Tunnel silicon oxide passivated contact solar cell and preparation method thereof

A technology for tunneling through a silicon-oxygen-nitride layer and a solar cell is applied in the field of solar cells, which can solve the problems of destroying the integrity of the silicon oxide layer, weakening the field passivation effect of the silicon wafer, affecting the filling factor, etc., so as to reduce the occurrence of leakage current and reduce the leakage current. Recombination speed, good chemical passivation effect, effect of reducing interface state density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

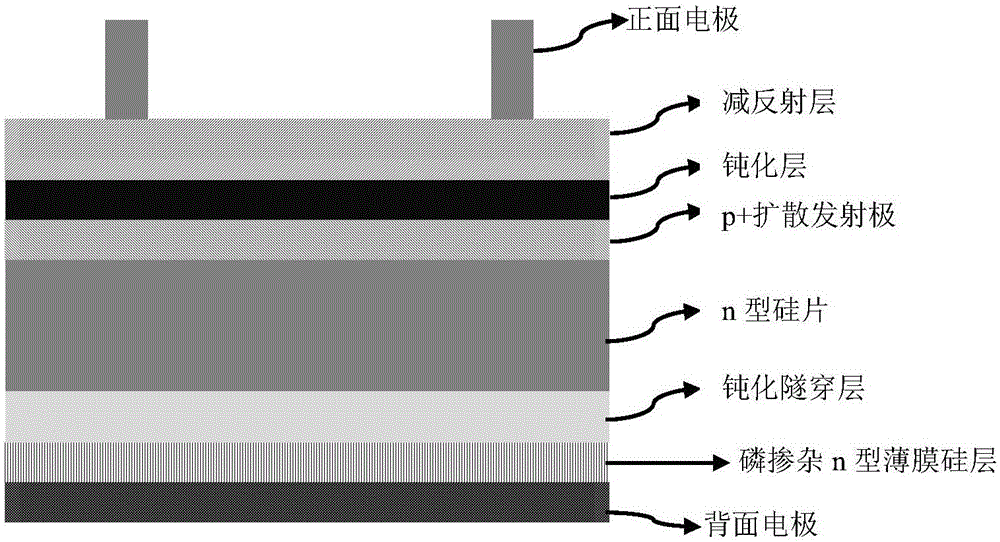

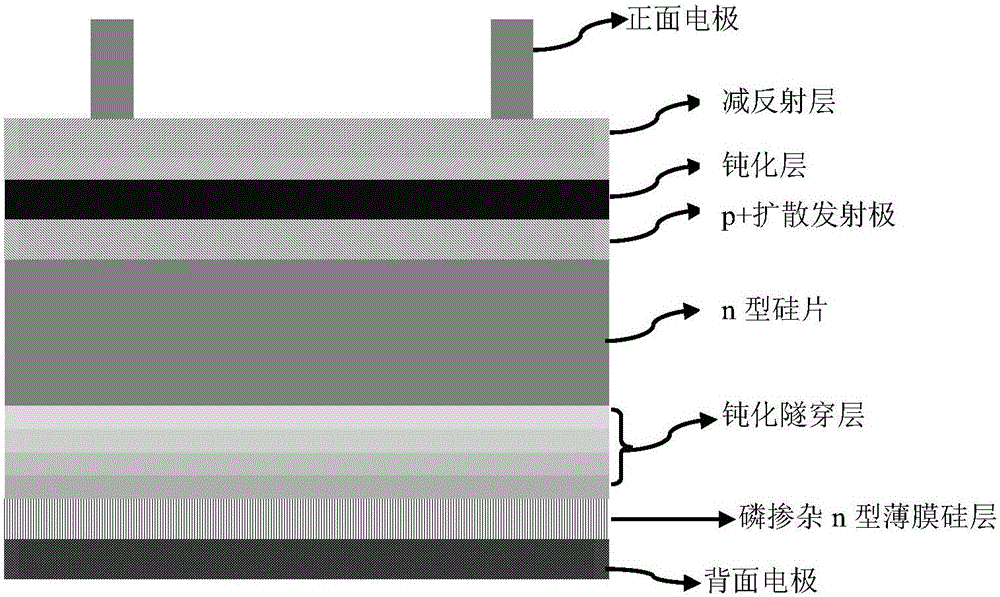

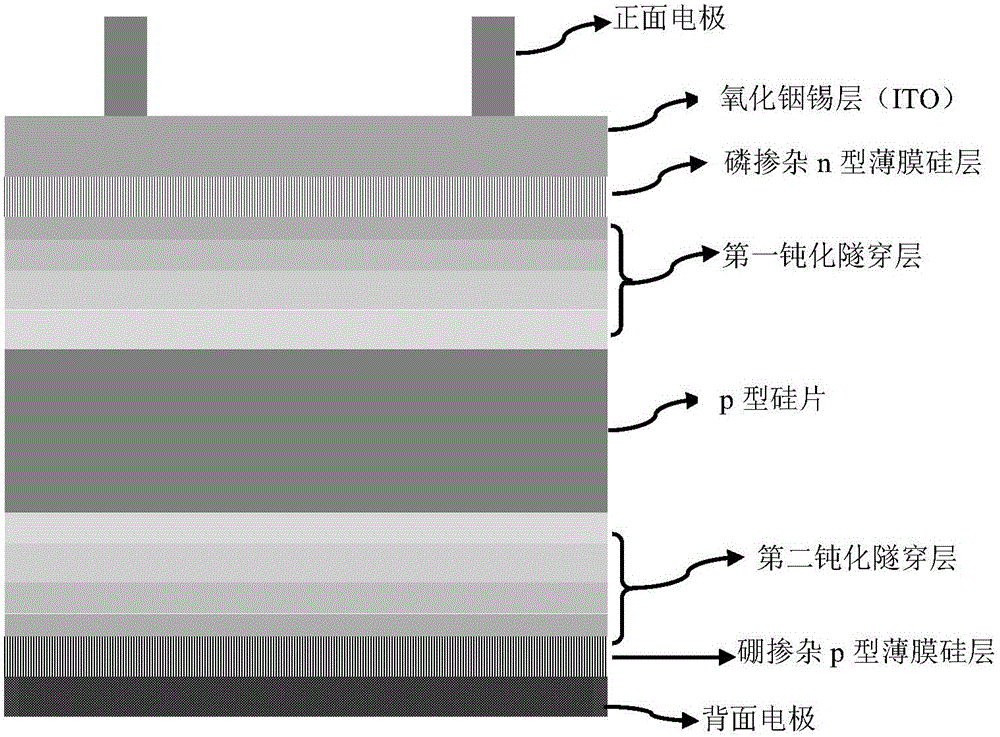

[0041] The invention provides a method for preparing a tunneling silicon oxygen nitride layer passivation contact solar cell, the solar cell includes a silicon wafer, a passivation tunneling layer, a doped thin film silicon layer, and the passivation tunneling layer Located between the silicon wafer and the doped thin-film silicon layer, wherein the preparation method includes the following steps: pretreating the silicon wafer, and forming a silicon oxide layer on one side or both sides of the pretreated silicon wafer Then generate a silicon oxynitride layer or a silicon nitride layer on the surface of the silicon oxide layer, and then anneal the obtained product; or generate a silicon oxynitride layer on one side or both sides of the pretreated silicon wafer , and then a silicon nitride layer is formed on the surface of the silicon oxynitride, and then the obtained product is annealed; or a silicon oxide layer is formed on one side or both sides of the pretreated silicon wafer...

Embodiment 1

[0075] In this embodiment, the n-type silicon wafer is used as the substrate. First, the n-type silicon wafer is pretreated. Carry out cleaning velvet, so that remove mechanical damage layer, greasy dirt and metal impurity, form undulating velvet surface simultaneously on the surface; On the n-type silicon wafer side after pretreatment, grow a layer thickness by 68% concentrated nitric acid 1.5nm silicon oxide (SiO x ) layer; then the n-type silicon wafer that generates the silicon oxide layer is placed in a plasma-enhanced chemical vapor deposition (PECVD) device, in the reaction gas SiH 4 The flow rate is 1sccm, NH 3 The flow rate is 10sccm, the cavity pressure is 10Pa, the temperature is 100°C, and the RF power is 50W, the reaction is 0.5min; after that, it is annealed at 800°C for 60min in a nitrogen-hydrogen mixed (FormingGas) atmosphere to eliminate defects and generate silicon oxide / Gradient silicon oxynitride stack; by plasma-enhanced chemical vapor deposition, the ...

Embodiment 2

[0078] Solar cells are prepared in the same manner as in Example 1, except that silicon oxide (SiO x ) layer; then the n-type silicon wafer that generates the silicon oxide layer is placed in a plasma-enhanced chemical vapor deposition (PECVD) device, in the reaction gas SiH 4 The flow rate is 1sccm, NH 3 The flow rate is 10sccm, the cavity pressure is 10Pa, the temperature is 100°C, and the radio frequency power is 50W, the reaction is 0.5min; then annealing is carried out at 850°C for 30min in a nitrogen-hydrogen mixed (FormingGas) atmosphere, and the solar cell A2 is obtained.

[0079] The surface saturation current density, open circuit voltage, short circuit current, fill factor, and conversion efficiency of solar cell A2 were measured in the same manner as in Example 1. The results of the passivation tunneling layer thickness and composition of solar cell A2 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com