Nano silver particles with multilevel structure and preparation method thereof

A nano-silver particle and nano-technology, which is applied in the field of nano-structured materials, can solve the problems of insufficient thermal conductivity and electrical conductivity of conductive silver paste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

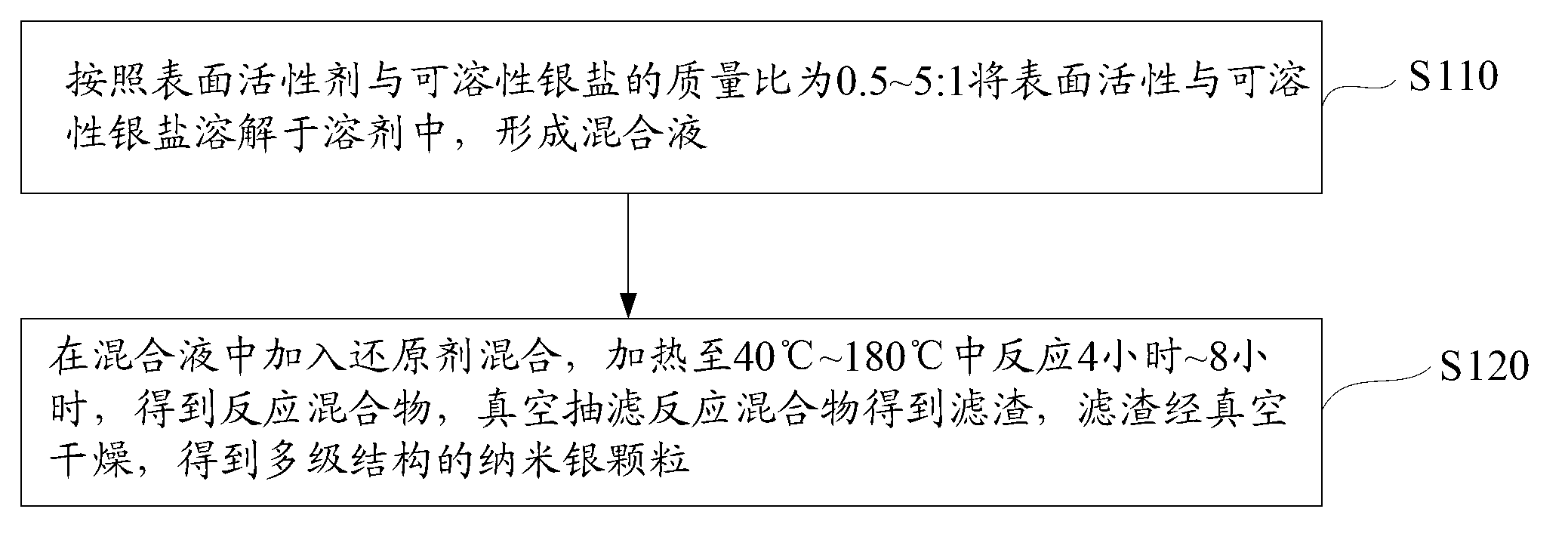

[0031] Such as figure 1 Shown, the preparation method of the nano-silver particle of the hierarchical structure of an embodiment, comprises the steps:

[0032] Step S110: dissolving the surfactant and the soluble silver salt in the solvent according to the mass ratio of the surfactant to the soluble silver salt being 0.5-5:1 to form a mixed solution.

[0033] Among them, the surfactant is sodium dodecylbenzene sulfonate, sodium hexadecyl sulfonate, sodium oleate, sodium stearate, alpha-olefin sulfonate and sodium dioctyl sulfosuccinate A sort of.

[0034] These kinds of surfactants are all anionic surfactants, which ionize long-chain anionic groups in polar solvents, and ionize soluble silver salts to form silver cations. Due to the attraction of positive and negative charges, the shape of the product can be controlled during reduction. .

[0035] Wherein, the soluble silver salt is a soluble silver salt commonly used in the art, for example, silver perchlorate, silver nitr...

Embodiment 1

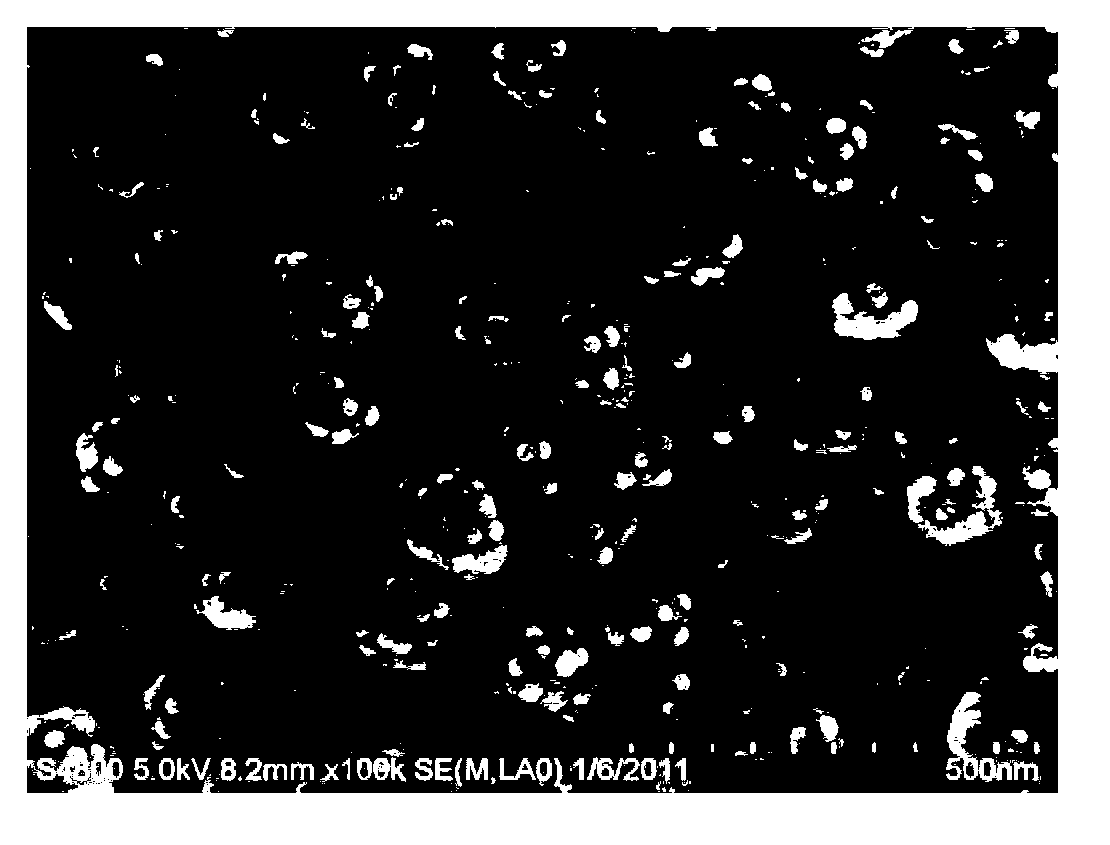

[0053] The preparation of the nano-silver particles of the hierarchical structure prepared by the present embodiment is as follows:

[0054] (1) Take 0.25 g of sodium dodecylbenzene sulfonate, add it to 25 ml of deionized water, and stir until the sodium dodecylbenzene sulfonate is completely dissolved after ultrasonic treatment to obtain water / sodium dodecylbenzene sulfonate solution;

[0055] (2) Take 0.5 g of silver nitrate, add it into 20 ml of deionized water, dissolve it completely, and obtain an aqueous solution of silver nitrate.

[0056] (3) After mixing the water / sodium dodecylbenzene sulfonate solution and the aqueous solution of silver nitrate evenly, add 2.0 grams of zinc flakes, and place them in a 200 ml stainless steel pressure reaction kettle with a polytetrafluoroethylene liner. In a digitally-programmed temperature-controlled high-temperature oven, heat-retain and react at 40°C for 1 hour, then raise the temperature to 100°C, and heat-react at 100°C for 7 h...

Embodiment 2

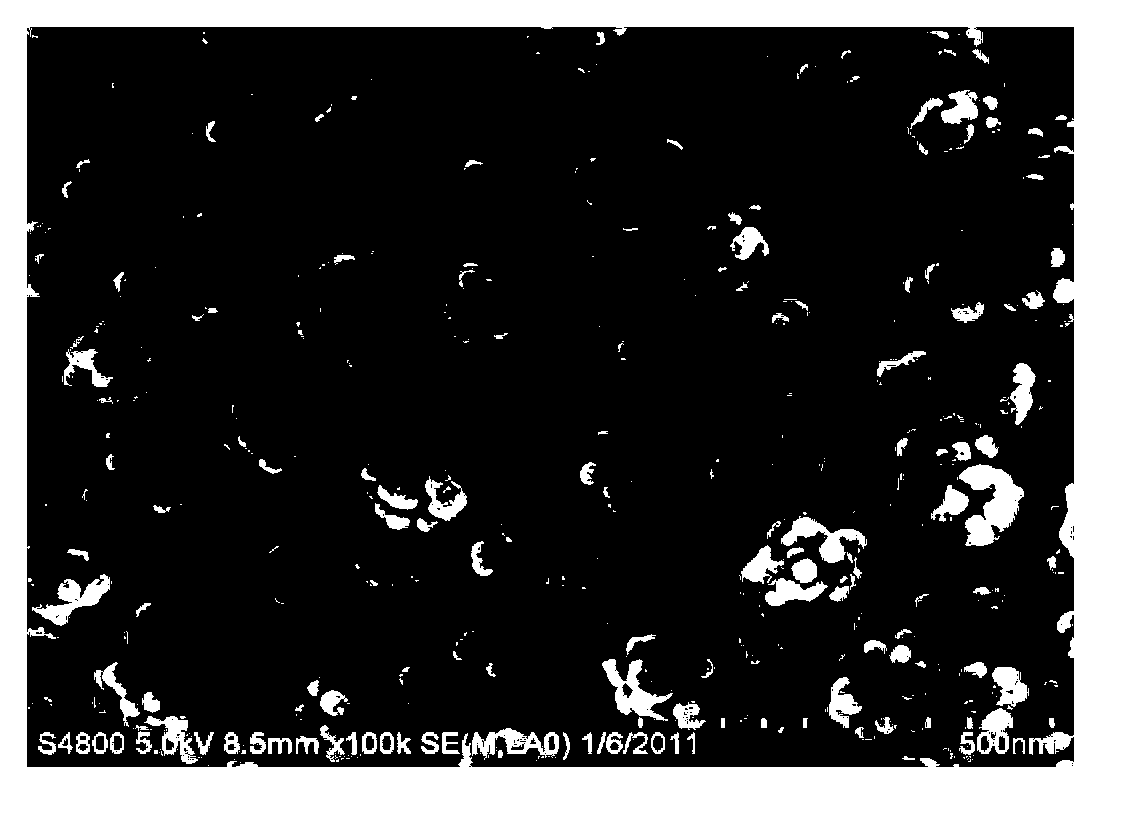

[0061] The preparation of the nano-silver particles of the hierarchical structure prepared by the present embodiment is as follows:

[0062] (1) Take 2.0 grams of sodium cetyl sulfonate, add it to 100 ml of glycerin, and stir after ultrasonic treatment until the sodium cetyl sulfonate is completely dissolved to obtain glycerol / sodium cetyl sulfonate solution;

[0063] (2) Take 1.0 g of silver nitrate, add it to 20 ml of glycerin, and dissolve it completely to obtain a solution of silver nitrate in glycerin.

[0064] (3) After mixing the glycerol / sodium cetyl sulfonate solution and the glycerol solution of silver nitrate evenly, add 4.0 grams of hydroxylamine hydrochloride and place it in a 200 ml stainless steel pressure reactor with a polytetrafluoroethylene liner placed in a high-temperature oven with digital display program temperature control, kept at 120°C for 1 hour, then raised the temperature to 160°C, and kept at 160°C for 4 hours to obtain a reaction mixture.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com