Variable-angle automatic spot welding device moving along with profiling track

An automatic spot welding and orbital technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unsatisfactory production consistency, high labor intensity of operators, and difficult guarantee of welding quality, so as to improve the quality of welding , Reduce labor intensity, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

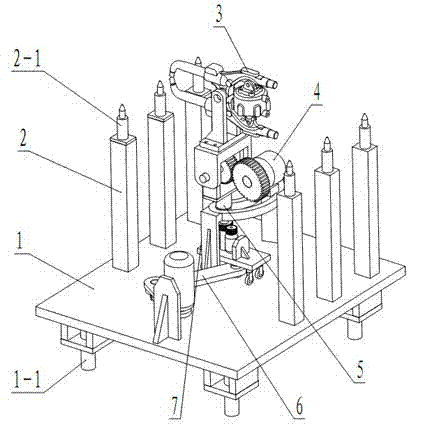

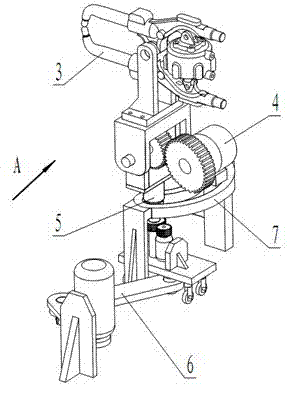

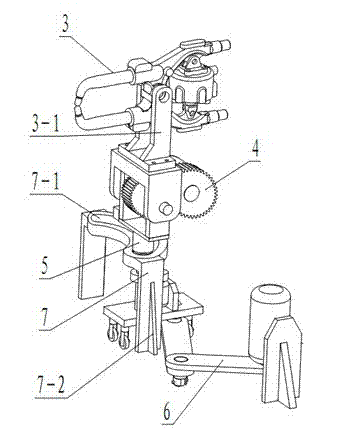

[0024] See Figure 1, figure 2 , image 3 , the present invention includes a base 1, a workpiece positioning mechanism 2, a welding machine 3, a welding machine space angle adjustment mechanism 4, a welding machine rotating mechanism 5, a welding machine moving drive mechanism 6 and a profiling track seat 7, and the welding machine 3 passes through the welding The machine fixing base 3-1 is fixedly installed on the welding machine space angle adjustment mechanism 4, the welding machine space angle adjustment mechanism 4 is assembled with the welding machine rotation mechanism 5, and the welding machine rotation mechanism 5 is arranged on the welding machine space angle adjustment mechanism 4. Between the mechanism 4 and the welding machine moving driving mechanism 6, the welding machine moving driving mechanism 6 and the profiling track seat 7 are located on the base 1, and the workpiece positioning mechanism 2 is symmetrically arranged on the left and right sides of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com