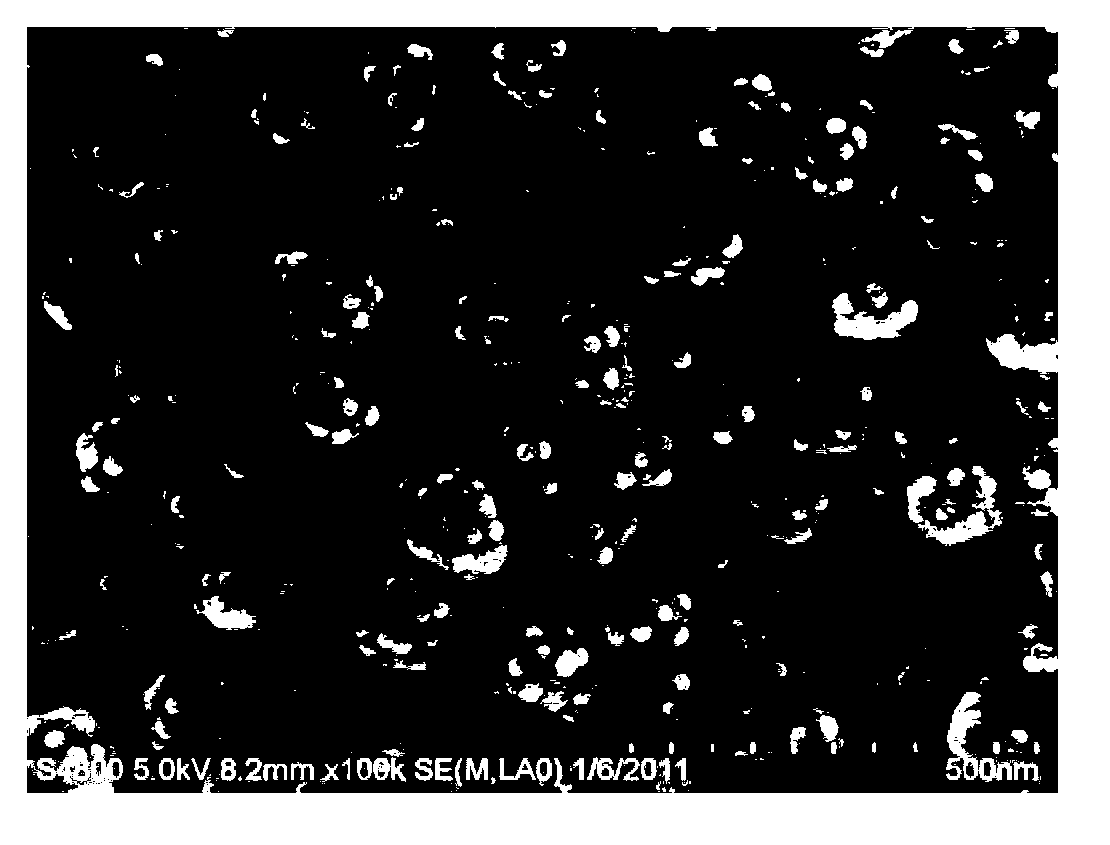

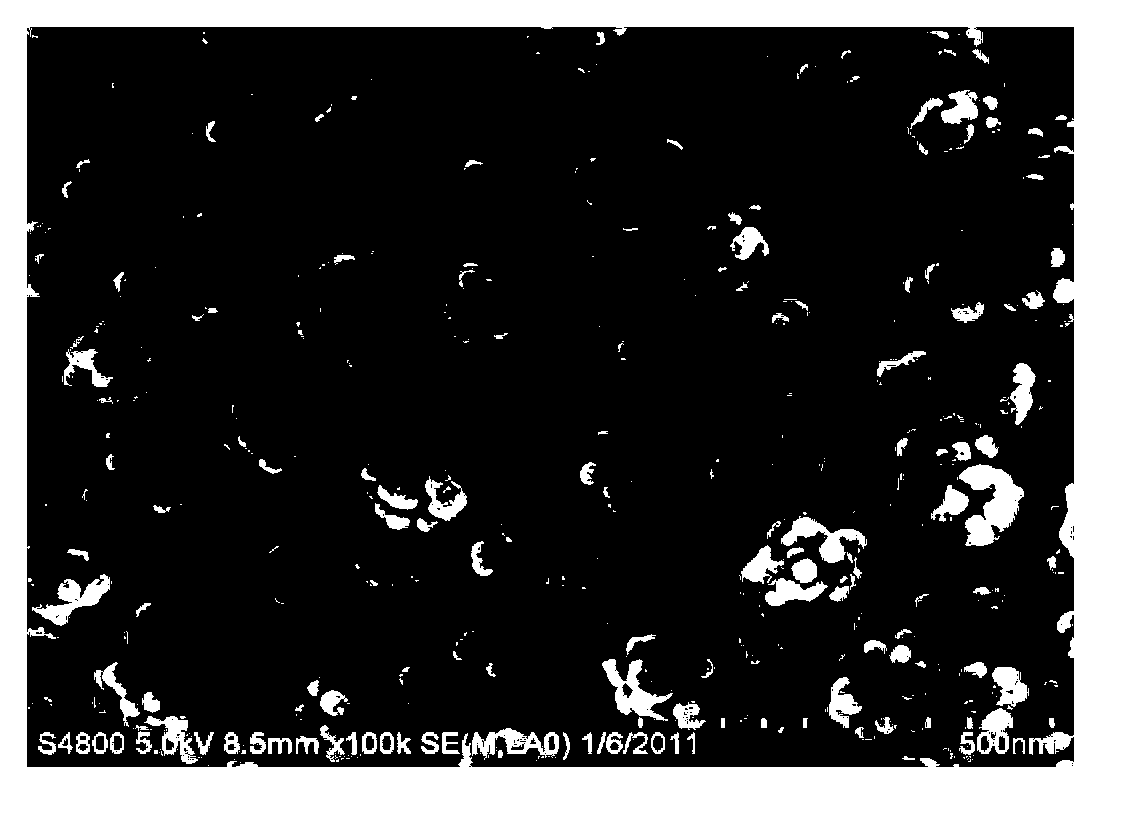

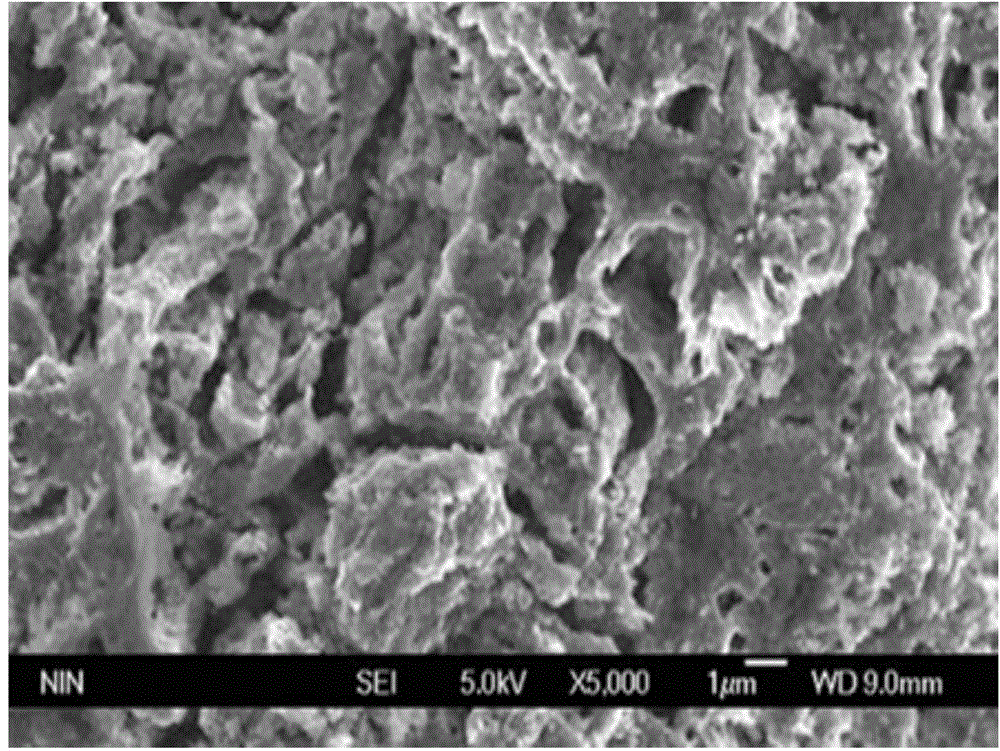

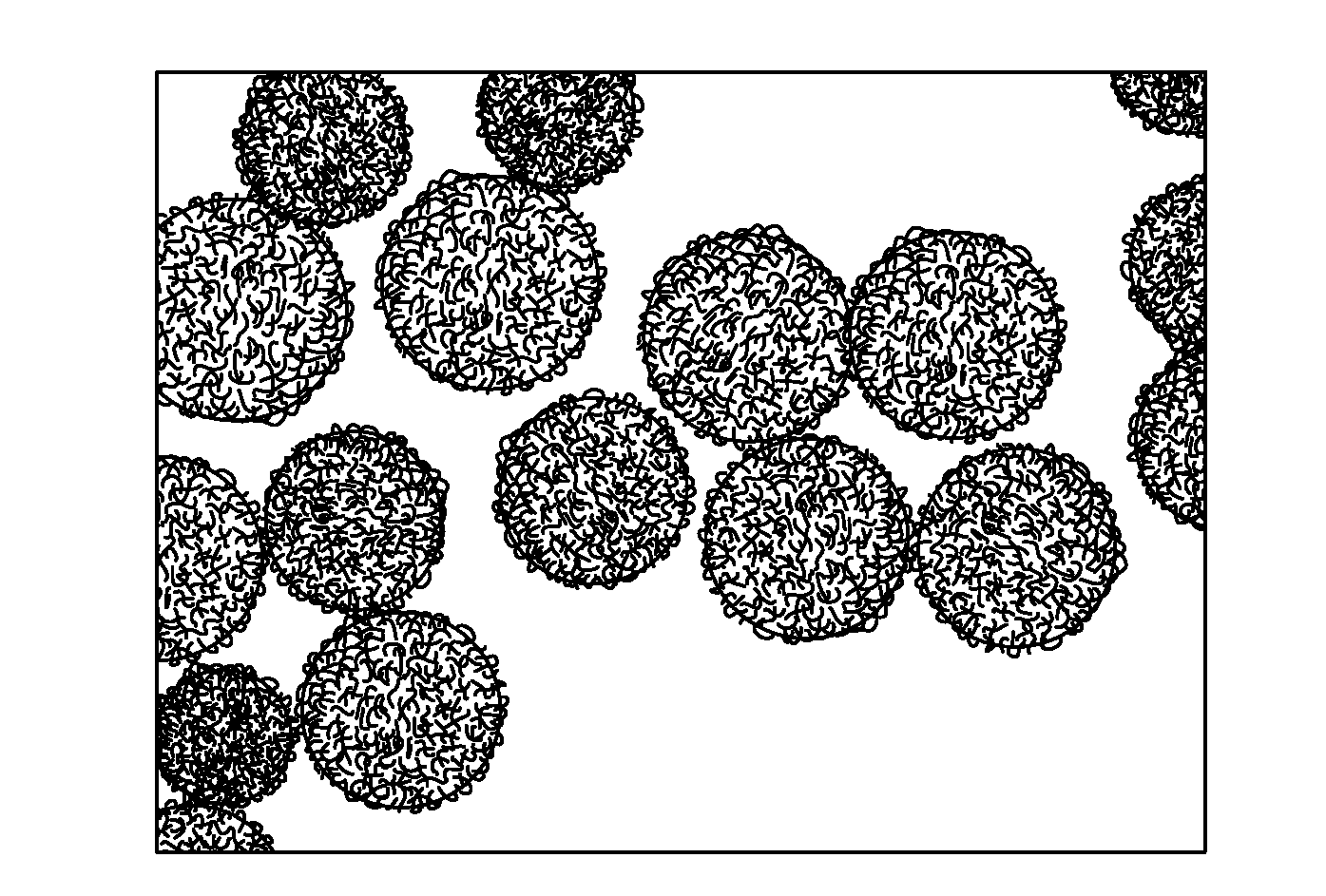

Nano silver particles with multilevel structure and preparation method thereof

The invention relates to nano silver particles with a multilevel structure, which comprise silver inner cores with the particle sizes of 100 nm to 200 nm and a plurality of silver nano microparticles with the particle sizes of 5 nm to 20 nm. Conductive silver paste obtained by the nano silver particles with the multilevel structure has a large surface area and has better dispersibility after being mixed with epoxy resin, the binding force between the conductive silver paste and the epoxy resin is strengthened and holes of the epoxy resin are reduced, so that passages capable of further conducting heat and electricity are provided, and thus, the conductive silver paste prepared from the nano silver particles with the multilevel structure has better heat conduction and electricity conduction performances. Moreover, the invention also aims to provide a preparation method of the nano silver particles with the multilevel structure.

Owner:SHENZHEN INST OF ADVANCED TECH

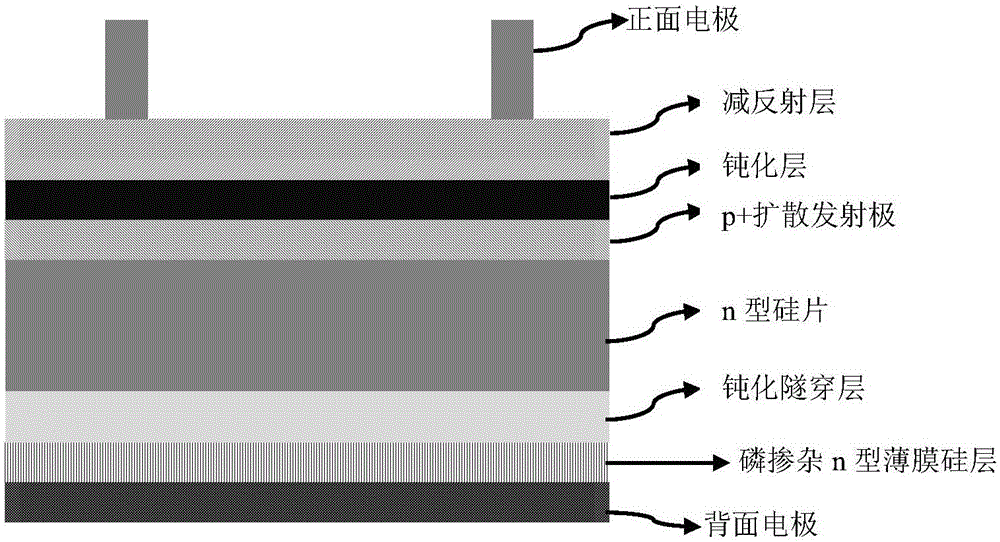

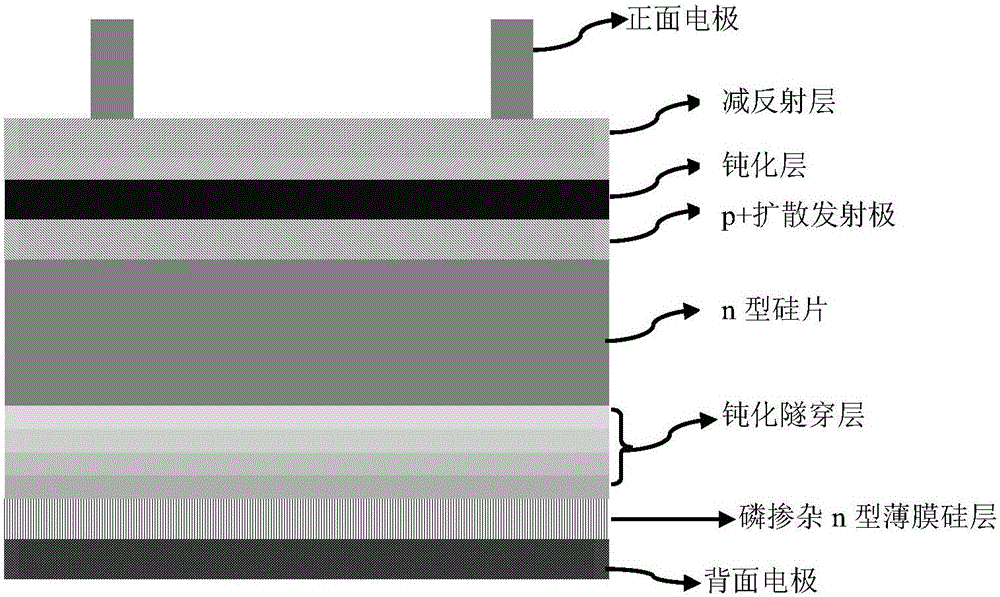

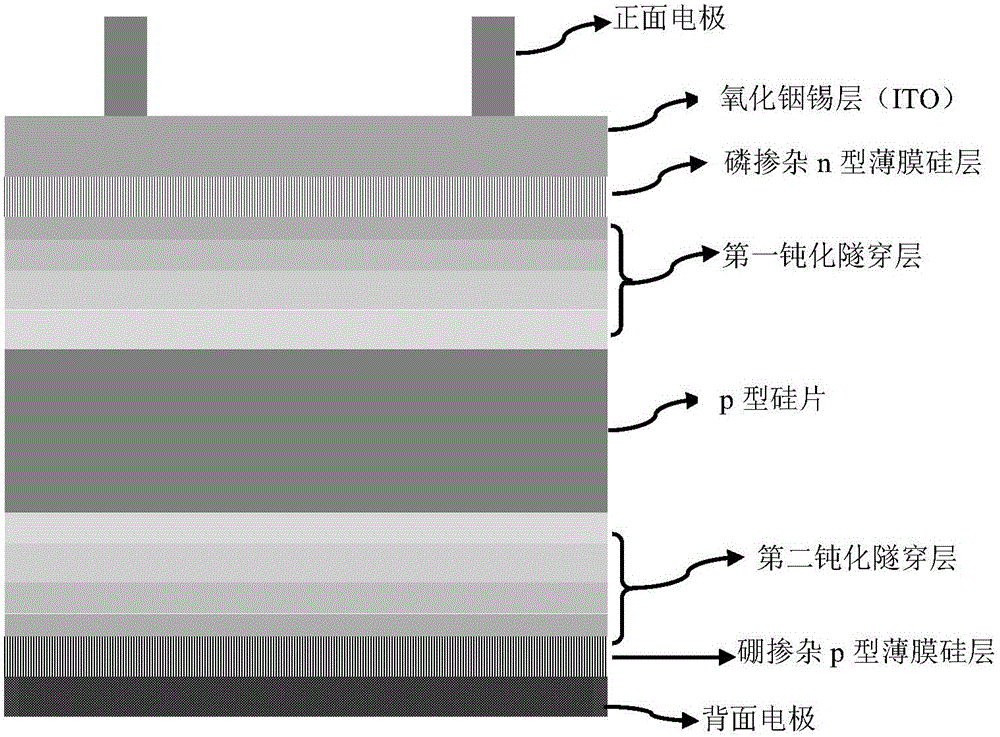

Tunnel silicon oxide passivated contact solar cell and preparation method thereof

ActiveCN105742391AReduce holesReduce generationPhotovoltaic energy generationSemiconductor devicesSilicon oxideSolar cell

The invention provides a solar cell. The solar cell comprises a silicon wafer, a passivated tunnel layer and a doping thin film silicon layer, wherein passivated tunnel layer is arranged between the silicon wafer and the doping thin film silicon layer, the passivated tunnel layer is one of a silicon oxide / silicon oxynitride gradient lamination layer, a silicon oxynitride / silicon nitride gradient lamination layer and a silicon oxide / silicon oxynitride / silicon nitride gradient lamination layer, the silicon oxynitride is nitrogen doping silicon oxide or oxygen doping silicon nitride, and the nitrogen concentration of the silicon oxide / silicon oxynitride gradient lamination layer, the silicon oxynitride / silicon nitride gradient lamination layer and the silicon oxide / silicon oxynitride / silicon nitride gradient lamination layer is gradiently reduced from a part far away from a silicon wafer side to the silicon wafer side. Since the tunnel barriers of silicon nitride and silicon oxynitride are relatively low, the thickness of the passivated tunnel layer can be appropriately widened on the premise of ensuring the tunnel efficiency, thus, the holes of the passivated tunnel layer are favorably reduced, the generation and combination rate of current leakage are reduced, the process window is expanded, and the process stability is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

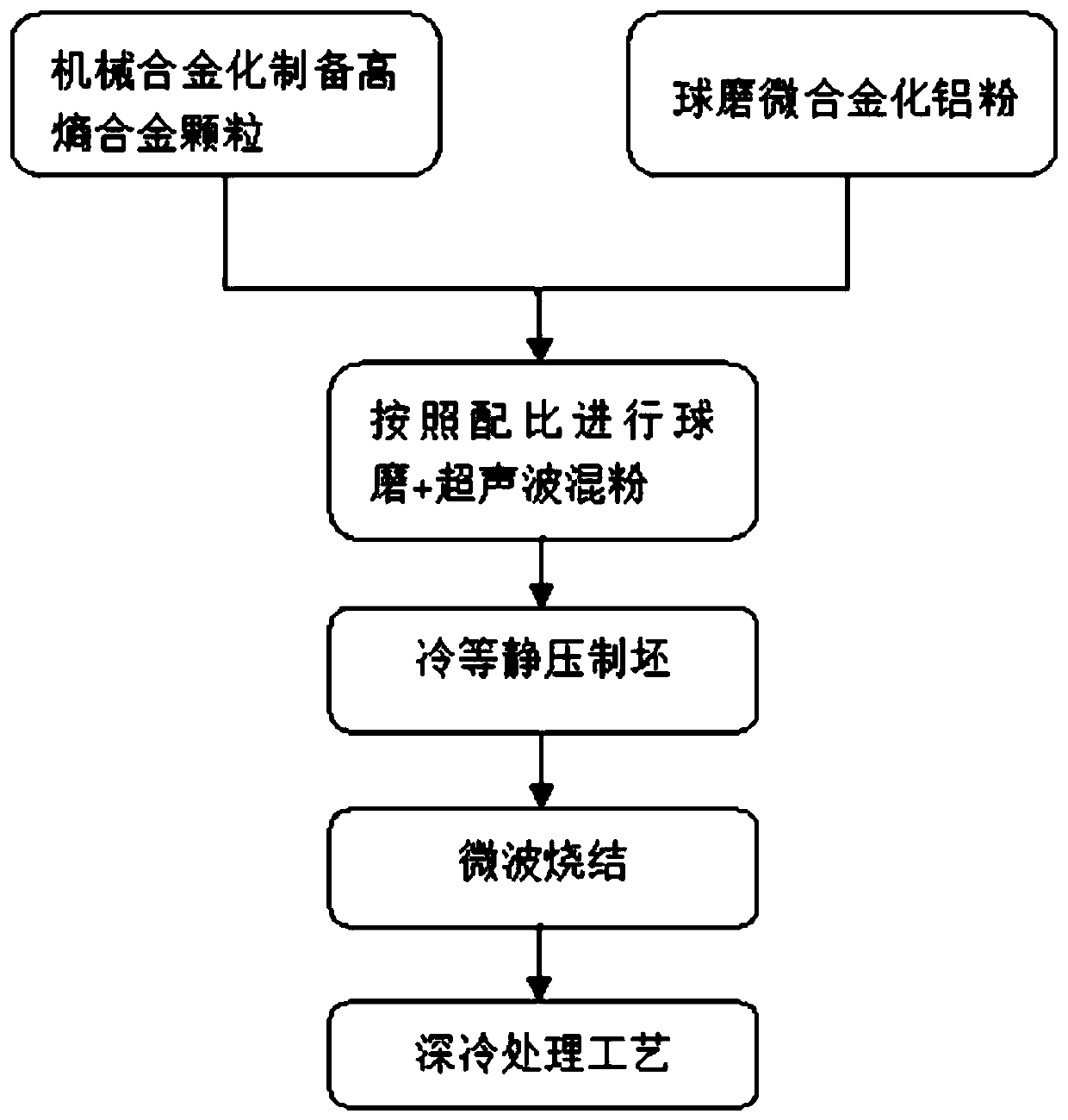

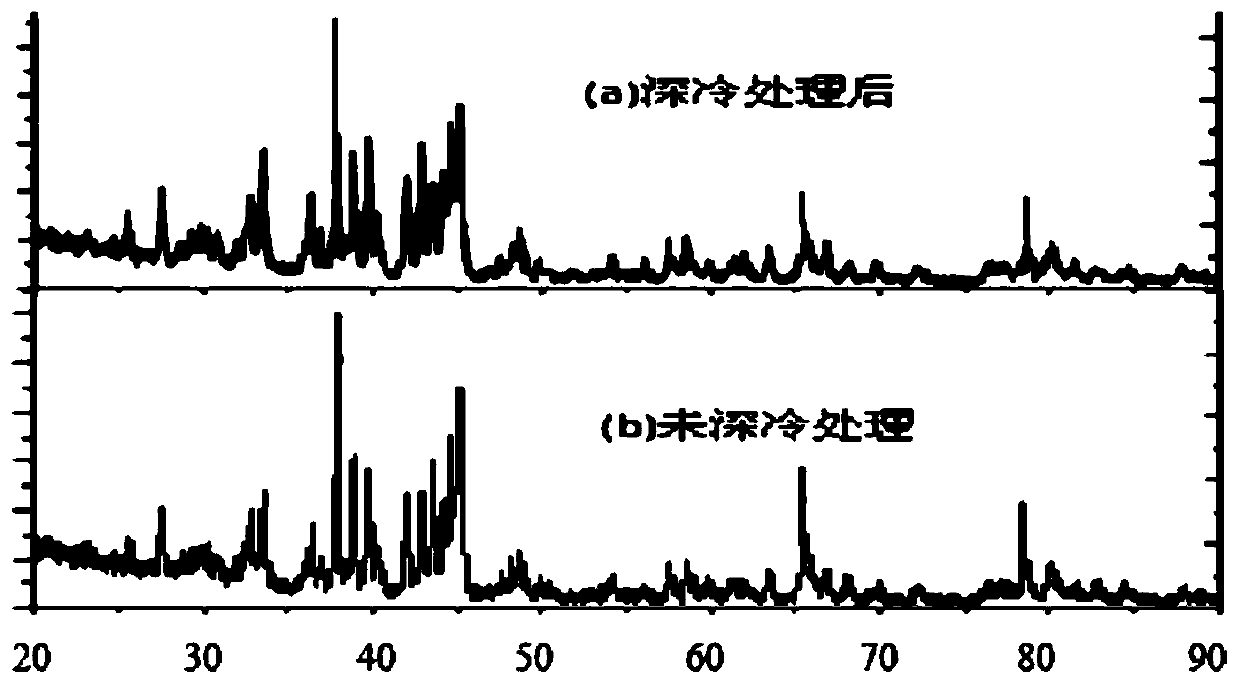

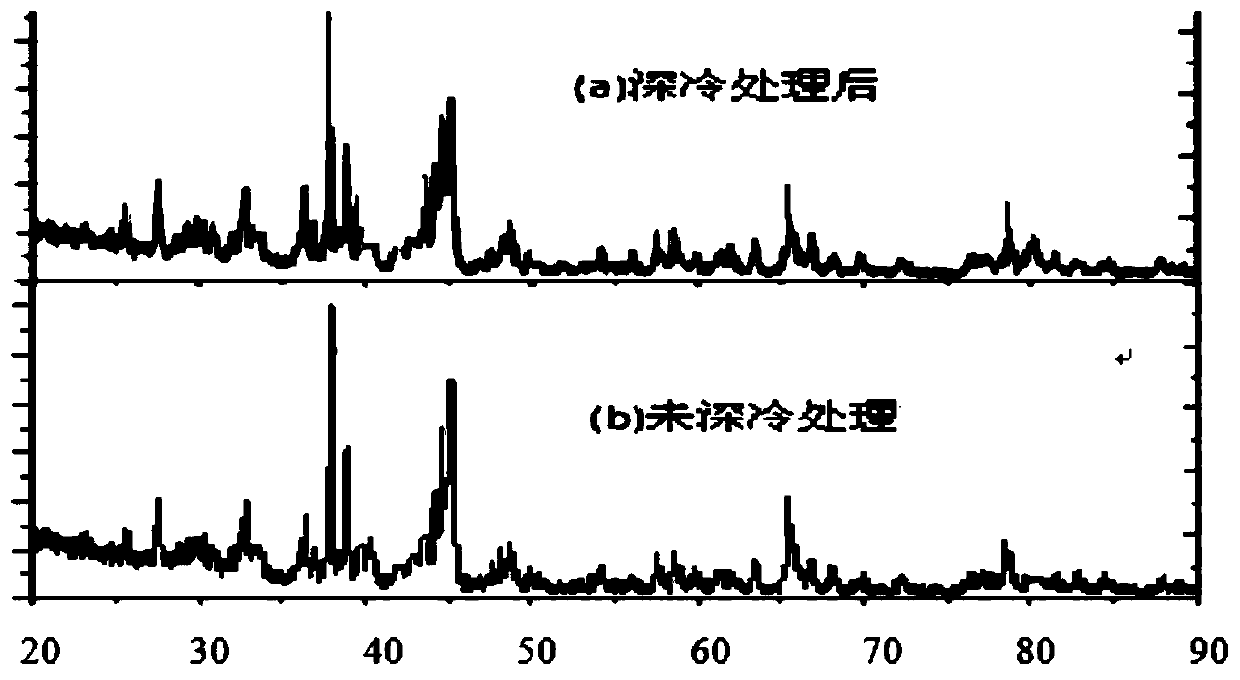

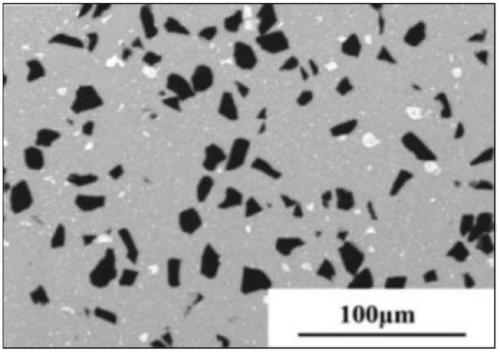

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

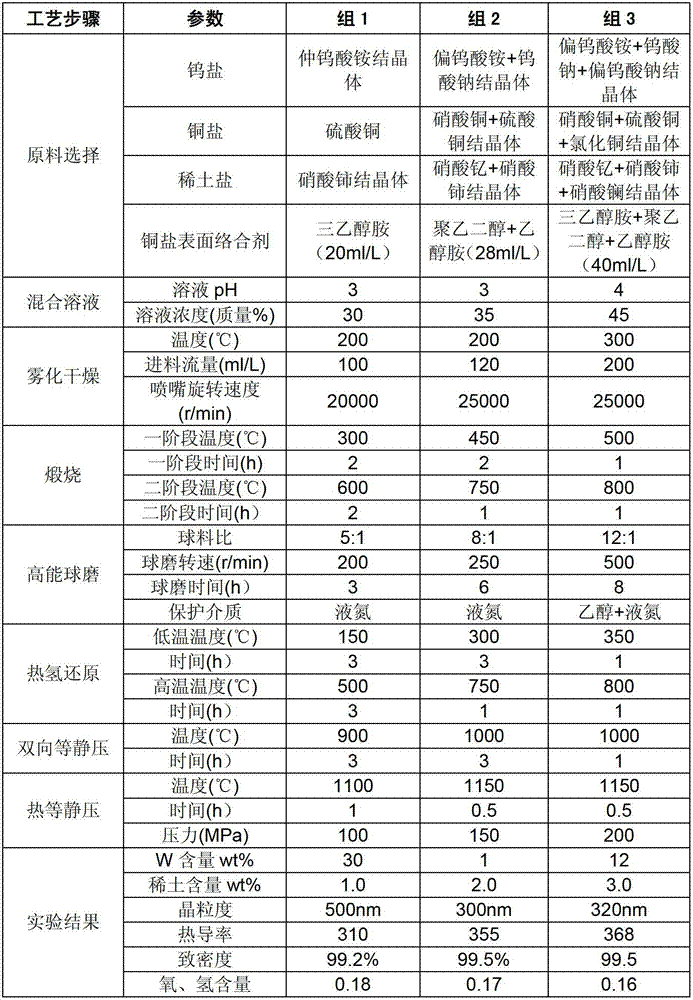

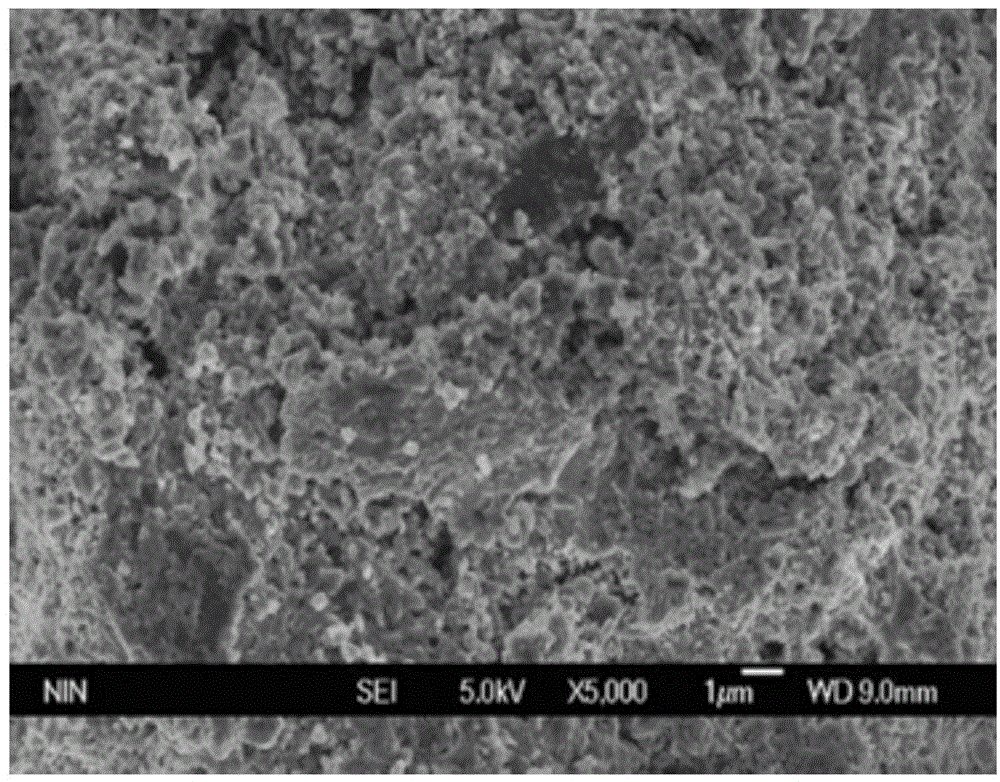

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

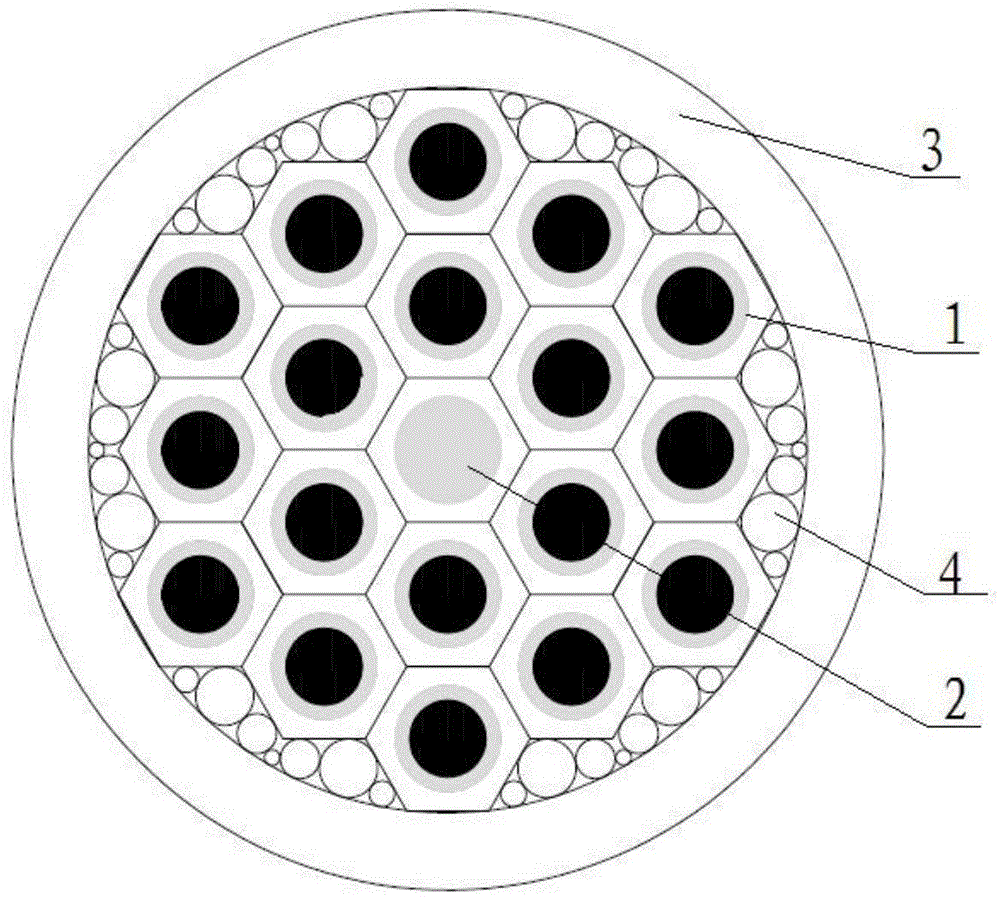

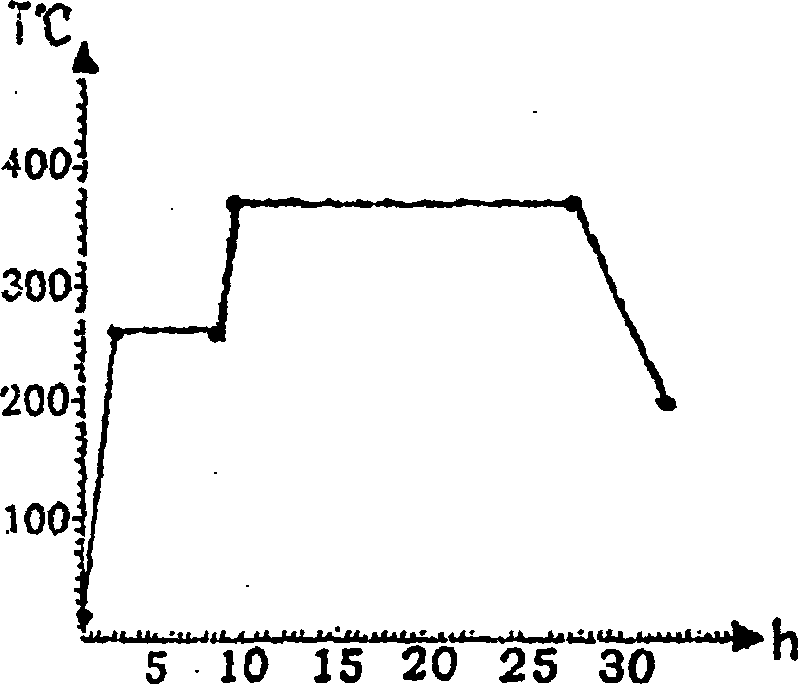

Method for manufacturing multi-core MgB2 superconductive wires through extrusion technology

ActiveCN104091651AImprove compactnessHigh yield strengthCable/conductor manufactureComposite strengthMachining deformation

The invention discloses a method for manufacturing multi-core MgB2 superconductive wires through the extrusion technology. The method includes the steps that first, precursor powder is prepared; second, the precursor powder is installed in a pipe to prepare a primary complex, and single-core wires are obtained through drawing machining; third, the precursor powder is installed in a pipe to prepare a secondary complex; fourth, the secondary complex processed through pre-heating seal welding is extruded, and multi-core rods are obtained; fifth, the multi-core rods are stripped and drawn to obtain multi-core wires, the multi-core wires are subjected to heat treatment, and then the multi-core MgB2 superconductive wires are obtained. According to the method, on the basis of a traditional power pipe-installing technology, a large single-pass machining deformation amount is adopted for manufacturing the multi-core MgB2 superconductive wires, in other words, the extrusion technology is adopted for manufacturing the multi-core MgB2 superconductive wires, because the secondary complex is in a very favorable three-dimensional stress state in extrusion, good metallurgical bonding will be achieved between different metal interfaces in the secondary complex along with the large extrusion deformation amount, the manufactured multi-core rods are high in composite strength, and the compactness and the yield strength of the multi-core MgB2 superconductive wires can be significantly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

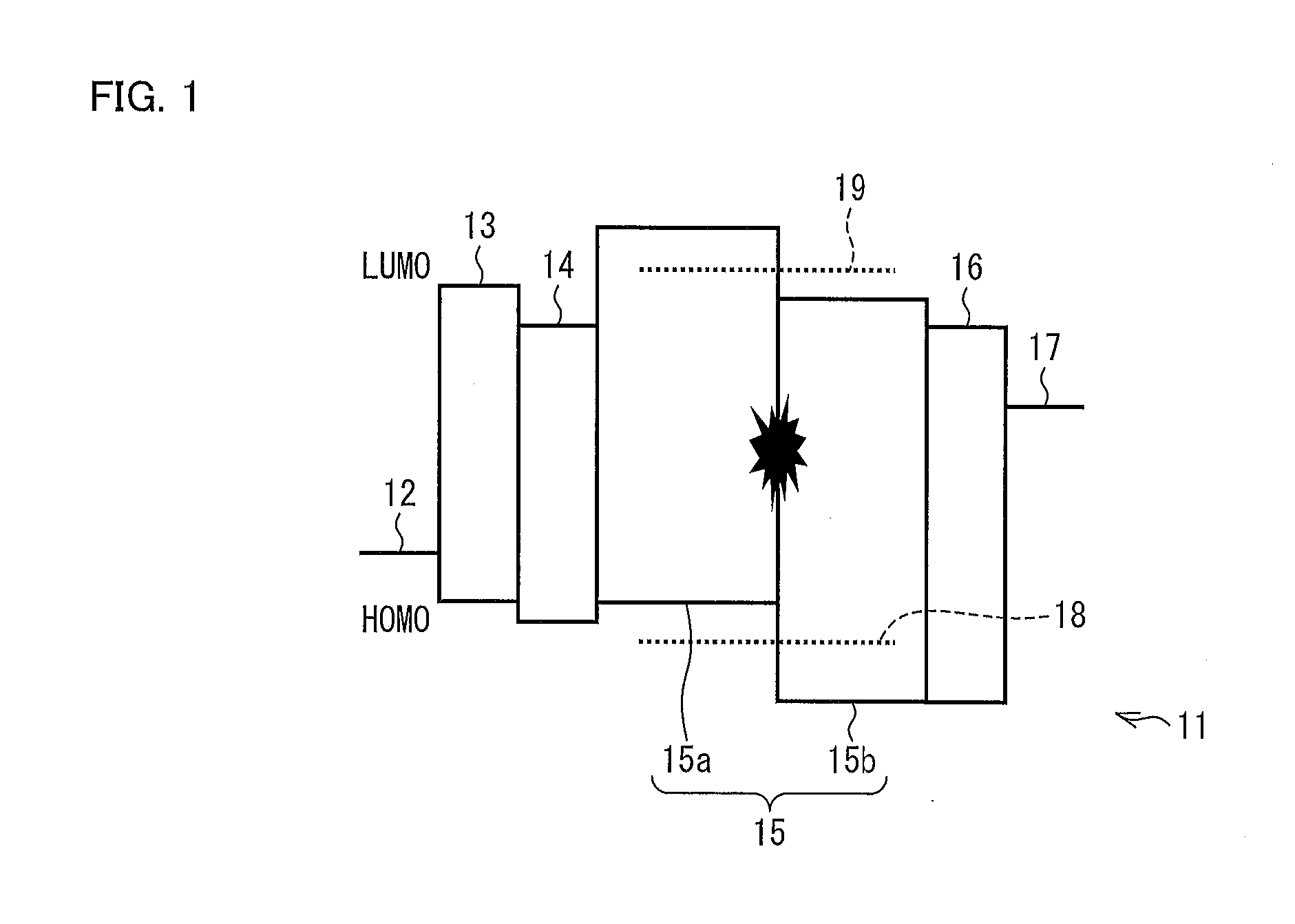

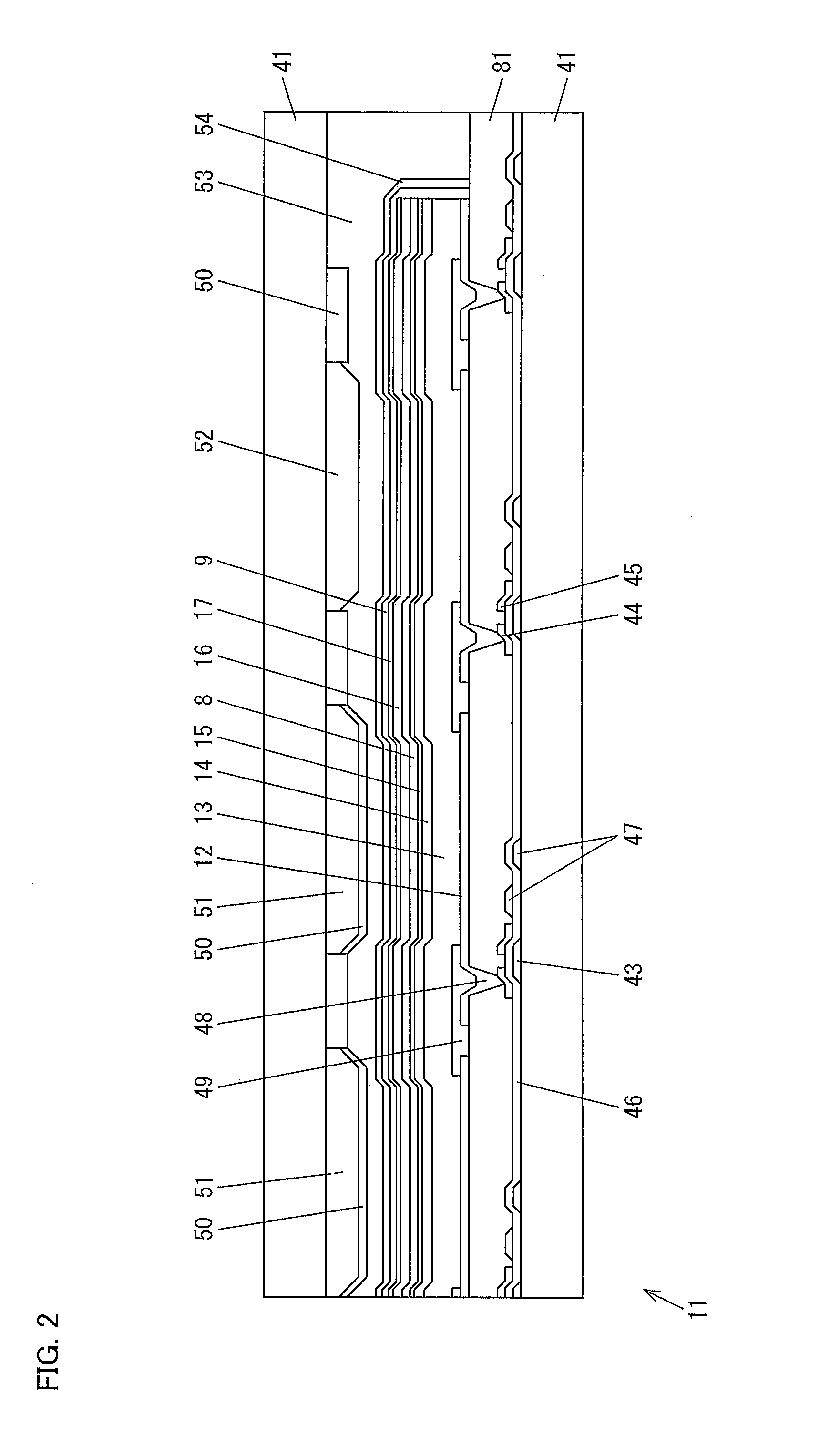

Organic electroluminescence element, manufacturing method thereof, and organic electroluminescence display device

ActiveUS20120261653A1Reduce holesImprove internal quantum yieldElectroluminescent light sourcesSolid-state devicesPhysicsOrganic electroluminescence

An organic EL element (11) includes a light emitting layer (15) which has a two-layer structure, and a first light-emitting layer (15a) is made from a host material which includes LUMO shallower than (i) LUMO (19) of a phosphorescent light emitting material and (ii) LUMO of a host material, from which a second light-emitting layer (15b) is made (|LUMO (host material for first light-emitting layer)|<|LUMO (host material for second light-emitting layer)| and |LUMO (host material for first light-emitting layer)|<|LUMO (phosphorescent light emitting material)|).Further, the second light-emitting layer (15b) is made from a host material which includes HOMO deeper than (i) HOMO (18) of the phosphorescent light emitting material and (ii) HOMO of the host material, from which the first light-emitting layer (15a) is made (|HOMO (host material for second light-emitting layer)|>|HOMO (host material for first light-emitting layer)| and |HOMO (host material for second light-emitting layer)|>|HOMO (phosphorescent light emitting material)|). This makes it possible (i) to block holes from moving to the second light-emitting layer (15b) and (ii) to block electrons from moving to the first light-emitting layer (15a). As a result, a probability that the holes and the respective electrons recombine with each other is increased. It is therefore possible to reduce a driving voltage of an organic EL element (11). This improves light emitting efficiency.

Owner:SHARP KK

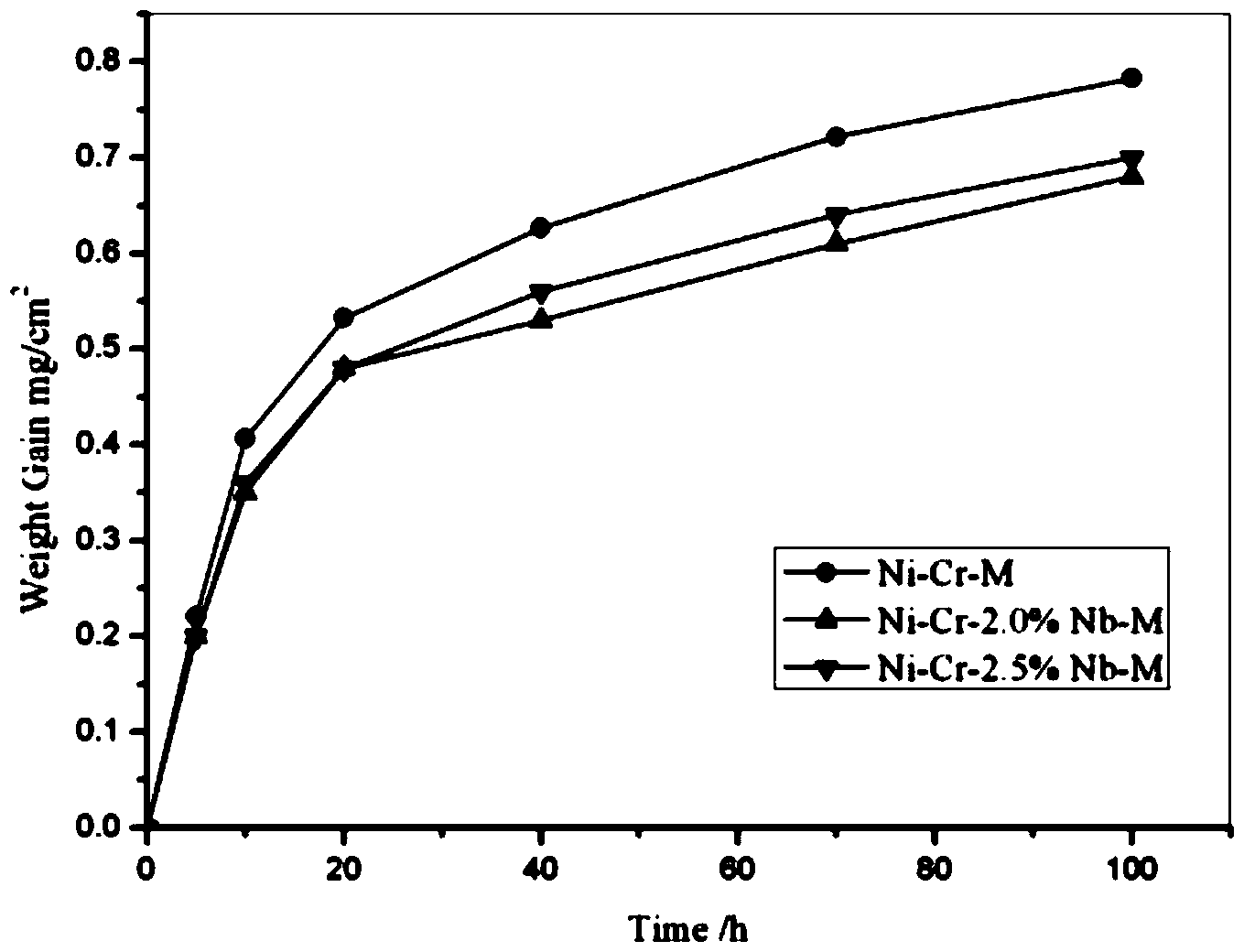

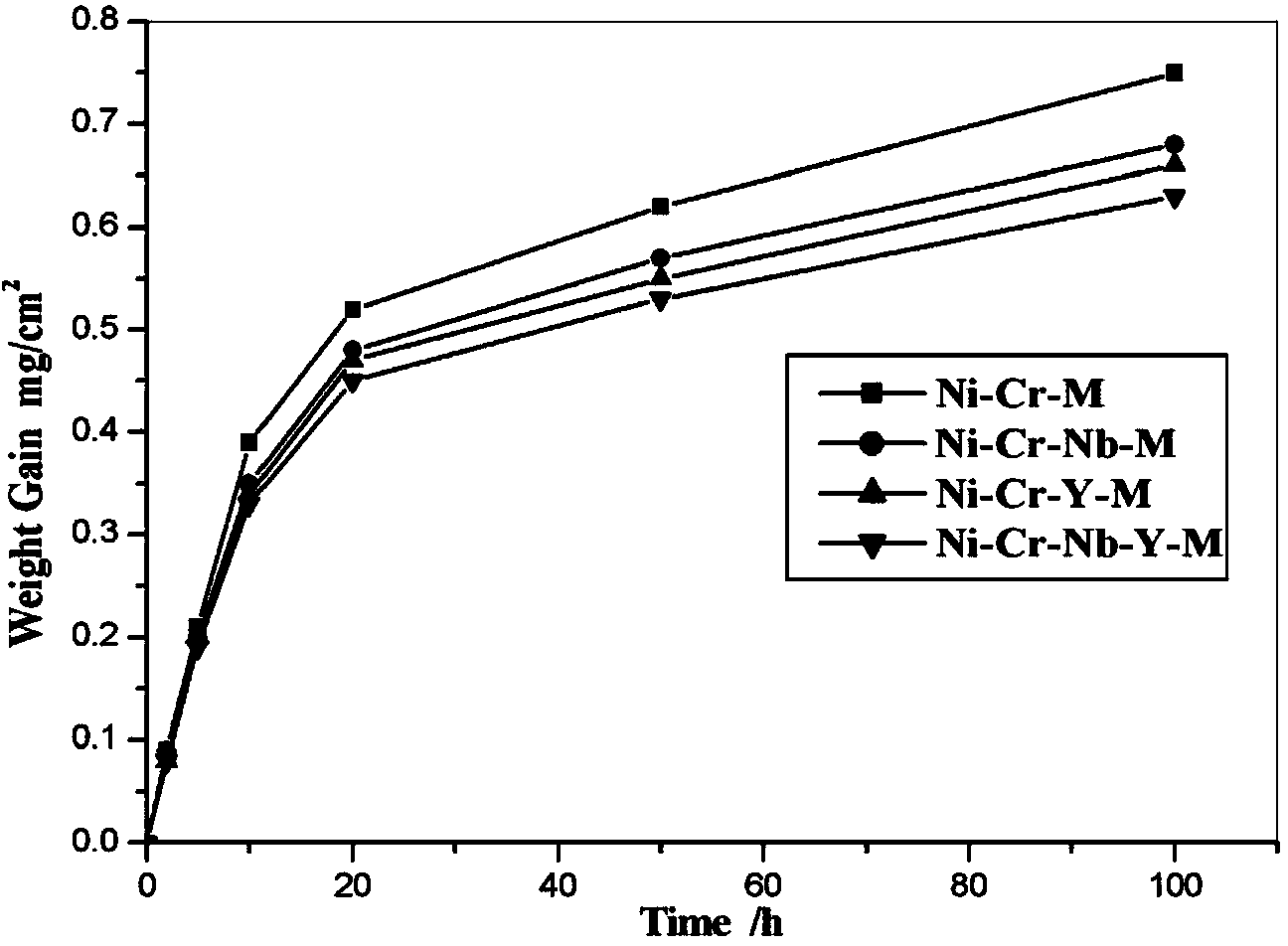

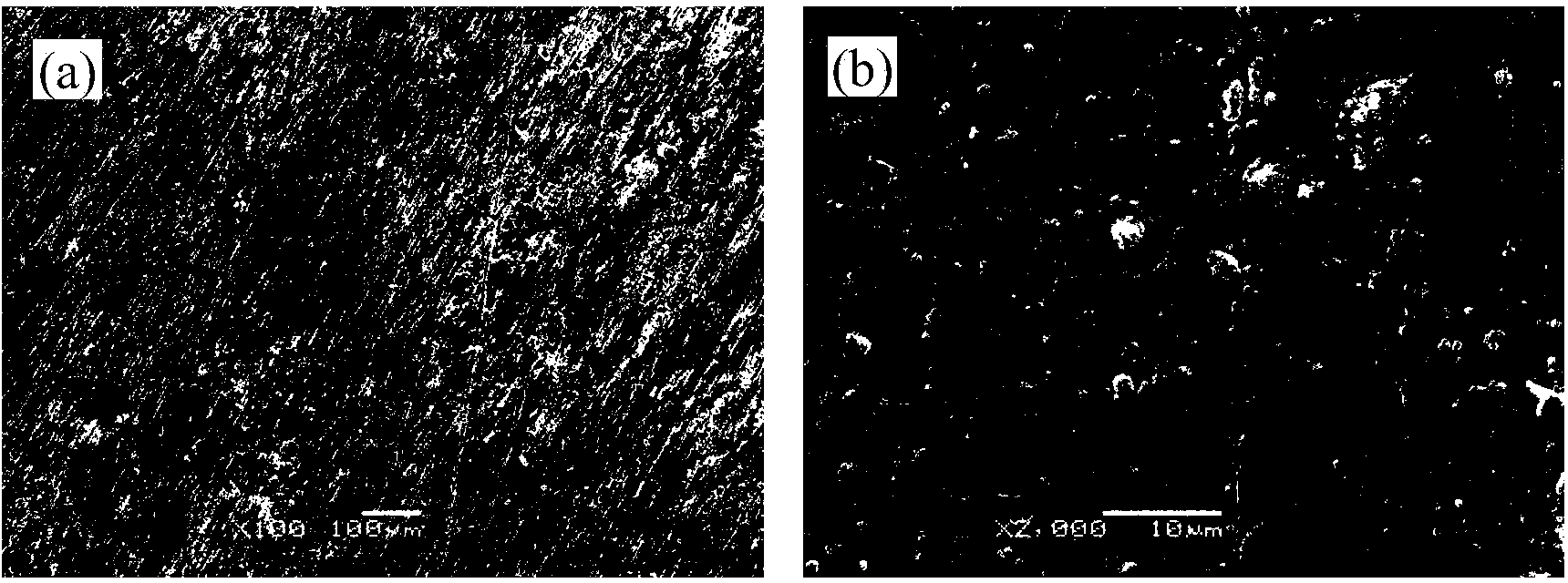

Nickel-based high temperature alloy, preparation method thereof as well as application thereof in spark plug electrode

The invention relates to a nickel-based high temperature alloy, a preparation method thereof as well as application thereof in a spark plug electrode. The nickel-based high temperature alloy contains the following components in percent by weight: 0.04%-0.06% of C, 19%-21% of Cr, 7%-9% of W, 5%-7% of Mo, 1%-2% of Ti, 0.5%-2% of Al, 0.004%-0.006% of B, 0.03%-0.05% of Zr, 0.7%-0.9% of Fe, 0-3% of Nb, 0-1% of Y, and the balance of Ni and inevitable impurities. The preparation method of the nickel-based high temperature alloy comprises the following steps of: mixing the components in a vacuum electric-arc melting furnace according to a proportion, smelting, getting out and forming; heating up to 1200 DEG C in a heating furnace, carrying out thermal-insulation solid-solution treatment for 4 hours, and carrying out air-cooling; and carrying out thermal-insulation aging treatment for 10 hours at 800 DEG C, and carrying out air-cooling to prepare the nickel-based high temperature alloy. The nickel-based high temperature alloy disclosed by the invention has good high-temperature oxidation resistance and corrosion resistance, and can be applied to the spark plug electrode material so as to prolong the service life of an electrode and the service life of a spark plug.

Owner:SHANDONG UNIV

Fireproof materials for pressed repairing and method for preparing same

The present invention relates to refractory material for pressing repair and its preparation process. The refractory material for pressing repair consists of organic binding agent in 3-35 weight portions, refractory material base in 20-80 weight portions and additive in 1-10 weight portions. The preparation process includes the following steps: preparing refractory material base with two or more of high alumina bauxite, bauxite, corundum, clay, SiC and carbon; adding additive; adding organic silicon resin, tar and thermoplastic phenolic resin, mixing homogeneously through stirring and heating at 60-200 deg.c to obtain the organic binding agent; mixing the refractory material base with additive and the organic binding agent; and packing.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Copper-based electric contact composite material and preparing method thereof

The invention discloses a copper-based electric contact composite material and a preparing method thereof, and belongs to the technical field of metal composite material preparing. The copper-based electric contact composite material comprises, by mass percentage, 10%-30% of chromium, 1%-5% of tungsten carbide and the balance copper. The copper-based electric contact composite material is high in compactness and even in structure and has high specific conductance and good anti-arc erosion performance. According to the preparing method, after chromium powder, tungsten carbide powder and copper powder are mixed, the spark plasma sintering technology is utilized for preparing a copper-chromium-tungsten carbide composite material. The obtained composite material has the high strength and high smelting point of chromium, good electrical conductivity and abrasion resistance of tungsten carbide and high electric conductivity and thermal conductivity of copper. The preparing method is controllable and environment-friendly, the technology is simple, cost is low, and the production period is short. The preparing of the electric contact composite material which has high anti-arc erosion performance, anti-welding capability, strength and electric conductivity performance is achieved, and the copper-based electric contact composite material is suitable for application and popularization.

Owner:HENAN UNIV OF SCI & TECH

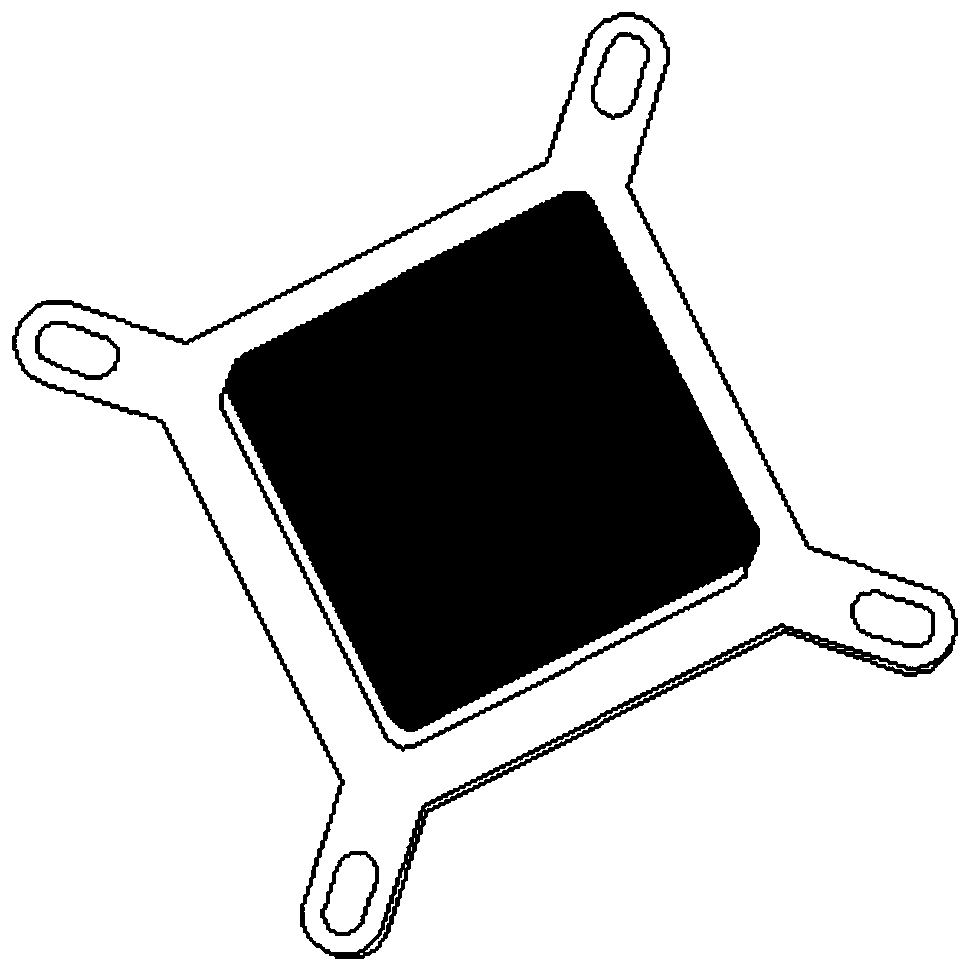

Preparing method for coating pmma particles with silicon dioxide

ActiveUS20110143029A1Improve abilitiesImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsSilica particleSolvent

A preparing method for coating polymethylmethacrylate (PMMA) particles with silicon dioxide is disclosed and includes the following steps of: preparing a silicon dioxide solution by mixing a silicon dioxide powder and a solvent; adding a dispersant-and-interface-modifier agent into the silicon dioxide solution; performing a wet grinding to the silicon dioxide solution with the dispersant-and-interface-modifier agent so as to obtain a plurality of nano-sized silicon dioxide particles with negative charge; performing an interface modification to a plurality of PMMA particles to be charged with positive charge; adding the PMMA particles into the silicon dioxide solution; making the PMMA particles adsorb the nano-sized silicon dioxide particles; and performing a solid-liquid separation process to the silicon dioxide solution so as to obtain the chemical composite particles.

Owner:NAT CHUNG SHAN INST SCI & TECH

Graphene modified silicone rubber cable sheath material

InactiveCN106280475AAvoid attackReduce attackInsulated cablesInsulated conductorsPolymer scienceFumed silica

The invention discloses a graphene modified silicone rubber cable sheath material. The material is prepared from raw materials as follows: phenyl siloxane rubber, methyl vinyl silicone rubber, fluororubber, polybutadiene rubber, polyurethane, ethylene-acrylate rubber, zinc oxide, stearic acid, 2,4-dichlorobenzoyl peroxide, an assistant crosslinker TAIC, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, cerium oxide, fumed silica, carbon black, nano calcium carbonate, stearic acid modified magnesium hydroxide, ammonium polyphosphate, modified graphene oxide, nano silicon carbide, magnesium stearate, triphenyl phosphate, tributyl citrate, an accelerator, an anti-aging agent and silane modified cellulose. The graphene modified silicone rubber cable sheath material is high in strength, excellent in heat resistance and flame retardation, good in aging resistance and long in service life.

Owner:ANHUI LAND GRP

3D printing process method of high-strength aluminum-magnesium alloy

ActiveCN111872386ALow costImprove qualityAdditive manufacturing apparatusTransportation and packaging3D modelingMaterials science

The invention relates to a 3D printing process method of a high-strength aluminum-magnesium alloy, and belongs to the technical field of 3D printing. Firstly, high-strength aluminum-magnesium alloy raw materials are mixed evenly through heating and melting; then high-quality aluminum-magnesium alloy powder is prepared from the high-strength aluminum-magnesium alloy in a molten state through a gasatomization technology, and aluminum-magnesium alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is carried out according to 3D model data of parts in printing equipment with inert gas introduced, and a 3D printing product with the high-strength aluminum-magnesium alloy as a raw material is obtained. Compared with the prior art, as for the product printed through the process method, the relative density can reach 99% or above, the Vickers hardness can reach 110 HV or above, the tensile strength can reach 430 MPa or above, the elongation can reach 21%, through proper heat treatment, the Vickers hardness of a sample can reach 150 HV or above, the tensile strength can be further increased to 520 MPa or above, and the elongation is maintained at 17% or above.

Owner:TONGJI UNIV

Preparation method of copper based graphene composite with high heat conductivity

ActiveCN110408969AReasonable ratioImprove wettabilityElectrolytic coatingsCurrent conducting devicesElectricityHigh intensity

The invention belongs to the field of heat conduction materials, and specifically discloses a preparation method of a copper based graphene composite with high heat conductivity. According to the preparation method, a novel sediment composition is used for direct-current electrodeposition, a certain quantity of additives are added to sediments, and the reasonable electrodeposition frequency is selected to prepare the novel copper based graphene composite with high strength and high heat conductivity. According to the copper based graphene composite prepared by using an electrodeposition preparation technique, the heat conductivity can reach 390 to 1112 W / m.k, the tensile strength reaches 300 to 450 MPa, and the application to the field of heat conduction can be met.

Owner:CHANGZHOU UNIV

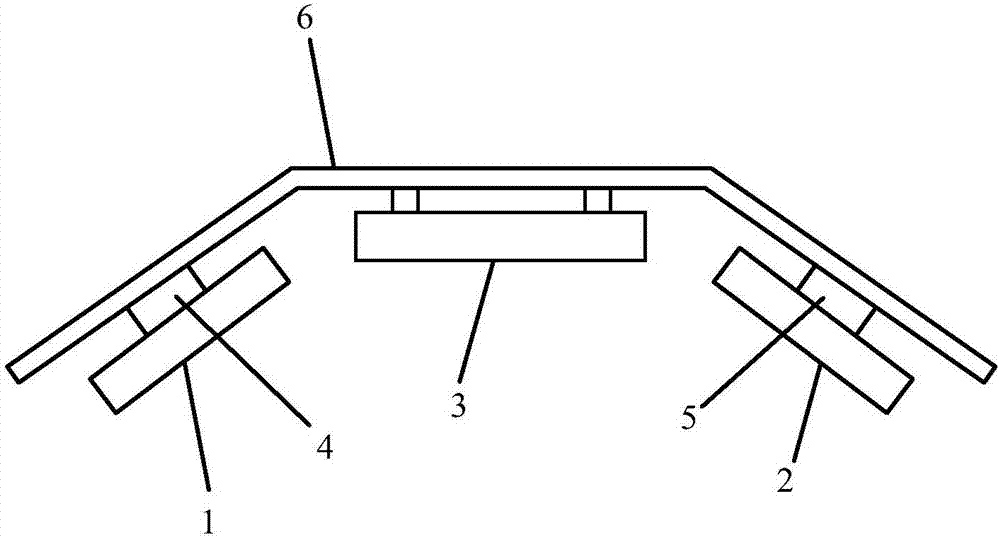

Heating friction stir welding method

InactiveCN101829845AImprove liquidityImprove plastic deformation abilityNon-electric welding apparatusFriction weldingEngineering

The invention discloses a heating friction stir welding method, and belongs to the field of friction stir welding technology. The heating friction stir welding is that in the friction stir welding process, a workpiece is heated continuously by a heating device until the welding is completed. The heating friction stir welding method is characterized by comprising the following steps of: before welding, polishing the workpiece to be welded, fixing the workpiece on a holding device, and then fixing the holding device on a temperature-controllable heating device; and adjusting the temperature of the heating device according to different materials until the temperature is proper, and heating the workpiece until the temperature is stable, wherein in the friction stir welding process, the heating temperature of the heating device maintains unchanged until the welding process is completed. Compared with a welding point not subjected to the heating friction stir welding, a welding point by the welding process has the tensile property improved by 50 percent, and the problem that high-melting point and low-plasticity materials are difficult to be subjected to the friction stir welding is solved.

Owner:CHONGQING UNIV

High-moisture-resistance metallized polypropylene film capacitor and processing method thereof

InactiveCN110164691AImprove bindingImprove moisture resistanceFixed capacitor electrodesThin/thick film capacitorAdhesiveMoisture resistance

The invention discloses a processing method of a high-moisture-resistance metallized polypropylene film capacitor, and relates to the technical field of capacitors. The method comprises the followingsteps: S1, film coating: carrying out low-temperature plasma corona treatment on the surface of a polypropylene film so that a dangling bond can be formed on the surface of the polypropylene film, andthen plating a metal coating on the surface of the polypropylene film; S2, metal spraying: performing metal spraying treatment on the core (a metal spraying material is a zinc-aluminum wire), and coating the surface of the core with an aluminum foil adhesive tape after metal spraying is completed; S3, energizing: automatically testing the core on an energizing machine; S4, welding: automaticallyfeeding the core to a welding machine through a vibrating disc, and then performing the welding operation after the distance between the welding joints is adjusted to be equal to the pin distance of the capacitor. The invention has the beneficial effects that the capacitor manufactured through the method can meet the requirements of the service life test of 85 DEG C, 85% of RH, 1-time of rated voltage and 1000 hours, and the capacity attenuation of the capacitor is smaller than 10%.

Owner:艾华新动力电容(苏州)有限公司

3D printing process method of high-strength aluminum manganese alloy

InactiveCN111659889ALow costImprove qualityAdditive manufacturing apparatusTransportation and packagingManganese3D modeling

The invention relates to a 3D printing process method of a high-strength aluminum manganese alloy, and belongs to the technical field of 3D printing. The 3D printing process method comprises the stepsthat firstly, a high-strength aluminum manganese alloy is mixed evenly by heating and melting; then the melted high-strength aluminum manganese alloy is subjected to a gas atomization technology to prepare high-quality aluminum manganese alloy powder, and aluminum manganese alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is conducted according to three-dimensional model data of parts in printing equipment introduced with inert gas, and a 3D printing product with the high-strength aluminum manganese alloy as a raw material is obtained. Compared with the prior art, according to the product printed by the process method, the relative density can reach more than 99%, the Vickers hardness can reach more than 140 HV, the tensile strengthcan reach more than 440 MPa, the elongation can reach 20%, after proper hear treatment, the hardness of a sample can reach more than 180 HV, the tensile strength can be further increased to more than565 MPa, and the elongation is maintained at or above 19%.

Owner:TONGJI UNIV

Depth image obtaining method

ActiveCN107403447AThe method of obtaining is simple and reliableHigh precisionImage enhancementImage analysisVisual field lossField of view

Owner:MECH MIND ROBOTICS TECH LTD

Rapid preparation method of ceramic matrix composite material

The invention relates to a rapid preparation method of a ceramic matrix composite material. A polymer of C / SiC and SiC / SiC semi-finished product composite materials after CVI at a room temperature is subjected to dipping and curing, so that preliminary sealing and filling of microcracks in SiC matrix are achieved; splitting of an SiBCN precursor is carried out in the heating process of a CVI process; additive splitting and ceramization of the SiBCN precursor are finished in the matrix deposition process; contraction of a self-healing layer is inhibited; final sealing and filling of micro-cracks in the SiC matrix are finished; and holes and cracks in the self-healing layer and the SiC matrix are reduced. The holes and the cracks in the ceramic matrix composite material obtained by the invention are filled with the SiBCN; the material compactness is improved; and meanwhile, the service lifetime of the composite material in a high-temperature water and oxygen coupled environment is prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

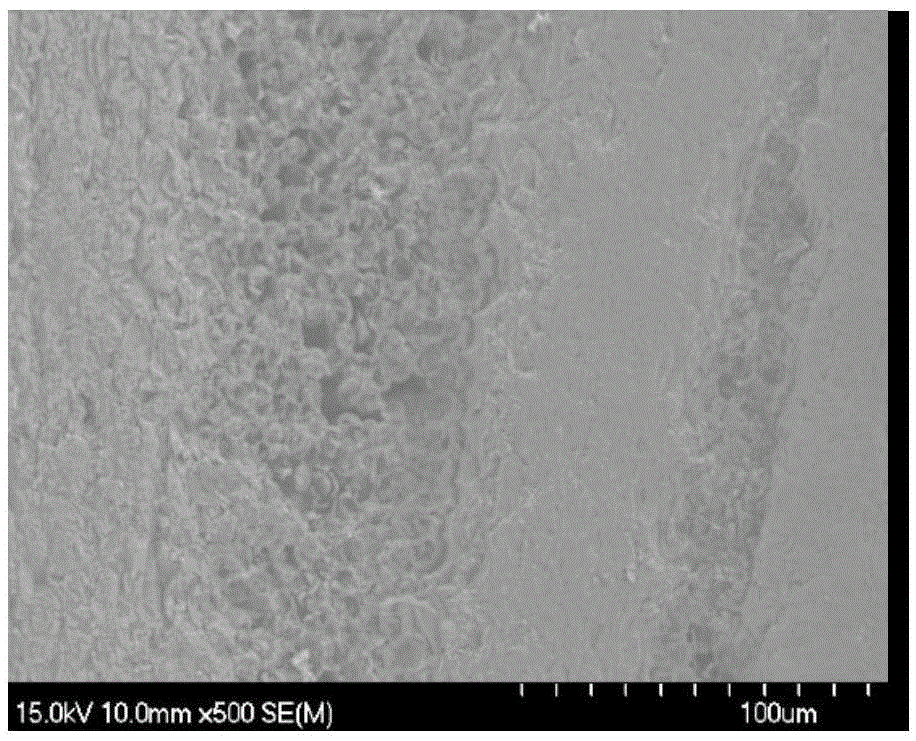

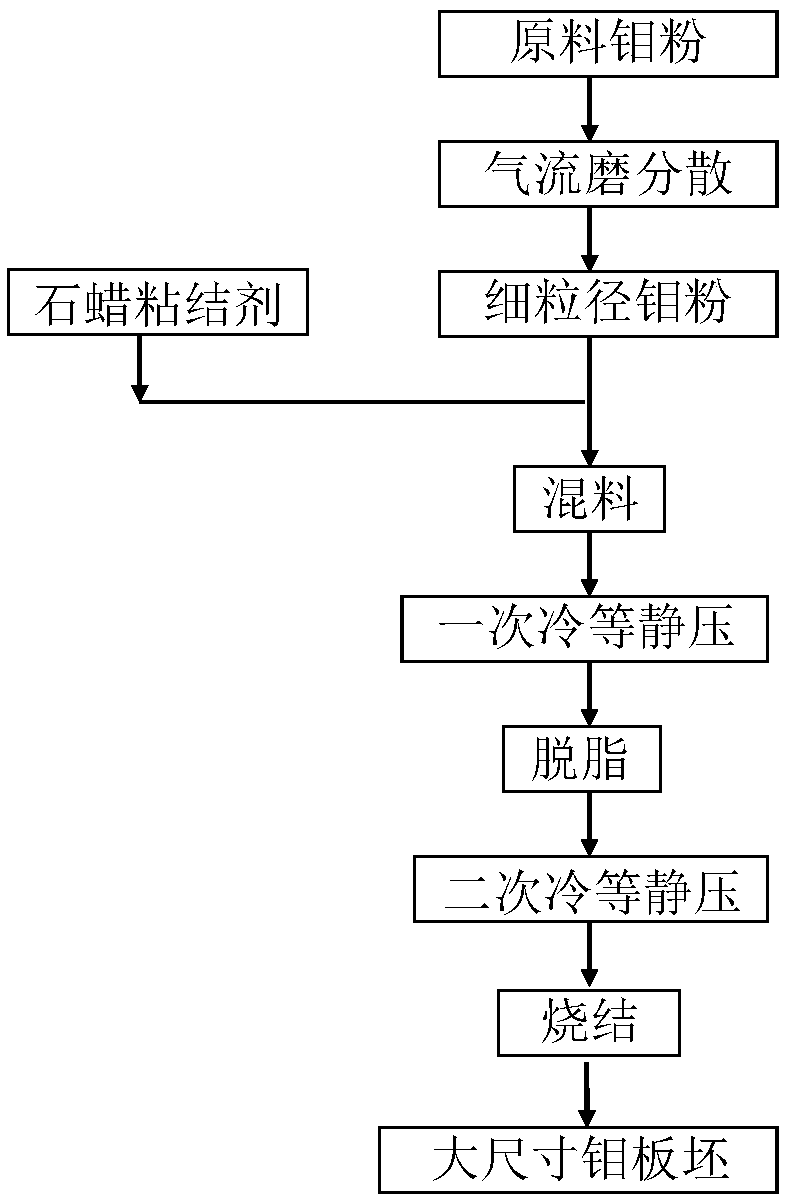

Method for preparing large-size molybdenum plate blank

ActiveCN108907211AGood dispersionUniform particle size distributionTransportation and packagingMetal-working apparatusHigh pressureMaterials science

The invention provides a method for preparing a large-size molybdenum plate blank, and belongs to the technical field of powder metallurgy. The method includes the steps that reducing molybdenum powder serves as a raw material, and small-granularity molybdenum powder which is evenly dispersed, has narrow granularity distribution and is nearly spherical is obtained through airflow milling treatment; then the small-granularity molybdenum powder and a paraffin binder are evenly mixed, and a mixture is obtained; and then by the adoption of a secondary isostatic cool pressing forming process, a degreased blank is isostatically pressed into a secondary blank under high pressure intensity. A sintering method of low-temperature slow heating and high-temperature rapid heating is adopted, specifically, slow heating is carried out at a low-temperature sintering stage, the blank is fully reduced in order to reduce the oxygen content in a blank body, and therefore the sintering activity of the blank is kept; and rapid heating is carried out at a high-temperature sintering stage, grain growth can be reduced, and after sintering is completed, the thick molybdenum plate blank with high density andhigh tissue uniformity can be obtained. By means of the preparation method, the problems that local looseness and cracks are easily generated in former large-size thick molybdenum plates are solved,the density of the prepared molybdenum plate blank reaches 99% or above, and the uniformity and the consistency of tissue of the surface and the center position of the plate blank can be guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

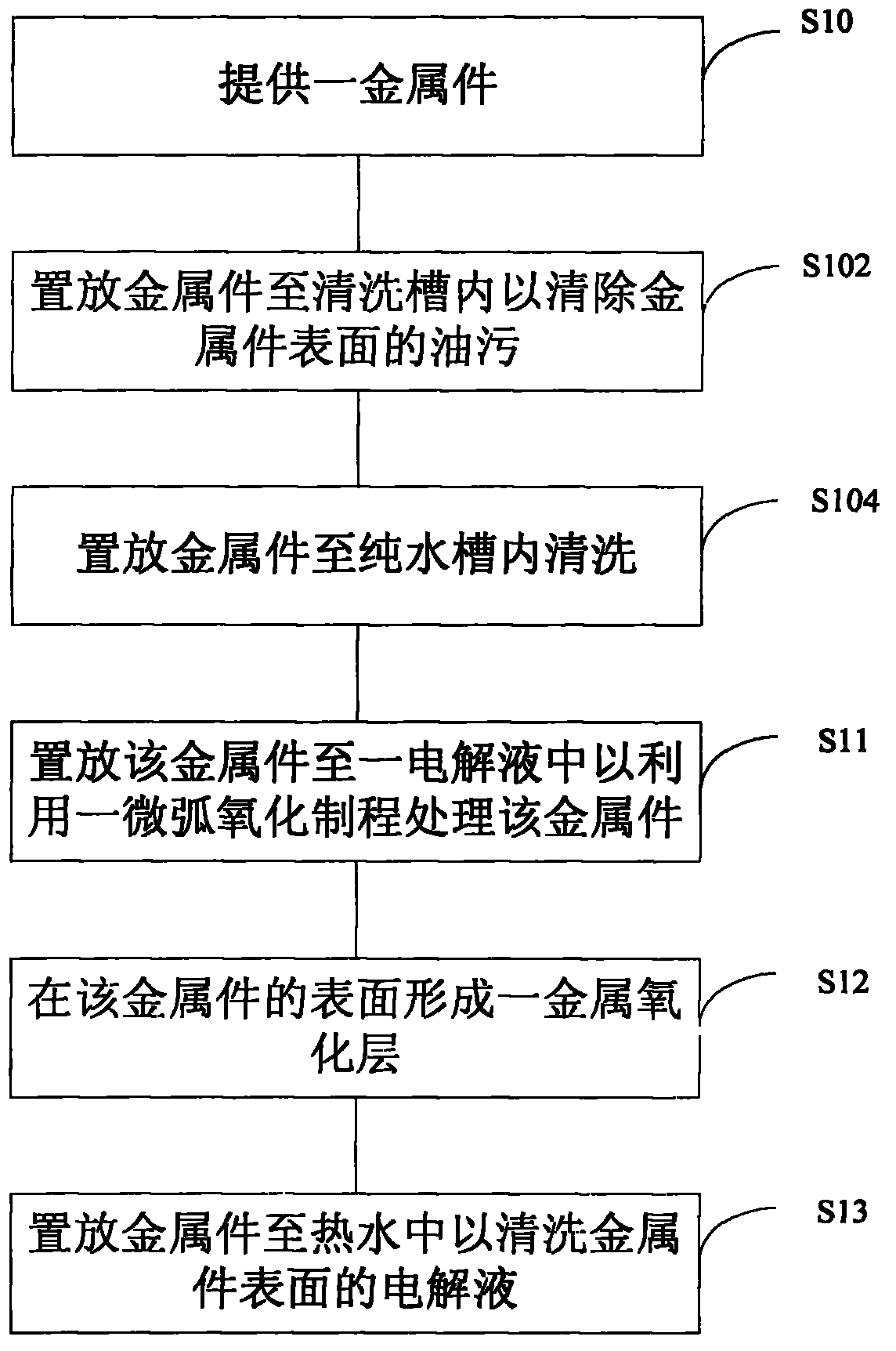

Manufacturing method of metal oxidation layer

InactiveCN103572347AHigh hardnessAvoid wear and tearAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a manufacturing method of a metal oxidation layer. The manufacturing method comprises the following steps: first, providing a metal member, then placing the metal member in an electrolyte to process the metal member by utilizing a micro-arc oxidation technology, and finally forming a metal oxidation layer on the surface of the metal member; wherein the electrolyte comprises the following components: sodium hexametaphosphate, sodium silicate, sodium metaaluminate, sodium hydroxide, sodium tungstate, and sodium carbonate. Thus a high hardness surface of the metal member is generated to avoid destructions and abrasions on the metal member, furthermore, the surface of the metal member is provided with small micro-holes to prevent accumulation of foreign substances, so that the metal member coated by the metal oxidation layer has a very high practicability.

Owner:萧祖荫 +2

Method for preparing particle-reinforced aluminum-based composite material adopting hot-pressing sintering under atmospheric atmosphere

The invention relates to a method for preparing a particle-reinforced aluminum-based composite material adopting hot-pressing sintering under an atmospheric atmosphere. The invention belongs to the field of powder metallurgy, in particular to the method for preparing the particle-reinforced aluminum-based composite material adopting hot-pressing sintering under the atmospheric atmosphere. The method aims to overcome the defects of complex process, high cost and low production efficiency of an existing composite material preparation process adopting the hot-pressing sintering. The method comprises the following steps that 1, ball-milling is carried out to mix powder, specifically, the ball-milling is carried out on ceramic particle reinforcement and an aluminum-based body for mixing the powder to obtain the mixed powder; 2, cold pressing is carried out to prepare a prefabricated body, specifically, step-by-step compaction is carried out on the mixed powder by adopting a graphite die soas to obtain the prefabricated body; and 3, the hot-pressing sintering is carried out on the prefabricated body under the atmospheric atmosphere, the graphite die is transferred into the air after thesintering is completed till the die is naturally cooled to the room temperature, and the die is removed to obtain the particle-reinforced aluminum-based composite material. The method is used for preparing the particle-reinforced aluminum-based composite material.

Owner:QIQIHAR XIANGKE NEW MATERIAL CO LTD

Aluminum foil for electric cable and production method

InactiveCN101383200AReduce burning lossReduce segregationNon-insulated conductorsInsulated cablesMagnesiumMaterials science

The invention discloses a cable aluminum foil and a production method thereof. The cable aluminum foil comprises components of the following weight percent: 0.79 to 0.83 percent of Si, 0.22 to 0.26 percent of Fe, at most 0.1 percent of Cu, at most 0.2 percent of Mn, at most 0.05 percent of Mg, at most 0.05 percent of Cr, at most 0.1 percent of Zn, at most 0.08 percent of Ti, at most 0.05 percent of single impurity content, at most 0.15 percent of the total content of impurities and Al as the rest, wherein the content summation of the Fe and the Si in weight percent is less than 1.1 percent. The production method comprises the production technical processes: burdening, melting, component analysis, feeding dilution, powder injection refining, N2 refining, on-line refining outside a furnace, casting, casting plate type detection, blank winding, cold rolling, vertical cutting and splitting, finished product annealing, detection, packing, storage and leaving a factory. The cable aluminum foil has good mechanical property, the tensile strength is from 90 to 105MPa, the extension rate is greater than 25 percent, the production requirement has larger development potential, and the enterprise benefit and the social benefit can be obviously increased.

Owner:河南省银湖铝业有限责任公司

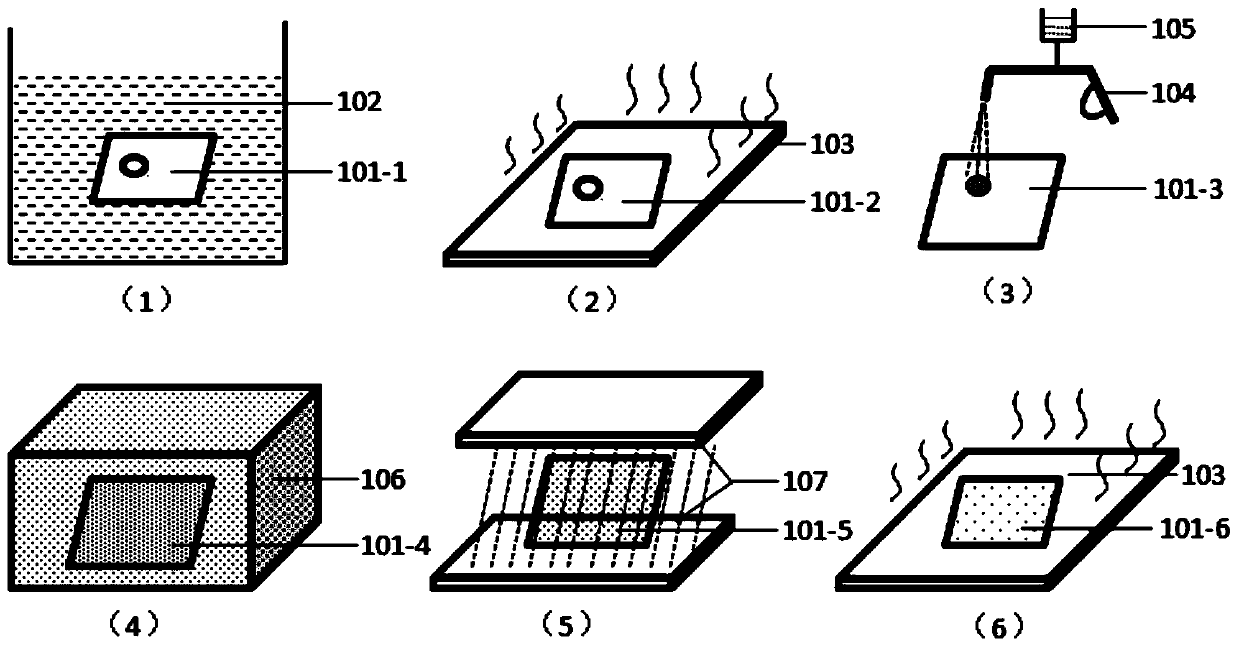

Method for repairing defects of perovskite thin film

ActiveCN111435708AFix bugsReduce holesSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention relates to a method for repairing defects of a perovskite thin film, which comprises the following steps of: 1, pretreating a prepared perovskite thin film, spraying a perovskite precursor solution on the surface of the perovskite thin film by adopting a spraying method, and performing air drying treatment or low-temperature drying treatment on the sprayed perovskite thin film; 2, processing the air-dried perovskite thin film by using hot steam; and 3, cleaning the perovskite thin film by using a cleaning solvent, and carrying out solvent drying on the cleaned perovskite thin film to obtain the repaired perovskite thin film. According to the method, the defects of the large-area prepared perovskite thin film are repaired through adoption of a series of treatment methods, themorphology of the perovskite thin film is adjusted, and the stability of the perovskite thin film is improved.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com