Copper-based catalyst taking nitrogen-modified activated carbon as carrier as well as preparation method and application thereof

A technology of copper-based catalyst and activated carbon, which is applied in chemical instruments and methods, hydrogen halide addition preparation, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

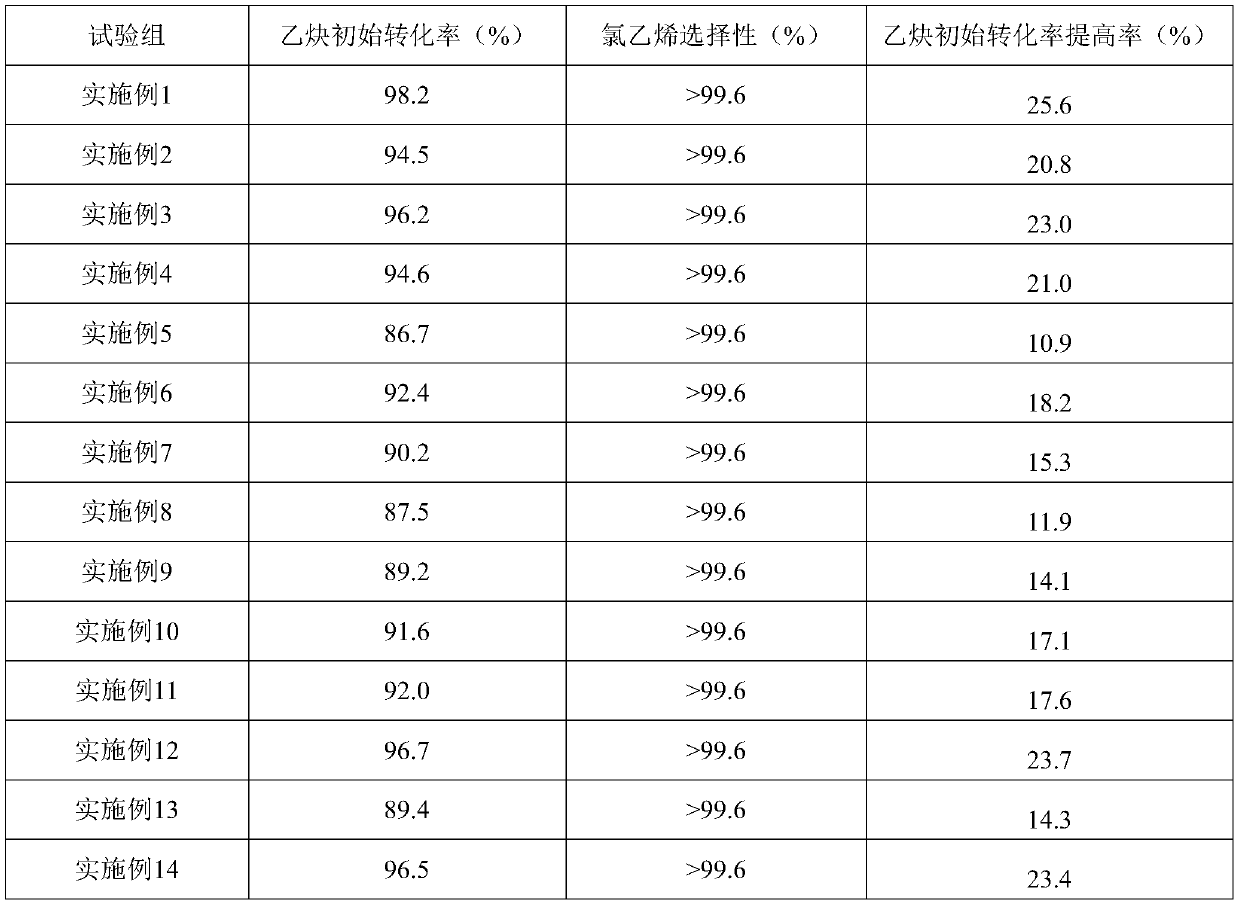

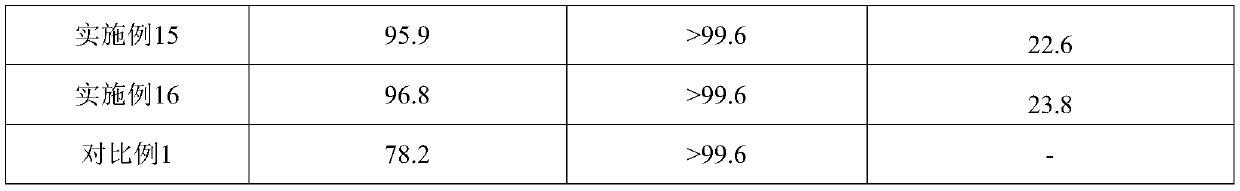

Examples

Embodiment 1

[0039] Combine the urea modifier with a specific surface area of 1400m 2 / g, ash content equal to 4% of the wood activated carbon is immersed in an appropriate amount of deionized water at a mass ratio of 1:1, stirred at 90°C for 12h, taken out, drained, and dried at 100°C for 10h for later use.

[0040] Put the above product on a fixed bed, heat it up to 800°C at a heating rate of 10°C / min under a nitrogen atmosphere, keep this temperature for 5 hours, then cool to room temperature under an inert atmosphere, and dry to obtain nitrogen-modified activated carbon.

[0041] Preparation and application of nitrogen-modified copper-based catalyst: The nitrogen-modified activated carbon obtained above is impregnated in equal volumes in the prepared copper nitrate solution. The concentration of the configured copper nitrate solution makes the copper content of the final catalyst 17% of the total weight. The soaking time is 8h. Evaporate to dryness in a water bath, put in an oven an...

Embodiment 2

[0044] Combine the urea modifier with a specific surface area of 1400m 2 / g, ash content equal to 4% wood activated carbon is immersed in an appropriate amount of deionized water at a mass ratio of 0.5:1, stirred at 90°C for 12h, taken out, drained, and dried at 100°C for 10h for later use.

[0045] Put the above product on a fixed bed, heat it up to 800°C at a heating rate of 10°C / min under a nitrogen atmosphere, keep this temperature for 5 hours, then cool to room temperature under an inert atmosphere, and dry to obtain nitrogen-modified activated carbon.

[0046] Preparation and application of nitrogen-modified copper-based catalyst: The nitrogen-modified activated carbon obtained above is impregnated in equal volumes in the prepared copper nitrate solution. The concentration of the configured copper nitrate solution makes the copper content of the final catalyst 17% of the total weight. The soaking time is 8h. Evaporate to dryness in a water bath, put in an oven and dry...

Embodiment 3

[0049] Combine the urea modifier with a specific surface area of 1400m 2 / g, ash content equal to 4% woody activated carbon impregnated in an appropriate amount of deionized water at a mass ratio of 5:1, stirred at 90°C for 12h, taken out, drained, and dried at 100°C for 10h for later use.

[0050] Put the above product on a fixed bed, heat it up to 800°C at a heating rate of 10°C / min under a nitrogen atmosphere, keep this temperature for 5 hours, then cool to room temperature under an inert atmosphere, and dry to obtain nitrogen-modified activated carbon.

[0051] Preparation and application of nitrogen-modified copper-based catalyst: The nitrogen-modified activated carbon obtained above is impregnated in equal volumes in the prepared copper nitrate solution. The concentration of the configured copper nitrate solution makes the copper content of the final catalyst 17% of the total weight. The soaking time is 8h. Evaporate to dryness in a water bath, put in an oven and dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com