Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about How to "Increase rolling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for setting concentration of emulsion in rolling of five-rack cold continuous rolling unit extremely thin band

InactiveCN103544340AIncrease rolling speedGuaranteed rolling efficiencyVibration control deviceSpecial data processing applicationsEmulsionBending force

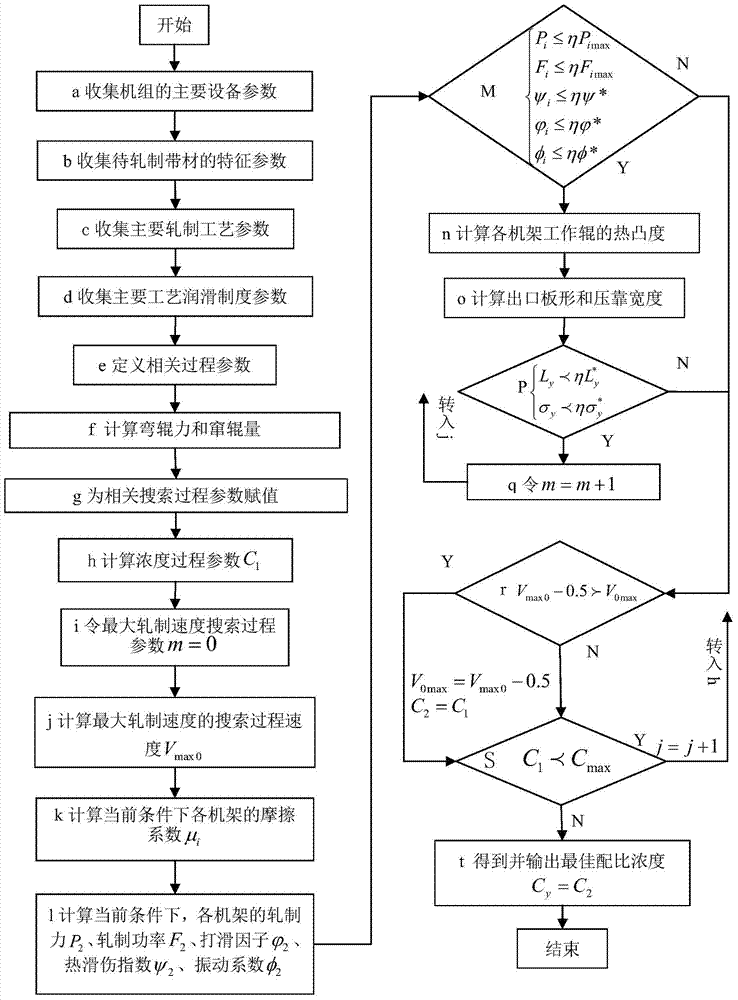

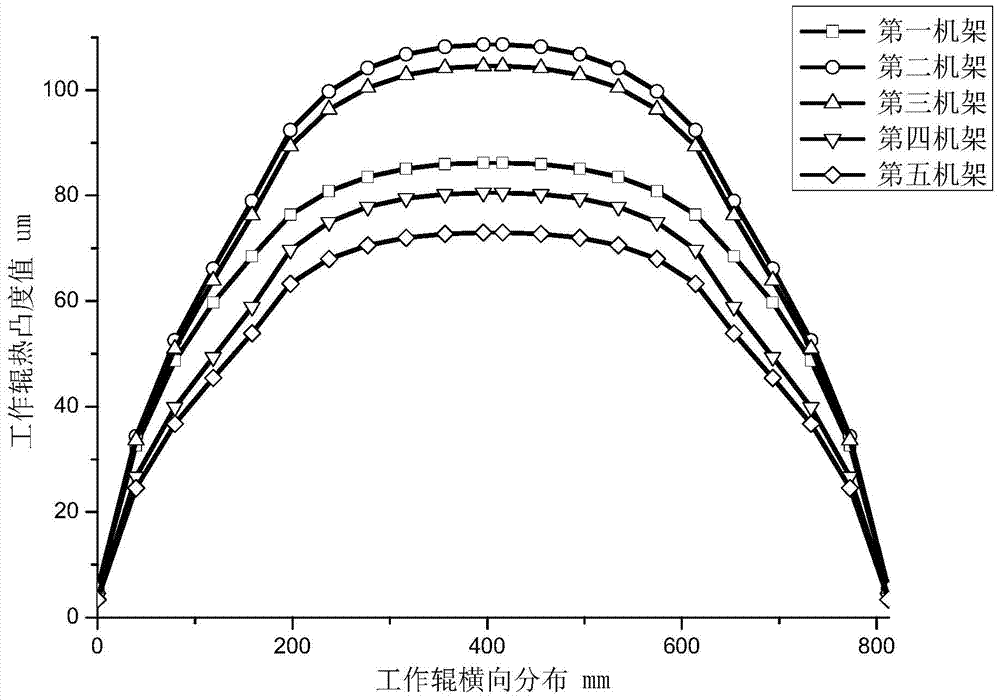

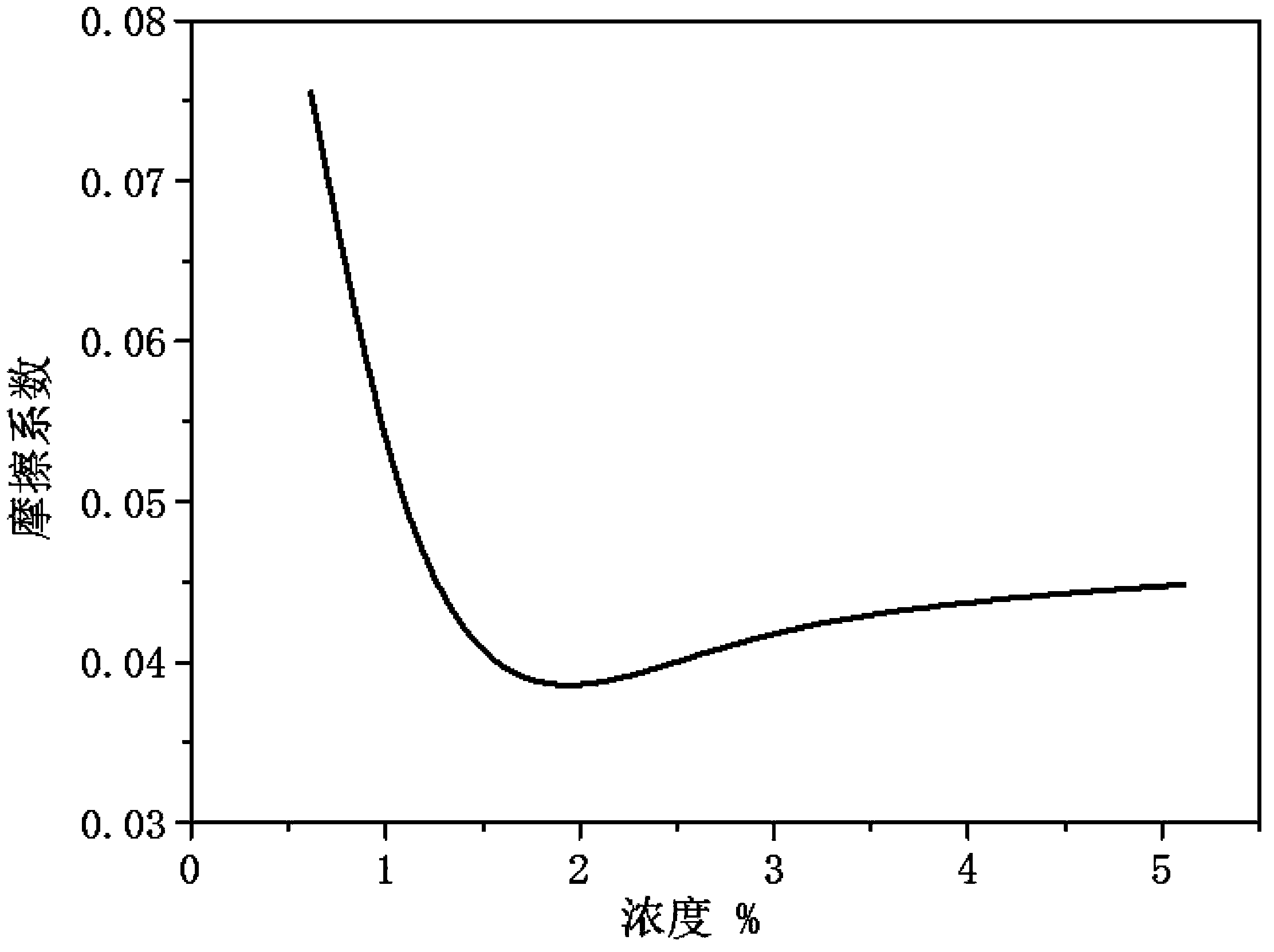

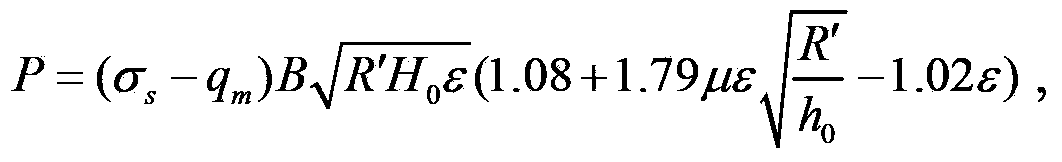

The invention discloses a method for setting concentration of emulsion in rolling of a five-rack cold continuous rolling unit extremely thin band. The method includes the following steps: (1) collecting characteristic parameters of main devices of a unit and to-be-rolled bands, main rolling process parameters and process lubricating system parameters, (2) defining related process parameters, (3) computing roll bending force and the roll channeling amount, (4) assigning related search process parameters, (6) computing concentration process parameters, (6) computing the search process speed of the highest rolling speed, (7) computing friction coefficients of various racks under the current condition, (8) computing rolling force, rolling power, slip factors, heat slip damage indexes and vibration coefficients of the various racks under the current condition, (9) computing heat convexity degrees of working rollers of the various racks, (10) computing an exit plate shape and the pressing width, and (11) obtaining and outputting the optimum proportion concentration. The steps are executed by a computer. According to the method, the rolling speed can be quickened, the rolling efficiency can be guaranteed, slip, heat slip damage and vibration are avoided, and it is guaranteed that the exit plate shape of the final rack and the pressing width of the roller ends of the working rollers are the smallest.

Owner:唐山扬邦钢铁技术研究院有限公司

Four-pass aluminum foil rolling process

The invention relates to a four-pass aluminum foil rolling process, and belongs to the technical field of aluminum foil rolling process. The process comprises the following steps: 1, selecting materials; 2, performing first-pass rolling; 3, performing second-pass rolling; 4, performing third-pass rolling; 5, folding; and 6, performing fourth-pass rolling. The four-pass aluminum foil rolling process has a simple process flow, reduces the loss of defective products caused by one-pass acceleration and deceleration by increasing the rolling reduction of each rolling pass, and simultaneously guarantees that the finished product has no defect such as twill, herringbone, hot blast and the like; the loss of defective products caused by each-pass acceleration and deceleration is about 1 percent, the loss of one-pass lap changing time is also saved, and the lost time of each lap changing is about 10 minutes; therefore, the rolling speed is improved, and the overall improved speed is about 13 percent.

Owner:SHANDONG NANSHAN ALUMINUM

Emulsified liquid concentration optimization setting method during automotive sheet cold rolling of double-rack four-roller mill

ActiveCN104289527AReduce slippageIncrease rolling speedMetal rolling arrangementsProfile control deviceField testsProcess engineering

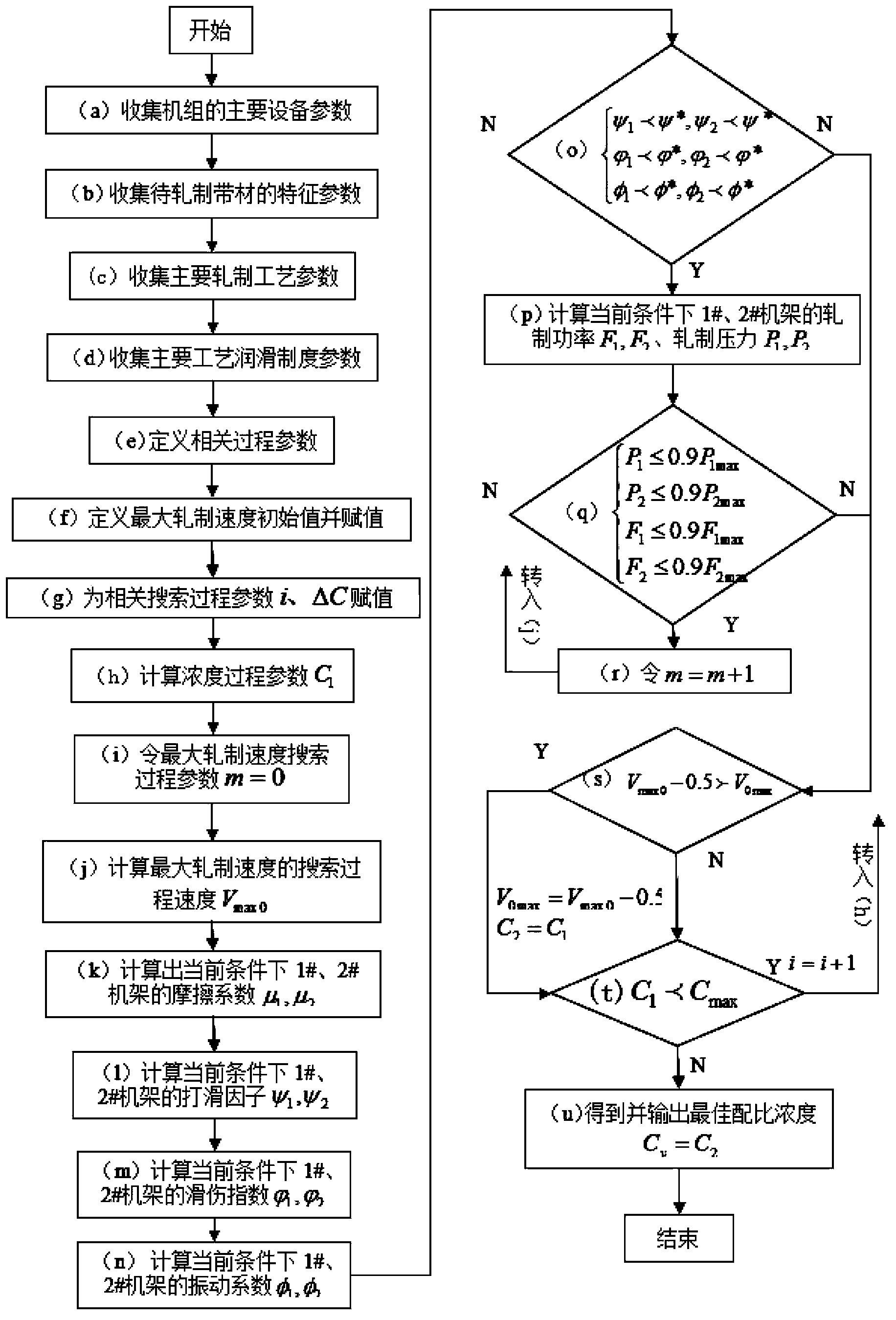

The invention discloses an emulsified liquid concentration optimization setting method in the high-stage automotive sheet cold rolling process of a double-rack four-roller mill. On the basis of a large amount of field test tracking and theoretical researching, in cooperation with equipment characteristics of the double-rack four-roller mill and process characteristics of high-stage automobile sheet rolling, on the premise that it is guaranteed that defects such as slippage, hot slip damage and vibration are avoided, an emulsified liquid concentration optimization setting technology suitable for the high-stage automobile sheet cold rolling process of the double-rack four-roller mill is provided with the highest rolling speed which can be reached as a target; two functions of improving the rolling speed to the maximum degree to guarantee the rolling efficiency and avoiding the defects such as the slippage, the hot slip damage and the vibration to the maximum degree can be achieved through the technology.

Owner:上海宝钢钢材贸易有限公司

Rolled member head shape controlling method

InactiveCN1451496AReduce labor intensityIncrease rolling speedTension/compression control deviceAutomatic controlControl system

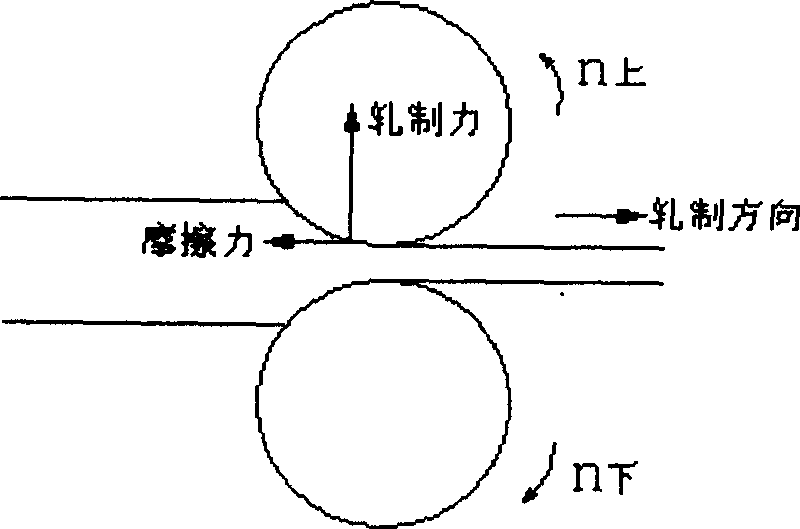

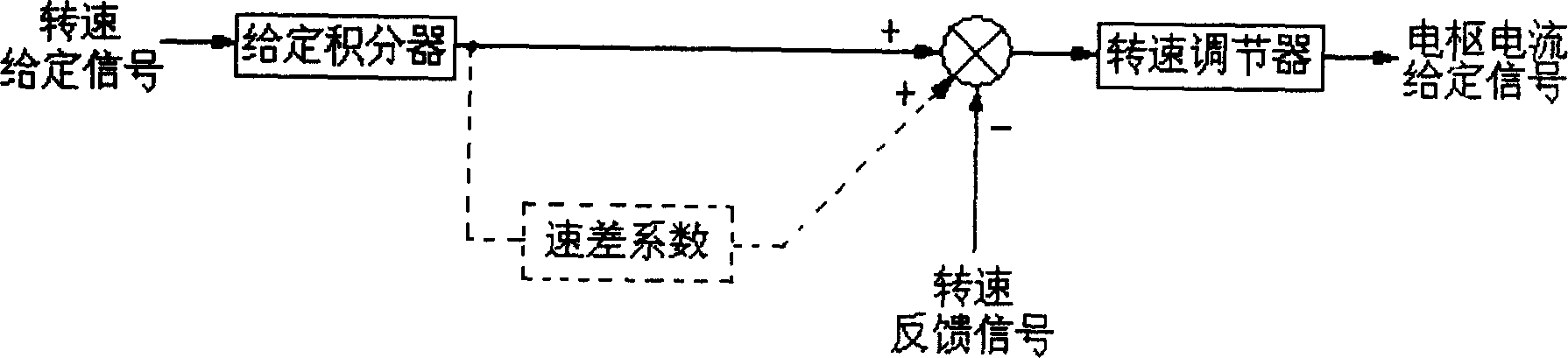

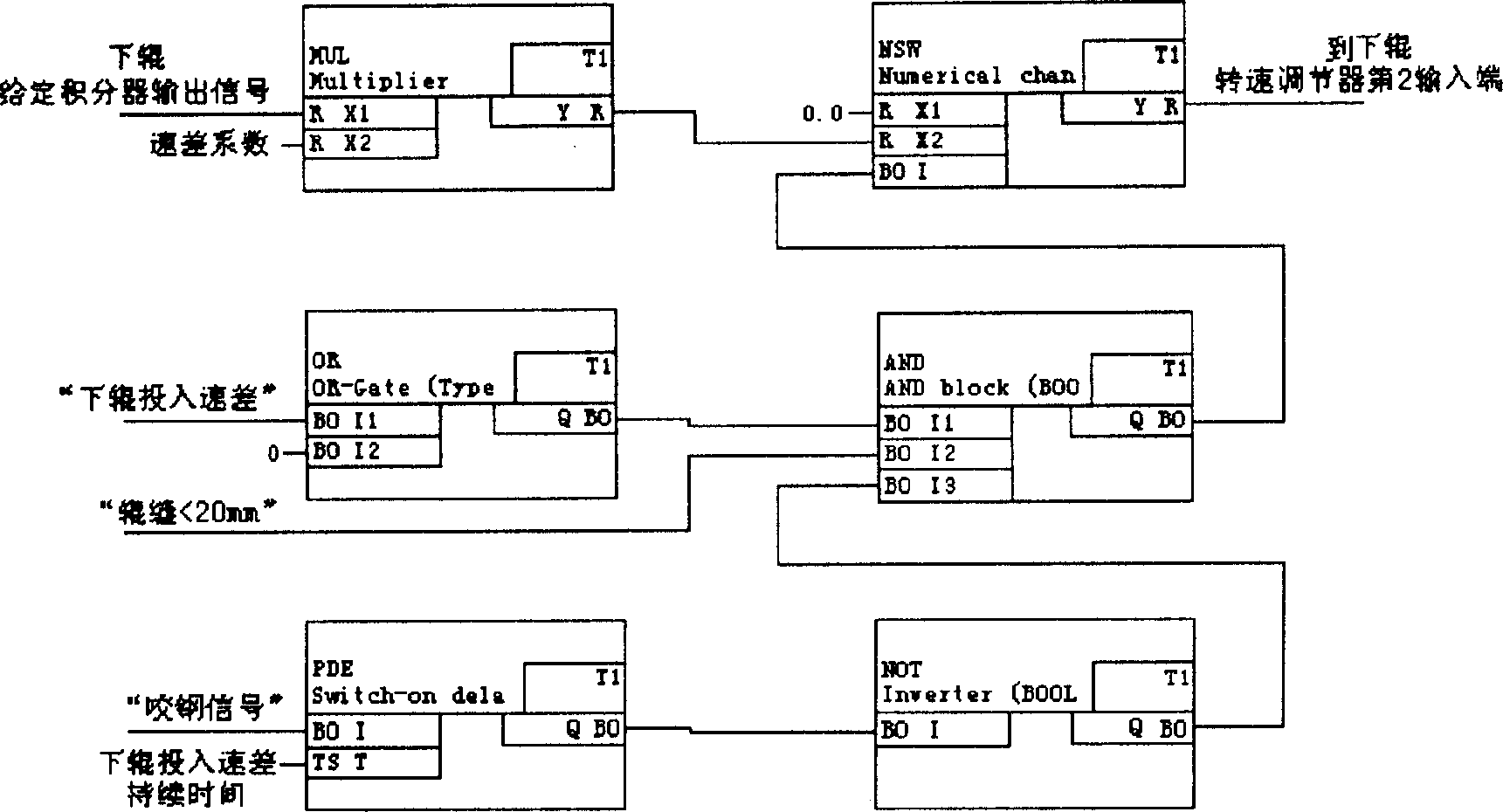

A method for controlling the head shape of the workpiece rolled by 4-roller rolling mill of middle-thickness plate is characterized by that an offset setting is applied to the rotation speed regulator of main motor for lower working rollers to change its speed, so preventing the head of workpiece from bending up or down.

Owner:NANJING IRON & STEEL CO LTD

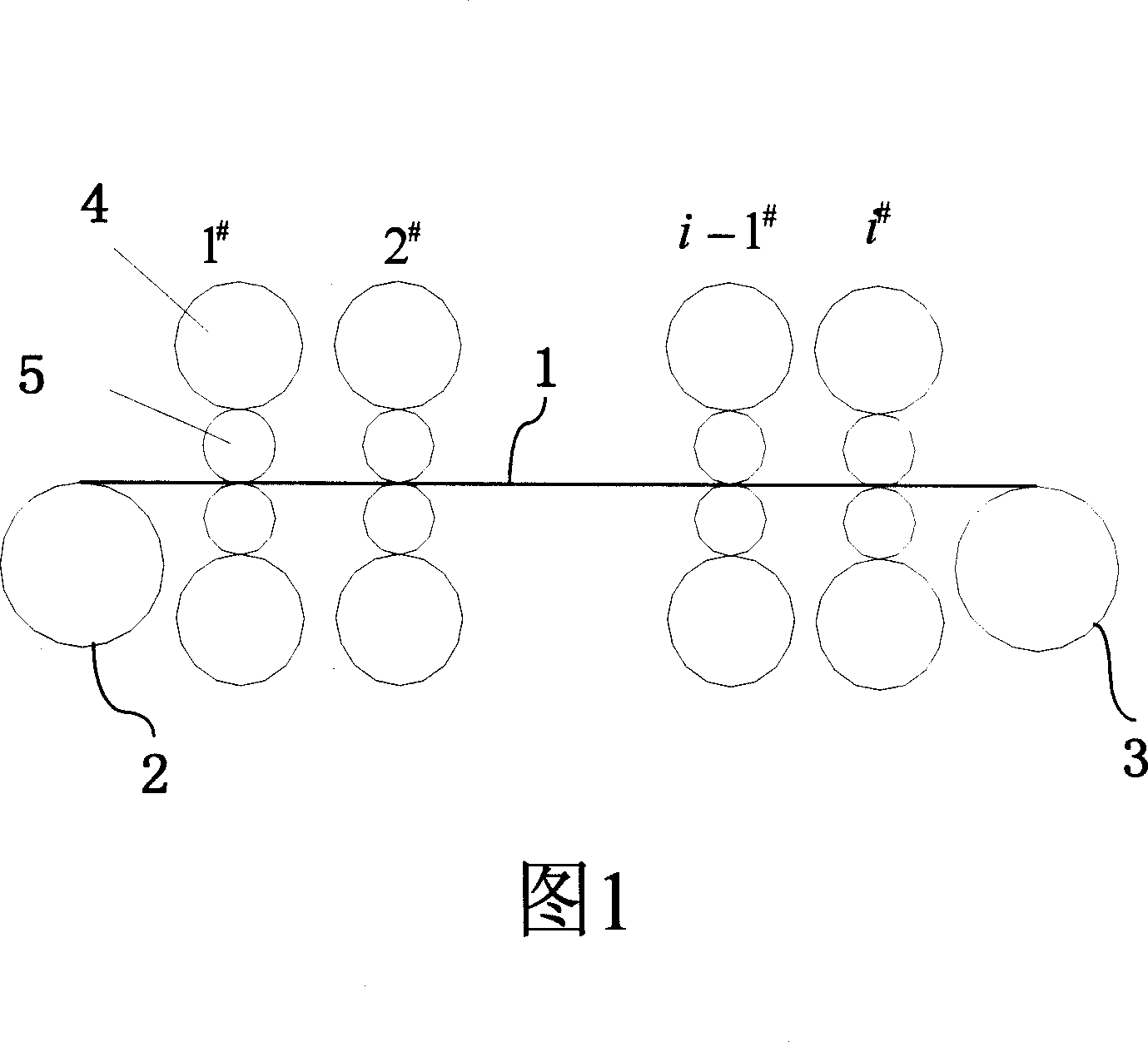

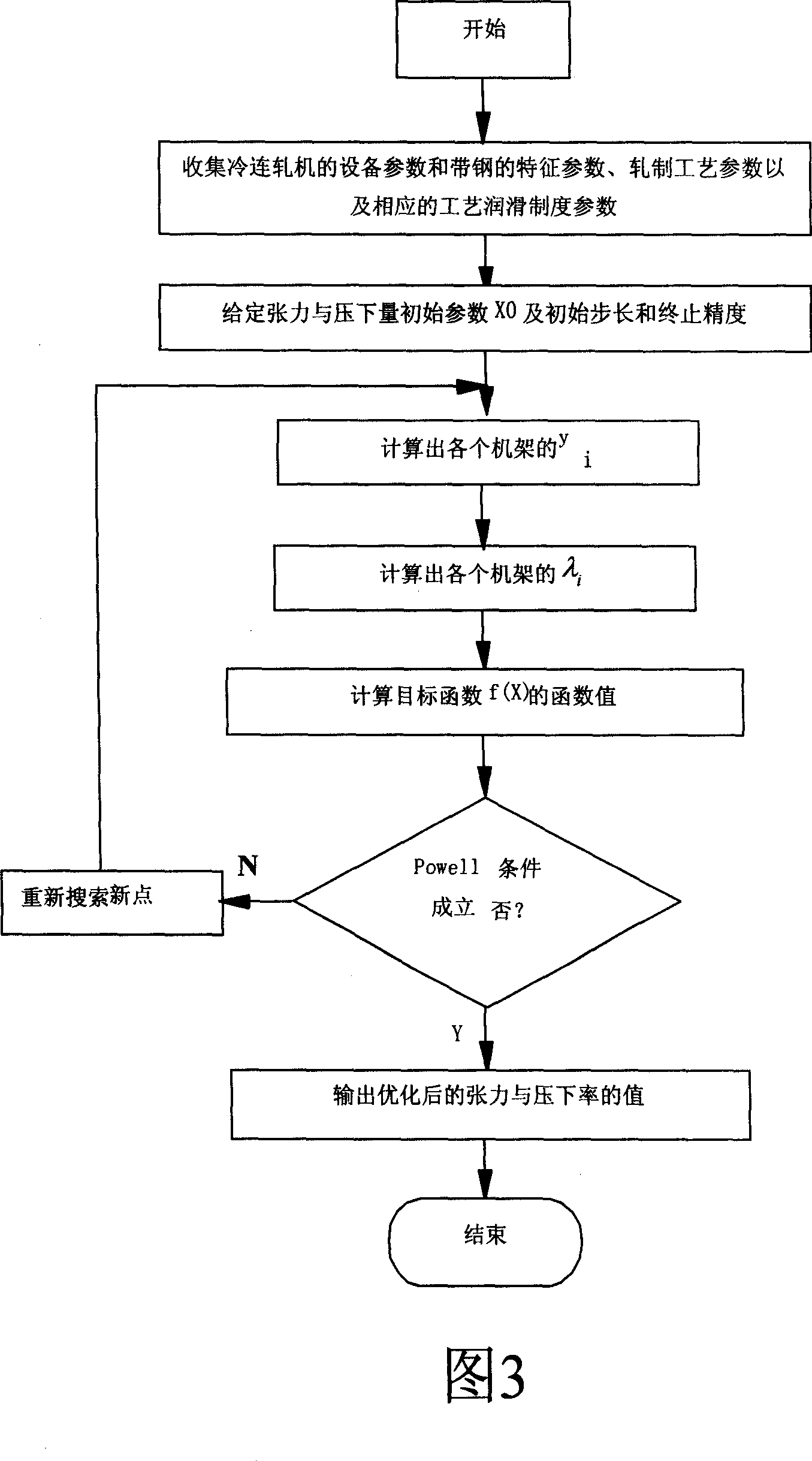

Optimizing method for preventing and controlling scrab in cold band-steel continuous milling machine

ActiveCN1979497ARealize your full potentialImprove surface qualitySpecial data processing applicationsProcess engineeringStrip steel

The invention discloses an optimizing method of using nick prevention and control as target in cold steel strip continuous-rolling machine, collecting equipment, steel strip characteristics, rolling process and other parameters of a cold continuous-rolling machine, and giving set values of initial tension and reduction of each machine frame, then separately finding skid factor and nick integrated judgment index value of each machine frame, and finding target function set for rolling rule optimization; then judging whether the target function meets Bauer' conditions, and finding the optimum tension and reduction set values. And it intrudes nick judgment concept, considers all machine frames of the cold continuous-rolling machine as a whole, and uses nick prevention and control as target to make on-line optimization settings on rolling rules, and can largely increase rolling speed and improve steel strip surface quality, and largely reduce huge economic losses of enterprises on the premise of assuring quality of products.

Owner:BAOSHAN IRON & STEEL CO LTD +1

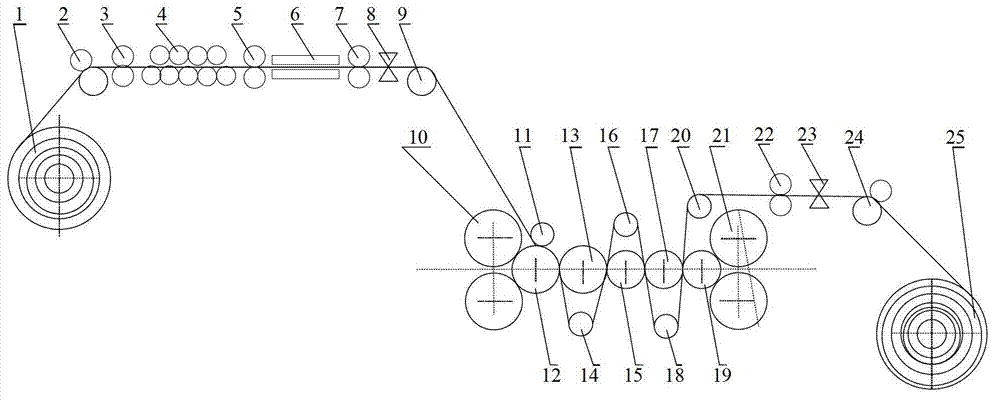

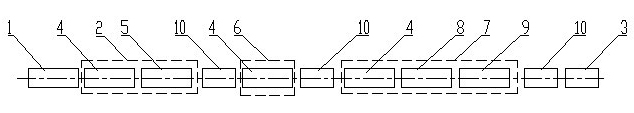

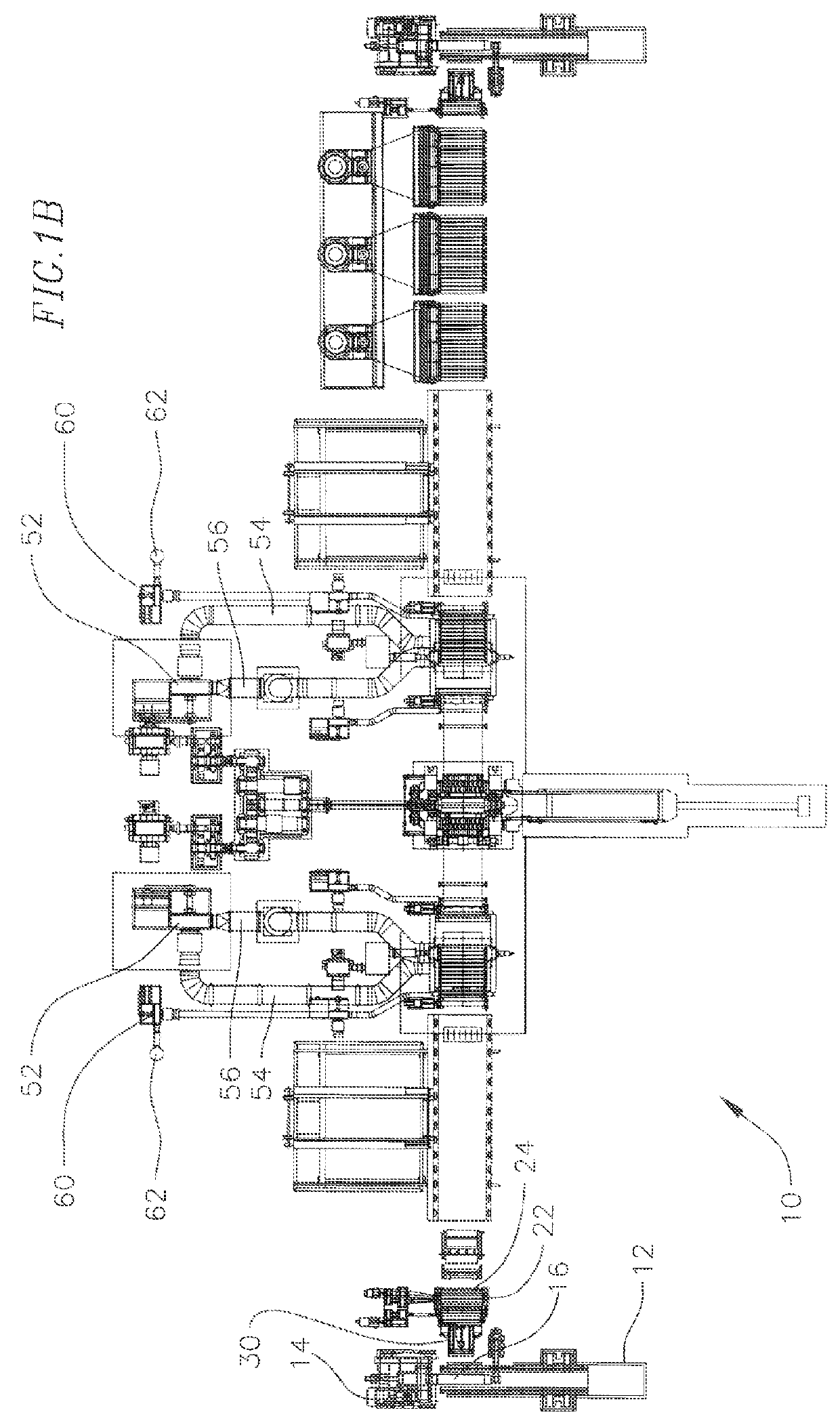

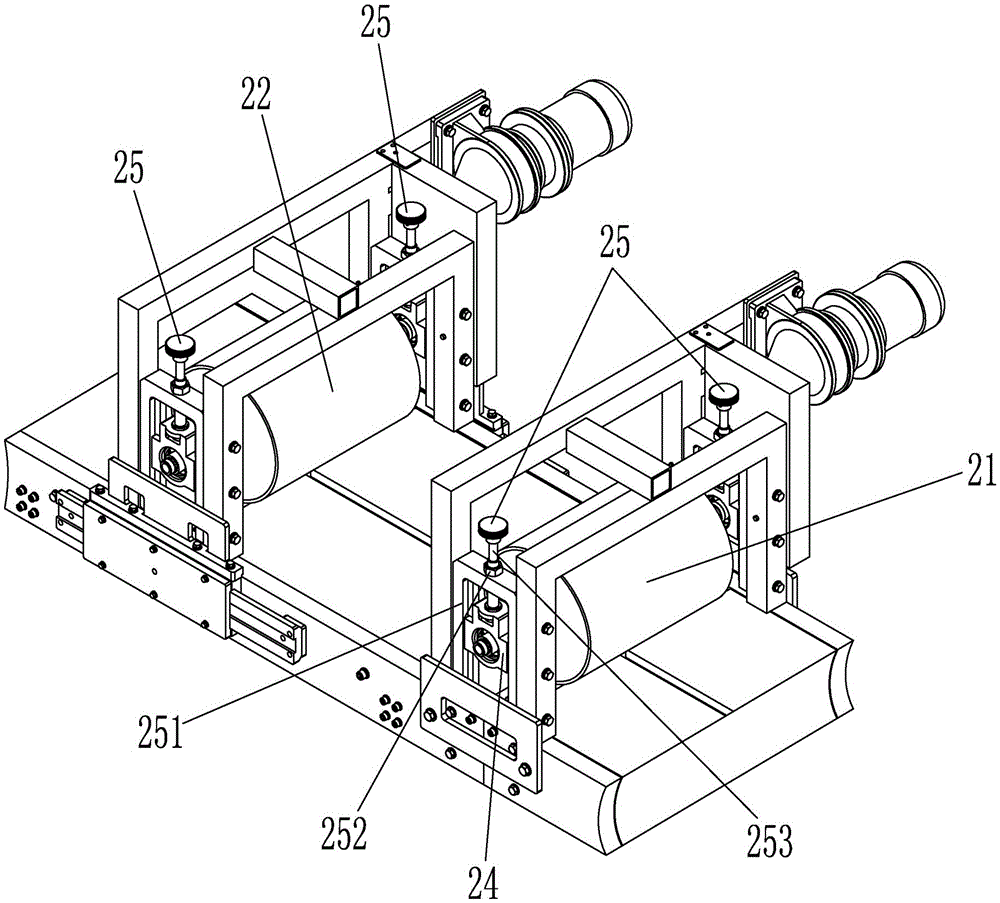

Continuous asynchronous rolling device of magnesium alloy sheet strip coil

InactiveCN102773255AStable rolling tensionRealized strip rollingMetal rolling arrangementsEngineeringEnergy consumption

The invention relates to a continuous asynchronous rolling device of a magnesium alloy sheet strip coil and belongs to the field of magnesium alloy materials. The continuous asynchronous rolling device conducts decoiling on the magnesium alloy strip coil through a decoiling device, the magnesium alloy strip coil enters a flattening machine to be flattened through a tension pinch roller and enters a strip coil preheating device through the tension pinch roller after being corrected to be heated to preset temperature, feeding material thickness is measured through a thickness gauge, then the strip coil enters a continuous asynchronous rolling machine for rolling, the rolled strip coil passes through the thickness gauge to measure thickness of a finished product and enters a rolling machine to be rolled through the tension pinch roller, and the whole coiling rolling is achieved after stable rolling tension is finished. The continuous asynchronous rolling device has the advantages of reducing rolling pressure and rolling torque, reducing energy consumption, increasing gate transformation quantity, improving rolling efficiency and the like, thereby being favorable for rolling production of strip coils of magnesium alloy which is hard to deform.

Owner:UNIV OF SCI & TECH BEIJING

Production method for double-zero aluminum foil

ActiveCN103785800ASmall grain sizeSurface streaks are reduced and reducedMetal rolling arrangementsAluminum foilUltimate tensile strength

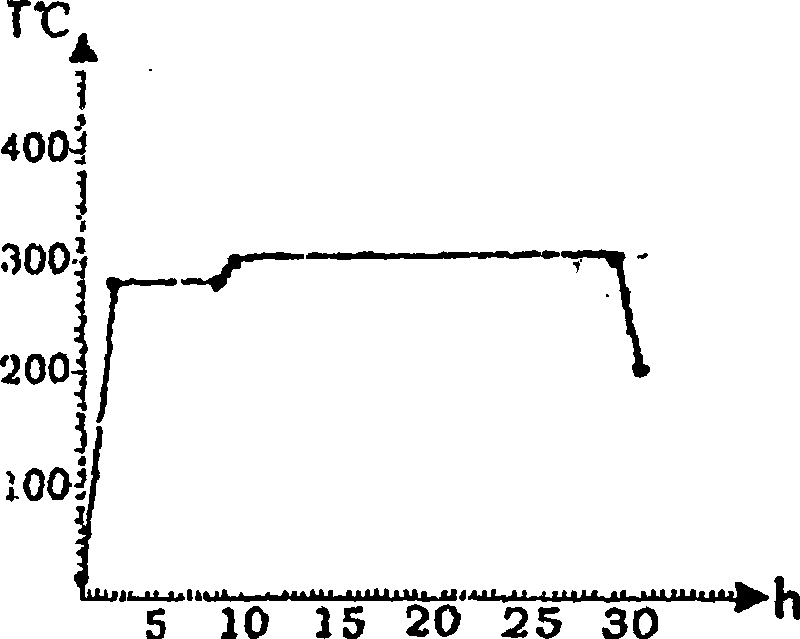

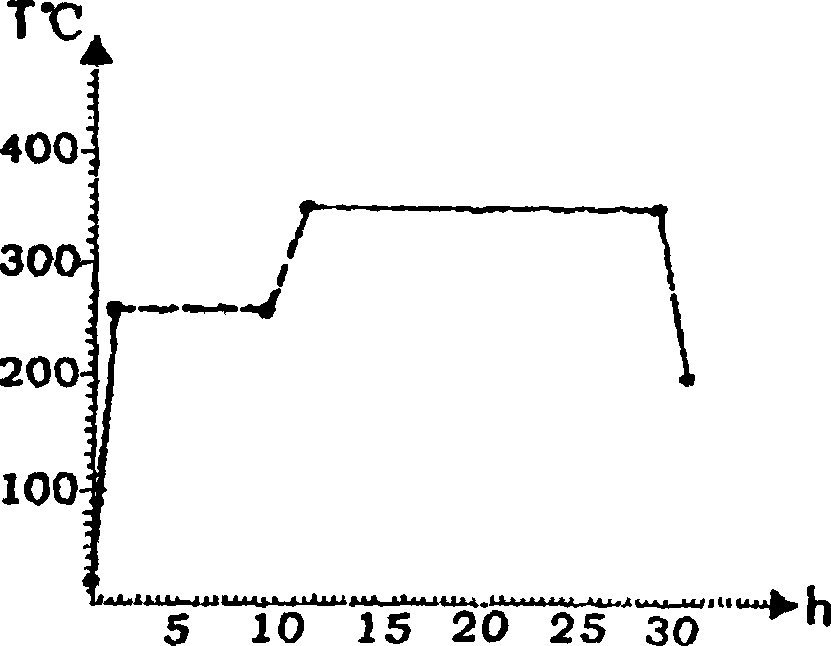

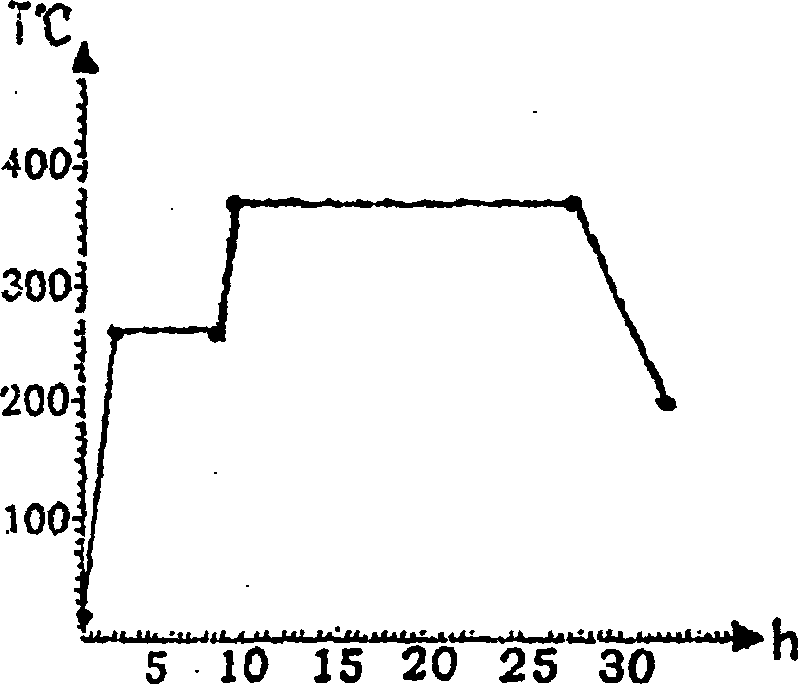

The invention discloses a production method for a double-zero aluminum foil. The production method includes subjecting an aluminum-alloy molten mass to cast rolling to produce a cast rolling coil with the thickness of 6.5-8.0mm after degassing and deslagging, subjecting the cast rolling coil to first cold rolling to produce an aluminum coil with the thickness of 2.0-3.0mm, performing first heat treatment on the aluminum coil subjected to the first cold rolling at the temperature of 450-550 DEG C for 15-20 hours, subjecting the aluminum coil subjected to the first heat treatment to second cold rolling to produce an aluminum coil with the thickness of 0.6-0.8mm, and performing second heat treatment on the aluminum coil subjected to the second cold rolling at the temperature of 300-380 DEG C for 6-12 hours; subjecting the aluminum coil subjected to the second heat treatment to third cold rolling to produce an aluminum coil with the thickness of 0.05-0.1mm, heating the aluminum coil to the aluminum-foil recrystallization critical temperature of 250-310 DEG C, keeping the aluminum coil at the temperature for 5-10 hours, and subjecting an aluminum foil to fourth cold rolling to produce the double-zero aluminum foil with the thickness of 0.006-0.009mm. The double-zero aluminum foil produced by the production method has tensile strength of more than 95Mpa, ductility of more than 3.1%, small blank grain size, few surface stripes, few needle holes and stable quality.

Owner:LUOYANG WANJI ALUMINUM PROCESSING CO LTD

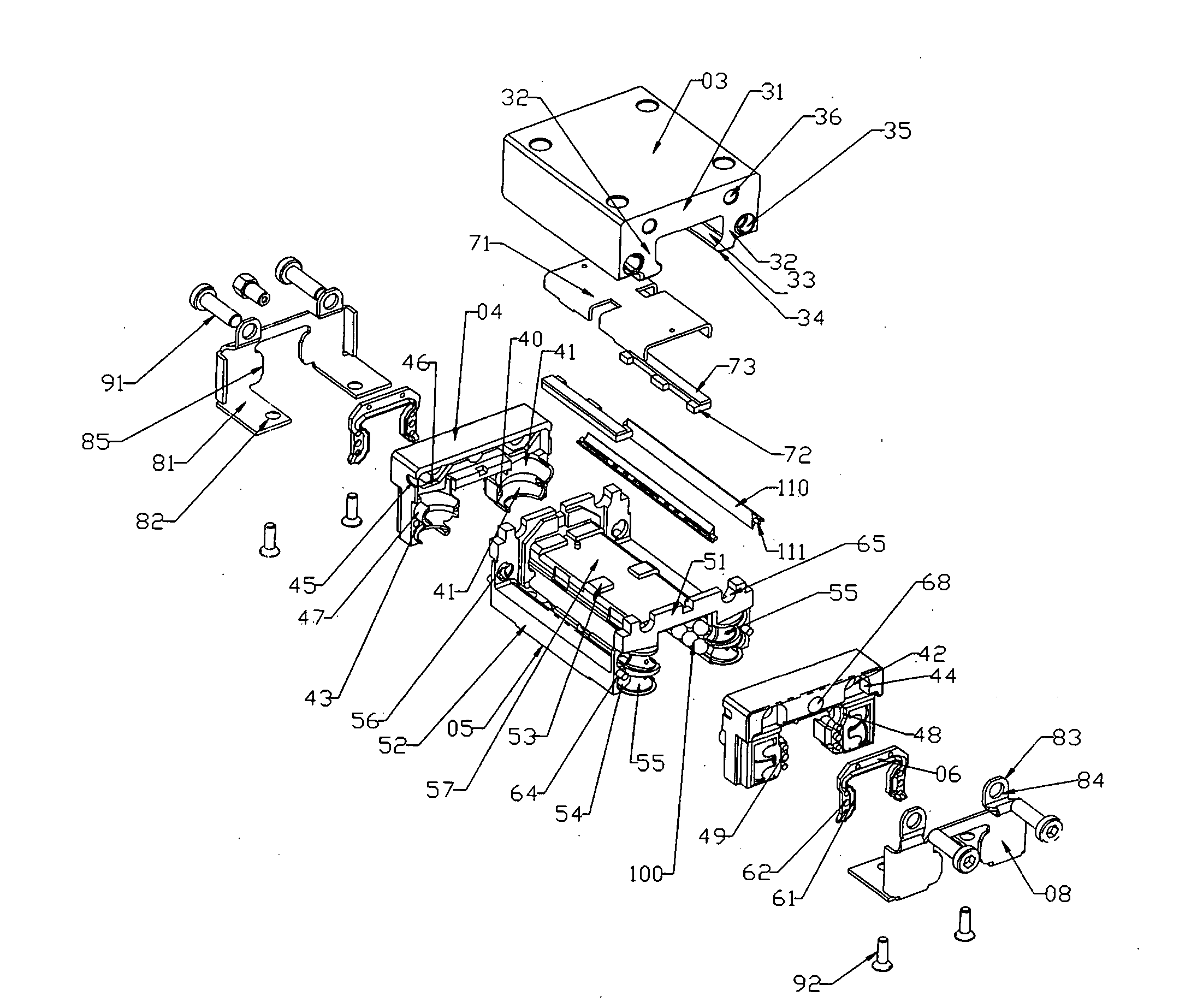

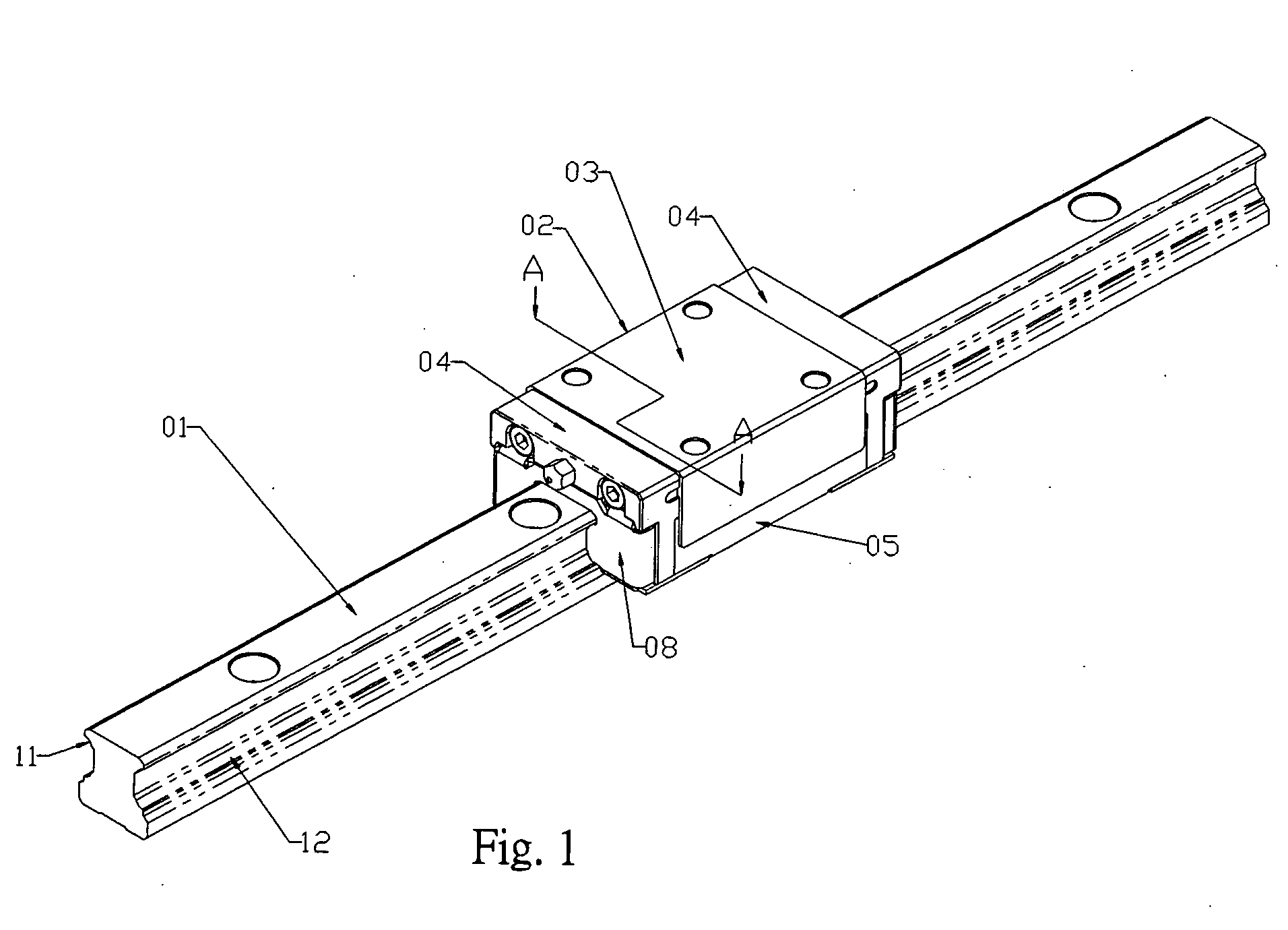

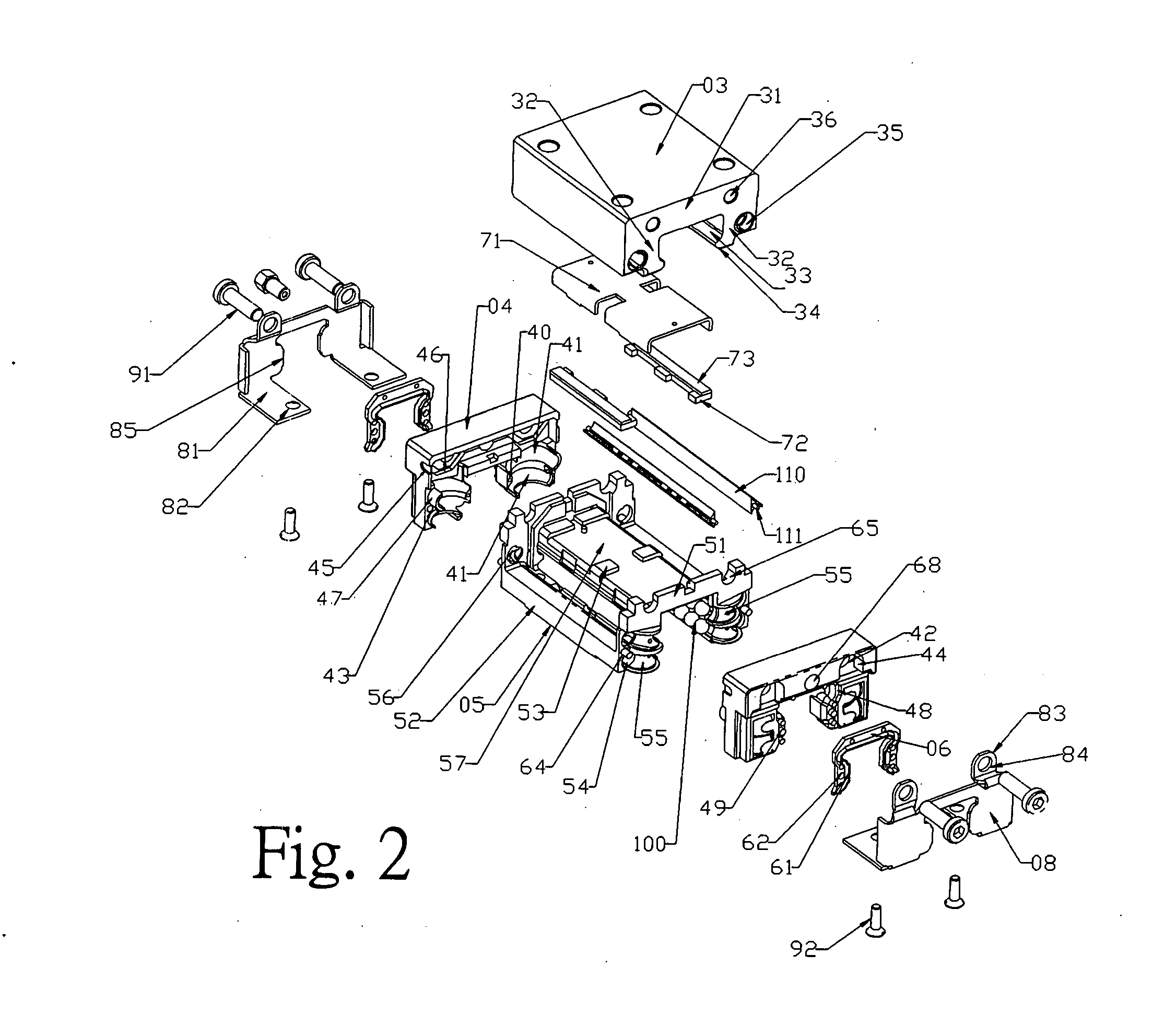

Linear guide device

ActiveUS20070140602A1Shorten the lengthHigh strengthLinear bearingsRolling contact bearingsEngineeringLubrication

A linear guide device comprises a rail, at least a slide member and multiple rows of rolling elements. The slide member comprises a rigid body; a bottom frame; a pair of end caps and a pair of reinforce plates. The rail and rigid body provide multiple rows of raceways opposed for the rolling elements. The bottom frame contains a plurality of lubricant reservoirs with lubrication pads inside and directly outstretch from the openings of said lubricant reservoirs to contact with the rolling elements in the raceway zone to supply lubricant on the rolling elements continuously. There are passages or tubes, having lubricating string inside, connecting the extending lubricant reservoirs. Two reinforce plates, each having two extending plates folded and stretched to the bottom of the two leg portions of the rigid body, and are attached on two end caps.

Owner:CHIEFTECH PRECISION

F-shaped steel mill roll double-hole type and rolling method

ActiveCN103357663AIncrease rolling speedImprove rolling stabilityRollsMetal rolling arrangementsProduction lineEngineering

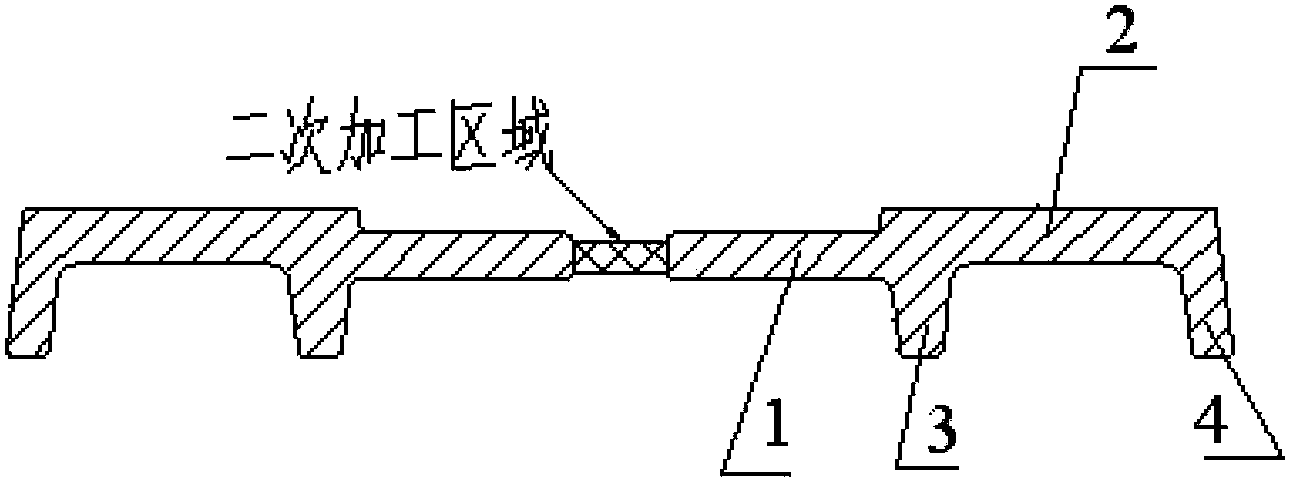

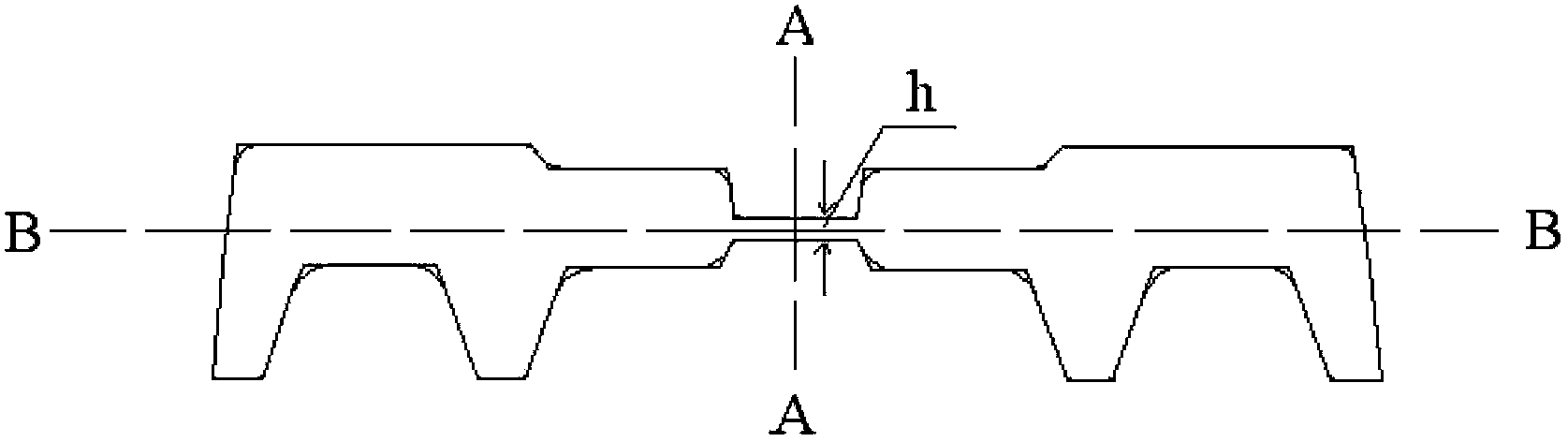

The invention discloses an F-shaped steel mill roll double-hole type and a rolling method. The double-hole type is formed by splicing an upper roll and a lower roll of a rolling mill and is a pair of F-shaped steel hole types which is symmetric along an axial line AA and are communicated through a connecting area. The axial line AA is perpendicular to the horizontal central ling BB of the double-hole type; and the connecting area is used for connecting one side, corresponding to the free end of a wing plate of the rolled F-shaped steel, of each F-shaped steel hole type. According to the rolling method, rolling is performed through a production line consisting of a reversible roughing mill and a universal rolling mill group; and each universal rolling mill of the universal rolling mill group is provided with the mill roll of the F-shaped steel mill roll double-hole type. The F-shaped steel mill roll double-hole type is used for rolling, so the rolling speed, namely the yield of steel per hour can be increased, the production cost can be reduced, the rolling stability can be improved, and the yield of finished products can be increased.

Owner:LAIWU IRON & STEEL GRP

Aluminum foil for electric cable and production method

InactiveCN101383200AReduce burning lossReduce segregationNon-insulated conductorsInsulated cablesMagnesiumMaterials science

The invention discloses a cable aluminum foil and a production method thereof. The cable aluminum foil comprises components of the following weight percent: 0.79 to 0.83 percent of Si, 0.22 to 0.26 percent of Fe, at most 0.1 percent of Cu, at most 0.2 percent of Mn, at most 0.05 percent of Mg, at most 0.05 percent of Cr, at most 0.1 percent of Zn, at most 0.08 percent of Ti, at most 0.05 percent of single impurity content, at most 0.15 percent of the total content of impurities and Al as the rest, wherein the content summation of the Fe and the Si in weight percent is less than 1.1 percent. The production method comprises the production technical processes: burdening, melting, component analysis, feeding dilution, powder injection refining, N2 refining, on-line refining outside a furnace, casting, casting plate type detection, blank winding, cold rolling, vertical cutting and splitting, finished product annealing, detection, packing, storage and leaving a factory. The cable aluminum foil has good mechanical property, the tensile strength is from 90 to 105MPa, the extension rate is greater than 25 percent, the production requirement has larger development potential, and the enterprise benefit and the social benefit can be obviously increased.

Owner:河南省银湖铝业有限责任公司

Titanium alloy coil rod and production method thereof

The invention provides a titanium alloy coil rod and a production method thereof. The titanium alloy coil rod comprises the following components in percentage by weight: 15.0 to 6.0 percent of A, 3.0 to 4.0 percent of V, less than or equal to 0.25 percent of Fe, less than or equal to 0.06 percent of C, less than or equal to 0.05 percent of N, less than or equal to 0.012 percent of H, less than or equal to 0.16 percent of O and the balance of Ti and unavoidable impurities. The titanium alloy coil rod is obtained by performing steps of heating, rough rolling, medium rolling, pre-finish-rolling, finish rolling, spinning looping, air cooling, coil collection and air cooling. According to the invention, heating only needs to be carried out once; the rhythm of production is rapid; production efficiency and yield of the titanium alloy coil rod are greatly improved; mass continuous production can be realized; heating cost is effectively reduced; the energy saving effect is obvious; large-coil heavy titanium alloy coil rod can be efficiently produced by utilizing the method; and the product has high size accuracy and good structure property.

Owner:WUKUN STEEL

Production method of industrial pure titanium wire rod

InactiveCN102974610AIncrease productivityHigh yieldTemperature control deviceMetal rolling arrangementsWire rodTitanium

The invention provides a production method of an industrial pure titanium wire rod, which comprises the following steps of heating of an industrial pure titanium square billet, rough rolling, middle rolling, prefinish rolling, finish rolling, spinning in circles, wind cooling, coil collection and air cooling, and then the industrial pure titanium wire rod is obtained. The industrial pure titanium wire rod, the piece weight of which exceeds 400 kg, can be produced, the production efficiency and the yield of the industrial pure titanium wire rod are effectively increased, the problems of easiness in oxidation and hydrogen embrittlement of industrial pure titanium in prior art are solved, the heating cost of the industrial pure titanium square billet is effectively reduced, continuous production on a large scale can be realized, the rolling speed and the rolling power are increased, and an ideal metallographic structure and physical properties are obtained. By utilizing the method, the industrial pure titanium wire rod with large coil weight can be efficiently produced, the precision of the product size is high, and the structure property is good.

Owner:WUKUN STEEL +1

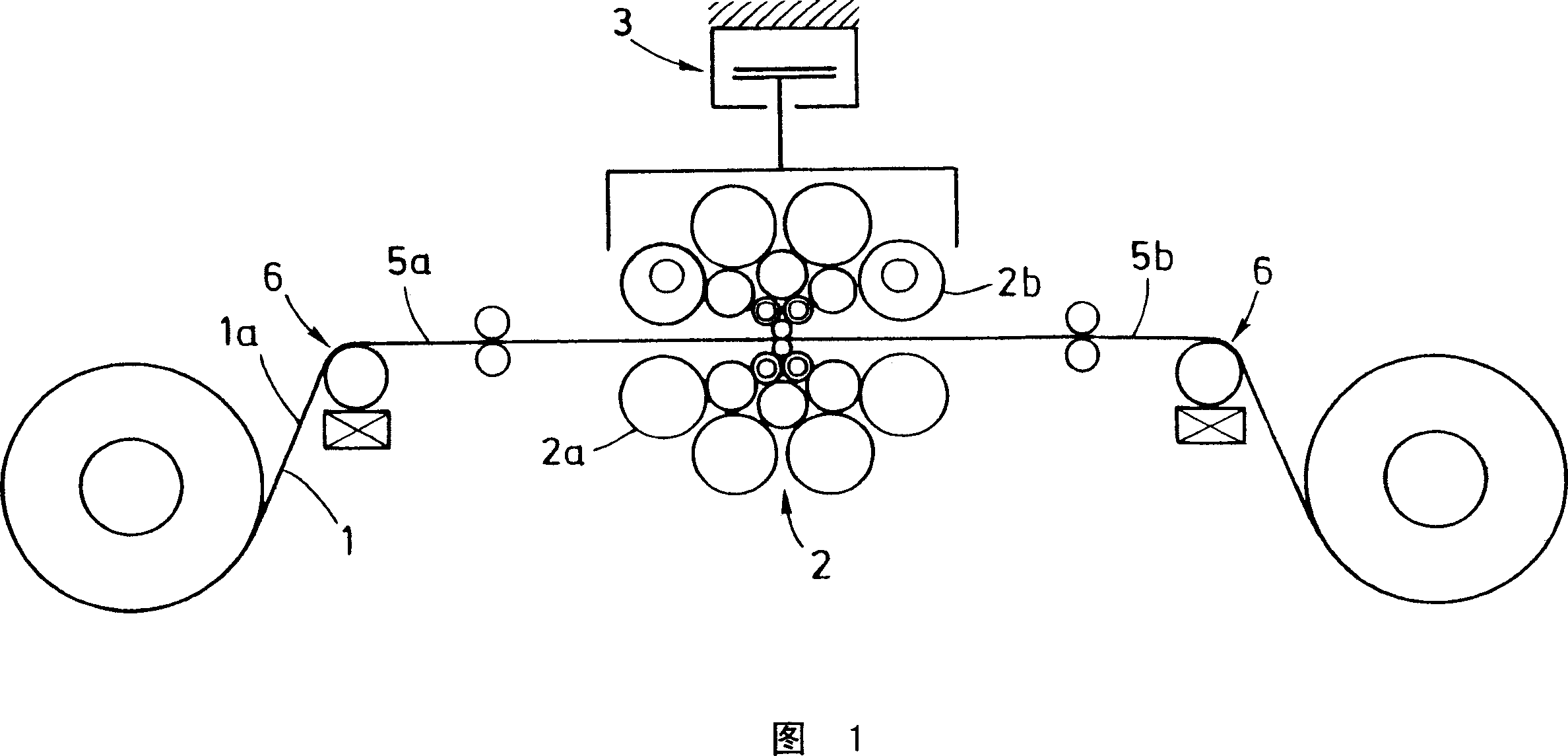

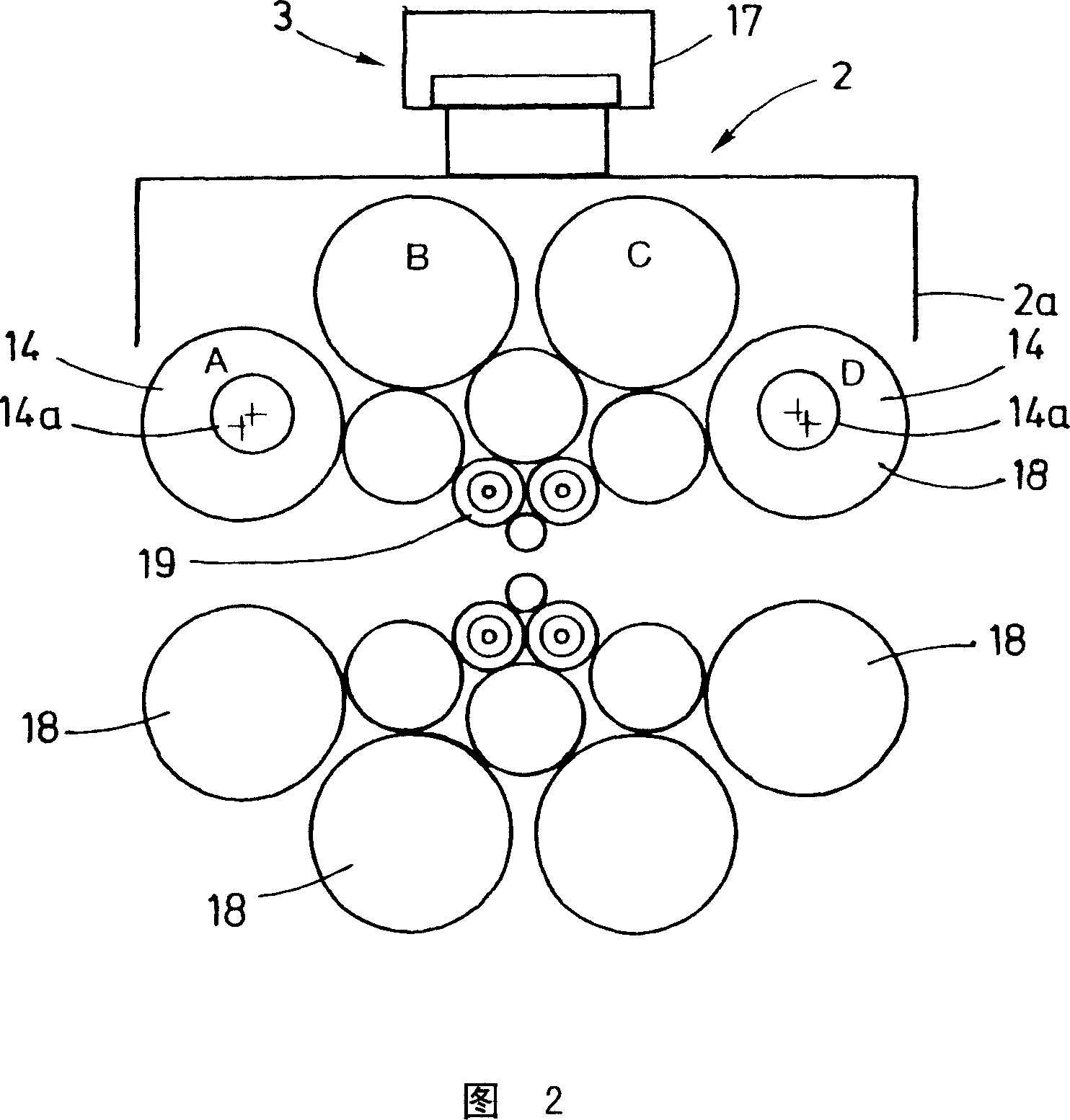

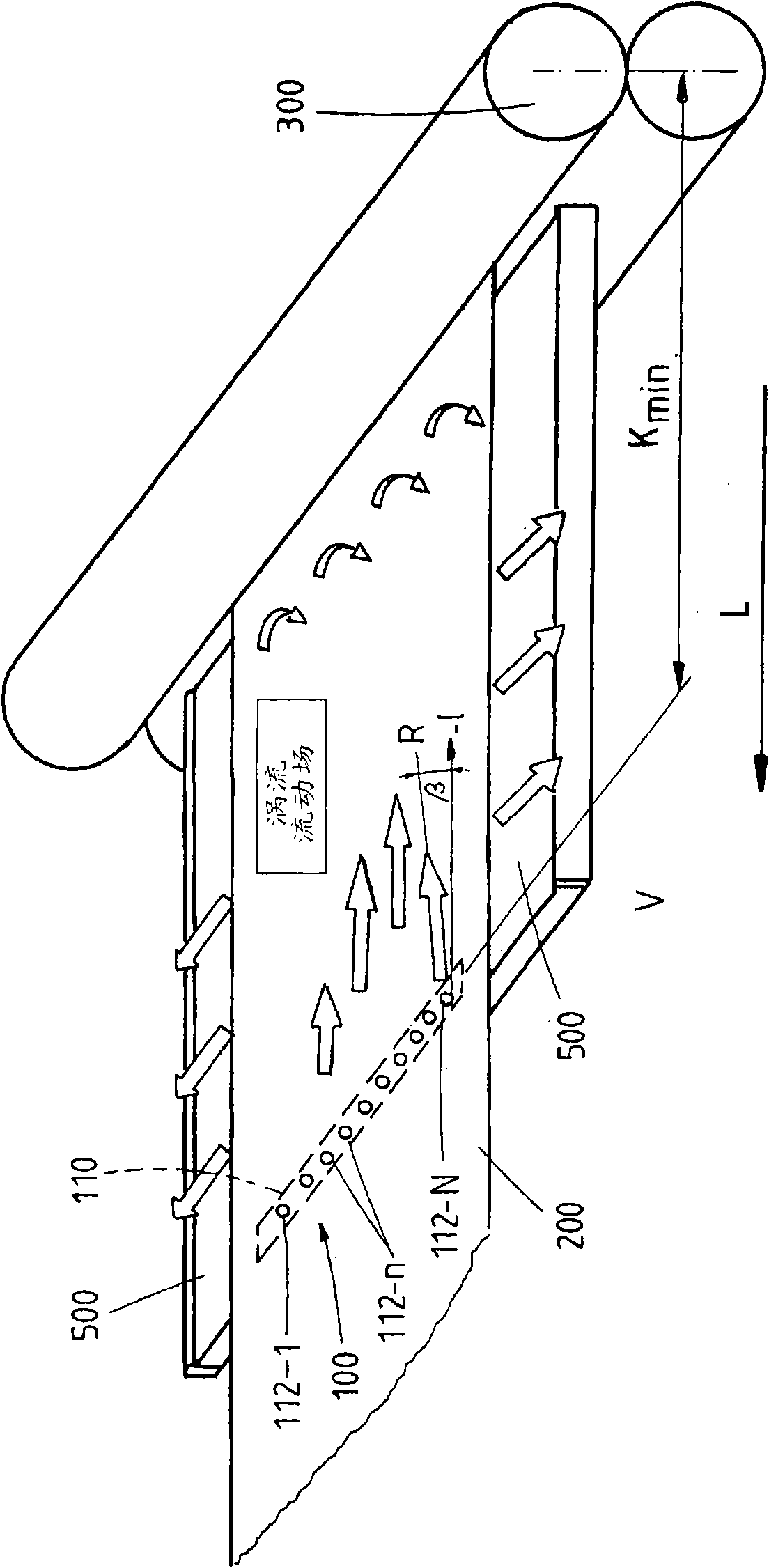

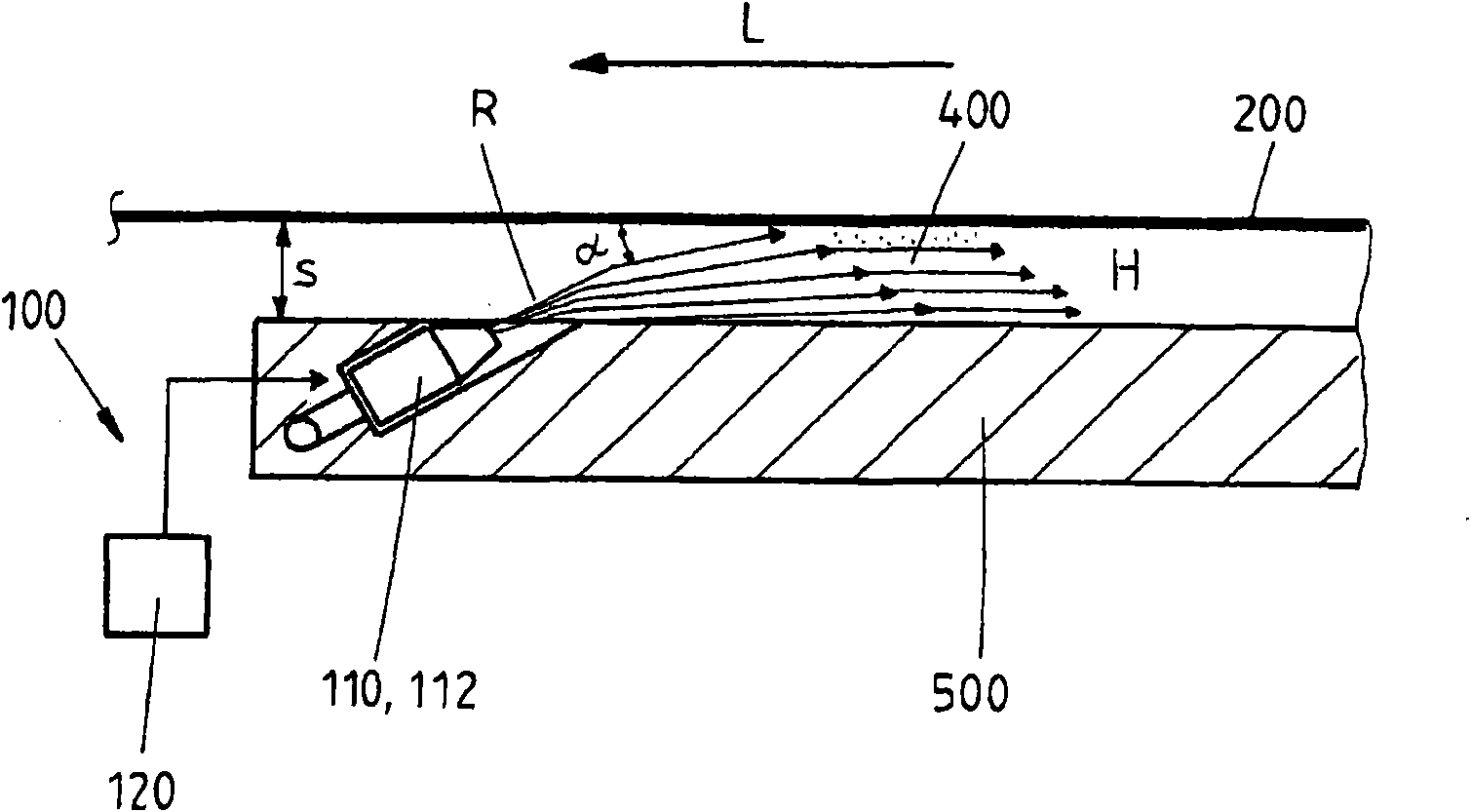

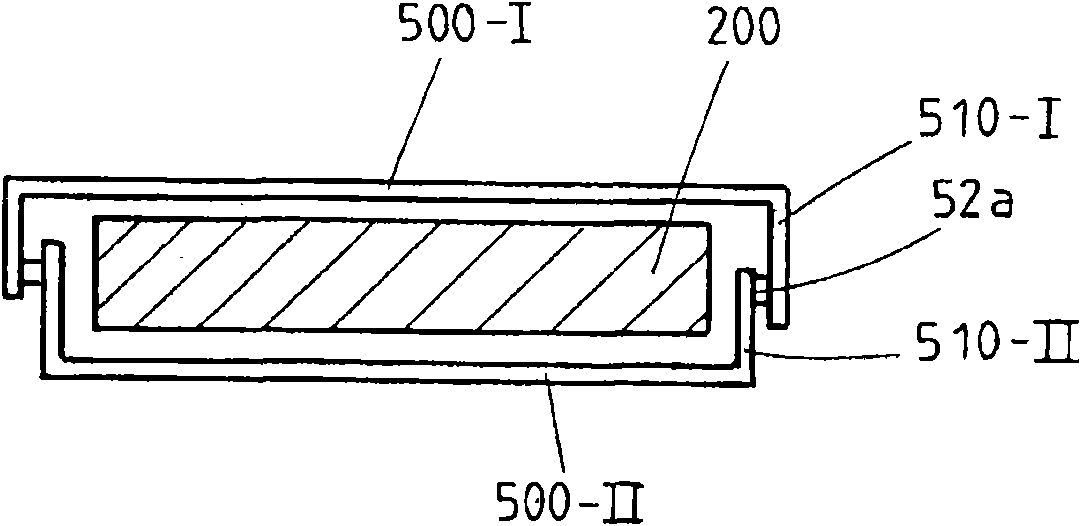

Method and device for measuring and adjusting the evenness and/or tension of a special steel strip or special steel film in a multi-roll stand, particularly in a 20-roll sendzimir rolling machine

ActiveCN1980752AReduce the burden onShorten the timeMetal rolling stand detailsMeasuring devicesSteel beltRolling mill

A method and device for measuring and adjusting the evenness and / or tension of a stainless steel strip (1) during cold rolling in a 4-roll stand (2) provided with at least one control loop (4) comprising several actuators (3), resulting in more precise measurement and adjustment due to the fact that an evenness defect (10) is determined by comparing a tension vector (8) with a predefined reference curve (9), whereupon the characteristic of the evenness defect (10) along the width of the strip is broken down into proportional tension vectors (8) in an analysis building block (11) in a mathematically approximated manner and the evenness defect proportions (C1...Cx) determined by real numerical values are supplied to respectively associated control modules (12a; 12b) for actuation of the respective actuator (3).

Owner:SMS DEMAG AG

Rolling method of high-grade non-oriented silicon steel

ActiveCN108655173AIncrease heat of deformationReduced edge cracking tendencyRoll force/gap control deviceTension/compression control deviceTemperature controlReduction ratio

The invention relates to a rolling method of high-grade non-oriented silicon steel. Through four-time rolling, reduction ratios are increased so as to increase deformation heat of strip steel, so thata rolling temperature of the strip steel is increased, and a temperature of an incoming material is controlled to reach 55 DEG C to 60 DEG C; the scheme of the four-time reduction ratios comprises that the reduction ratio for the first time is 37 percent to 41 percent, the reduction ratio for the second time is 36 percent to 39 percent, and the reduction ratio for the third time is 34 percent to37 percent; rolling force for the four times is respectively controlled as follows: 4750kN to 5000kN, 4600kN to 5000kN, 4400kN to 4600kN and 3900kN to 4200kN; and unit tension adjustment on rolling atthe previous two times is carried out. The rolling method of the high-grade non-oriented silicon steel disclosed by the invention has the advantages that the rolling times are simplified, the trend of edge cracking of an edge part of the strip steel is reduced, and production of double -rib wave is reduced.

Owner:ANGANG STEEL CO LTD

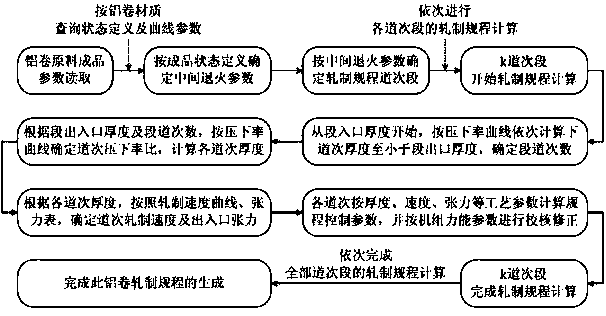

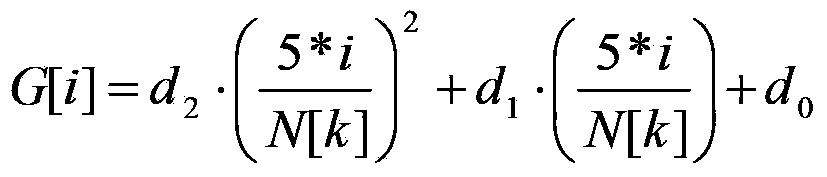

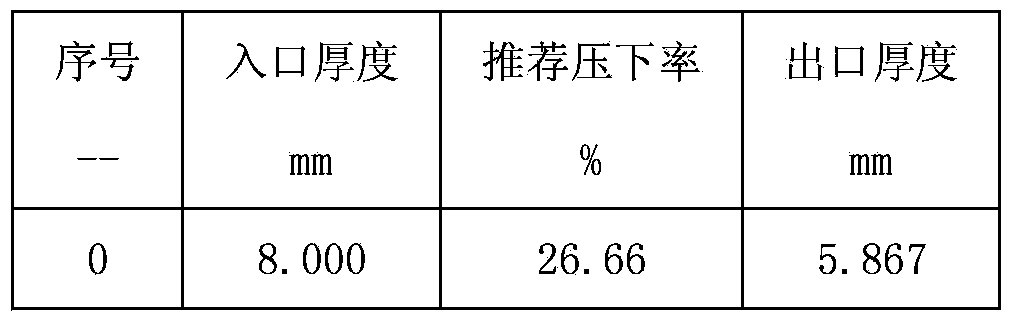

Aluminum cold-rolling mill rolling schedule generation method based on material states and parameter curves

ActiveCN103406361AImprove stabilityIncrease productivityRoll force/gap control deviceTension/compression control deviceMathematical modelControl parameters

The invention relates to an aluminum cold-rolling mill rolling schedule generation method based on material states and parameter curves. The method includes determining intermediate annealing process parameters in a rolling schedule in terms of a material finished product state according to raw materials and finished product parameter requirements of aluminum rolls, determining process parameters such as the times of rolling passes, thickness of each pass and rolling speed according to the parameter curves, then calculating rolling schedule control parameters according to a mathematical model, and checking and correcting according to mechanical parameters of a unit so as to automatically generate the rolling schedule of the aluminum rolls. According to the method, after finished product definition and parameter curves of a certain material are determined according to process requirements and empirical data, automatic rolling schedule generation aiming for aluminum rolls made of the material and in various dimensions can be realized, maintenance and extension according to materials are facilitated, and a systematized rolling schedule generation technique is formed.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Hot-rolled edge quality control method for low-temperature and high-magnetic-inductance oriented silicon steel

ActiveCN109590339AImprove edge qualityReduce the degree of oxidationMetal rolling arrangementsProfile control deviceSlip coefficientQuality control

The invention discloses a hot-rolled edge quality control method for low-temperature and high-magnetic-inductance oriented silicon steel. The control method comprises the steps of in the process of heating the low-temperature and high-magnetic-inductance oriented silicon steel by a heating furnace high-temperature section, controlling an air-fuel ratio of an upper secondary heating section to an upper soaking section of the low-temperature and high-magnetic-inductance oriented silicon steel to be less than or equal to a first preset value, and controlling an air-fuel ratio of a lower secondaryheating section to a lower soaking section of the low-temperature high-magnetic-inductance oriented silicon steel to be less than or equal to a second preset value, wherein the first preset value isgreater than the second preset value; reducing the temperature of the heating furnace high-temperature section by 10-20 DEGC; and performing three pass of rough rolling on the low-temperature and high-magnetic-inductance oriented silicon steel by a first vertical roll and a second vertical roll, wherein the rolling speed in each pass in rough rolling is controlled at 2.6-4.8 m / s, and the best slope matching speed and backward slip coefficient between the vertical rollers E2 and R2 in each pass. The hot-rolled edge quality control method solves the technical problem of high occurrence rate of 'cake brittleness' defect at the edge of the strip.

Owner:武汉钢铁有限公司

Production of copper or copper-alloy pipes

ActiveCN1981982AHigh strengthIncrease wall thicknessTemperature control deviceMetal rolling stand detailsMachining processUltimate tensile strength

A method for manufacturing copper (or Cu-alloy) tube includes such steps as removing surficial oxide layer from raw tube, high-speed rolling by a 4-roller rolling mill, fast cooling by a two-pass cooler, and straight cold drawing.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP +1

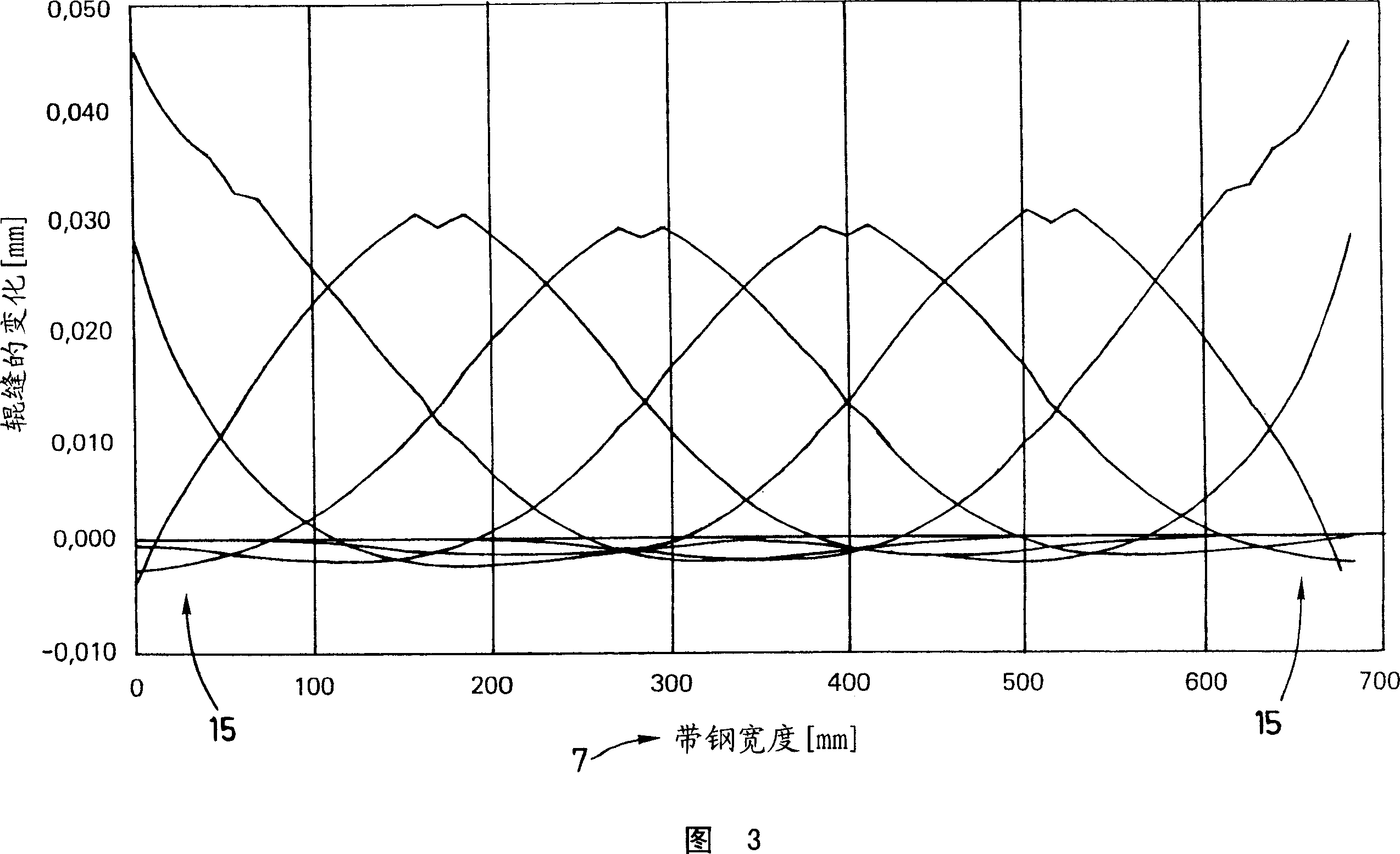

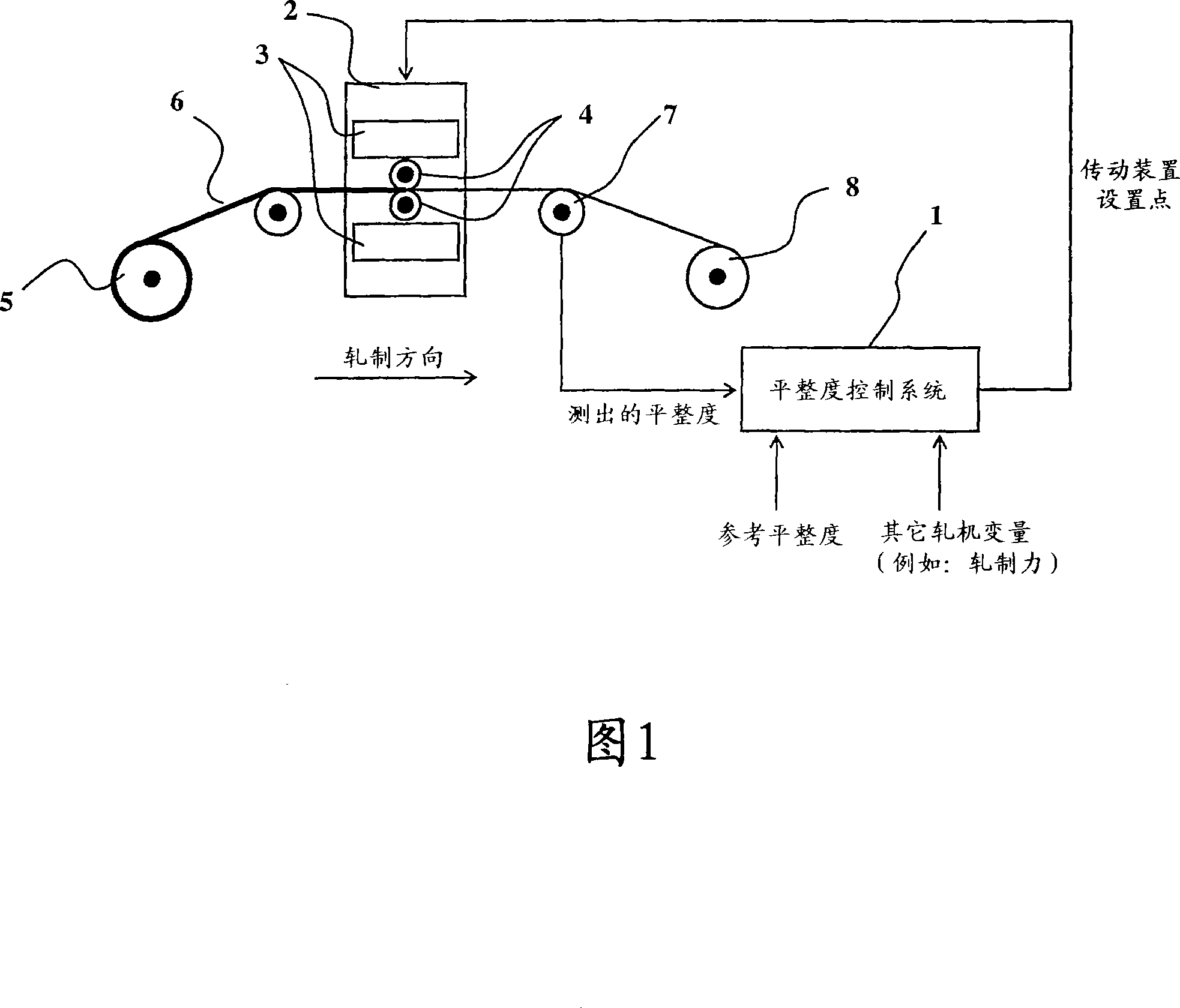

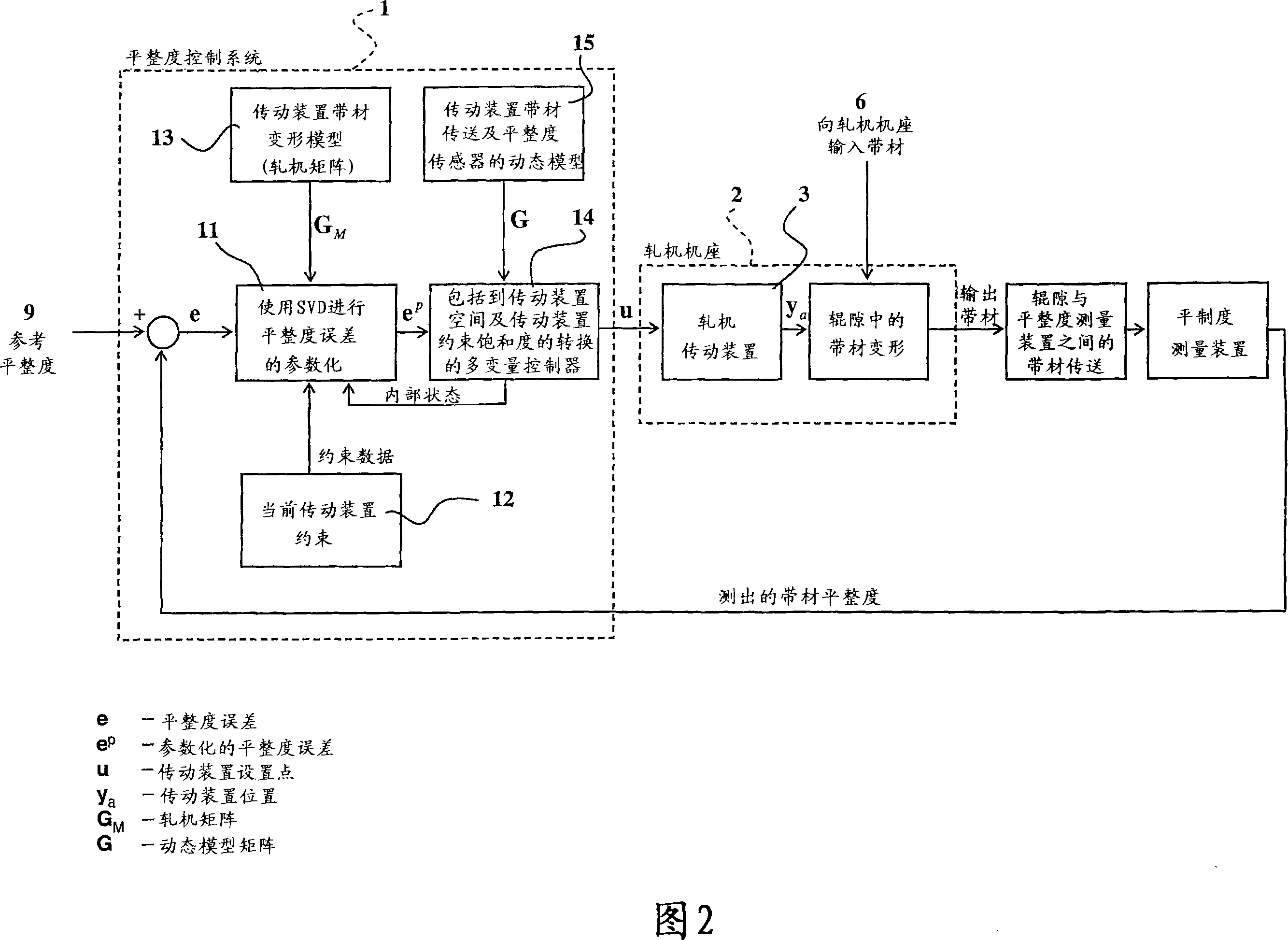

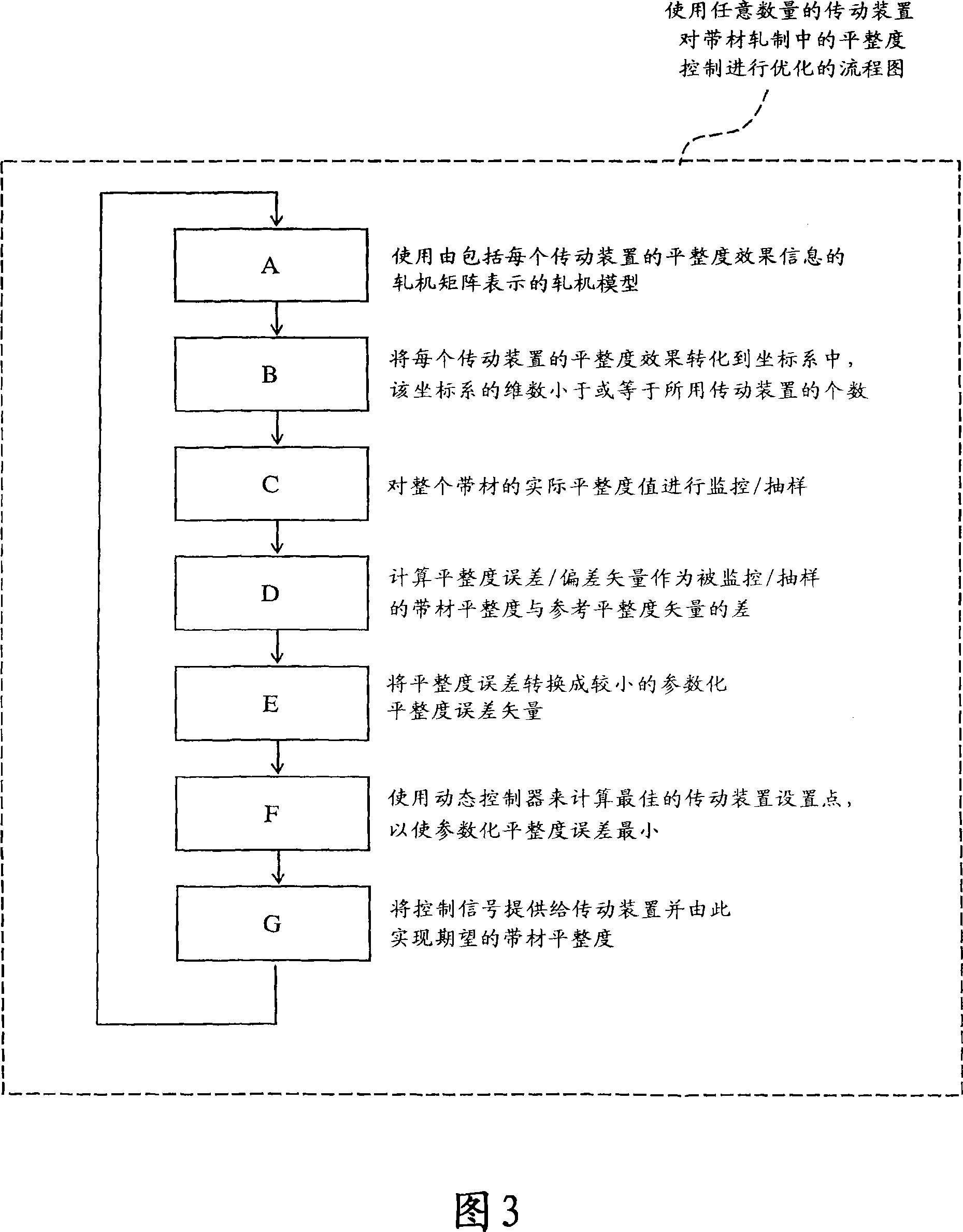

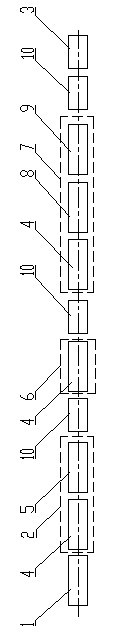

Method and device for optimization of flatness control in the rolling of a strip

ActiveCN101208161AStable and robust flatness control systemIncrease productionMeasuring devicesUsing optical meansActuatorComputer science

The present invention relates to a method and a device for optimization of flatness control in the rolling of a strip using any number of mill stands and actuators. The invention is achieved by using a mill model represented by a mill matrix that contains information of the flatness effect of each actuator, translating each actuator's flatness effect into a coordinate system, whose dimension is less or equal than the number of actuators used, monitoring / sampling the actual flatness values across the strip, computing a vector of the flatness error / deviation as the difference between the monitored / sampled strip flatness and a reference flatness vector, converting the flatness error into a smaller parameterized flatness error vector, using a dynamic controller to calculate optimized actuator set-points in order to minimize the parameterized flatness error, thereby achieving the desired strip flatness. The invention also relates to a system for optimization of flatness control in the rolling of a strip.

Owner:ABB (SCHWEIZ) AG

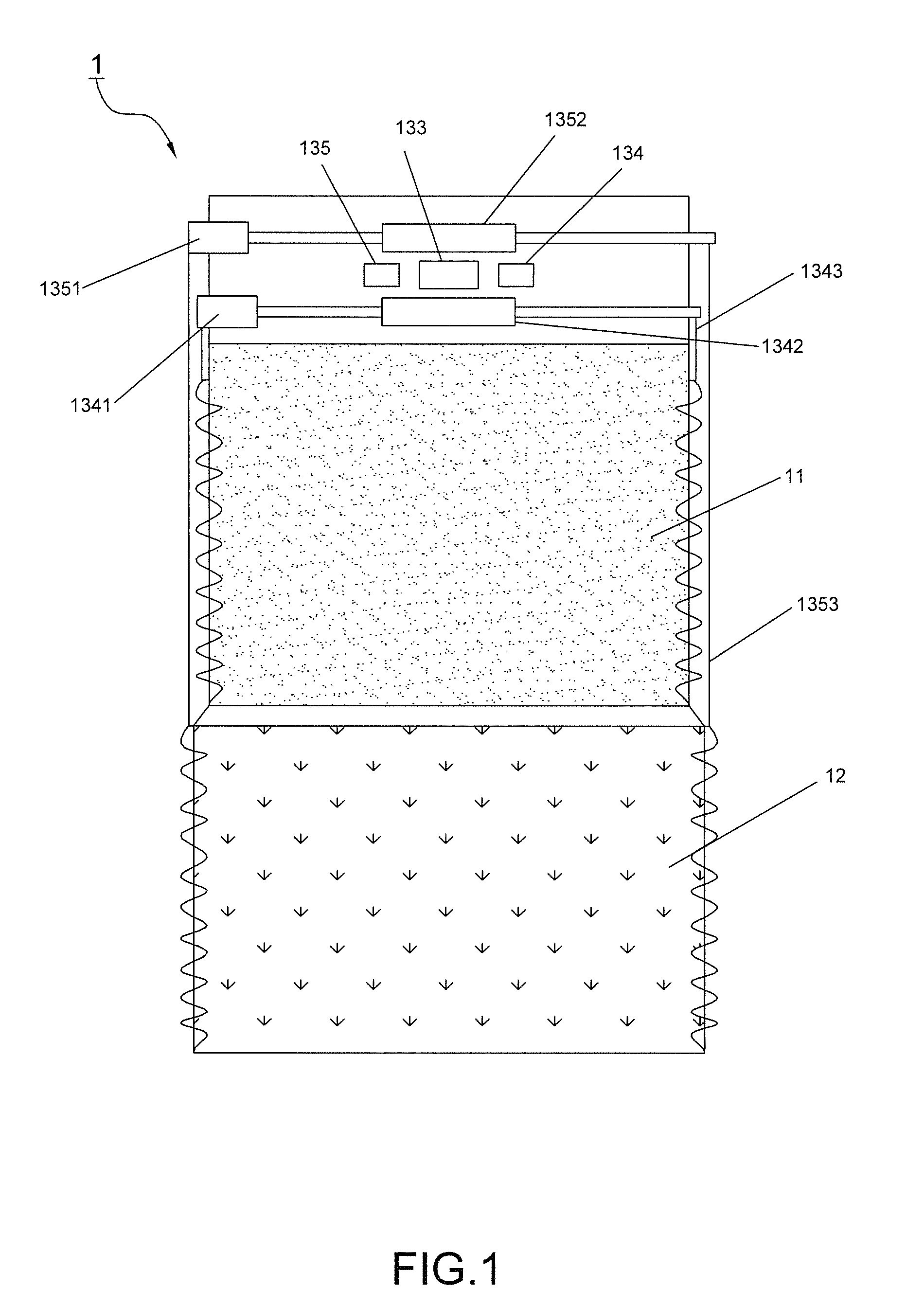

Production device of high-strength fine-grain hot rolled ribbed steel bars and production process thereof

ActiveCN102179403AGood for low temperature rollingFacilitate the realization of low temperature rollingTemperature control deviceMetal rolling arrangementsThermal insulationRebar

The invention discloses a production device of high-strength fine-grain hot rolled ribbed steel bars, which comprises a blank pretreatment unit, a low-temperature isothermal fast rolling unit and a finished product treatment unit, wherein the number of the low-temperature isothermal fast rolling unit is at least 1, the production device comprises a continuous rolling machine set and a head-shedding, thermal insulation and heat compensation roller way device arranged after the continuous rolling machine set, the continuous rolling machine set is used for performing low-temperature isothermal fast large-deformation rolling on a rolled piece by the low-temperature isothermal fast rolling unit, then the head-shedding, thermal insulation and heat compensation roller way device is used for thermal insulation and heat compensation, temperature control large-deformation rolling can be continuously performed according to needs, and the temperature of the whole rolling process is controlled at 750-950 DEG C. Not only continuous casting and direct heat transfer rolling can be realized, and energy consumption can be reduced, but also low-temperature isothermal rolling, temperature control rolling and large-deformation rolling can be realized, crystal grains are further fined, and the product performances are improved. In addition, through temperature control cooling, cooling recovery and other means, rolling temperature of the rolled piece in all the units can be controlled, the uniform temperature of the cross section of the rolled piece is ensured, and the fining of the grains is also ensured.

Owner:CISDI ENG CO LTD

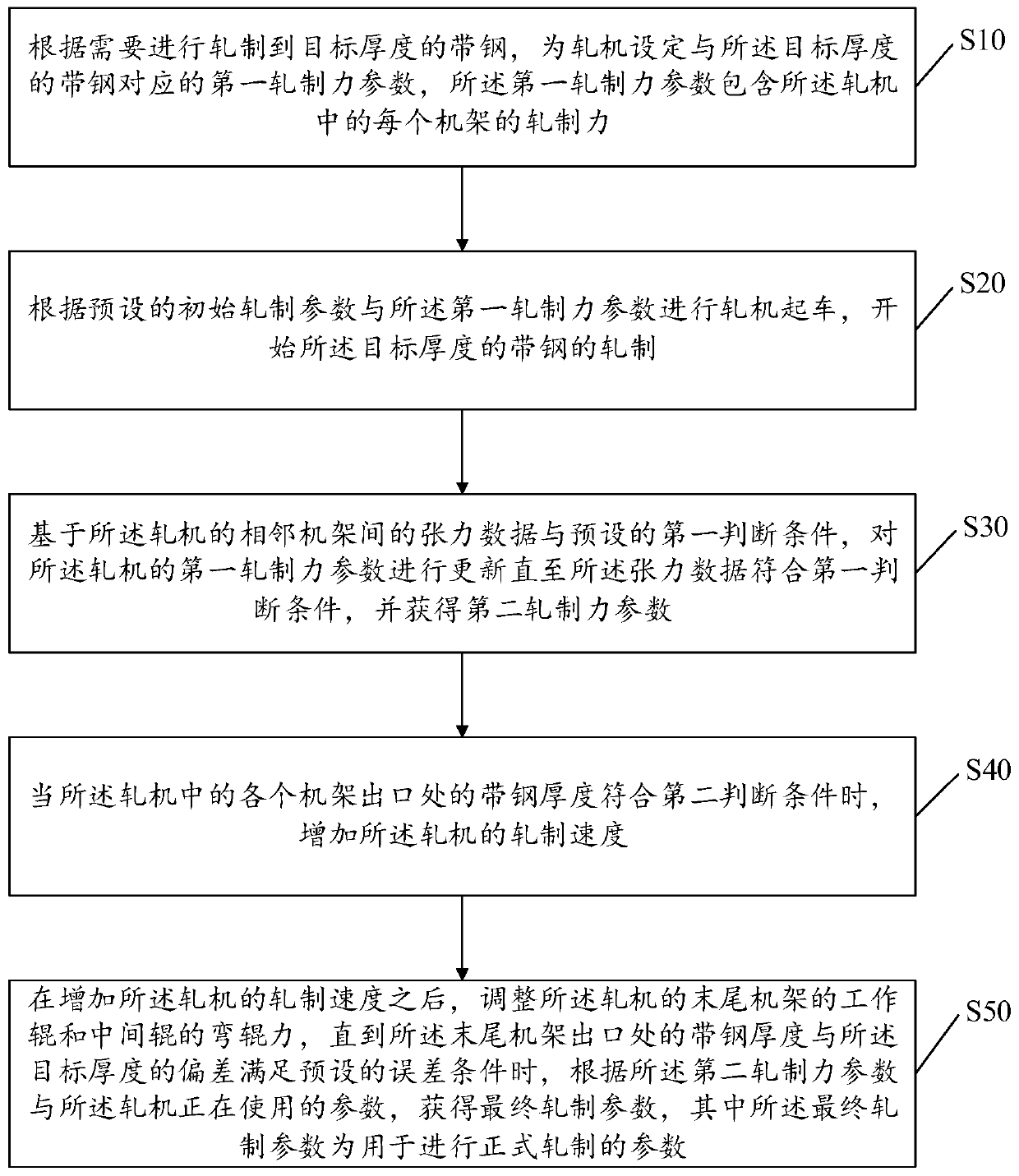

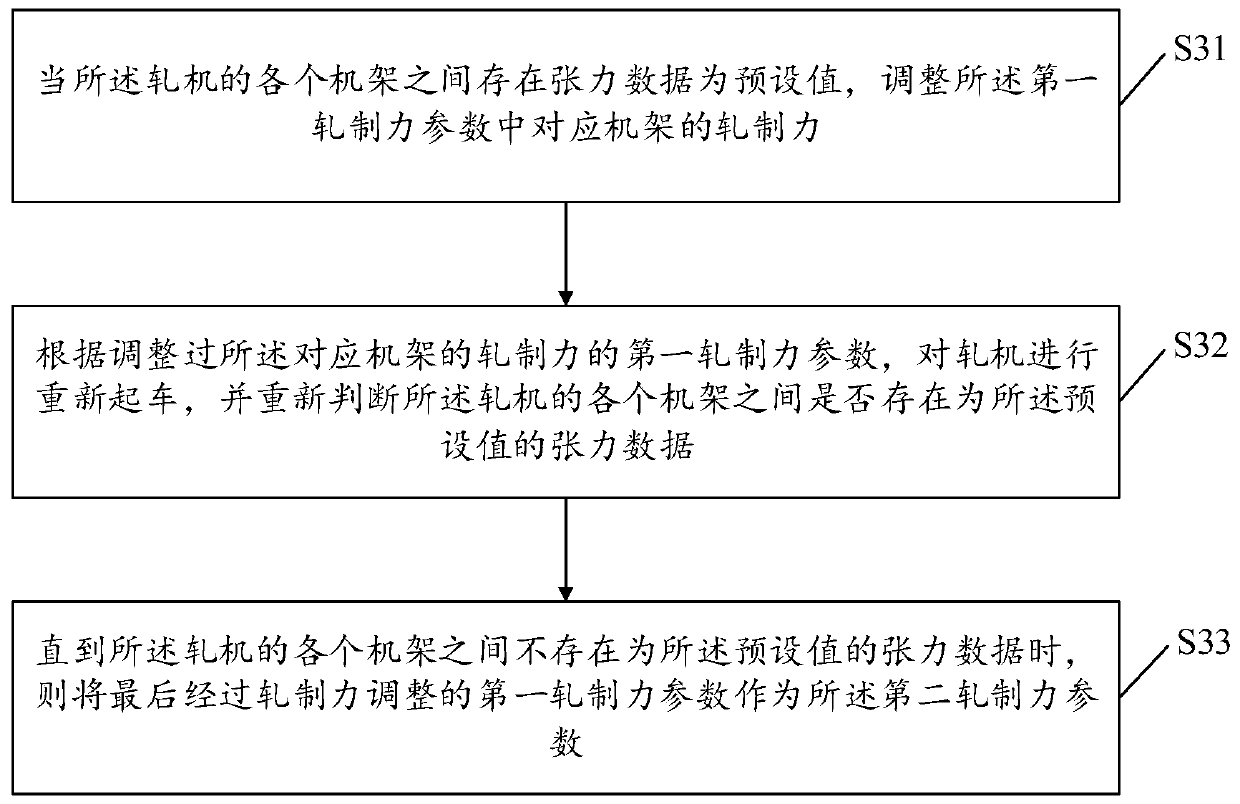

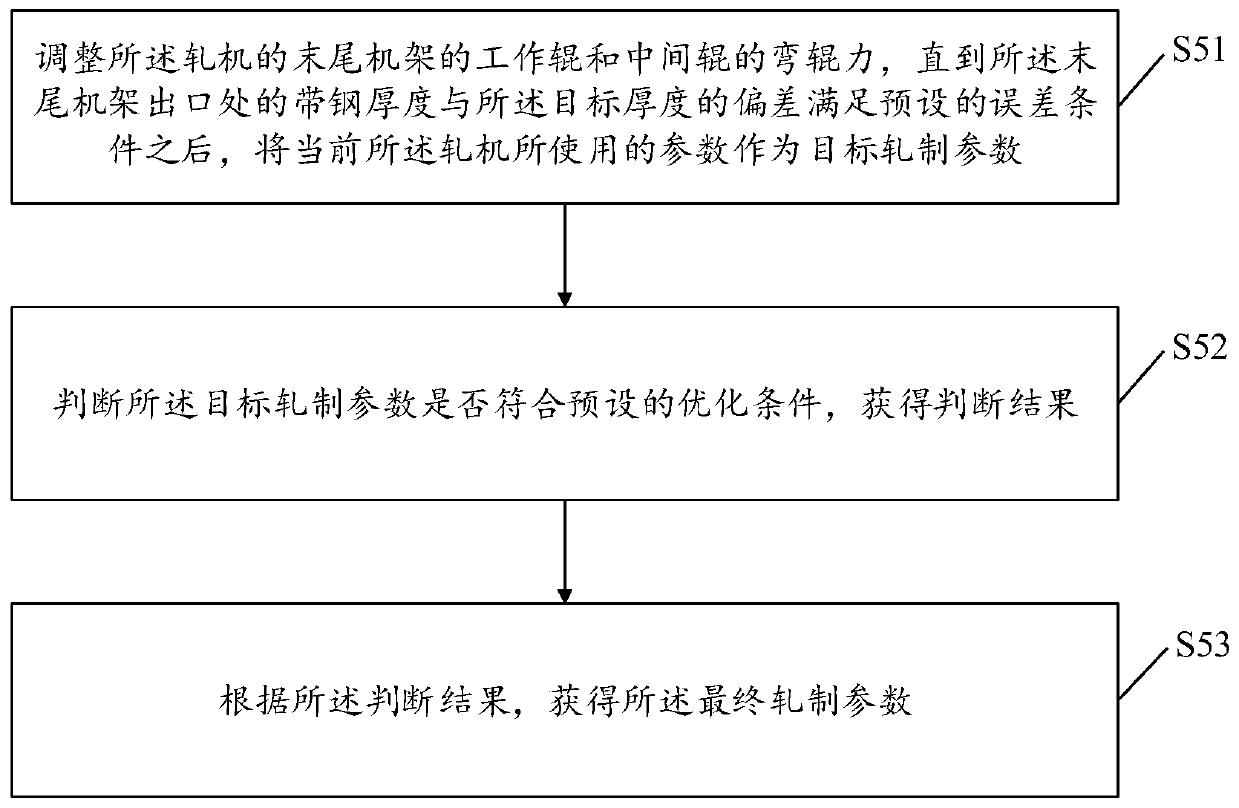

Cold continuous rolling mill starting control optimization method and device

ActiveCN109894482AIncrease rolling speedImprove work speedRoll force/gap control deviceStrip steelBending force

The invention provides a cold continuous rolling mill starting control optimization method and device. The method comprises the following steps that a first rolling force parameter corresponding to strip steel with the target thickness is set for a rolling mill according to the strip steel with the target thickness needing to be rolled; rolling mill starting is carried out according to a preset initial rolling force parameter and the first rolling force parameter; according to tension data between adjacent machine frames of the rolling mill and a preset first judgment condition, a second rolling force parameter is obtained; when the thickness of the strip steel at an outlet of each machine frame in the rolling mill meets a second judgment condition, the rolling speed of the rolling mill isincreased; and then, the roll bending force of a working roller and a middle roller of the tail machine frame of the rolling mill is adjusted until the deviation between the thickness of the strip steel at the outlet of the tail machine frame and the target thickness meets a preset error condition, and a final rolling force parameter is obtained according to the second rolling force parameter andthe parameter which is being used by the rolling mill. According to the method and the device, the control precision of the rolling mill can be greatly improved, and the success rate of starting rawmaterial plates of new type of steel is improved.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

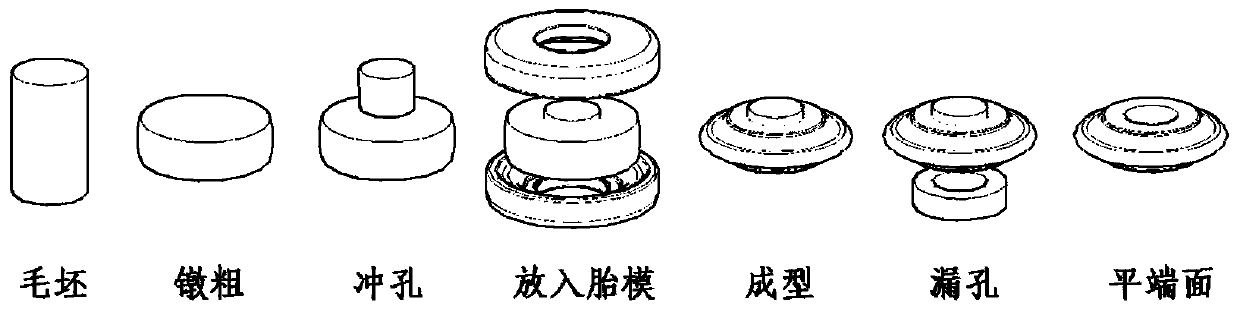

Rolling method for specially-shaped alloy steel ring part with section containing suddenly-changing curve

ActiveCN110666081AFine internal organizationIncrease profitEngine componentsMetal rollingFiberUltimate tensile strength

The invention discloses a rolling method for a specially-shaped alloy steel ring part with a section containing a suddenly-changing curve. The rolling method for the specially-shaped alloy steel ringpart with the section containing the suddenly-changing curve comprises the following steps: blanking to obtain an initial blank; preparing a ring rolling blank from the initial blank which reaches a forging temperature requirement; and placing the ring rolling blank in a ring rolling machine, and carrying out ring rolling forming to obtain a forged ring part with the specially-shaped section. Therolling method for the specially-shaped alloy steel ring part with the section containing the suddenly-changing curve is capable of realizing rolling for the specially-shaped ring part with the section containing the suddenly-changing curve; the deformation force needed by the specially-shaped ring rolling is greatly reduced, and the production cost is lowered; the rolling achieves high internal quality and close internal structure, crystalline grains are fine, fibers are arrayed in the circumferential direction, the mechanical strength and the wear resistance are obviously improved, and the fatigue life is obviously prolonged; high product accuracy, a low machining amount and a high material utilization rate are achieved; high production efficiency and a high rolling speed are achieved; the defects of incomplete filling, fishtail pits, dimension deviation and the like in the ring rolling process are solved; and the method is capable of realizing the most economic and efficient batch production as one-process rolling forming.

Owner:BEIJING NORTH VEHICLE GROUP CORP

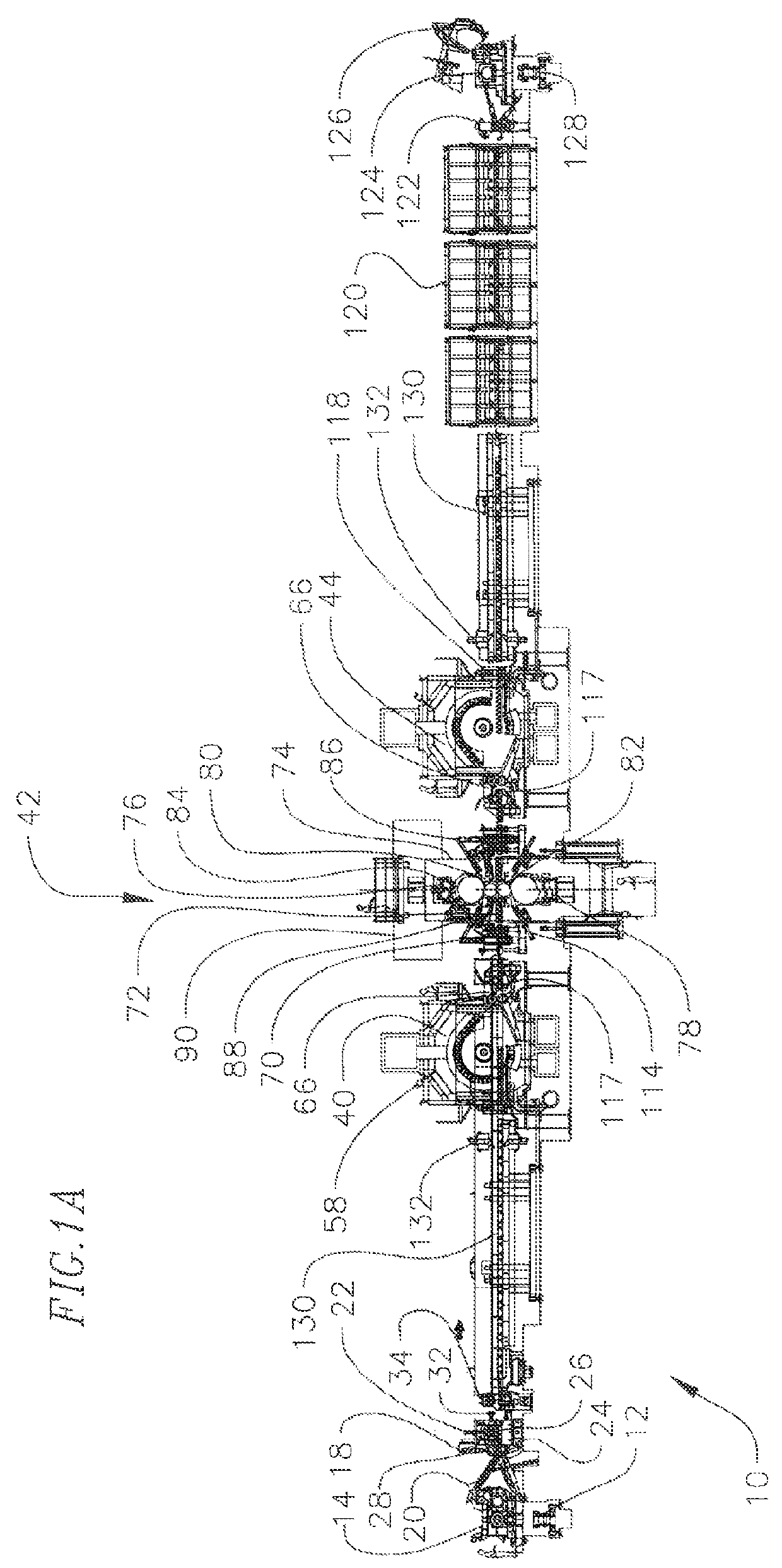

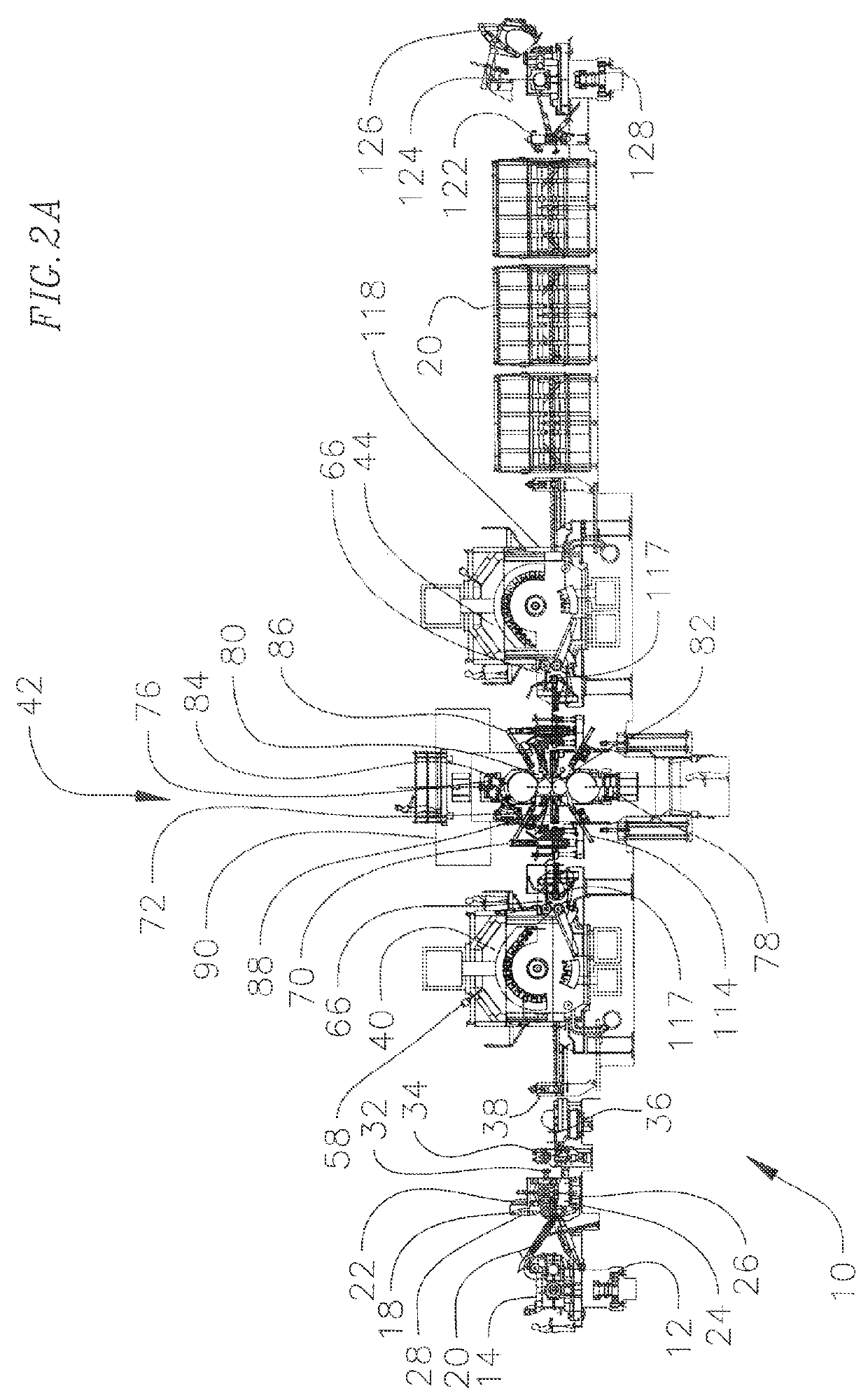

Magnesium roll mill

ActiveUS9248482B2Good molding effectFine surfaceMaterial accumulating devicesFurnace typesWork rollStrip mill

A magnesium hot rolling mill system including a rolling mill having at least two work rolls for rolling of magnesium sheet or plate, a hot coiler positioned on either side of the rolling mill for heating and maintaining a desired temperature of the magnesium sheet or plate, active thermal roller tables, a mill drive system for independently driving the work rolls for asymmetrical rolling of the magnesium sheet and a warm coil loading and payoff station.

Owner:DANIELI & CO

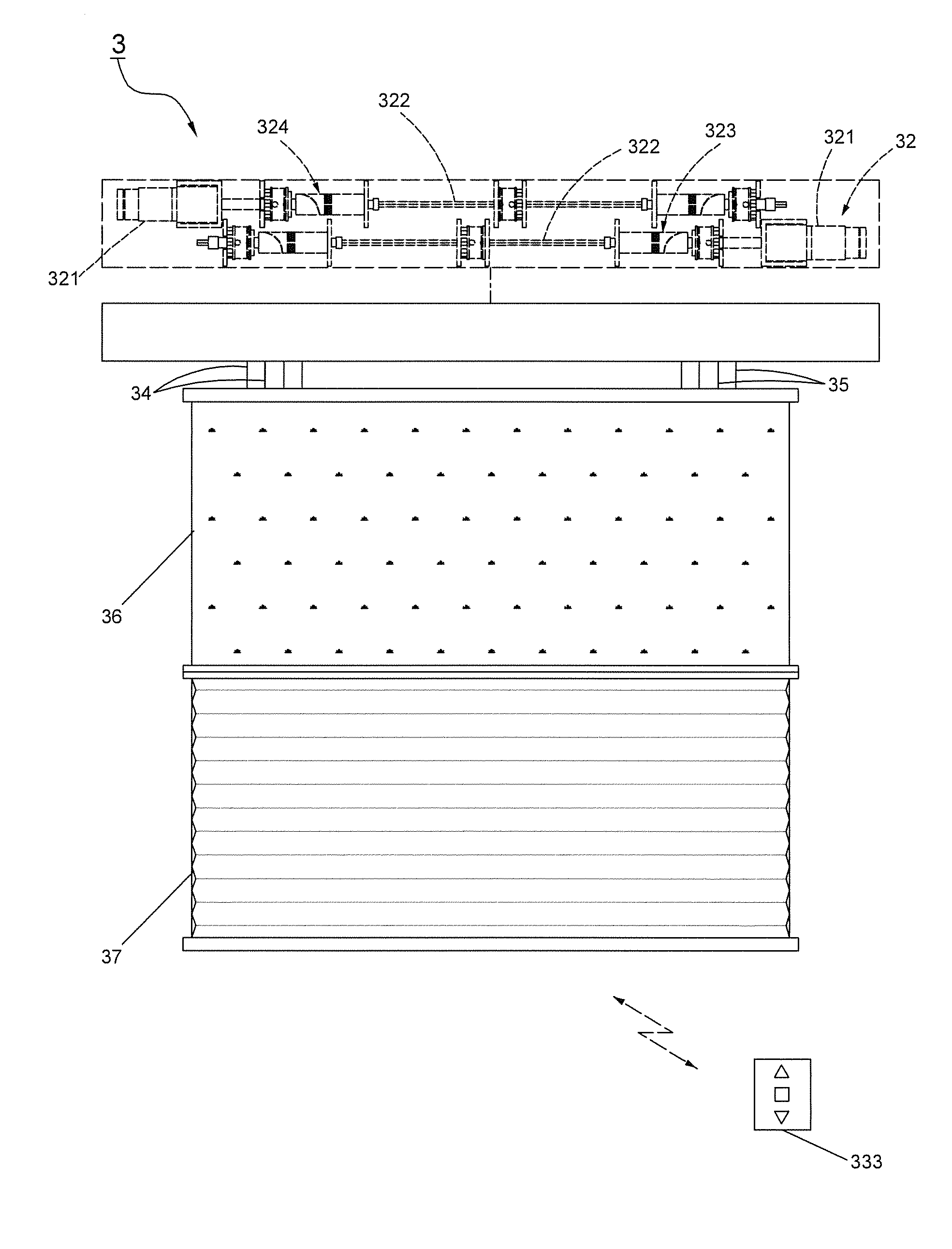

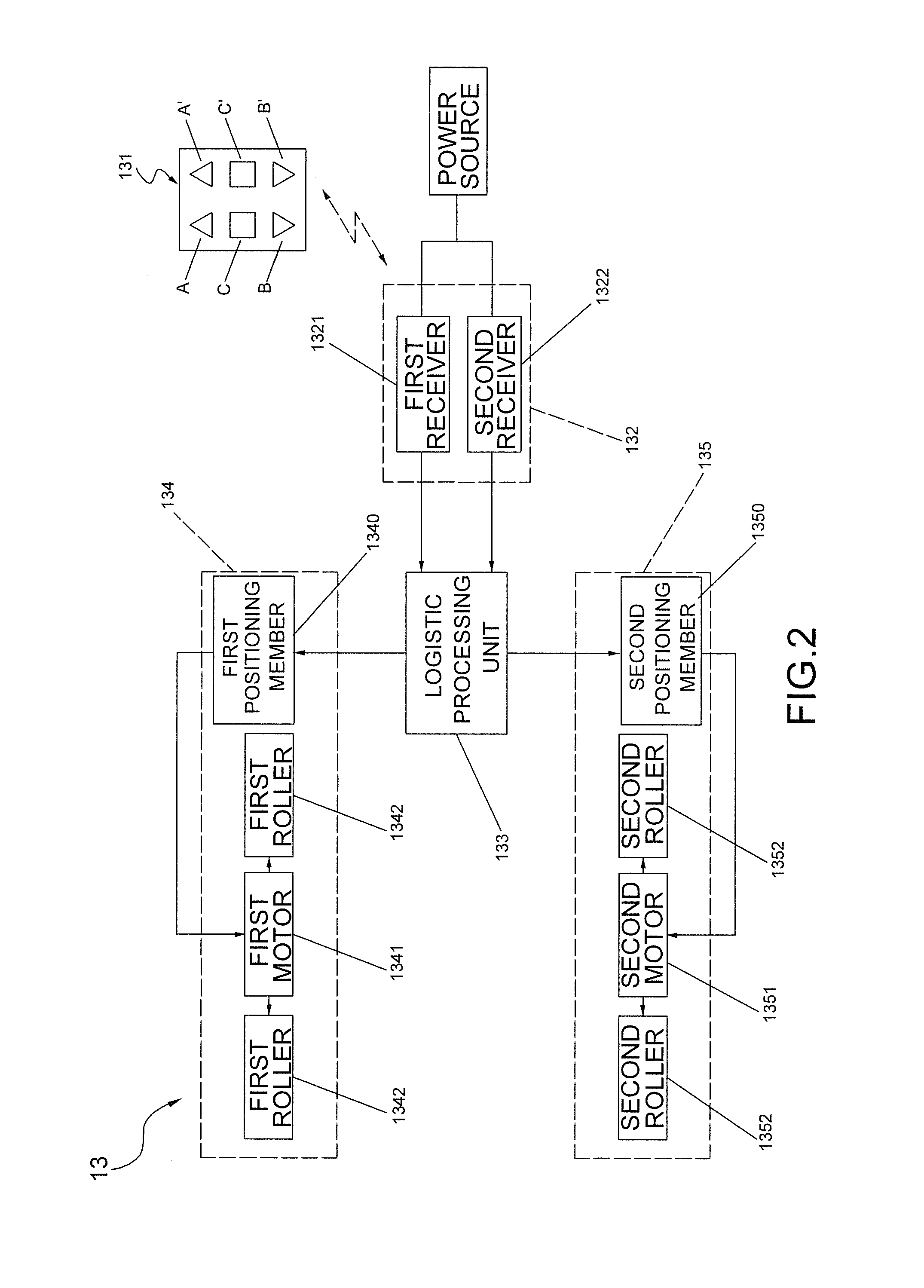

Duet power-driven window shade

InactiveUS20140000816A1Increase rolling speedSolve the poor convenience of useBurglar alarm by openingShutters/ movable grillesControl signalProcessing element

A duet power-driven window shade comprises a controlling device to receive an external controlling signal, which is then analyzed, determined and compared with a preset value in a memory unit of the controlling device. A driving signal is output via a processing unit according to a comparing result. A power source thence brings convolutions of a first covering sheet and a second covering sheet in sequence or concurrently for increasing the rolling speed and the using convenience and allowing the connecting members connected to the covering sheets to be efficiently rolled up without entanglement so that the duet power-driven window shade is smoothly operated.

Owner:BIN TERNG ENTERPRISE

Cooling device for cooling a metal strip

ActiveCN101687236AReduce reflection lossFacilitate heat exchangeWork cooling devicesMetal rolling arrangementsMetal stripsMetal

Owner:SMS DEMAG AG

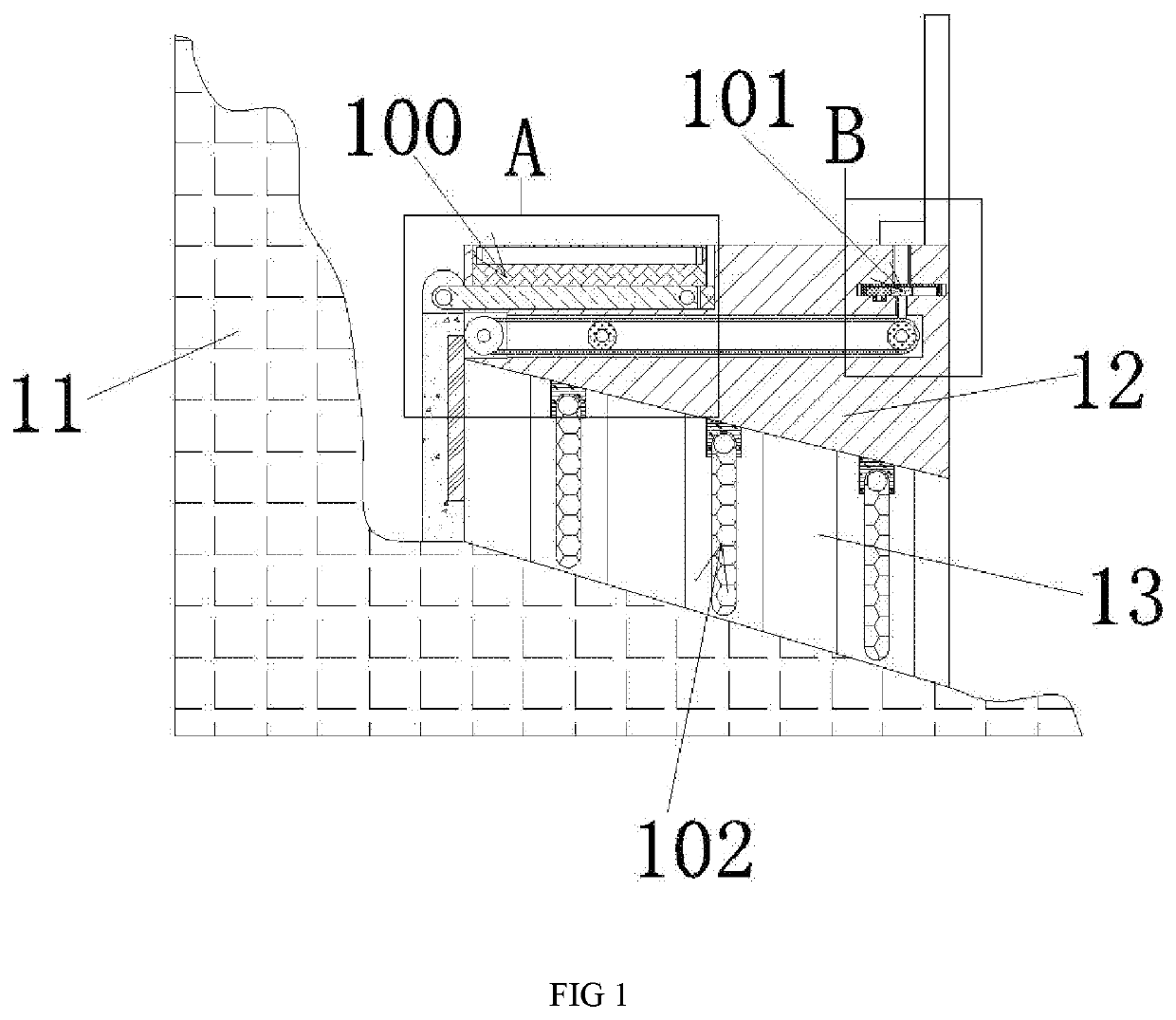

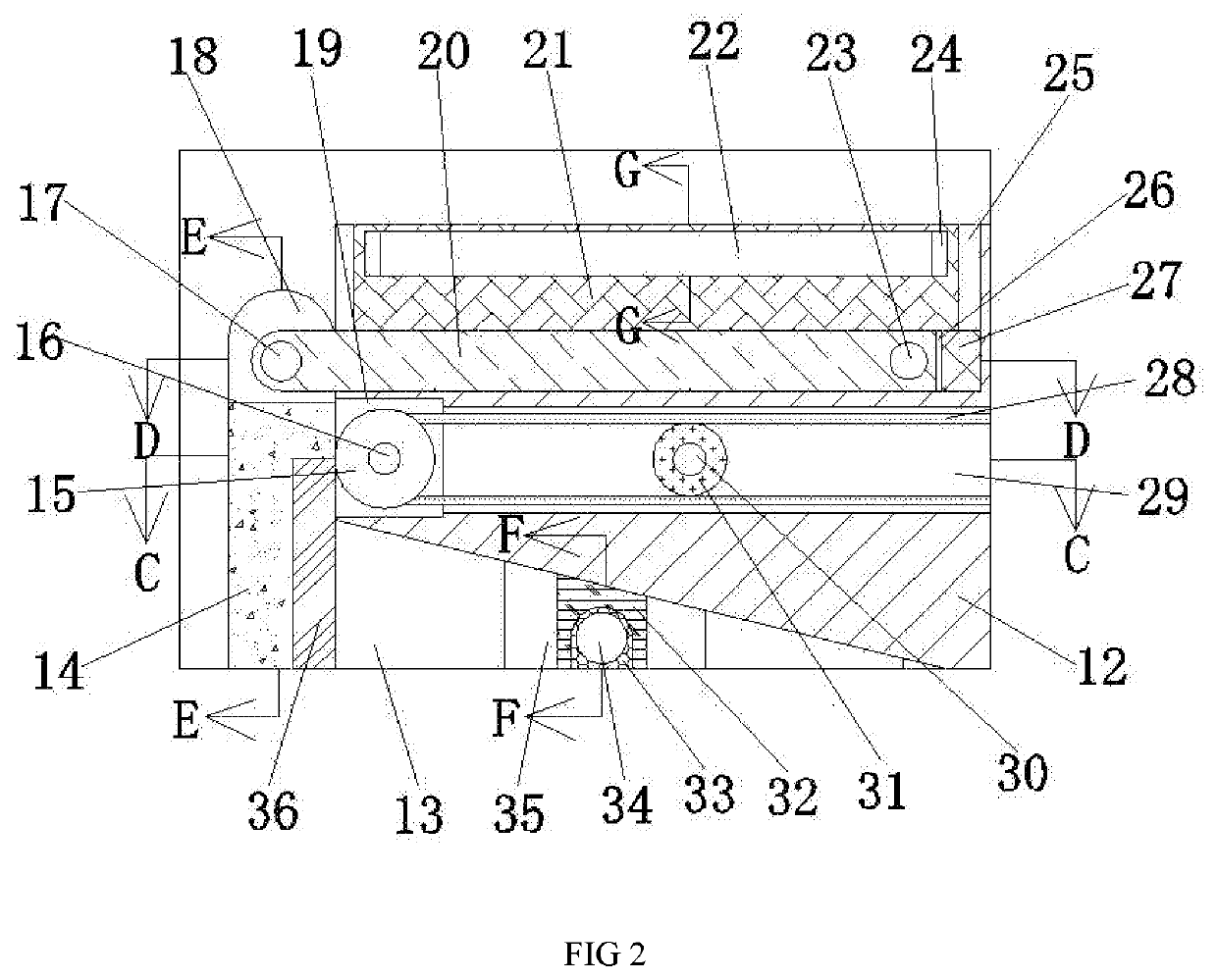

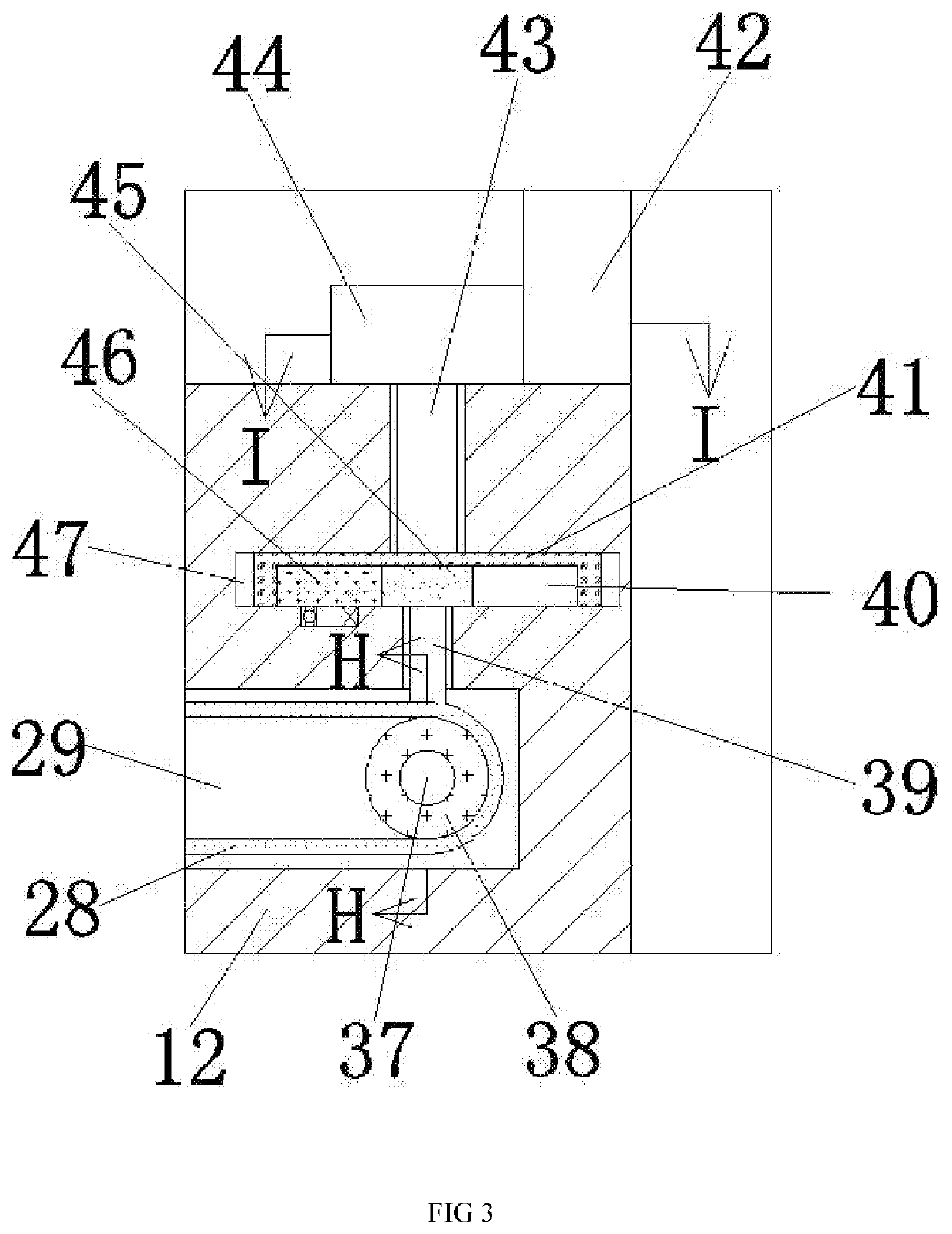

Landslide protection device

InactiveUS20200123720A1Avoid traffic jamsHigh frequencyProtective constructionGearingMining engineeringTraffic congestion

A landslide protection device disclosed by the present invention includes a mountain body and a roadbed. The roadbed is fixedly disposed at the upper end of the mountain body. Cavities are formed in the roadbed to penetrate left and right. Rolling stones can roll down the mountain through the cavity to prevent rolling stones from falling on the upper end surface of the roadbed to block traffic. The cavity is provided with a buffer device. The present invention is arranged in the roadbed in the area where the frequency of landslides is high. It can avoid traffic congestion caused by falling rocks directly on the road. Because the mountain has a certain slope, the speed of the rolling rocks is faster. When the rocks are cleared, the rolling speed is slowed down and the device is restored to the initial state after the landslides And can automatically clear the rolling stones that fell on the road.

Owner:ZAHNG YESHA

Round steel all-purpose method rolling technology

ActiveCN103357661AUniform deformationHigh dimensional accuracyRollsMetal rolling arrangementsMetallurgySteel bar

The invention discloses a round steel all-purpose method rolling technology, comprising the steps that raw blanks are rolled into round blanks with middle fracture surfaces in a rough rolling unit; and the round blanks with the middle fracture surfaces are subjected to all-purpose method continuous rolling deformation or all-purpose method reciprocating rolling deformation for no less than two passes to be rolled into round steel products. By using the round steel all-purpose method rolling technology, the product size precision can be obviously improved, the problem that the out-of-roundness of the round steel products is severer is solved, the production specification ranges of smooth round bars and deformed steel bars are widened, the deformation of each pass is improved, the rolling deformation pass is reduced, the production efficiency is improved, the surface quality of rolled round steel is improved, the internal stress of rolled pieces after rolling is improved, the product yield is improved, and the rolling load, the production energy consumption and the production cost are reduced.

Owner:CISDI ENG CO LTD

Candy forming machine

PendingCN105533086ACompact structureRealize automatic oilingConfectionerySweetmeatsMolding machineEngineering

The invention discloses a candy forming machine, comprising a compression roller mechanism, a shaping mechanism and a forming pressing wheel mechanism which are arranged sequentially from an input end of a conveying table to an output end of the conveying table, wherein the compression roller mechanism comprises an upper compression roller and a lower compression roller of which the axial directions are both vertical to the conveying direction of the conveying table; a feeding end of the upper compression roller and a feeding end of the lower compression roller are respectively provided with a feeding mechanism; and the side of the upper compression roller and the side of the lower compression roller are respectively provided with an oiling mechanism. According to the candy forming machine, the oiling mechanisms are arranged at the sides of the upper compression roller and the lower compression roller, so that a uniform and thin oil layer is coated on each of the upper compression roller and the lower compression roller, so as to realize automatic oiling on the surface of massecuite; after the oiled massecuite is processed by the shaping mechanism, the required thickness of the massecuite can be realized; and then the massecuite is formed once through the forming pressing wheel mechanism, so that the massecuite is made to be small candies. The candy forming machine has high rolling speed and high rolling efficiency.

Owner:金冠(中国)食品有限公司

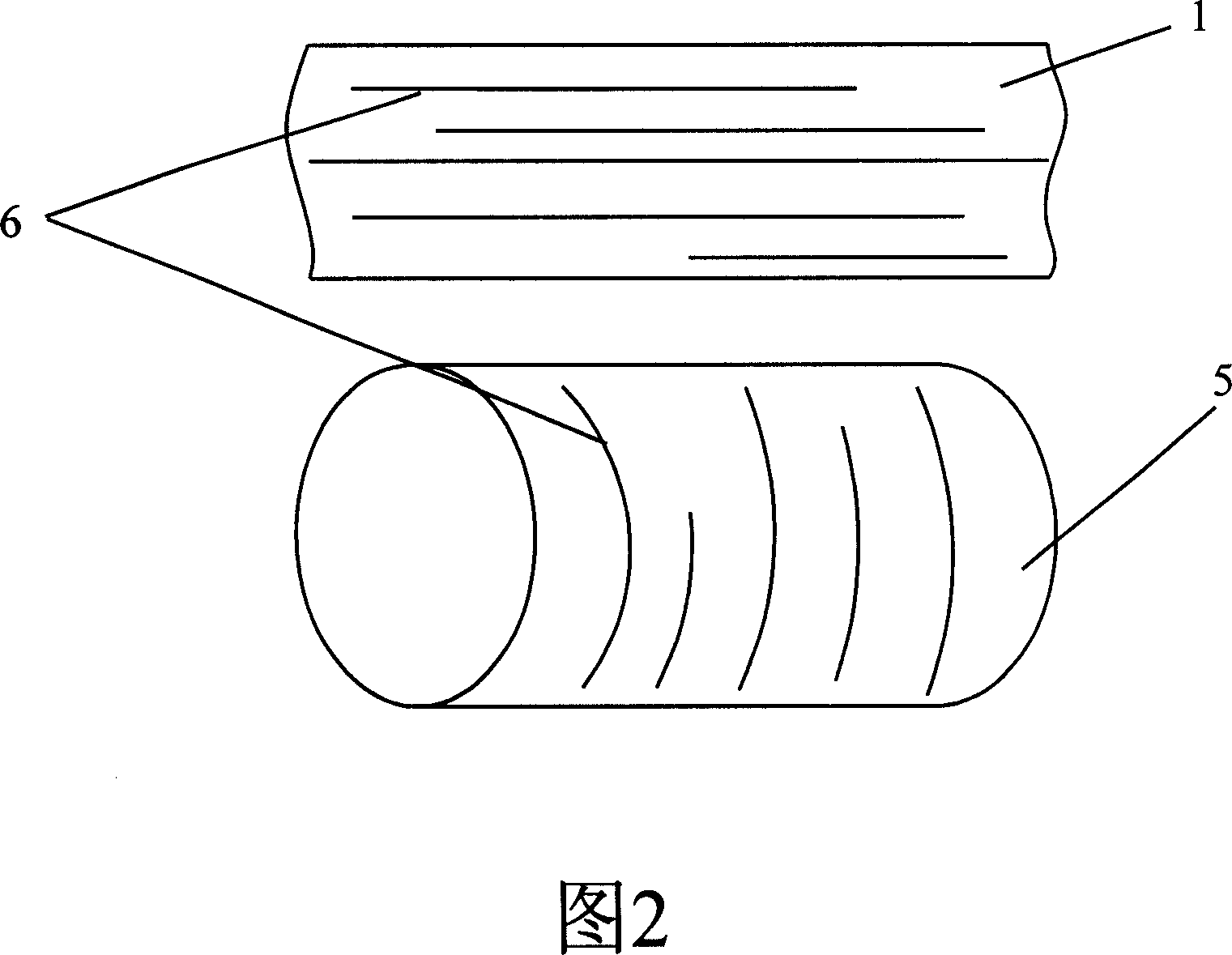

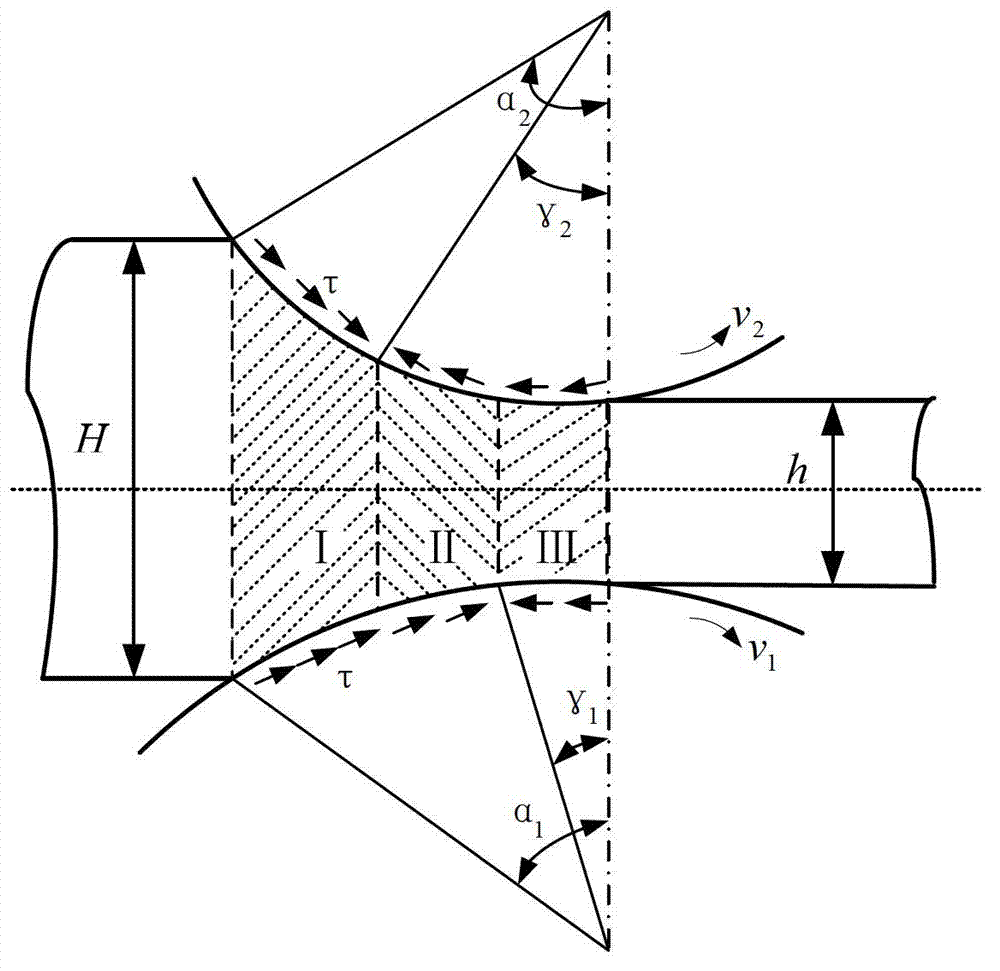

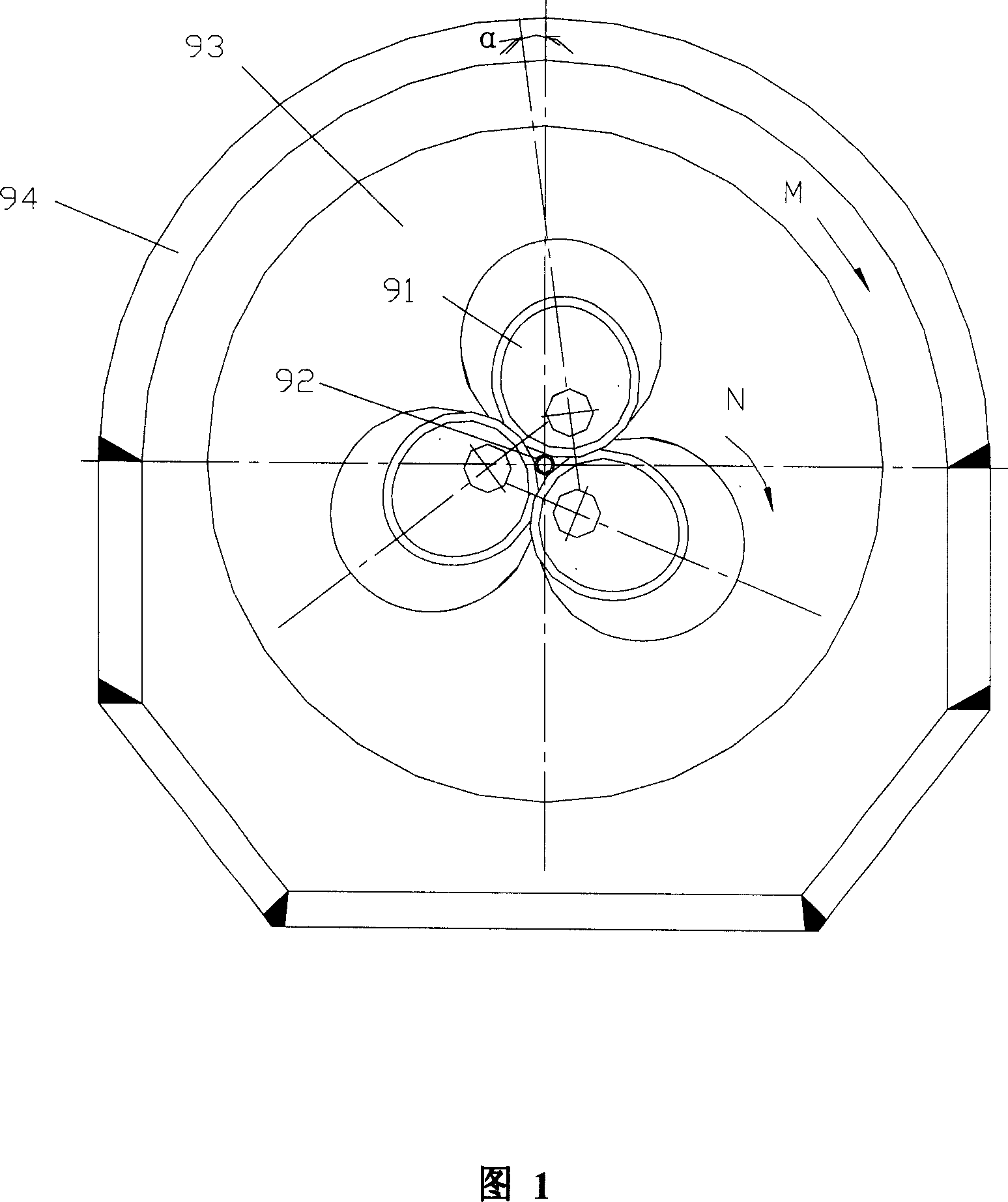

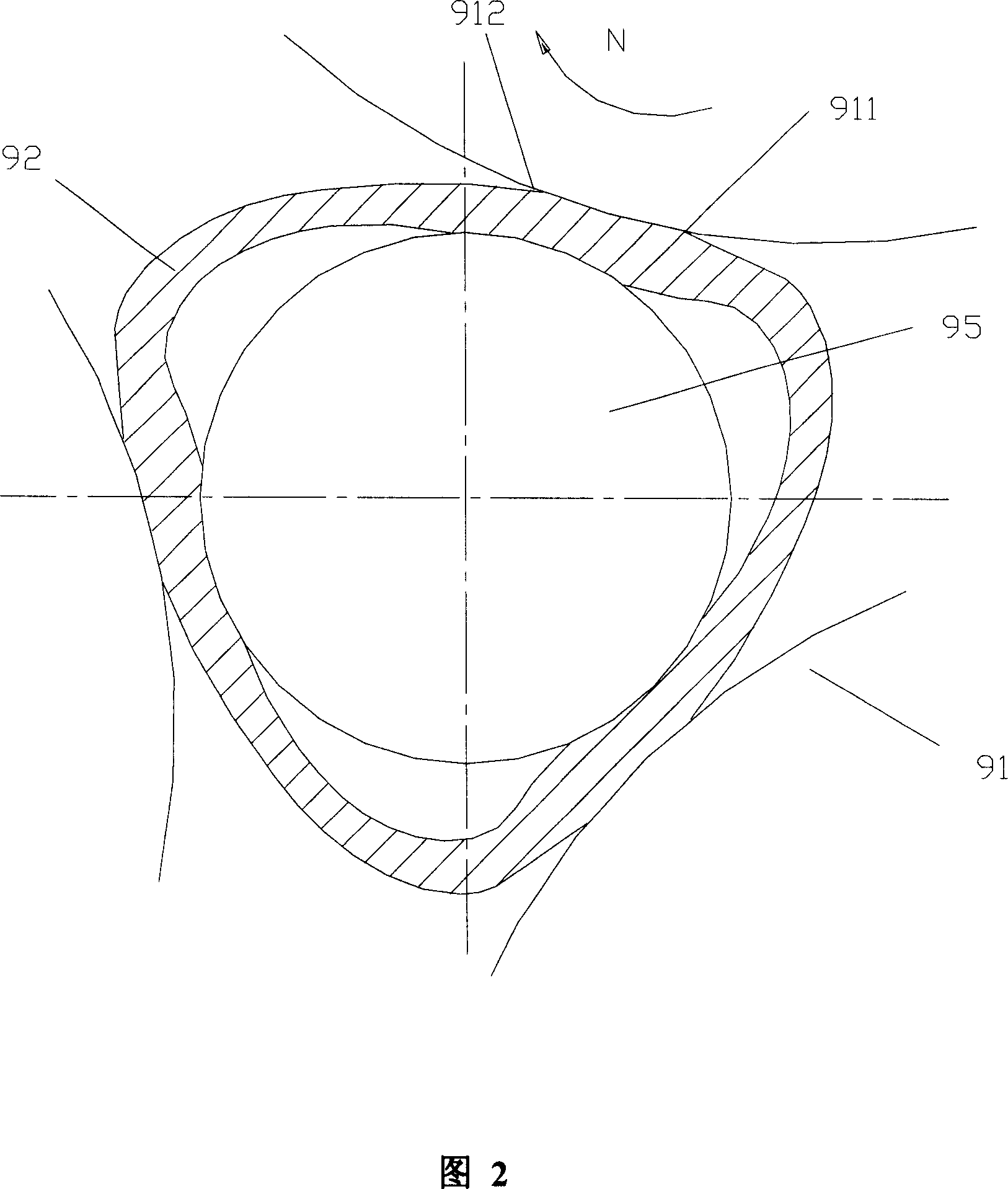

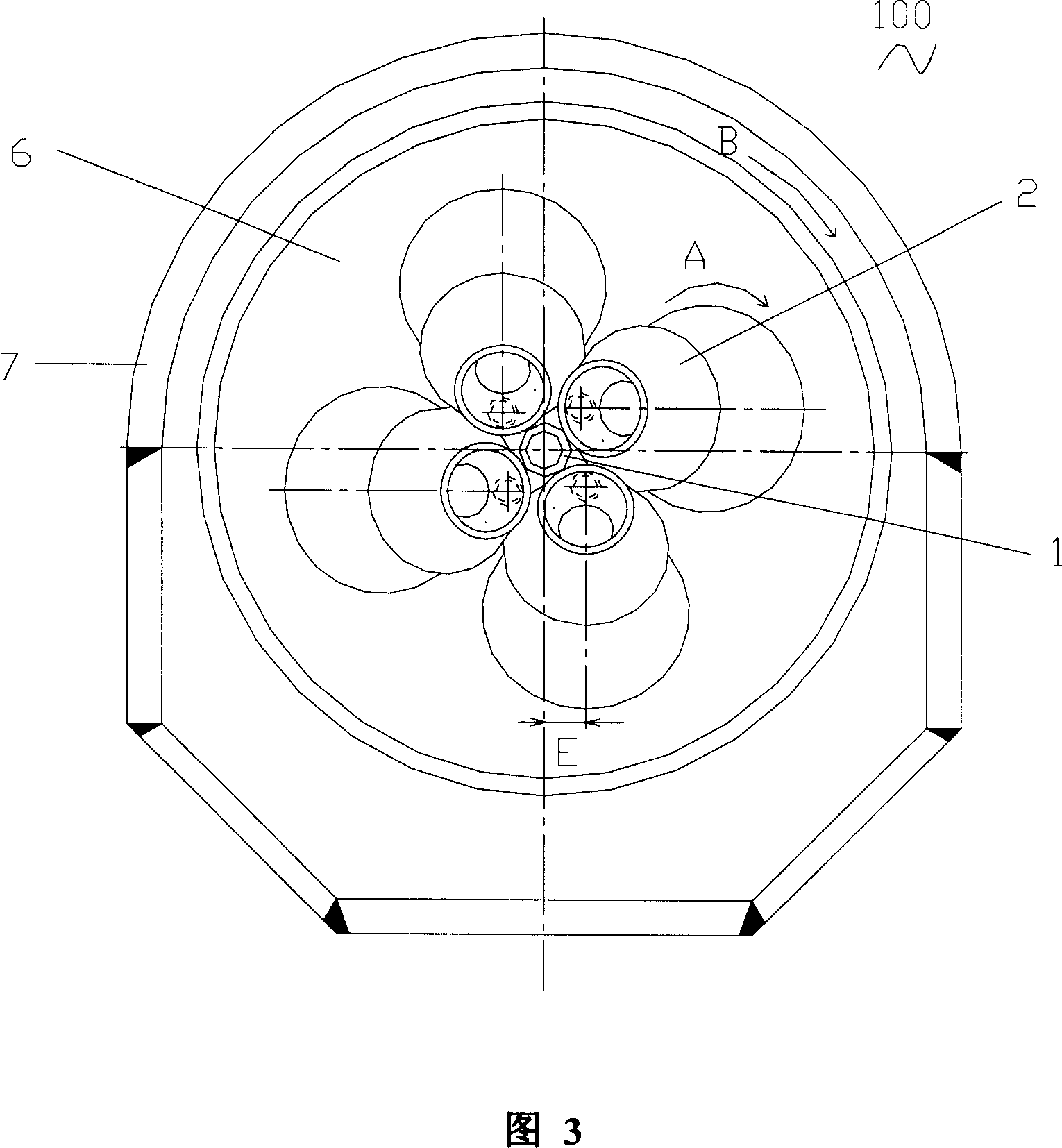

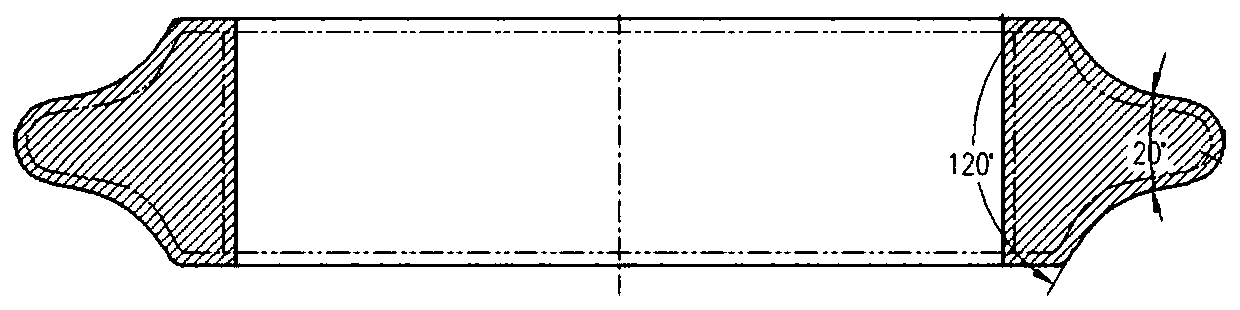

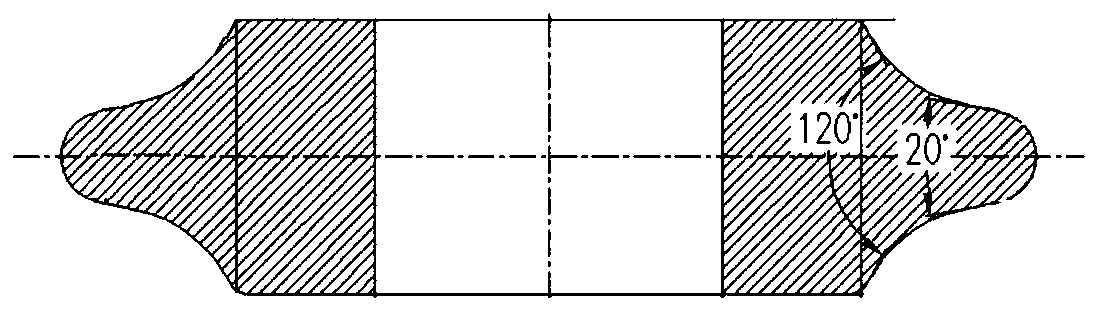

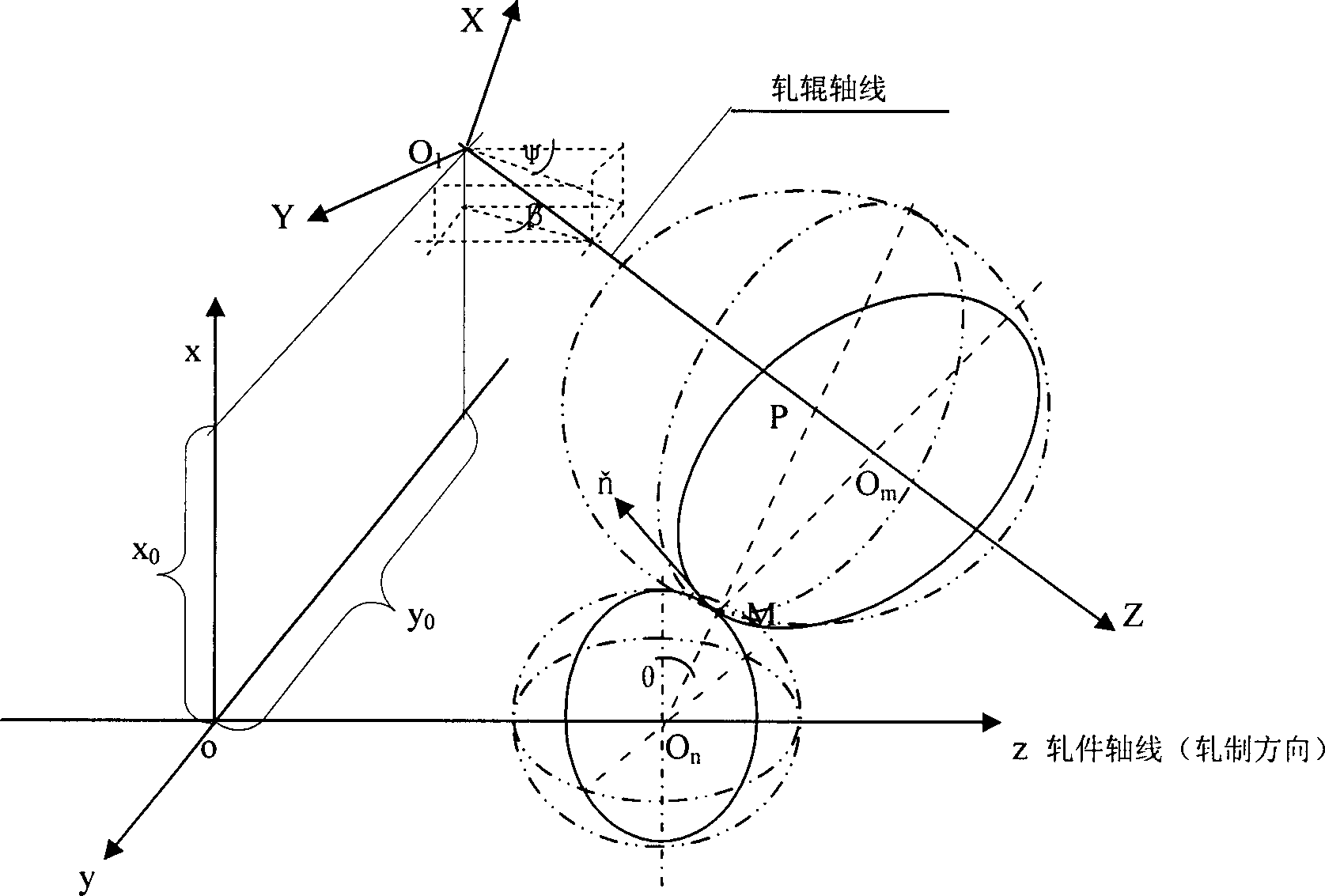

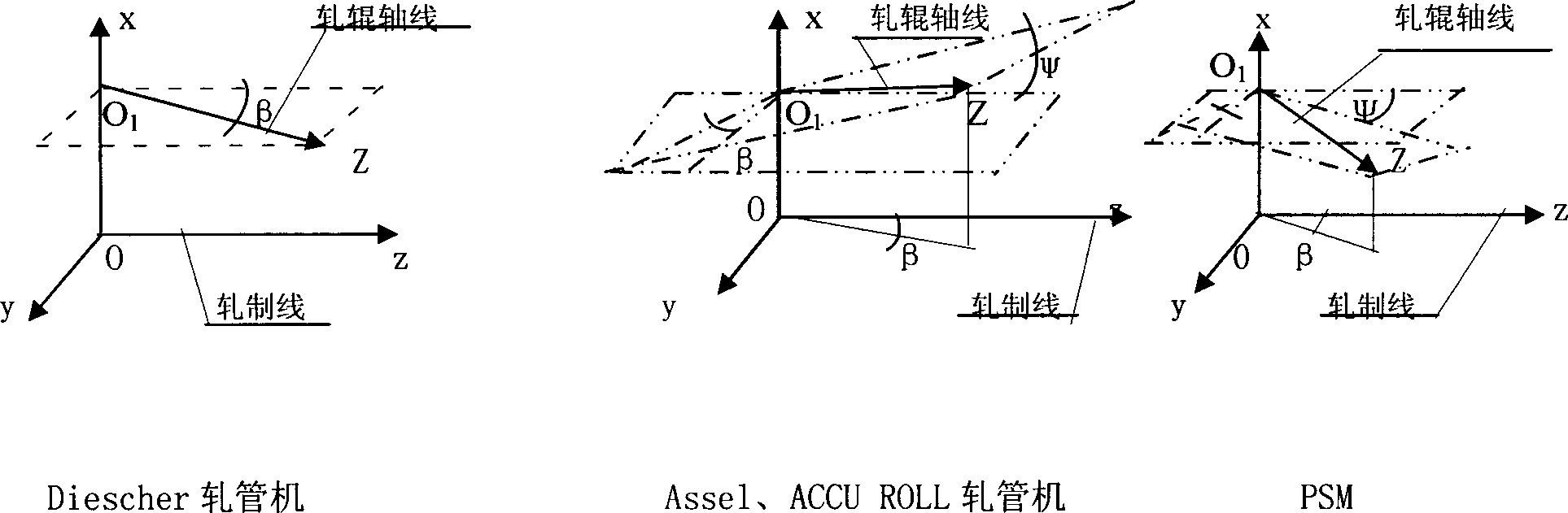

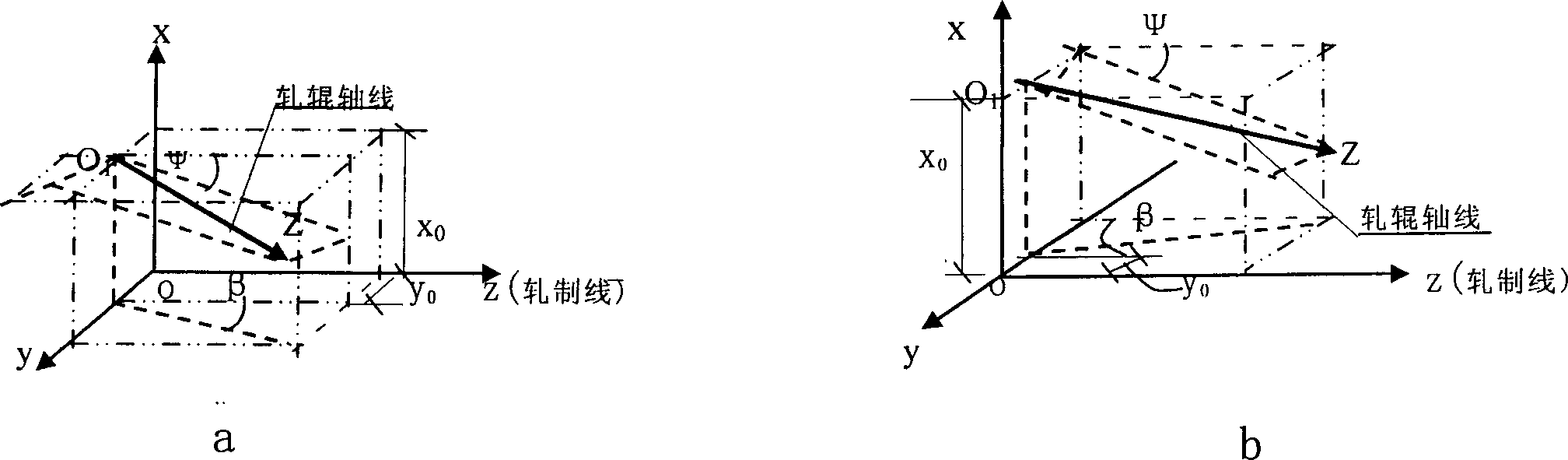

Geometric model of new elongater for skew rolling tubular products

InactiveCN1796016AReduce "bulging"Increase rolling speedRoll mill control devicesMetal rolling arrangementsGreek letter betaGeometric modeling

The present invention relates to hot-rolled pipe elongation technique. Said technique can be directly used in skew-rolled pipe elongation equipment. Said invention provides a new geometrical model of pipe material elongator. It is basically characterized by that its rolls are arranged according to convergent form, namely, the cone angle Psi is less than O, in the coordinate system oxyz, the offset amount yo is not equal to O, and its feed angle beta and the offset amount yo can not be identical in size. Besides, said invention also provides four sets of equations, and utilizes them to make optimization calculation so as to obtain the invented geometrical model of skew-rolled pipe material elongator.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

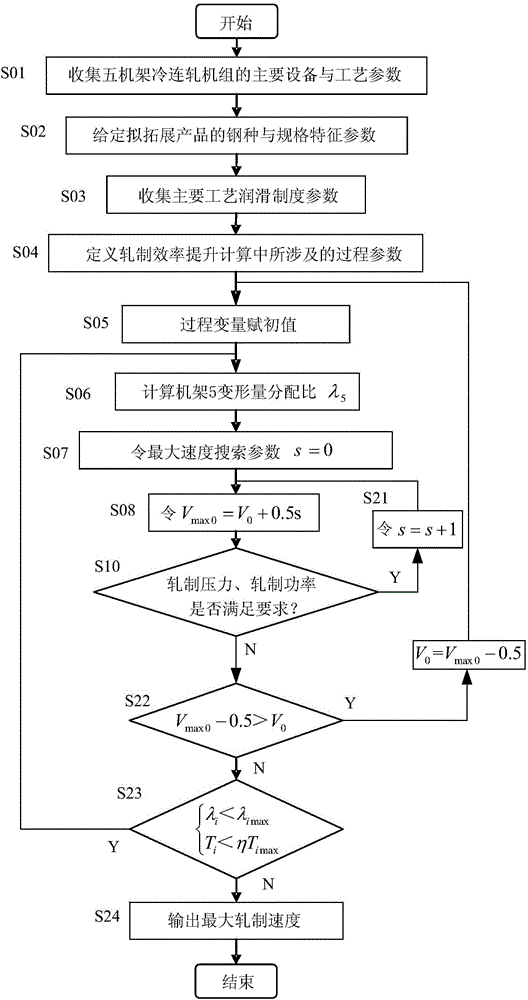

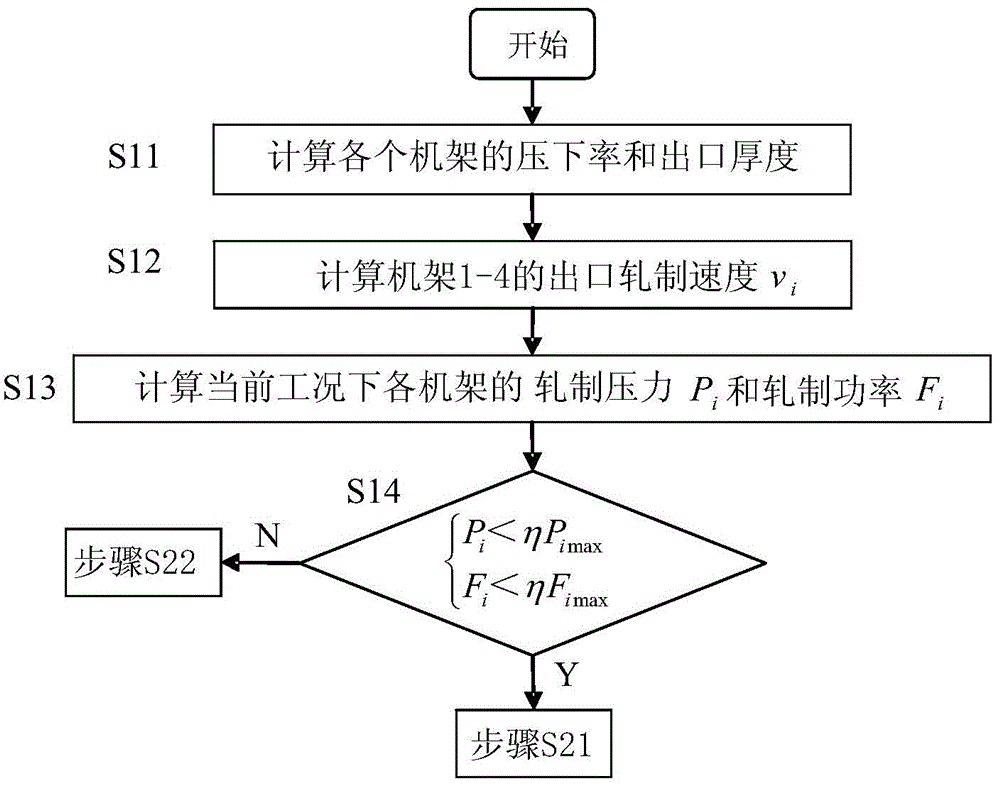

Rolling efficiency improvement method suitable for five-stand cold continuous rolling units

ActiveCN104785540AIncrease limit rolling speedIncrease rolling speedTension/compression control deviceMetal rolling arrangementsControl systemProcess engineering

The invention relates to a control device or method special for metal rolling mills or machined products of the metal rolling mills, in particular to a rolling efficiency improvement method suitable for five-stand cold continuous rolling units. According to existing device parameter and technological parameter data of a cold continuous rolling unit control system and steel types and specification characteristic parameters of products for expansion, the rolling pressure and the rolling power are calculated, and then synthetic judgment is carried out according to the permission safety factors of the units; on the premise of guaranteeing the safety margin of rolling production, by optimally distributing the rolling reduction and the outlet tension of each stand, the limit rolling speed of the units is increased to the maximum degree under the specific technological lubrication system, the maximum rolling speed is searched and regarded as a control parameter, and the rolling speed of limit specification products is increased; on the condition without increasing the equipment investment, the range of the limit specification products of the cold continuous rolling units can be expanded, and the capacity and the production efficiency of the cold continuous rolling units can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

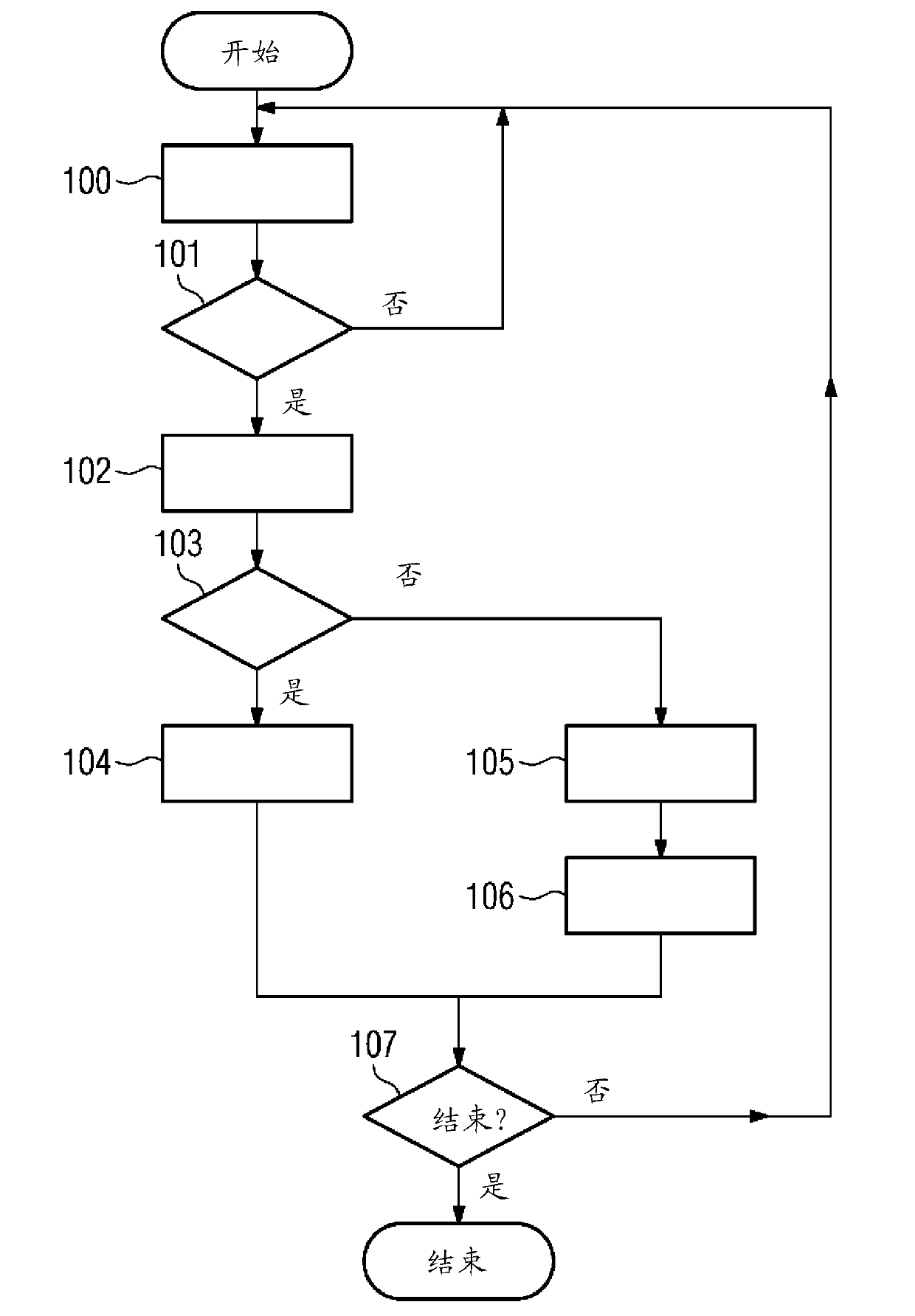

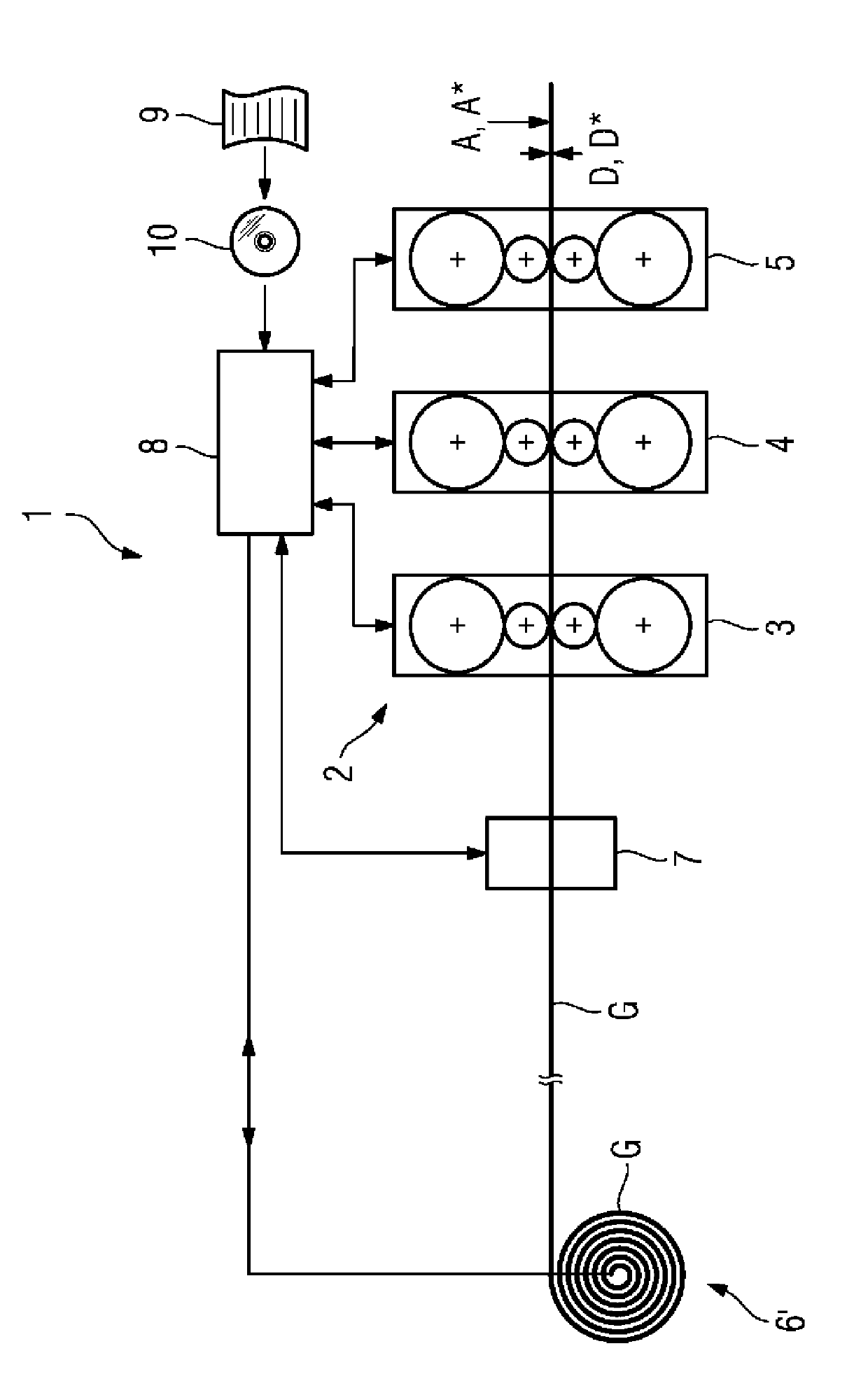

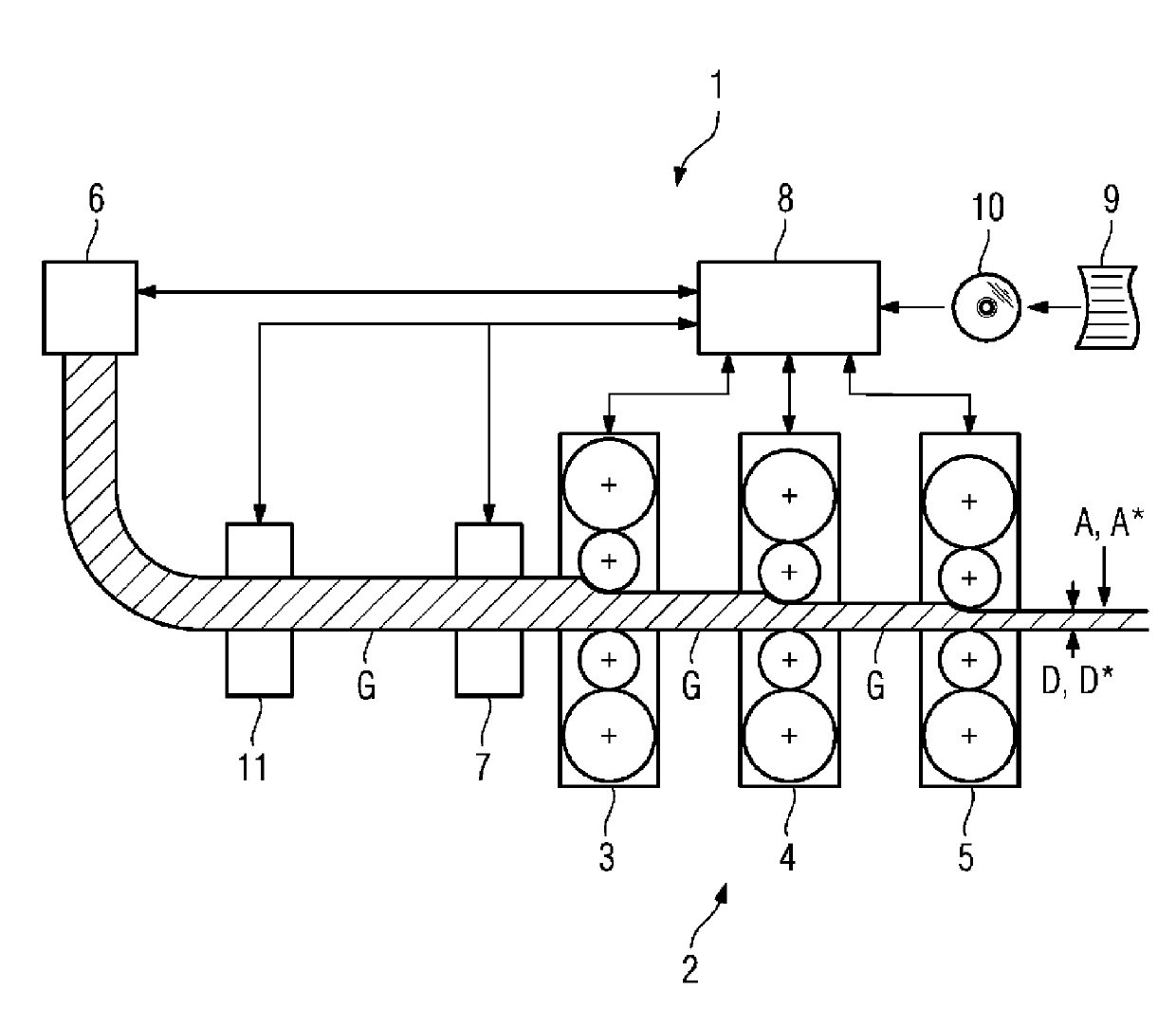

Method for producing rolling stock rolled in a rolling train of a rolling mill, control and/or regulation device for a rolling mill for producing rolled rolling stock, rolling mill for producing rolled rolling stock, machine-readable program code and storage medium

ActiveCN102413955AGuaranteed uptimeReduce conveying speedRoll mill control devicesMetal rolling arrangementsProcess deviationsFailure causes

The invention relates to a rolling mill (1) for producing rolled rolling stock (G), a machine-readable program code (9), a storage medium (10), a control and / or regulation device (8) for a rolling mill (1) for producing rolled rolling stock (G), and a method for producing rolling stock (G) which was rolled in a rolling train (2) of a rolling mill (1), in particular a continuous casting and rolling mill, wherein the rolling mill (1) is operated in a continuous manner by means of integrally forming the rolling stock during scheduled operation from a supply device (6, 6') which supplies the rolling stock to the rolling mill (1), in particular a casting device (6) and / or a winding device (6') for rolling stock, to at least one finishing rolling train (2) that is arranged downstream of the rolling stock supply device (6, 6'), as viewed in a mass flow direction, by means of guiding the rolling stock (G) into the finishing rolling train (2) in a continuous manner and rolling it to form a first outflow product (A) in the finishing rolling train (2) in a continuous manner. The operation of the rolling mill (1) is monitored for the occurrence of a deviation from the scheduled operation of the rolling mill (2) that influences the rolling process, wherein in case of a deviation measures are taken to examine (100, 101) whether a second outflow product (A*), which is different from the first outflow product, can still be produced (102) considering the deviation. If the second outflow product cannot be produced, the operation of the rolling mill (1) is altered from a continuous operation to a discontinuous operation (106), whereby means can be provided for reducing production failures caused by undesired process deviations in a rolling mill.

Owner:PRIMETALS TECH GERMANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com