Intelligent welding system and method

A welding system and intelligent technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of high price, low degree of intelligence, complex structure, etc., achieve high degree of intelligence, improve work efficiency and product quality , The effect of reducing the workload of manual debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

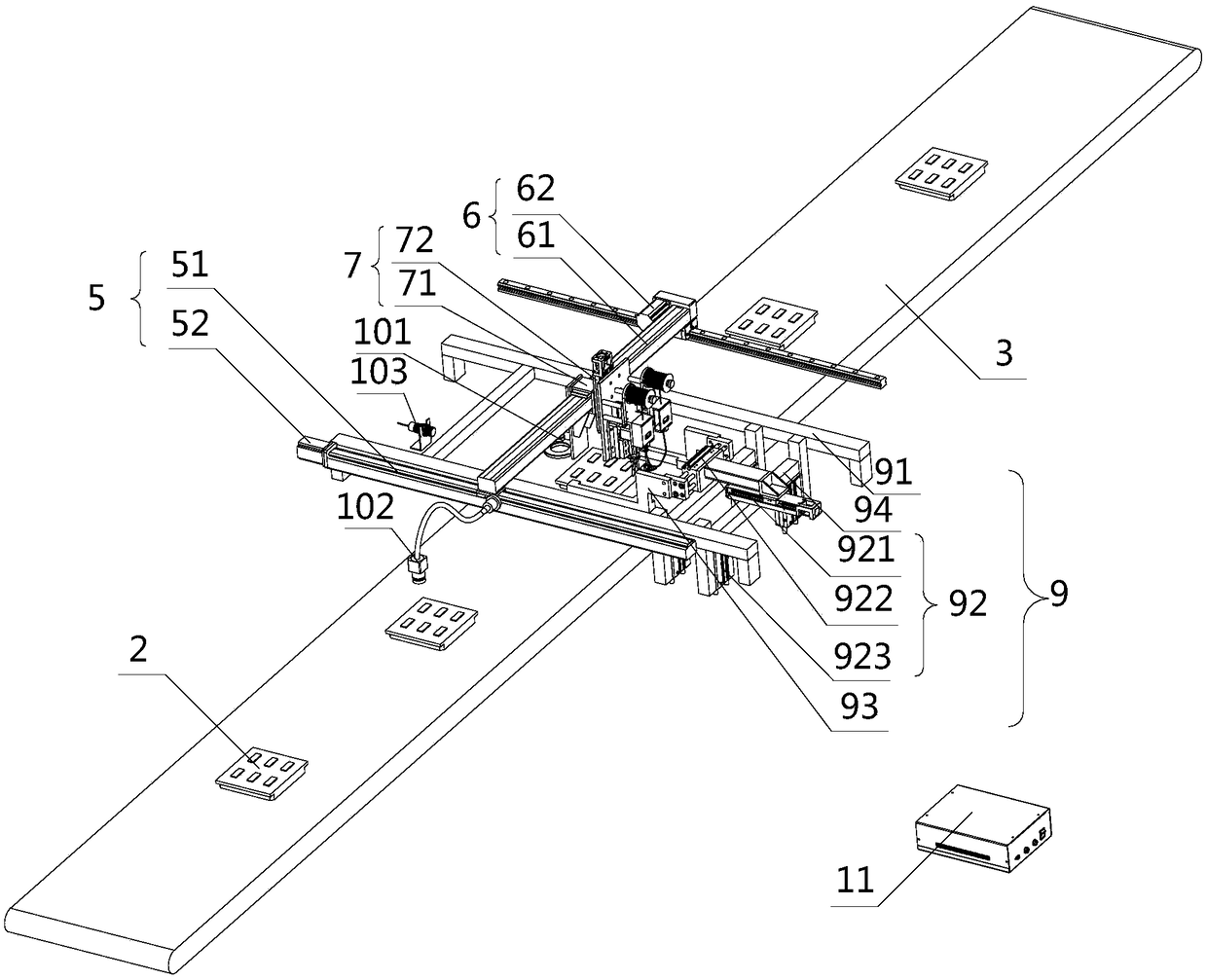

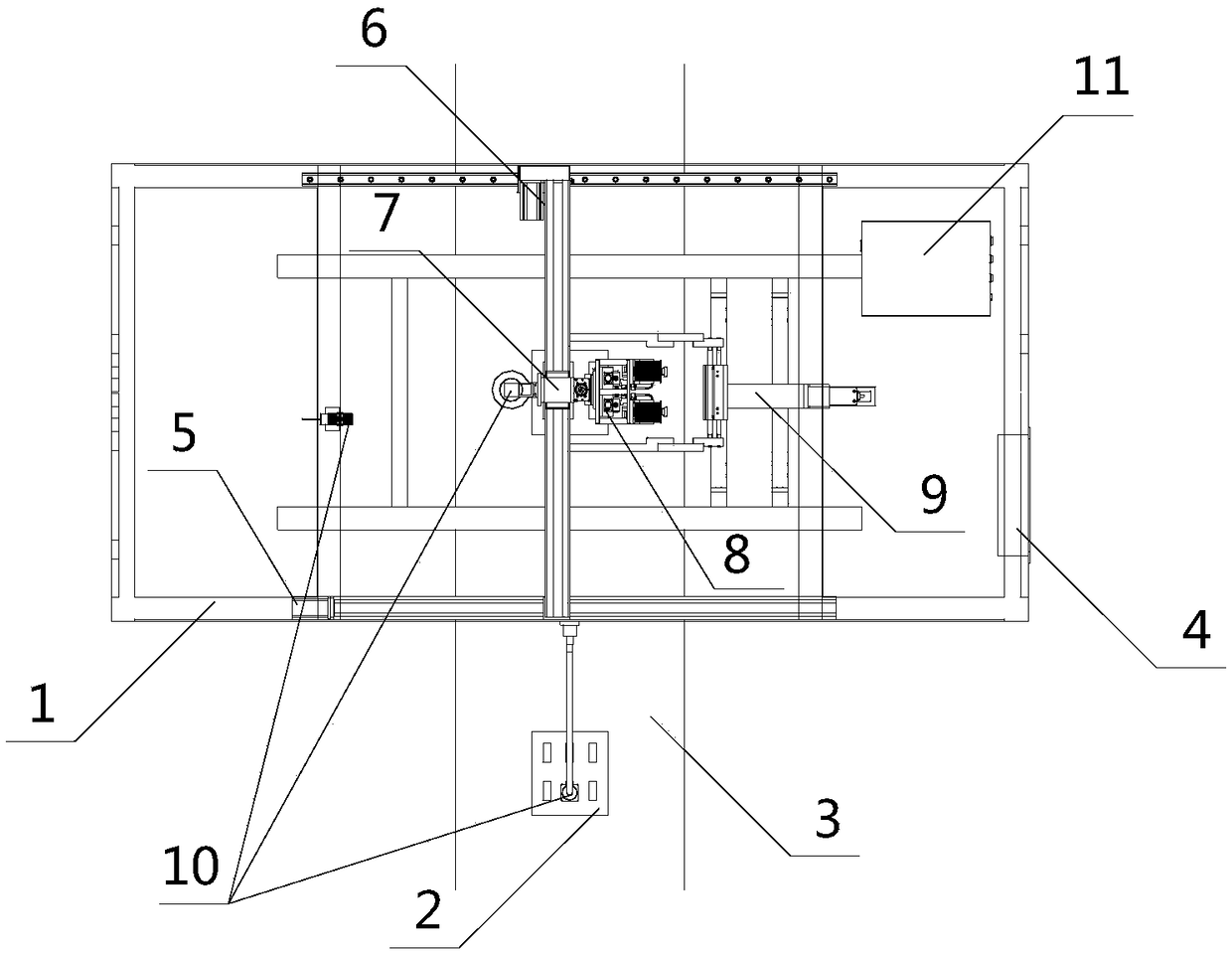

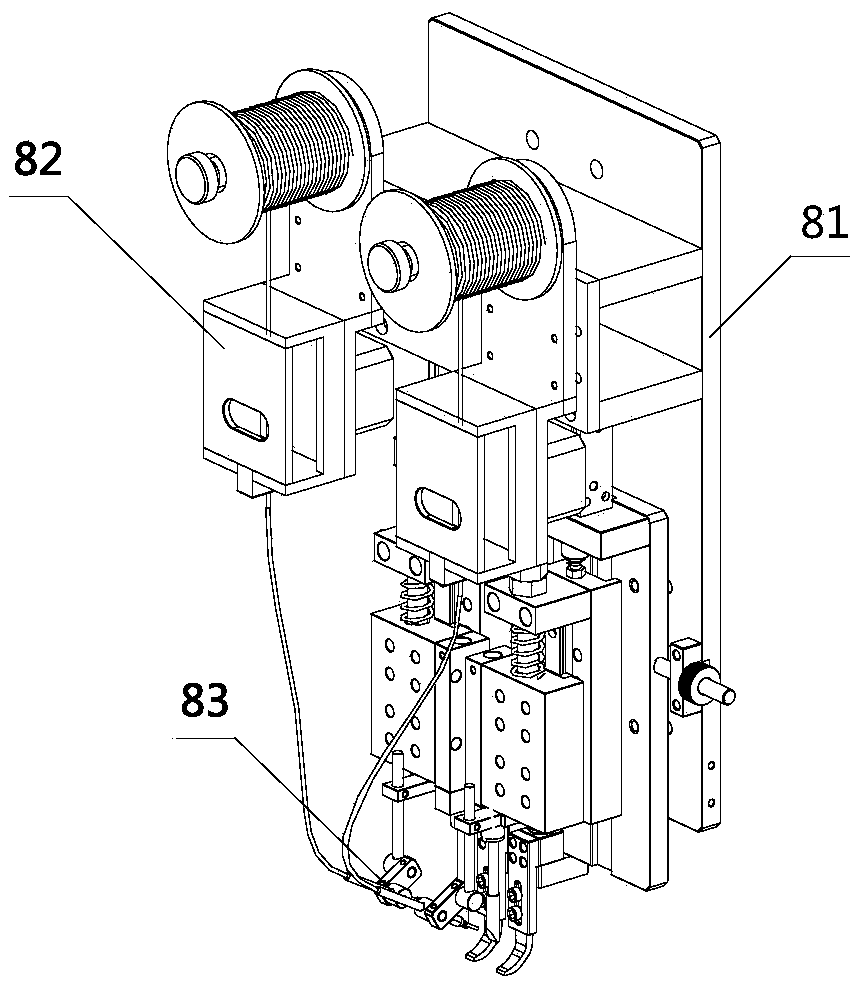

[0042] Such as figure 1 and figure 2 As shown, an intelligent welding system includes a rectangular parallelepiped cabinet 1, an assembly line 3 for transferring circuit boards 2 to be welded, and an industrial computer 4, and the assembly line 3 runs through the cabinet along the width direction of the cabinet 1 1. The cabinet 1 is provided with a motion platform, a clamping assembly 9, a vision system 10 and a welding assembly 8, and the vision system 10, the clamping assembly 9 and the welding assembly 8 are respectively arranged on the motion platform, and the The assembly line 3, the motion platform, the clamping assembly 9, the welding assembly 8 and the vision system 10 are respectively electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com