Aluminum foil for electric cable and production method

A production method and technology of aluminum foil, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of difficulty in entering high-end cable manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

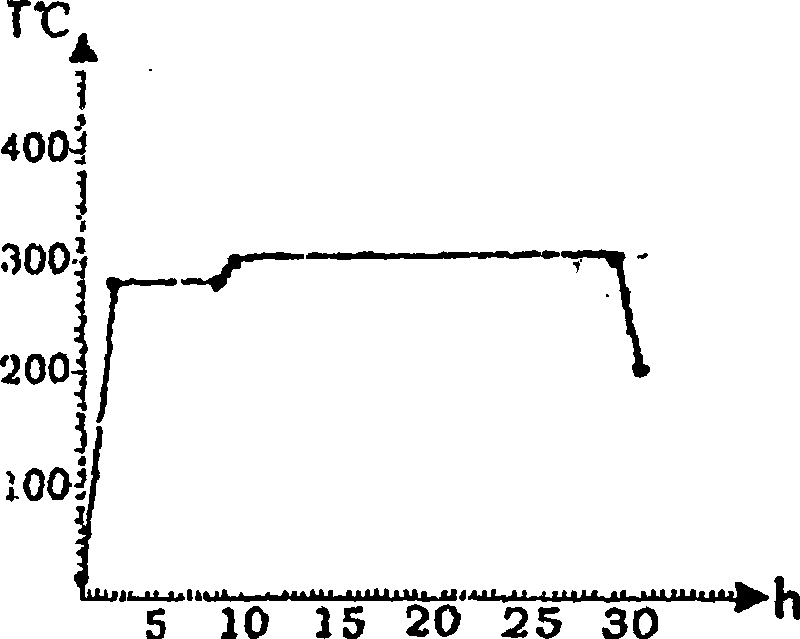

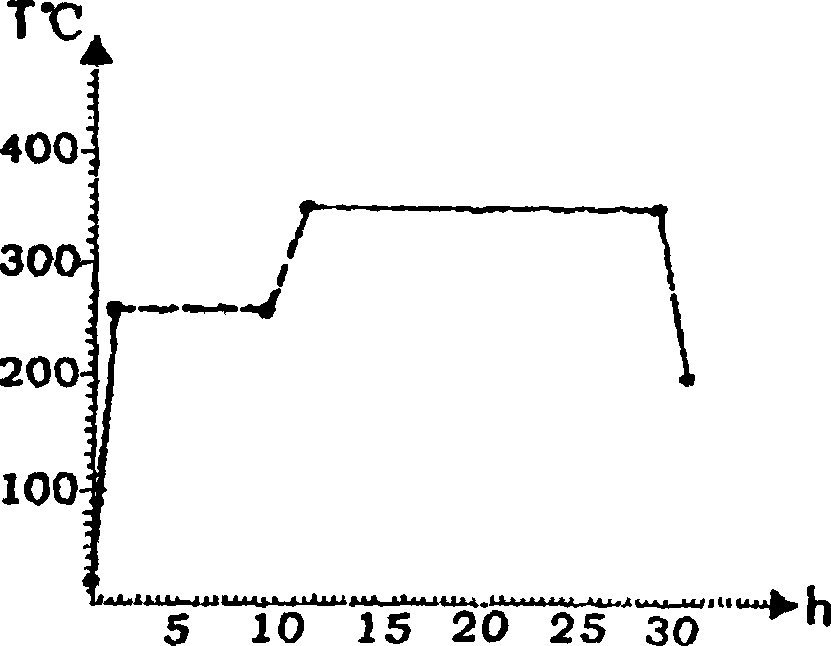

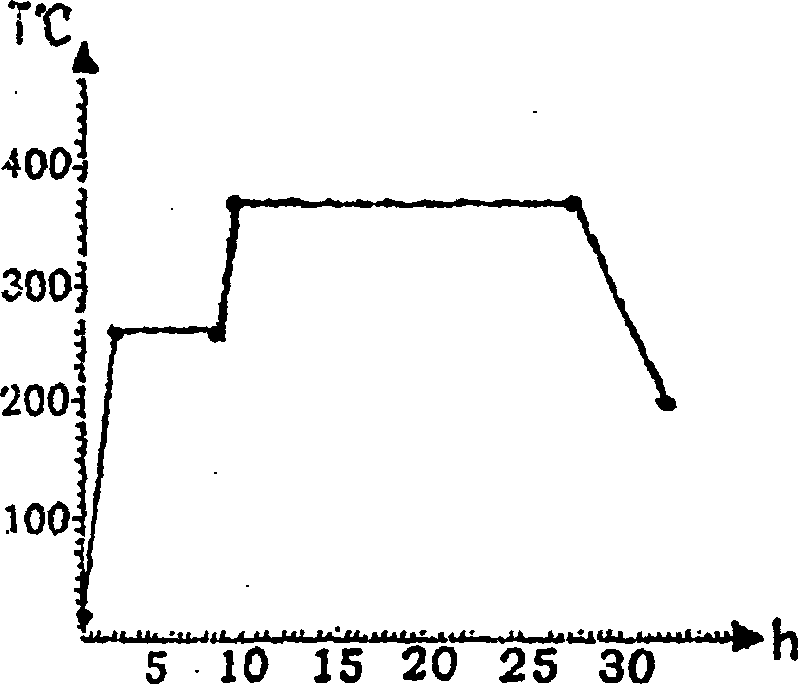

Image

Examples

Embodiment

[0068] Embodiment: A kind of aluminum foil for electric cable, its composition by weight percentage is: silicon Si 0.79%, iron Fe 0.22%, copper Cu≤0.1%, manganese Mn≤0.2%, magnesium Mg≤0.05%, chromium Cr≤0.05% , zinc Zn≤0.1%, titanium Ti≤0.08%, single impurity content≤0.05%, total impurity content≤0.15%, and the balance is aluminum Al.

[0069] The above-mentioned production method of aluminum foil for electric cables, its concrete technological process is:

[0070] a. Use aluminum ingots and cold-rolled waste as ingredients;

[0071] b. Heating and melting at a temperature of 780-790°C;

[0072] c. Sprinkle an appropriate amount of covering agent to reduce oxidation and slagging;

[0073] d. Stir to make the chemical composition and temperature uniform;

[0074] e, slag removal to keep the melt clean

[0075] f. Sampling test: quickly analyze the chemical composition in front of the furnace with a spectrometer;

[0076] g. Composition adjustment---feeding or diluting, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com