Novel liquid silicon anti-channeling cement slurry used in well cementation

A technology of cement slurry and liquid silicon, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of density, fluidity thickening time fluctuation, reduce the compressive strength of cement stone, etc., and achieve simple mixing and use. , Good uniformity, wide density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

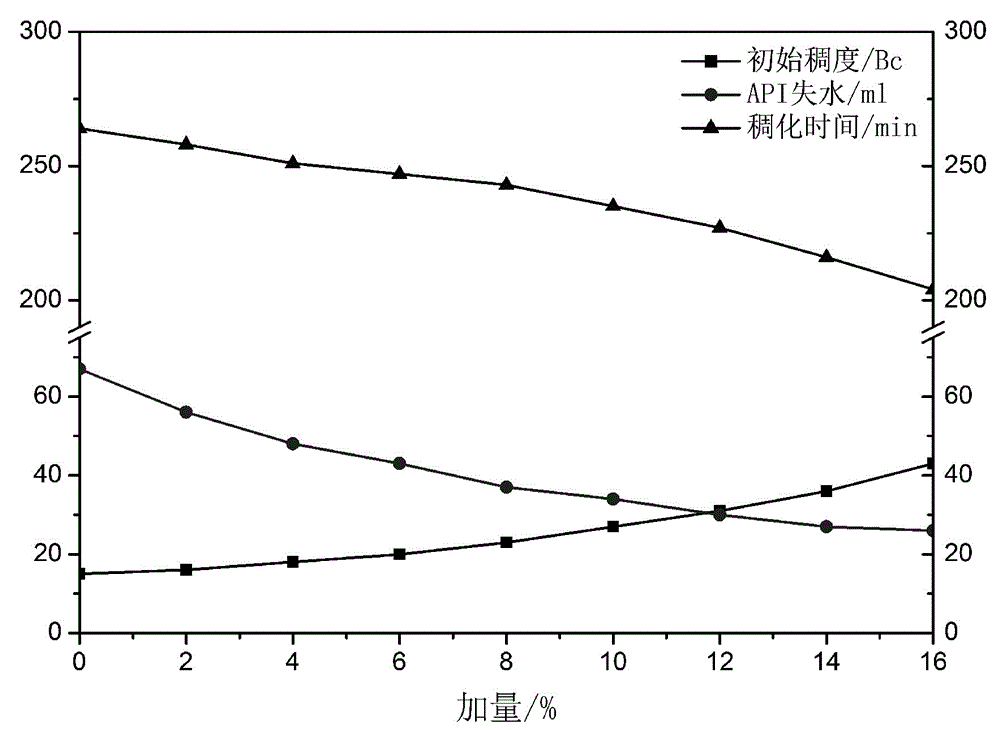

Method used

Image

Examples

Embodiment and

[0032] Embodiment and comparative example are as follows:

Embodiment 1

[0033] [Example 1] A new type of liquid silicon anti-channeling cement slurry for well cementing provided by the present invention, low density (1.50g / cm 3 ), which contains the following raw materials in parts by weight, 95 parts of G-grade cement, 10 parts of strength stabilizer, 0.5 part of retarder, 0.1 part of defoamer, 5 parts of filler, 0.5 part of dispersant, 5 parts of anti-air channeling agent , 5 parts of fluid loss reducer, 20 parts of lightening agent, 100 parts of water. The strength stabilizer is microsilicon, the retarder is AMPS polymer, the defoamer is polyether, the filler is ultrafine particle material, and the dispersant is aldehyde-ketone condensate. The anti-air channeling agent is liquid silicon, the water loss reducing agent is AMPS polymer, and the lightening agent is floating beads. The raw materials were mixed and stirred evenly to prepare well cementing cement slurry, and the relevant properties of the cement slurry were measured. The results are ...

Embodiment 2

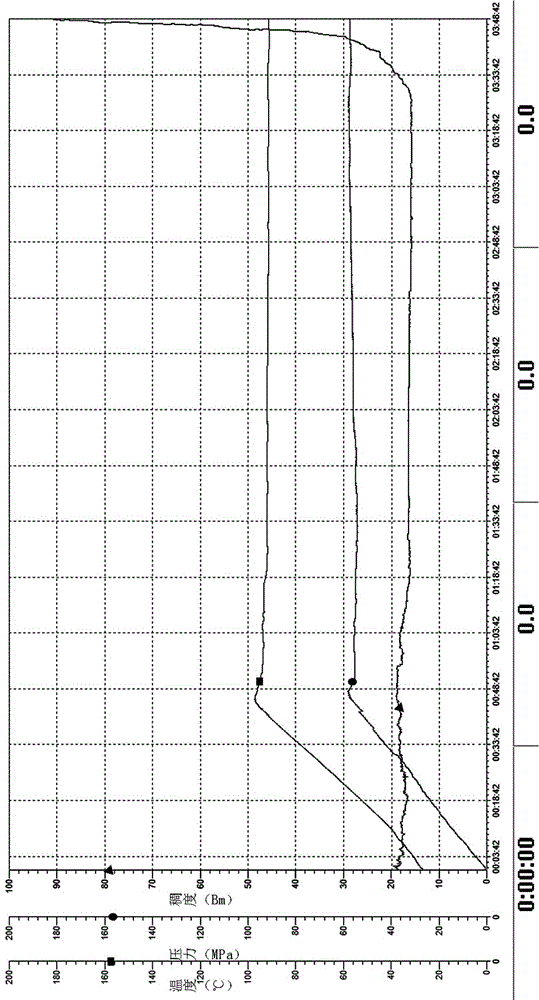

[0034] [Example 2] A new type of liquid silicon anti-channeling cement slurry for well cementing provided by the present invention contains the following raw materials in parts by weight, 100 parts of G-grade cement, 15 parts of strength stabilizer, 1.5 parts of retarder, 0.15 Parts of defoamer, 10 parts of filler, 1 part of dispersant, 8 parts of anti-air channeling agent, 2 parts of fluid loss reducer, 100 parts of water. The strength stabilizer is amorphous silica with a purity of 98%, the retarder is AMPS polymer, the defoamer is polyether, the filler is ultrafine particle material, and the dispersant It is a naphthalene-based dispersant, the anti-air channeling agent is silica sol, and the fluid loss reducing agent is PVA. The raw materials were mixed and stirred evenly to prepare well cementing cement slurry, and the relevant properties of the cement slurry were measured. The results are shown in Table 1. The thickening curve at 120°C is as follows: figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com