Inner and outer circumference welding machine for cylinder

A technology of cylindrical and ring welding machines, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of uneven solder, high labor intensity of operators, unqualified welding quality, etc., and achieve simple equipment structure design, The equipment has a wide range of applications and the effect of adjustable wire feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

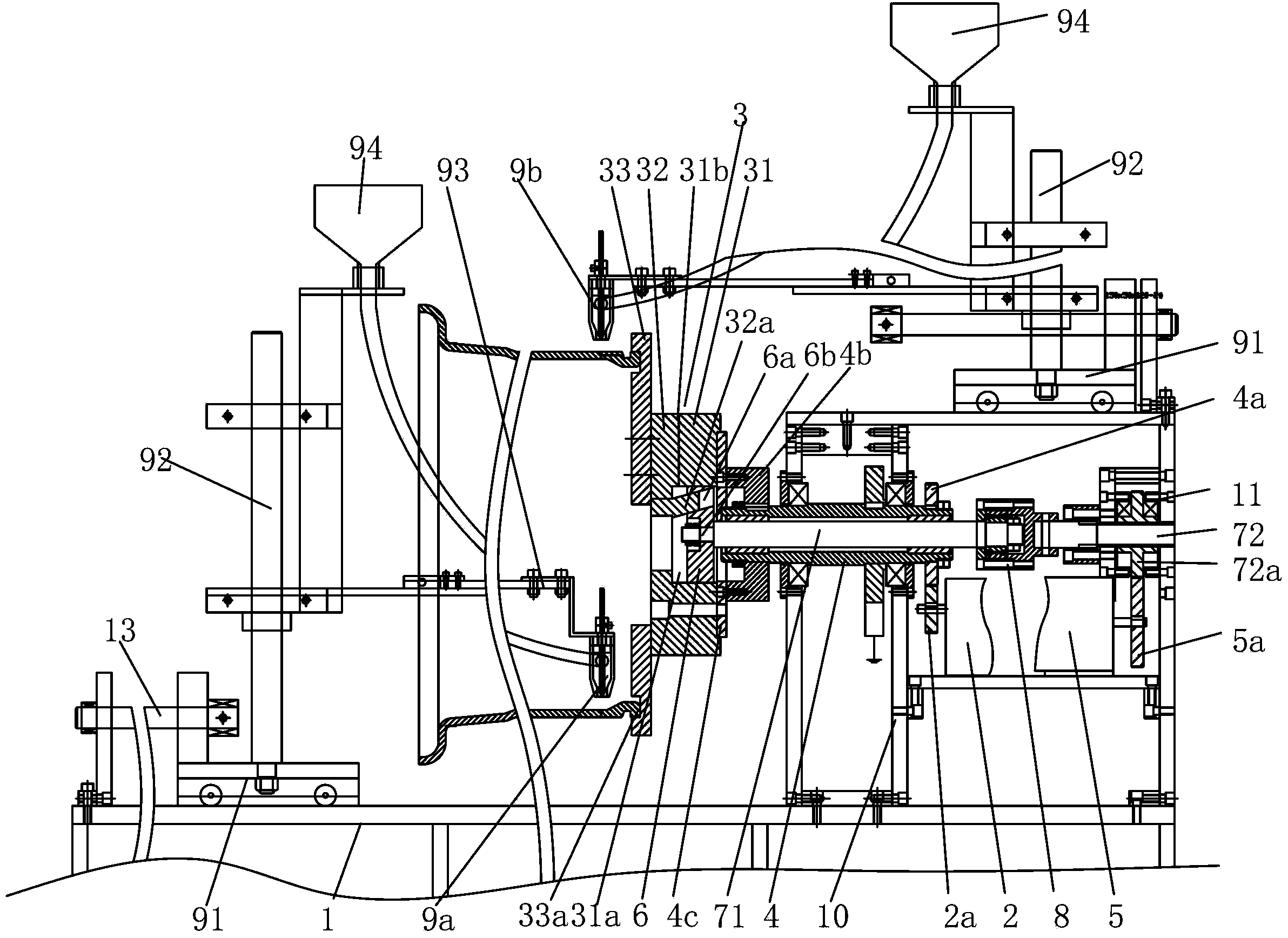

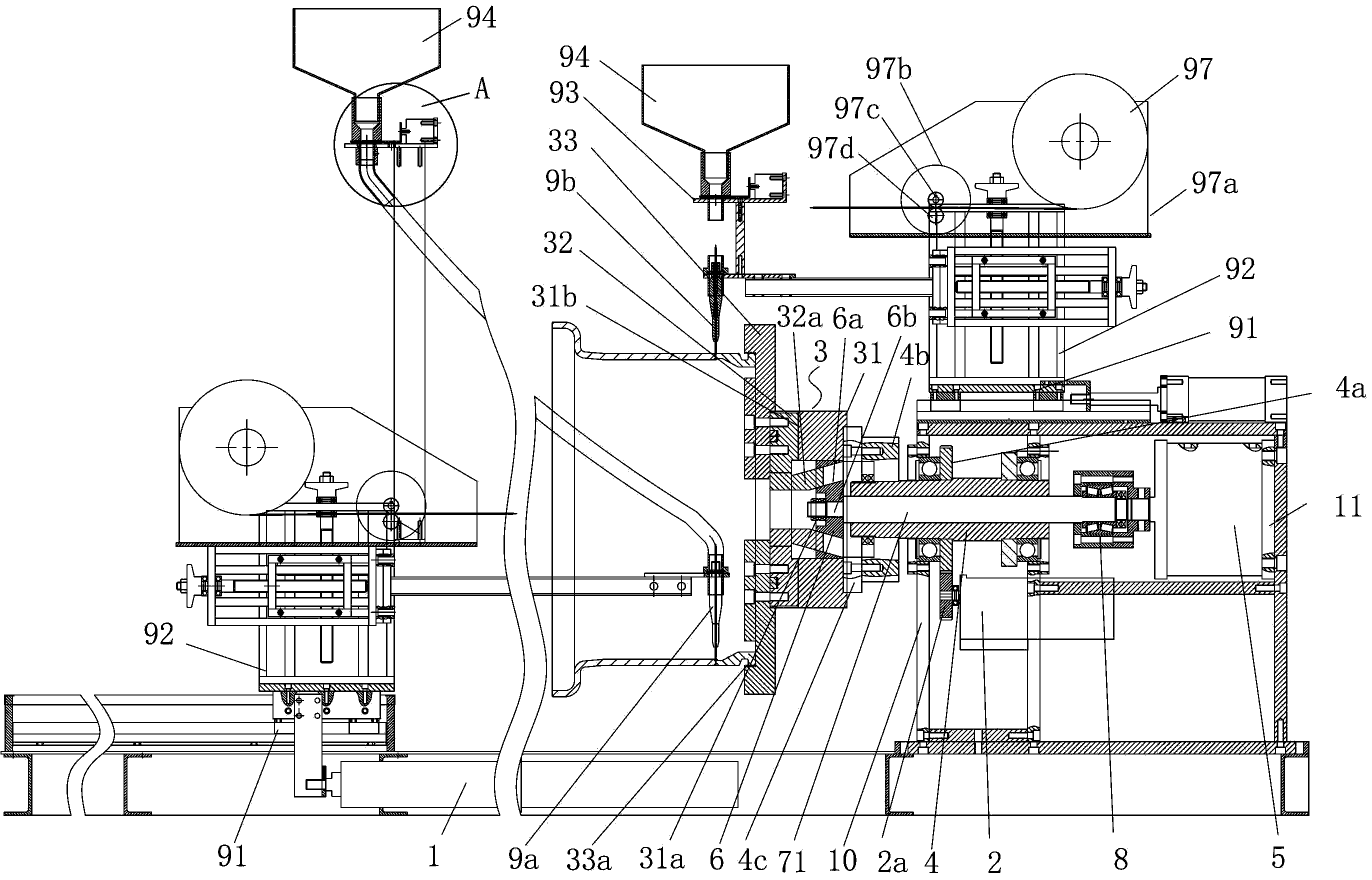

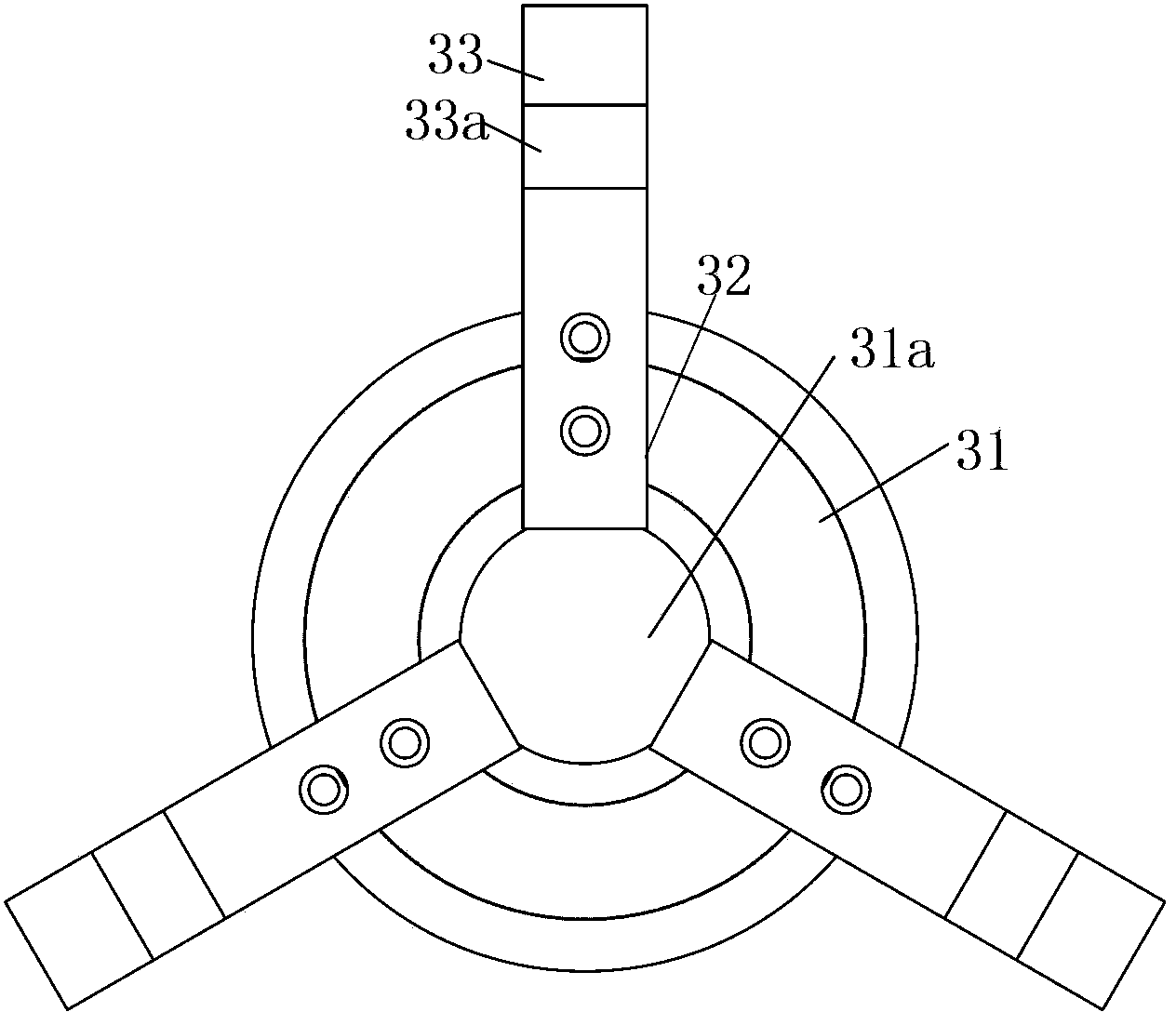

[0035] figure 1 Shown is the structural diagram of the cylindrical internal and external circumferential welding machine of the first embodiment of the present invention (the welding torch feeding device, welding wire feeding mechanism and position adjustment mechanism are not shown in the figure), figure 2 Shown is a structural diagram of a cylinder inner and outer girth welding machine according to the second embodiment of the present invention. Depend on figure 1 , figure 2 It can be seen that the cylindrical internal and external circumferential welding machine of the present invention includes: a power device 2, which is placed on the base 1; a clamp 3 for clamping the cylinder to be welded is connected with the power device 2 through a transmission mechanism, so that the power device 2 Driven by the device 2, the cylinder to be welded is driven to rotate; the inner and outer torches 9a, 9b are placed on the base 1, respectively located on the inside and outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com