Welding positioner special for upper and lower square butt joint welding seams of excavator movable arms and using method of welding positioner

A welding positioner and flat butt welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Operation level and other issues, to achieve the effect of being conducive to on-site management, solving low production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

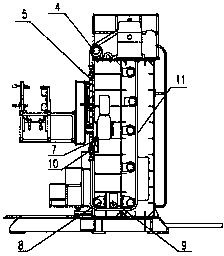

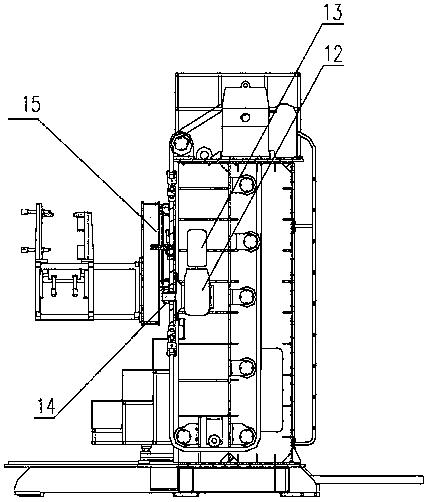

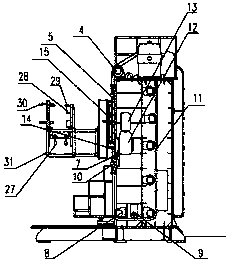

[0053] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 , a special welding positioner for the upper and lower flat butt welds of the excavator arm, which can be welded at any position, and uses a lifting and shifting mechanism, which is specially used for welding the upper and lower flat butt welds of the excavator arm, including a lifting device and a turning device 1. Arbitrary station state adjustment device and special boom clamping device; the lifting device: two square rails 10 are installed on the side of the frame 6, and the two corners below are respectively equipped with a reversing wheel 8 and a tensioning wheel 9. Equipped with a lifting motor 1, the lifting motor 1 is connected to the lifting reducer 2 in transmission, through the lifting reducer 2, the output shaft of the lifting reducer 2 is connected to the spr...

Embodiment 2

[0074] The chain 11 and sliding seat 5 of the lifting device adopt a non-closed loop, and the up and down strokes are controlled by electrical appliances; the power is transmitted by hydraulic cylinders; The horizontal direction of boarding ladder 16 and left boarding ladder 17 moves, and power is transmitted by mechanism traction; Others are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com