Method and device for preparing colloid probe

A technology of probes and colloids, which is applied in the field of probe modification, preparation and processing, can solve the problems of unrepresented device method steps, etc., achieve convenient and fast production operations, improve contrast and observability, and facilitate observation and The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

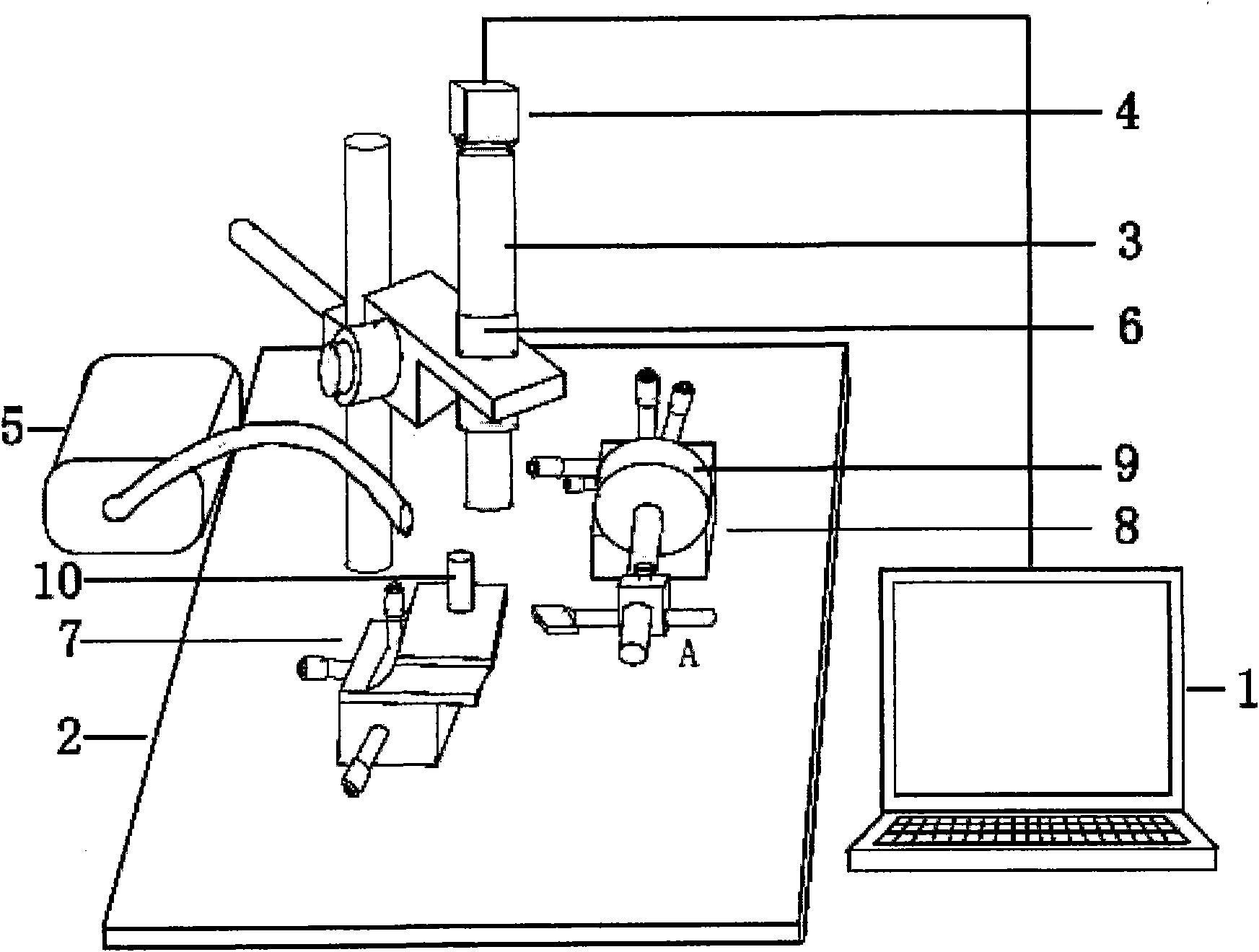

[0053] A device used in the method for preparing a colloidal probe, including a computer 1, an operating table 2, an optical microscope 3, a CCD 4, an external light source 5, a coaxial light source 6, two three-dimensional mobile platforms 7, 8, two copper Column 10, probe holder 18 and infrared oven lamp (not shown in the figure); Wherein,

[0054] Two three-dimensional mobile platforms 7, 8 and a support are fixed on the square operating platform 2, and the support is provided with an optical microscope 3 in the vertical direction, and the optical microscope lens is downward, and the two three-dimensional mobile platforms 7, 8 are respectively located on the optical microscope 3 On both sides directly below; the external light source 5 device box is placed on the side of the square operating table 2, the light source probe is located on the side of the optical microscope 3, and its beam shines on the area under the microscope lens;

[0055] The lens barrel of the optical mi...

Embodiment ( 1

[0086] (1) Disperse silicon microspheres with a diameter of 10 μm in an aqueous solution, disperse them by ultrasonic for 5 minutes, pipette a certain amount of solution with a pipette gun, add it dropwise on the mica sheet of the copper pillar 10, and let it dry naturally. The mica sheet is bonded to the copper pillar through the glass sheet with double-sided adhesive tape. Observe under a high power optical microscope 11 to find suitable microspheres for use.

[0087] (2) Prepare Epotek 377 optical glue drops. Drop a small amount of two-component epoxy resin optical glue on the glass sheet of the copper column in a ratio of 1:1, mix and mix thoroughly with a thin iron wire.

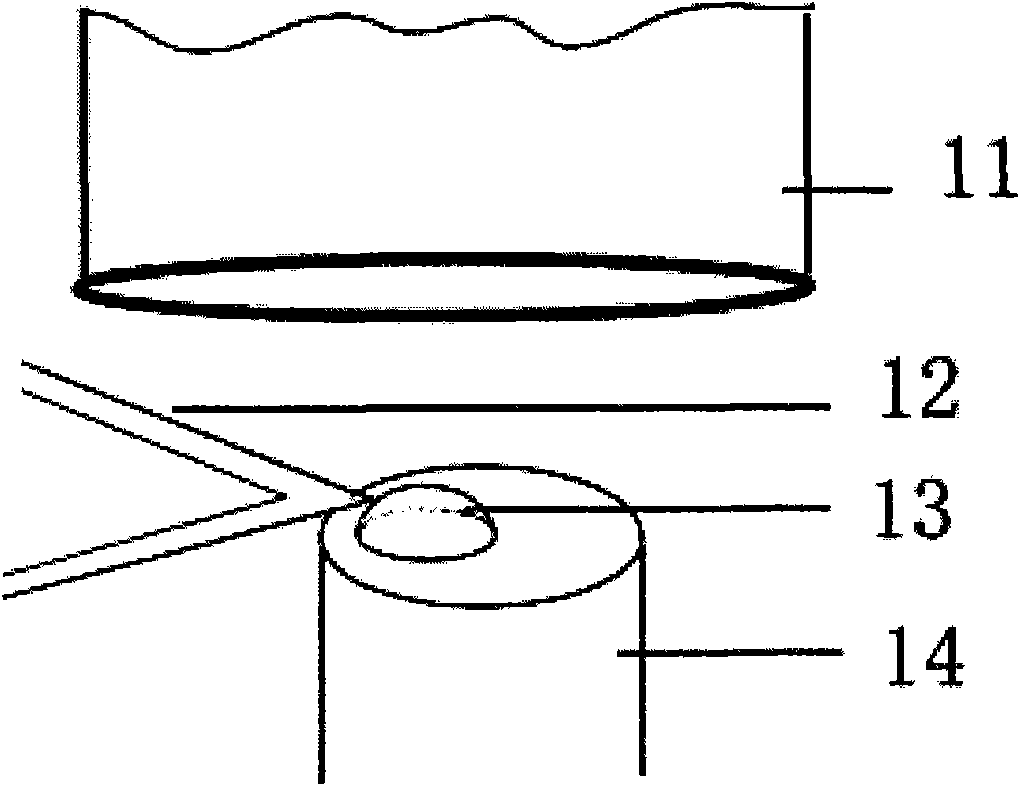

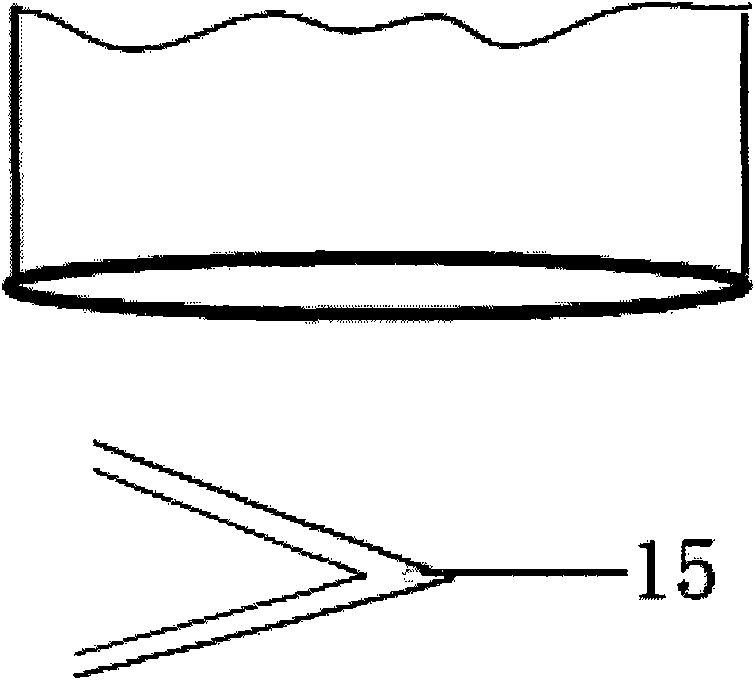

[0088] (3) Install the probe on the probe holder 18 , and then install the probe holder 18 on the bracket 22 of the three-dimensional mobile platform 8 . Under the observation of the high-power optical microscope 11, find the cantilever 12 of the probe, and observe whether the cantilever is damaged to...

Embodiment ( 2

[0097] (1) Disperse silicon microspheres with a diameter of 5 μm in an aqueous solution, disperse them by ultrasonic for 5 minutes, pipette a certain amount of solution with a pipette gun, drop it on the mica sheet of the copper pillar 10, and let it dry naturally. The mica sheet is bonded to the copper pillar through the glass sheet with double-sided adhesive tape. Under the high power optical microscope 11, adjust the magnification of the microscope to 3.5, observe and find suitable microspheres.

[0098] In other steps, the difference from the implementation example (1) is that when using a high-power optical microscope, attention must be paid to adjusting the magnification of the microscope in a timely manner, and gradually zooming in to an appropriate magnification for observation and manipulation of the microparticle bonding process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com