Hole sealing agent for thermal spraying coating and preparation method thereof

A technology of sealing agent and thermal spraying, which is applied in the direction of coating, metal material coating process, molten spraying, etc., and can solve the problems of increasing zinc consumption in the galvanizing production line, short service life of sinking rolls, and inconvenient production and operation. , to achieve good application prospects, high hardness, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

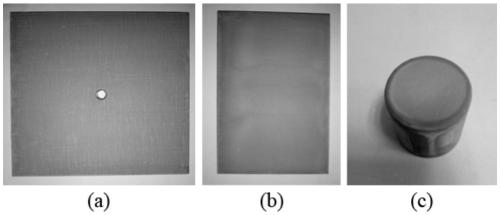

Image

Examples

Embodiment 8

[0036] Use the thermal spray coating sealing agent of embodiment 1: brush the thermal spray coating sealing agent on the sample, brush once, and dry at room temperature for 12 hours; put the sample after room temperature drying into a box-type resistance furnace Heating and curing, the heating conditions are 100°C for 3h, 150°C for 1h, 200°C for 1h, 250°C for 0.5h, and 300°C for 3h; after heating and curing, turn off the power and stop heating, and wait for the sample to cool to room temperature with the furnace Then take it out.

Embodiment 9

[0038] Use the thermal spray coating sealing agent of embodiment 2: brush the thermal spray coating sealing agent on the sample, brush once, and dry at room temperature for 12 hours; put the sample after room temperature drying into a box-type resistance furnace Heating and curing, the heating conditions are 100°C for 5h, 150°C for 1h, 200°C for 1h, 250°C for 0.5h, 300°C for 0.5h, 400°C for 0.5h, and 450°C for 2h; The power supply stops heating, and the sample is taken out after cooling to room temperature with the furnace.

Embodiment 10

[0040] Use the thermal spray coating sealing agent of embodiment 3: dip-coat the sample with the thermal spray coating sealing agent for 6 hours, and dry at room temperature for 24 hours; put the sample after room temperature drying into a box-type resistance furnace for heating and curing, and the heating conditions Insulate for 3.5 hours at 100°C, 1 hour at 150°C, 1 hour at 200°C, 0.5 hours at 250°C, 0.5 hours at 300°C, and 0.5 hours at 400°C; Let cool to room temperature and remove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com