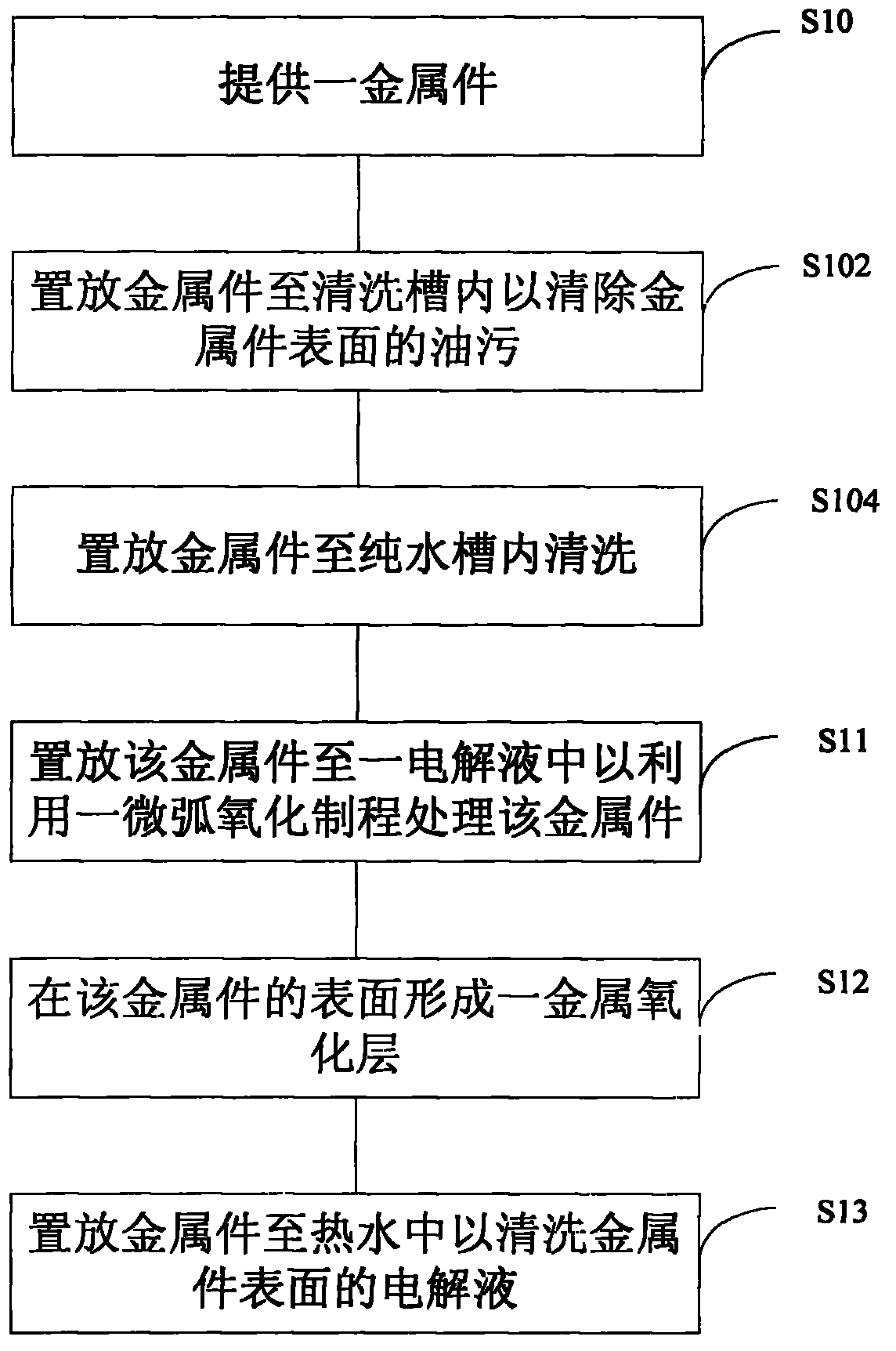

Manufacturing method of metal oxidation layer

A manufacturing method and oxide layer technology, applied in anodizing and other directions, can solve the problems of insufficient hardness, foreign matter filling and accumulation, different properties or expansion coefficients, etc., to save manufacturing time and cost, and avoid foreign matter accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0020] The metal surface treatment of the known technology, which pre-embeds the alloy cast iron in the metal or alloy casting process to form a wall surface different from the metal or alloy material, or directly applies electroplating or electroless nickel plating to the metal or alloy to make the metal or alloy There is a hard metal coating of a different material, but the hardness of the above method is not high, and it is easy to damage the problem, while the existing micro-arc oxidation treatment has the problem of too large holes, and there is still room for improvement in the hardness Therefore, the present invention aims at these deficiencies, and designs the manufacturing method of the metal oxide layer to achieve the goal of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com