Preparation method for cigarette filter tip adopting electrostatically spun cellulose acetate membrane

A technology of cellulose acetate membrane and filter tips, which is applied in the manufacture of cigarettes, etc., can solve the problems of limiting the filtering effect of harmful substances, achieve good market prospects, enhance filtering performance, and reduce the content of harmful components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

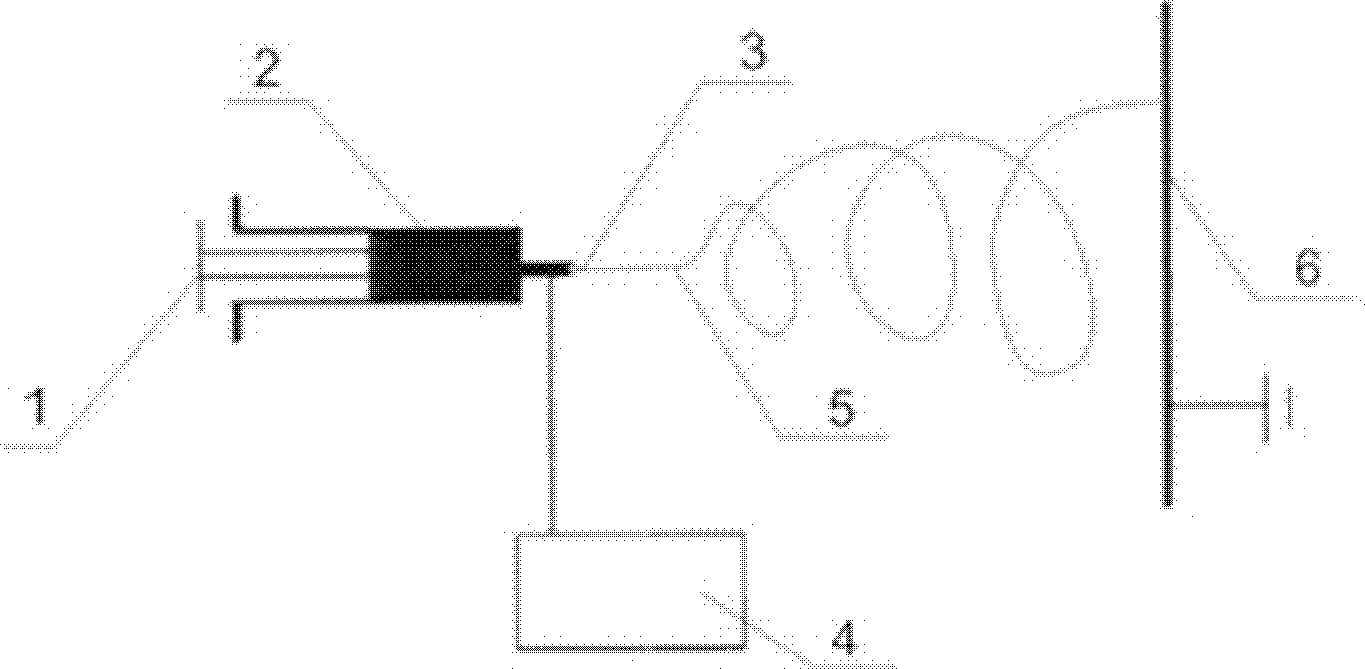

[0022] (1) dissolving cellulose diacetate in a mixed solution of acetone and dimethylacetamide (volume ratio 2:1), and performing electrospinning to obtain a nanometer cellulose acetate film;

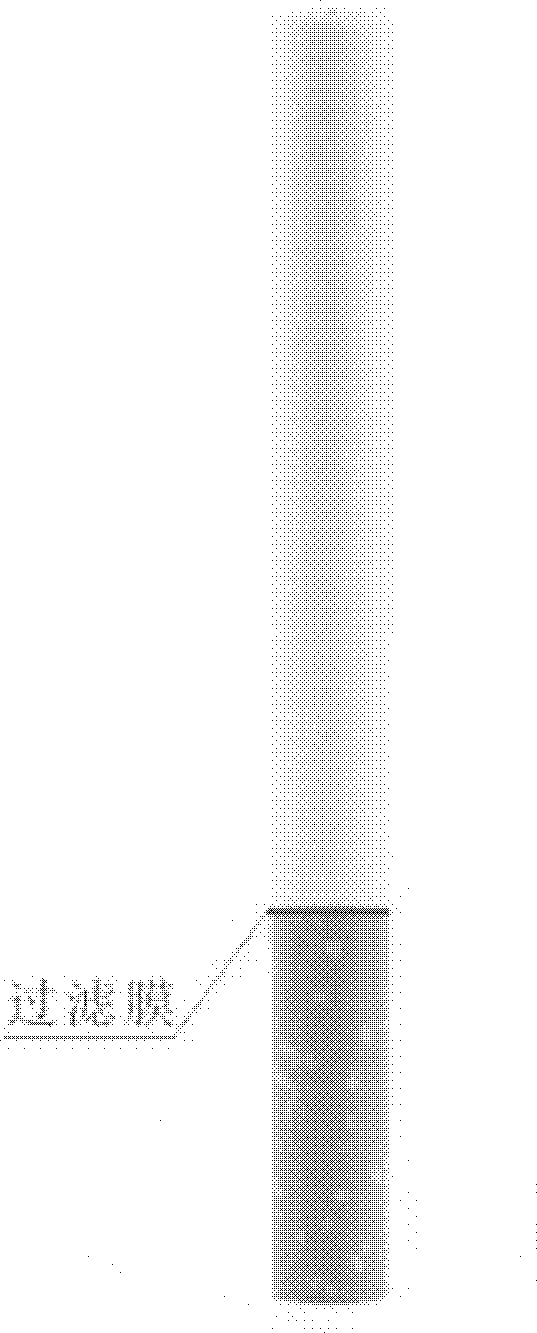

[0023] (2) Pull out the cellulose acetate tow in the cigarette, lay the above-mentioned nano-cellulose acetate film between the filter tip and the cigarette along the cross-sectional direction of the filter, and then put the cellulose acetate tow that was pulled out into the cigarette , Cut off the part of the filter beyond the tipping paper to make an improved cigarette filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com