Welding molten drop transition control device based on ultrasonic frequency pulse double-tungsten-electrode coordination and control method

A technology for droplet transfer and control equipment, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of reducing the flexibility and accessibility of the welding torch, unstable welding process, equipment jitter, etc., to improve flexibility and accessibility, eliminates weld directionality, and achieves the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Welding droplet transfer control equipment and control method based on super-audio frequency pulse double tungsten coordination, the specific implementation steps are as follows:

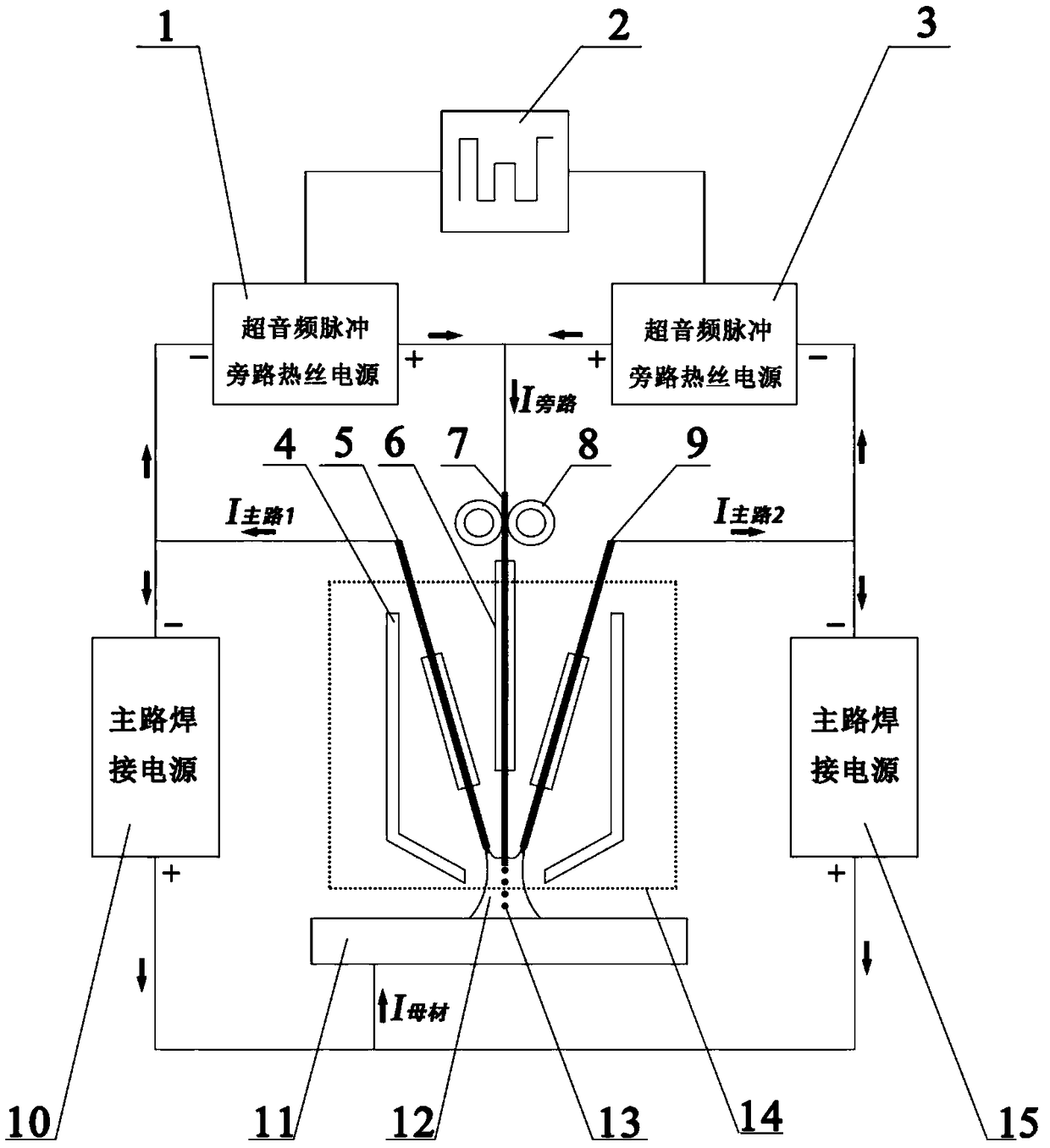

[0021] A welding droplet transfer control device based on super-audio pulse double tungsten coordination, its structure includes a first super-audio bypass hot wire power supply 1, a second super-audio frequency bypass hot wire power supply 3, a pulse coordination controller 2, a protection Gas cover 4, first tungsten electrode 5, second tungsten electrode 9, conductive tip 6, welding wire 7, wire feeding mechanism 8, first main circuit welding power source 10, second main circuit welding power source 15, base material 11, conductive tip The center of 6 is the welding wire 7, the upper end of the contact tip 6 is connected with the wire feeding mechanism 8, the two sides of the contact tip 6 are the first tungsten pole 5 and the second tungsten pole 9, and the outer sides of the first tungsten...

Embodiment 2

[0036] Welding droplet transfer control equipment and control method based on super-audio frequency pulse double tungsten coordination. A transition control device and a control method belong to the fields of metal welding and additive manufacturing.

[0037] During the welding process, the thermal and mechanical behavior of the droplet transfer has an important influence on the weld formation and welding quality. Generally speaking, a good form of droplet transfer is conducive to improving the shape of the weld, reducing welding spatter and improving the quality of the joint. In the existing metal gas shielded welding method, because the wire melting and transition mode are directly related to the current, it is difficult to control the wire melting speed and droplet transfer independently. For example, when gas metal shielded welding is performed under low current conditions, the force to promote droplet transfer is small, and only large droplet or short-circuit transfer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com