Heating friction stir welding method

A technology of friction stir and welding methods, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of plastic deformation of materials and insufficient flow, limited frictional heat, and reduced heat input of welded joints, etc., to improve flow The effects of increased resistance and plastic deformation capacity, improved tensile properties, and increased width of the connecting zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

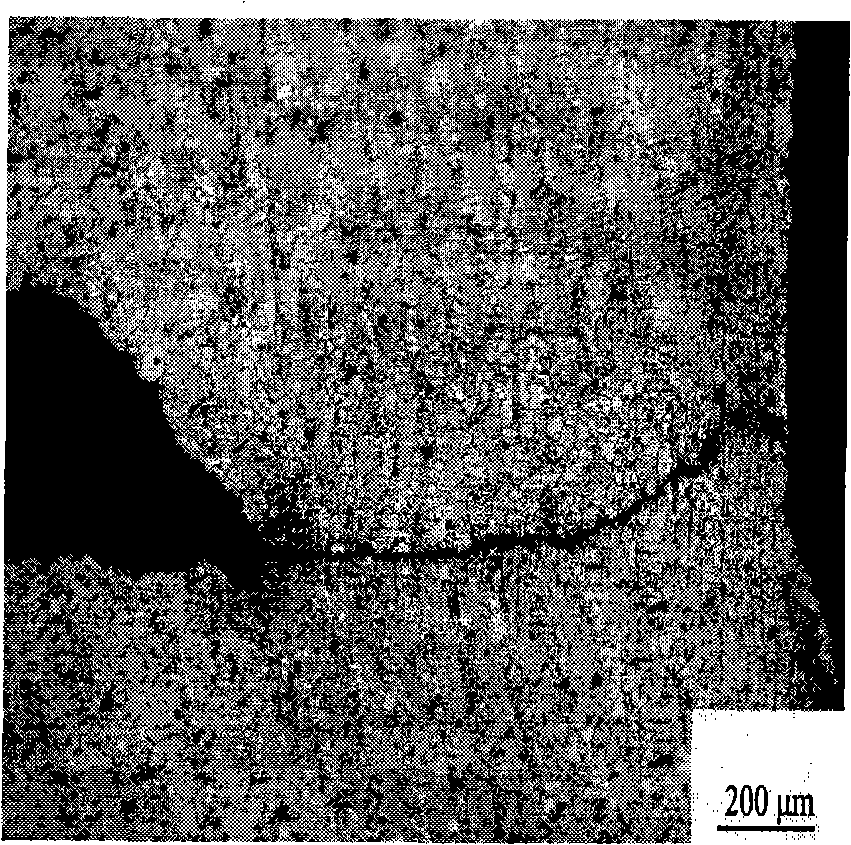

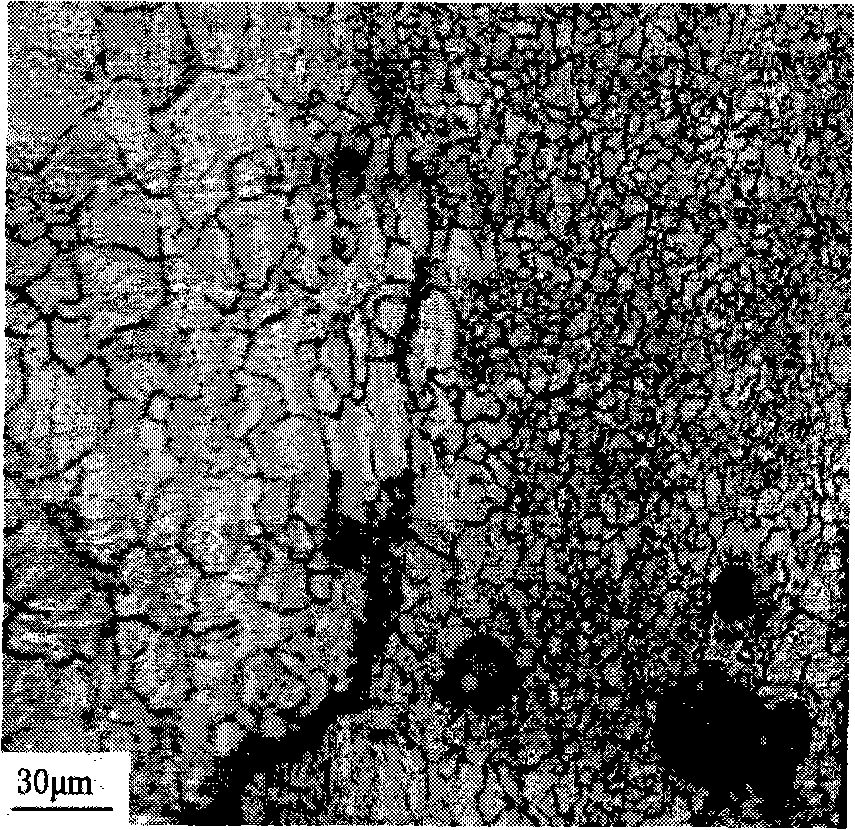

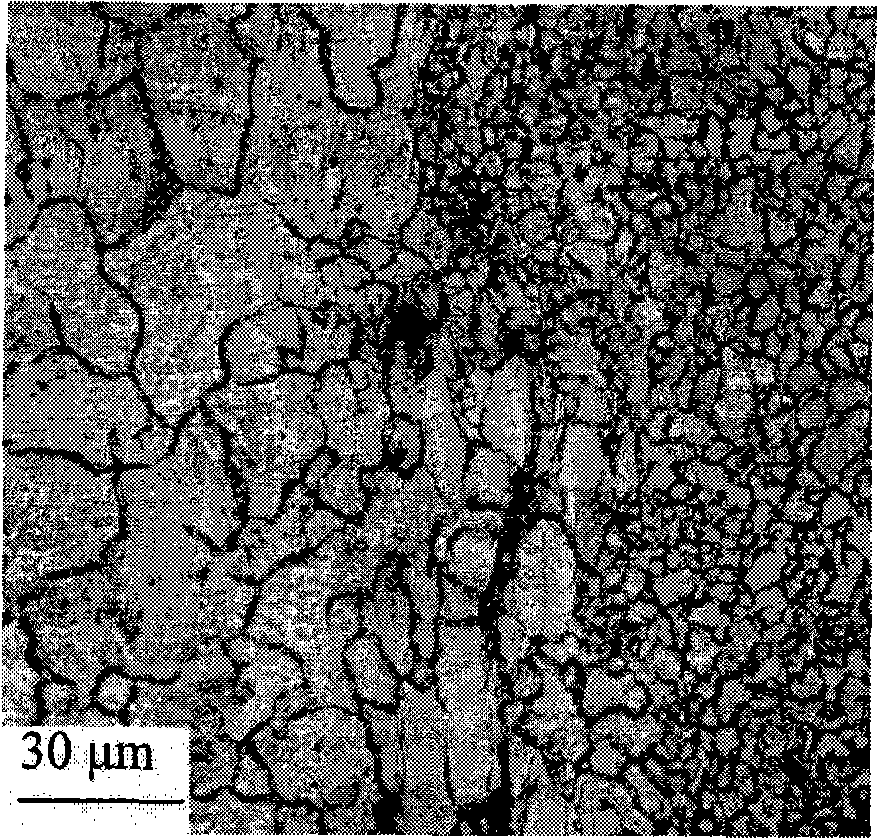

[0018] Before welding, the surface of the 3mm magnesium alloy AZ31 plate is ground and fixed on the clamping device, and then the clamping device is fixed on the temperature-controllable resistance furnace heating equipment. Then adjust the temperature of the resistance furnace to 300° C. and heat until the temperature is stable. During the friction stir welding process, the heating temperature of the resistance heating equipment remains constant until the end of the welding process.

example 2

[0020] Before welding, the surface of the 3mm magnesium alloy AZ31 plate is ground and fixed on the clamping device, and then the clamping device is fixed on the temperature-controllable resistance furnace heating equipment. Then adjust the temperature of the resistance furnace to 350° C. and heat until the temperature is stable. During the friction stir welding process, the heating temperature of the resistance heating equipment remains constant until the end of the welding process.

example 3

[0022] Before welding, the surface of the 3mm magnesium alloy AZ31 plate is ground and fixed on the clamping device, and then the clamping device is fixed on the temperature-controllable resistance furnace heating equipment. Then adjust the temperature of the resistance furnace to 400° C. and heat until the temperature is stable. During the friction stir welding process, the heating temperature of the resistance heating equipment remains constant until the end of the welding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com