Rolling efficiency improvement method suitable for five-stand cold continuous rolling units

A technology of five-stand continuous cold rolling and rolling power, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems that rarely take rolling speed into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

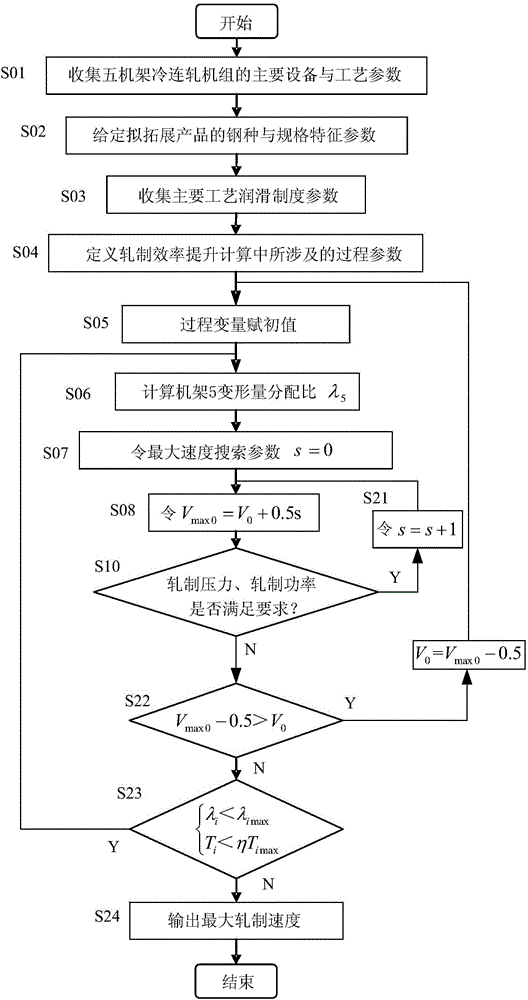

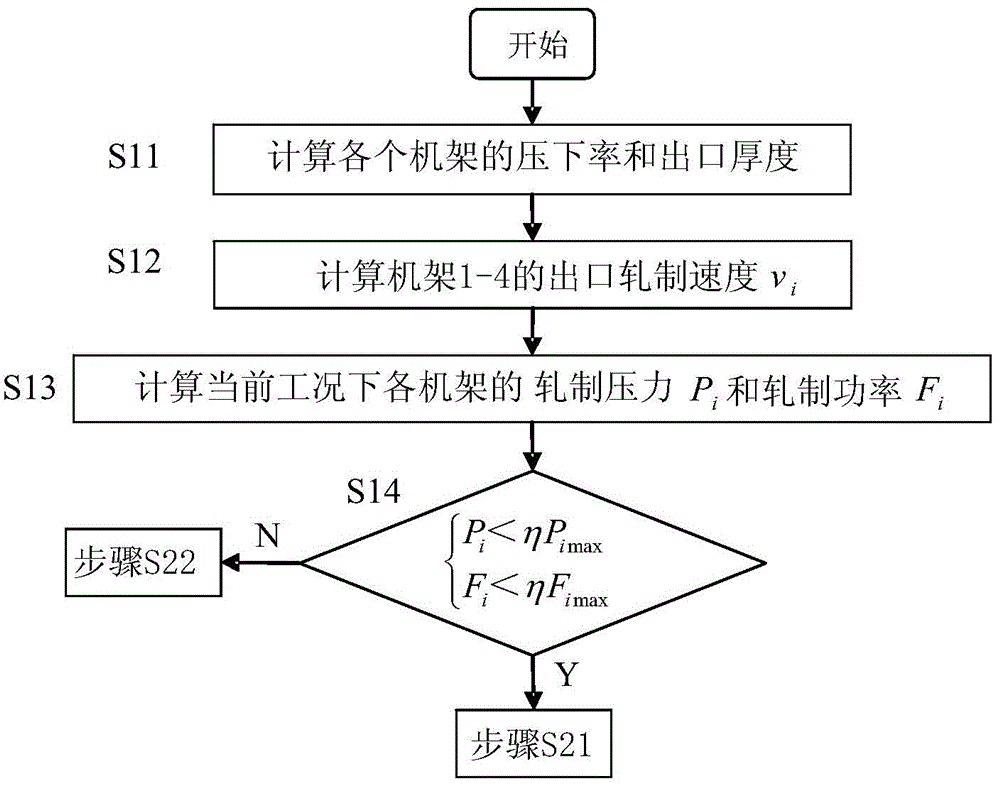

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the steel strip whose raw material type is MRT-5CA and the incoming material size is 2.01 mm×935 mm is taken as an example to illustrate the application process of the related technology described in the present invention.

[0036] In step S01, equipment and process parameters of the five-stand tandem cold rolling mill are collected, including:

[0037] Work roll diameter D of frame 1-5 iw ={482.89,486.32,459.24,386.21,394.5}mm,

[0038] Allowable maximum rolling pressure setting value P of stand 1-5 rolling mill imax ={1800,1800,1800,1800,1800}t,

[0039] Allowable maximum rolling power setting value F of stand 1-5 rolling mill imax ={2680,4000,4000,4000,4000}kw,

[0040] Uncoiler tension T 0 =70MPa,

[0041] The maximum allowable tension T at the exit of the rolling mill for stands 1-4 imax =250MPa,

[0042] The minimum allowable tension T at the exit of the rolling mill for stands 1-4 imin =80MPa,

Embodiment 2

[0098] In this embodiment, the steel strip whose raw material type is MRT-4CA and the incoming material size is 2.01mm×812mm is taken as an example to illustrate the application process of the related technology described in the present invention.

[0099] In step S01, equipment and process parameters of the five-stand tandem cold rolling mill are collected, including:

[0100] Work roll diameter D of frame 1-5 iw ={468.06,479.48,490.72,398.32,402.35}mm,

[0101] Allowable maximum rolling pressure setting value P of stand 1-5 rolling mill imax ={1800,1800,1800,1800,1800}t,

[0102] Allowable maximum rolling power setting value F of stand 1-5 rolling mill imax ={2680,4000,4000,4000,4000}kw

[0103] Uncoiler tension T 0 =70MPa,

[0104] The maximum allowable tension T at the exit of the rolling mill for stands 1-4 imax =250MPa,

[0105] The minimum allowable tension T at the exit of the rolling mill for stands 1-4 imin =80MPa,

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com