Gas protection method and apparatus for rotating arc narrow gap welding

A rotating arc and gas shielding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the complex shape and structure of the external box-shaped nozzle, unfavorable observation of the welding arc and molten pool, and low adjustment accuracy of the height adjustment device etc. to achieve the effects of improving observability, simplifying the design of the air supply mechanism, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

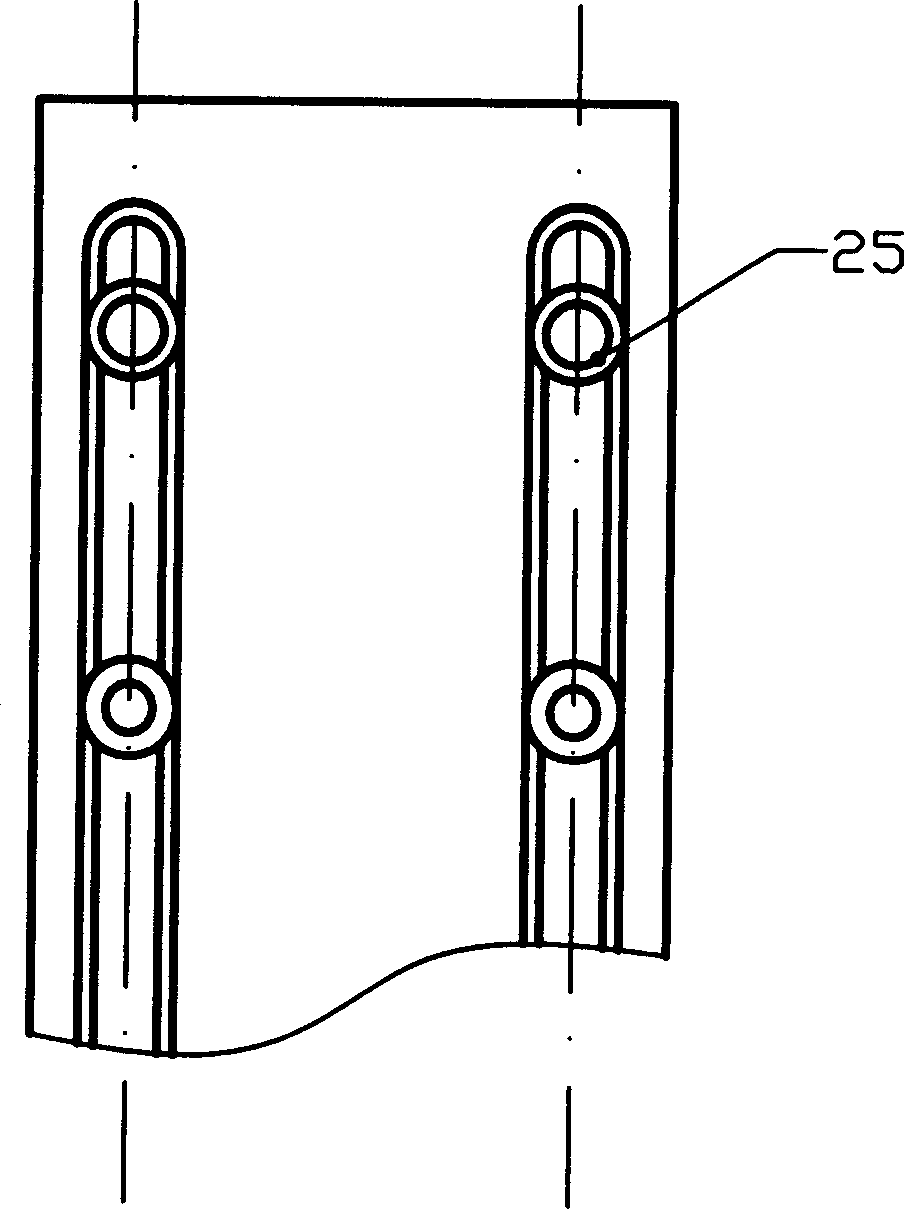

[0014] Embodiment 1 is suitable for providing gas shielding for the upper several layers of weld passes and cover welds of narrow gap grooves. Depend on figure 1 and figure 2 It can be seen that the present invention includes 1-adjusting hand wheel, 2-positioning nut, 3-flat nozzle seat, 4-locking screw, 5-flat nozzle, 6-guide groove, 7-carriage plate, 8-conductive rod, 9-Cooling water inlet, 10-Water-cooled nozzle seat, 11-Sleeve-shaped nozzle air inlet, 12-Sleeve-shaped nozzle, 13-Welding wire, 14-Electric arc, 15-Cooling water outlet, 16-Sliding groove, 17 -Nozzle connector, 18-locking handwheel, 19-connector, 20-adjusting rod, 21-gear, 22-rack, 23-support plate, 24-air inlet of flat nozzle, 25-guiding wheel.

[0015] Such as figure 1 As shown, it includes an air intake pipeline, a composite nozzle, and the composite nozzle includes a protruding flat nozzle (5) and its position adjustment mechanism, an external sleeve-shaped nozzle (12) and its height adjustment mechani...

Embodiment 2

[0017] Embodiment 2 is suitable for providing gas protection for the weld bead deep in the narrow gap groove. Depend on image 3 It can be seen that, with respect to embodiment 1, embodiment 2 has unloaded sleeve-shaped nozzle (12), increased dust cover (26), and all the other parts are the same as embodiment 1. Such as image 3 As shown, by adjusting the handwheel (1) to drive the carriage (7), the height of the water-cooled nozzle seat (10) is raised to expose a sufficiently long conductive rod (8) and eccentric conductive tip (27), so that the flat nozzle (5 ) into the depth of the narrow gap groove to supply air; at the same time, loosen the locking screws (4) on the flat nozzle seats (3) on both sides, and adjust the position of the flat nozzle (5) so that it is close to the welding arc (14). Therefore, effective gas shielding is implemented for the rotary arc welding area deep in the narrow gap groove to form high-quality welded joints.

Embodiment 3

[0018] Embodiment 3 is suitable for providing gas shielding for the upper layers of welds and cover welds of narrow gap grooves, and can also be used for other rotary arc welding occasions such as open groove welding and fillet welding. Compared with Example 1, the protruding flat nozzles (5) and their connectors (17) on both sides have been removed, and the positioning nut (2), flat nozzle seat (3), and locking screw (4) have been removed. The flat nozzle position adjustment mechanism that etc. constitute, all the other parts are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com